Permanent antistatic and low-temperature-resistant polystyrene material as well as production method and application thereof

A polystyrene, antistatic technology, applied in the field of modified plastics, can solve the problems of easy peeling off of the coating, unsatisfactory, loss of antistatic effect, etc., to improve antistatic performance, improve rheological properties, and optimize appearance effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

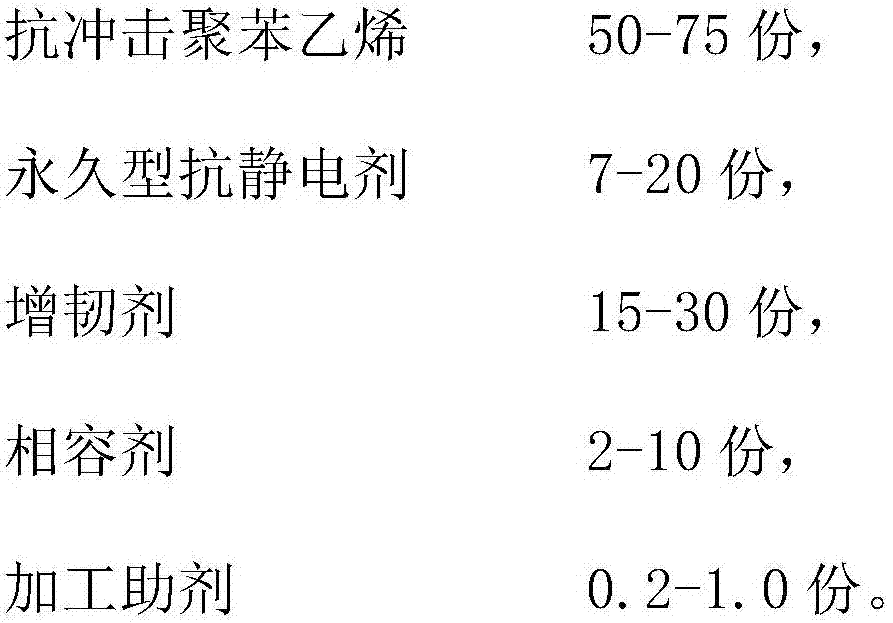

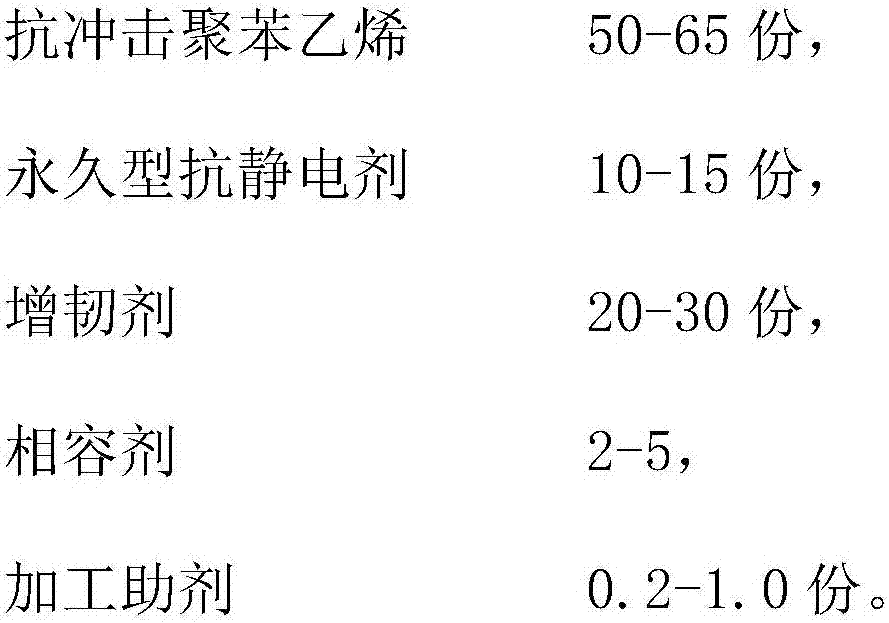

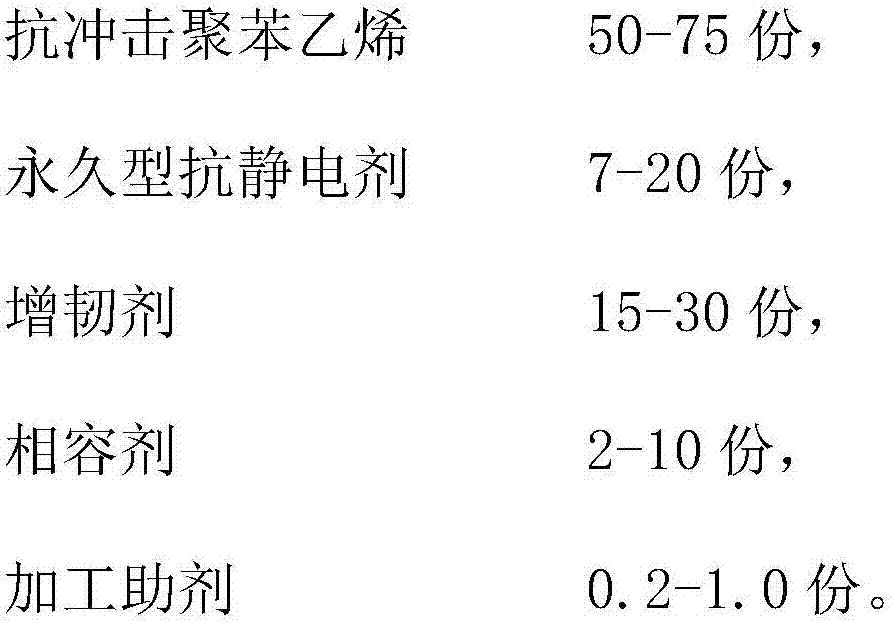

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the permanent antistatic and low-temperature resistant polystyrene material includes the following steps: the above-mentioned raw materials are uniformly mixed, and then fed from the main feed port of the extruder, and the raw materials are melted and extruded in the extruder. , After granulation, a permanent antistatic and low temperature resistant polystyrene material is obtained.

[0028] The extruder is a twin-screw extruder, and the melting temperature in the melting step is 190-220°C. The processing conditions of the melting step are as follows: the temperature in the first zone is 80-100°C, the temperature in the second zone is 170-190°C, the temperature in the third zone is 190-210, the temperature in the fourth zone is 200-220°C, and the temperature in the fifth zone is 200-220°C. The zone temperature is 200-220℃, the seven zone temperature is 190-210℃, the eight zone temperature is 190-210℃, the nine zone temperature is 200-210℃, and the...

Embodiment 1-4

[0031] In the permanent antistatic and low temperature resistant polystyrene material: the impact-resistant polystyrene is HIPS, the permanent antistatic agent is PELESTAT 6500 from Sanyo Kasei, and the permanent antistatic agent is Block copolymers containing polyamide segments or polyethers; the toughening agent is styrene-butadiene-styrene block copolymer (SBS); the compatibilizer is the Dutch polyscope SZ23110; The antioxidant is antioxidant 1010; the lubricant is ethylene bis-stearamide (EBS). See Table 1 for the recipe.

[0032] The preparation method of the permanent antistatic and low-temperature resistant polystyrene material includes the following steps: the above-mentioned raw materials are uniformly mixed, and then fed from the main feed port of the extruder, and the raw materials are melted and extruded in the extruder. , After granulation, a permanent antistatic and low temperature resistant polystyrene material is obtained.

[0033] The extruder is a twin-screw ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com