High-strength polypropylene composition and preparation method thereof

A technology of polypropylene composition and polypropylene, which is applied in the field of dynamic vulcanization to prepare the above-mentioned composition and high-strength polypropylene composition. Prospect of industrialization, reduce the degree of degradation, ensure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

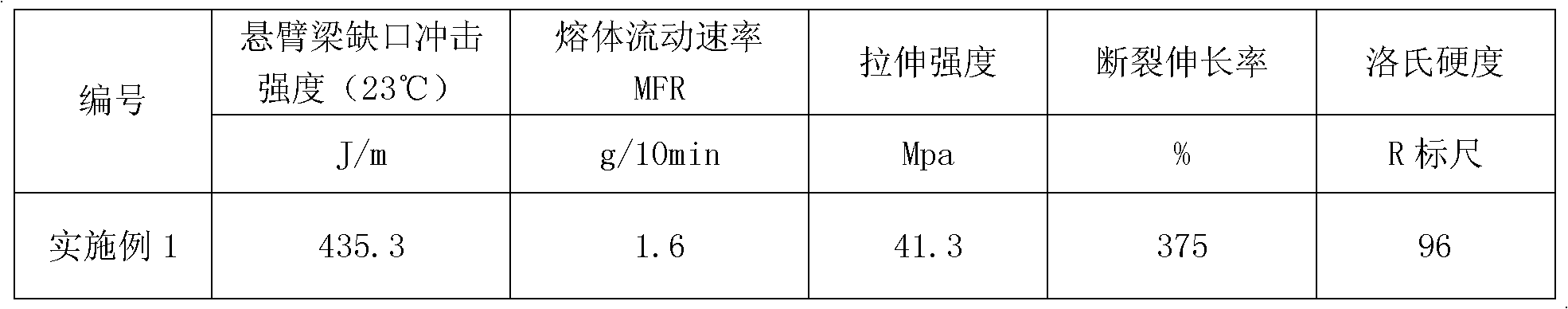

Embodiment 1

[0052] (1) Preparation of modified powdered styrene-butadiene rubber: Add 1kg of water and 3kg of carboxylated styrene-butadiene latex into a 15L coagulation kettle, feed low-pressure steam, heat the slurry to 55°C, stir and mix for 3min; add 60g of release agent and mix 3min; then add 2kg of unvulcanized powdered styrene-butadiene rubber 1500a and mix for 40min; stop stirring and discharge, centrifugal dehydration, and dry at 50°C for 24hrs to make modified powdered styrene-butadiene rubber.

[0053] (2) Preparation of polypropylene composition: first put 0.004kg TBHP and 0.01kg acetone solvent into a beaker and mix them; put 0.06kg carboxylated styrene-butadiene latex and 0.02kg sulfur into a beaker and mix them for 3 minutes, then pour them into Mix together for 3 minutes; put the mixed solution, 0.2kg modified powdered styrene-butadiene rubber 1500a, and 0.002kg BMI-MP into a high-speed mixer and mix at high speed for 5 minutes to make a premixed masterbatch;

[0054] Mix ...

Embodiment 2

[0056] (1) Preparation of modified powdered styrene-butadiene rubber: Add 1kg of water and 3kg of carboxylated styrene-butadiene latex into a 15L coagulation kettle, feed low-pressure steam, heat the slurry to 55°C, stir and mix for 3 minutes; add 70g of release agent and mix 3min; then add 2kg of unvulcanized powdered styrene-butadiene rubber 1500b and mix for 30min; stop stirring and discharge, centrifugal dehydration, and dry at 50°C for 24hrs to make modified powdered styrene-butadiene rubber.

[0057] (2) Preparation of polypropylene composition: first put 0.005kg TBHP and 0.01kg acetone solvent into a beaker and mix; put 0.1kg carboxylated styrene-butadiene latex and 0.03kg sulfur into a beaker and mix for 3 minutes, then pour the two into Mix together for 3 minutes; put the mixed solution, 0.3kg modified powdered styrene-butadiene rubber 1500b, and 0.003kg BMI-MP into a high-speed mixer and mix at high speed for 5 minutes to make a premixed masterbatch;

[0058] Mix the...

Embodiment 3

[0060] (1) Preparation of modified powdered styrene-butadiene rubber: Add 1kg of water and 3kg of carboxylated styrene-butadiene latex into a 15L coagulation kettle, feed low-pressure steam, heat the slurry to 55°C, stir and mix for 3 minutes; add 80g of release agent and mix 3min; then add 2kg of powdered styrene-butadiene rubber 1712a and mix for 30min; stop stirring and discharge, centrifugal dehydration, and dry at 50°C for 24hrs to produce modified powdered styrene-butadiene rubber.

[0061] (2) Preparation of polypropylene composition: first put 0.003kg TAHP and 0.01kg toluene solvent into a beaker and mix them; put 0.08kg carboxylated styrene-butadiene latex and 0.027kg sulfur into a beaker and mix them for 3 minutes, then pour them into Mix together for 3 minutes; put the mixed solution, 0.35kg modified powdered styrene-butadiene rubber 1712a, and 0.003kg BMI-MP into a high-speed mixer and mix at high speed for 5 minutes to make a premixed masterbatch;

[0062] Mix the...

PUM

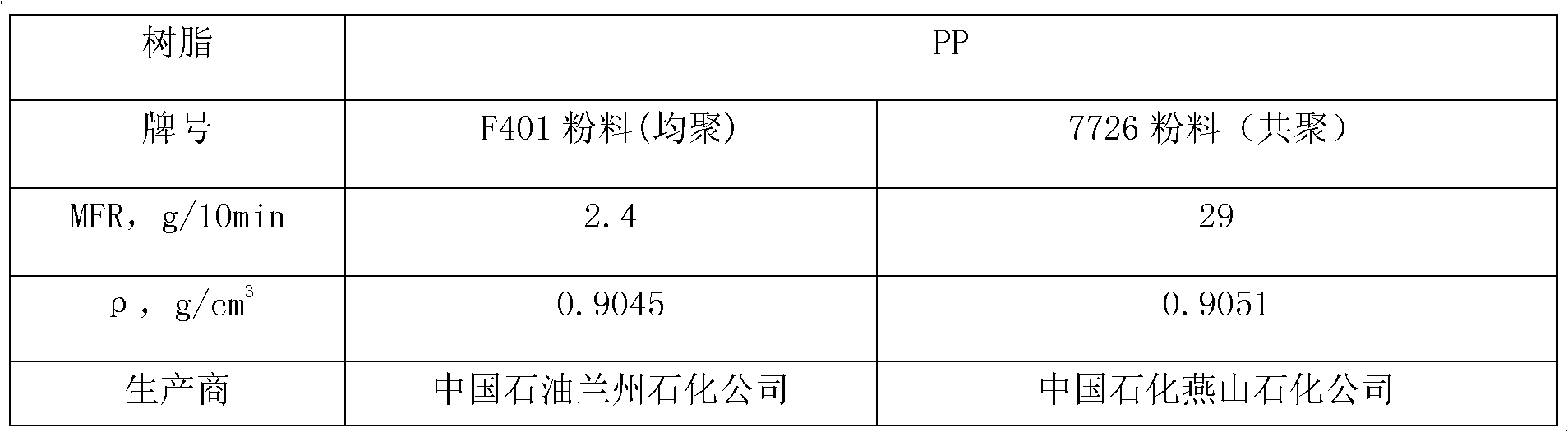

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com