Recovery processing method of ultrahigh molecular weight polyethylene dry spinning jelly and waste fiber solvent

A technology of ultra-high molecular weight and treatment process, which is applied in the field of solvent recovery of ultra-high molecular weight polyethylene fiber jelly waste silk, can solve the problem that the solvent cannot be recovered, and achieve the effect of low degradation degree and high solvent recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

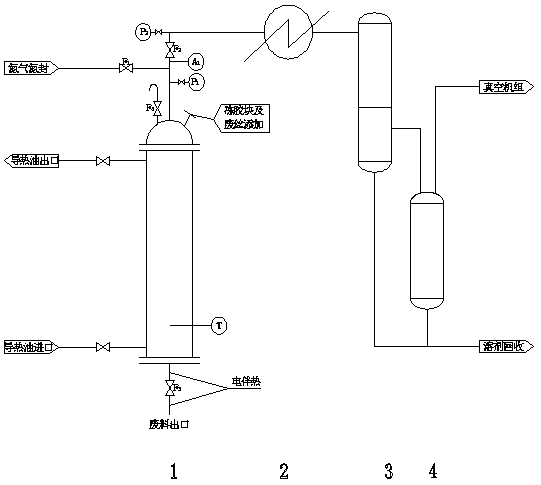

Image

Examples

Embodiment 1

[0016] The pressure of the rectification system is 0.35kpa, the solvent content of jelly collagen is 38%, the weight-average molecular weight is about 2 million measured by Ubbelohde viscometer, the length-to-diameter ratio of the melting tank is 15:1, the melting temperature is 160°C, and the melting time is 4 hours. The solvent content of the gel is ≤1%, and the weight-average molecular weight of the solid is measured by an Ubbelohde viscometer at ~1.9 million.

Embodiment 2

[0018] The pressure of the rectification system is 0.35kpa, the solid content of jelly is 90%, the weight average molecular weight is about 2.5 million measured by Ubbelohde viscometer, the length-to-diameter ratio of the melting tank is 15:1, the melting temperature is 160°C, and the melting time is 4 hours. The solvent content of the gel is ≤1.5%, and the weight average molecular weight of the solid is measured by an Ubbelohde viscometer at ~2.1 million.

Embodiment 3

[0020] The pressure of the rectification system is 0.1kpa, the solvent content of jelly silk is 27%, the weight average molecular weight is about ~2 million measured by Ubbelohde viscometer, the length-to-diameter ratio of the melting tank is 15:1, the melting temperature is 150°C, and the melting time is 4h. The solvent content of the gel is ≤1%, and the weight-average molecular weight of the solid is measured by an Ubbelohde viscometer at about ~2 million.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com