Preparation method for high-modulus para-aramid fiber

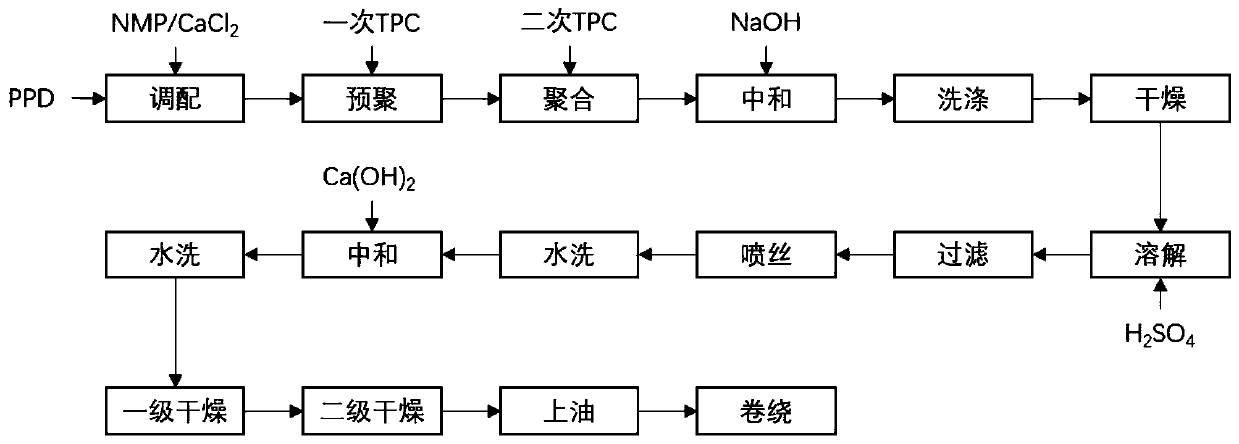

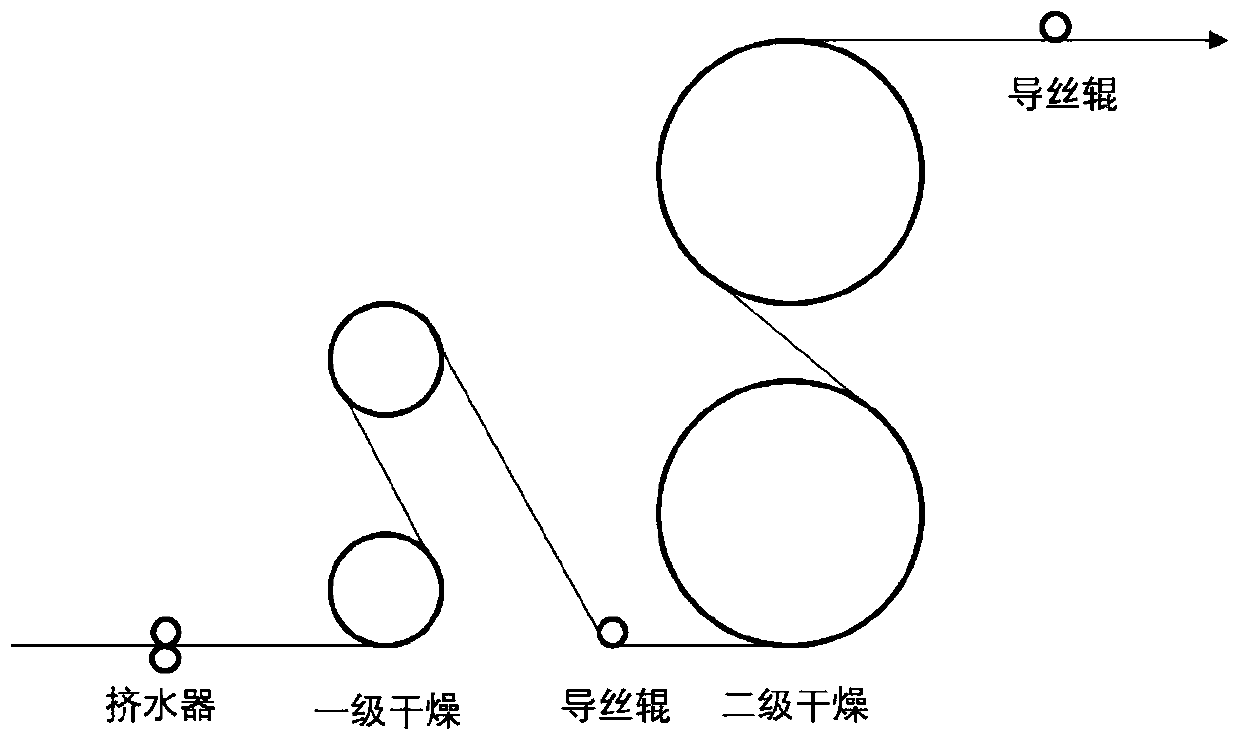

A para-aramid fiber and high modulus technology, which is applied in fiber treatment, fiber chemical characteristics, wet spinning, etc., can solve the problems of long drying time, more fluff, and low modulus, so as to reduce energy consumption, Improved fiber performance and high degree of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of preparation method of high modulus para-aramid fiber of the present invention: (1) preparation of polymer: under nitrogen protection, PPD is dissolved in NMP / CaCl 2 Stir and mix evenly in the solvent, use a condensing agent to control the temperature in the jacket of the reaction kettle at -5°C, add TPC twice, the molar ratio of TPC to PPD is 1.001:1, add 30% TPC for 8 seconds for the first time , then lower the temperature to -5~0°C, add 70% TPC for the second time to react for 30 minutes, transfer the reaction mixture to a neutralization tank and add 8% NaOH solution to neutralize it, and then use deionized Water graded washing 10 times, steam drying at 120°C to obtain PPTA with a water content of less than 100ppm and an intrinsic viscosity of 7.5-8.5dL / g;

[0021] (2) Preparation of spinning stock solution: at a temperature of 80-100°C, multi-stage jacket temperature control, under nitrogen sealing, mix and stir PPTA with an intrinsic viscosity of 7.5-8.5dL...

Embodiment 2

[0025] A kind of preparation method of high modulus para-aramid fiber of the present invention: (1) preparation of polymer: under nitrogen protection, PPD is dissolved in NMP / CaCl 2 Stir and mix evenly in the solvent, use a condensing agent to control the temperature in the jacket of the reaction kettle at -3°C, add TPC twice, the molar ratio of TPC to PPD is 1.001:1, add 40% TPC for 10 seconds for the first time , then lower the temperature to -5~0°C, add 60% TPC for the second time to react for 30 minutes, transfer the reaction mixture to a neutralization tank and add a 10% NaOH solution to neutralize it, and then use a deionized Water graded washing 10 times, steam drying at 130°C to obtain PPTA with a water content of less than 90ppm and an intrinsic viscosity of 7.5-8.5dL / g;

[0026] (2) Preparation of spinning stock solution: at a temperature of 80-100°C, multi-stage jacket temperature control, under nitrogen sealing, mix and stir PPTA with an intrinsic viscosity of 7.5-...

Embodiment 3

[0030] A kind of preparation method of high modulus para-aramid fiber of the present invention: (1) preparation of polymer: under nitrogen protection, PPD is dissolved in NMP / CaCl 2 Stir and mix evenly in the solvent, use a condensing agent to control the temperature in the jacket of the reaction kettle at -2°C, add TPC twice, the molar ratio of TPC to PPD is 1.002:1, add 45% TPC for 12 seconds for the first time , then lower the temperature to -5 ~ 0 ° C, add 55% TPC for the second time to react for 30 minutes, transfer the reaction mixture to a neutralization tank and add 12% NaOH solution for neutralization to neutrality, and then use deionized water for classification Washing 10 times, steam drying at 140°C to obtain PPTA with a water content of less than 70ppm and an intrinsic viscosity of 7.5-8.5dL / g;

[0031] (2) Preparation of spinning stock solution: at a temperature of 80-100°C, multi-stage jacket temperature control, under nitrogen sealing, mix and stir PPTA with an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com