Low-floating-fiber glass fiber reinforced polypropylene material and preparation method thereof

A technology of polypropylene material and glass fiber, which is applied in the field of glass fiber reinforced polypropylene material and its preparation, can solve the problems that glass fiber cannot be filled, and glass fiber exposure is poorly improved, so as to improve the apparent performance and mechanical performance, and achieve excellent performance , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

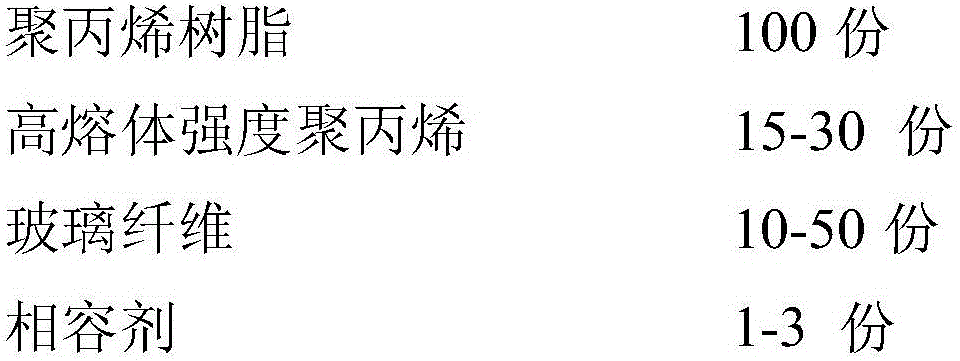

[0039] Described a kind of low float glass fiber reinforced polypropylene material, it comprises following composition:

[0040]

[0041] The polypropylene is selected from Yangzi Petrochemical S700 (isotactic polypropylene).

[0042] The glass fiber is an alkali-free glass fiber with a diameter of 8 μm.

[0043] The high melt strength polypropylene is a polypropylene resin having 0.05 long-chain branches per 1000 carbon atoms and a polydispersity coefficient of 4;

[0044] The compatibilizer is cyclic anhydride grafted polypropylene (PP-g-MAH);

[0045] The ethylene-propylene block copolymer is an ethylene-propylene block copolymer elastomer with an ethylene segment content of 15%;

[0046] The other additives described are flow modifier PE wax.

[0047] The preparation method of the low-floating glass fiber reinforced polypropylene material comprises the following specific steps: producing by melt extrusion and blending process, and the screw rod is divided into 10 hea...

Embodiment 2

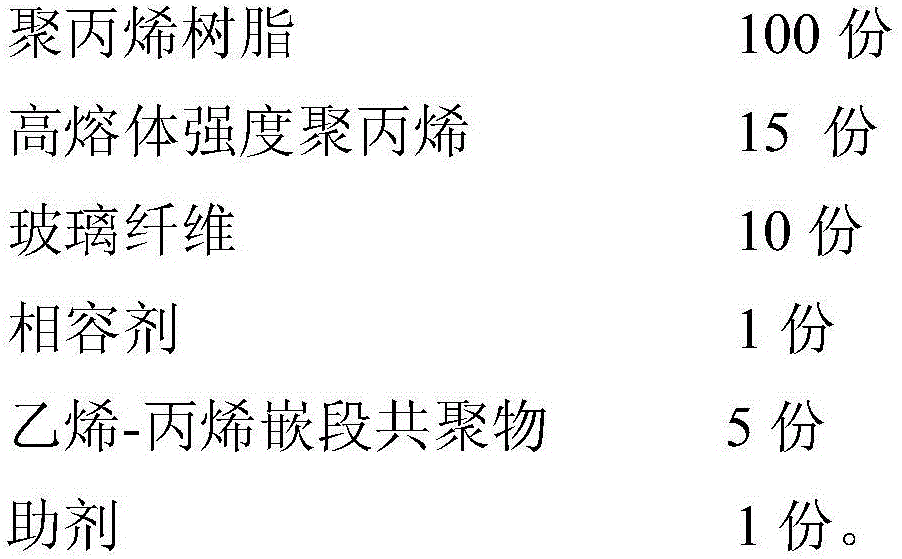

[0051] Described a kind of low float glass fiber reinforced polypropylene material, it comprises following composition:

[0052]

[0053] Described polypropylene is selected from Korea SK BX3800 (syndiotactic polypropylene);

[0054] The glass fiber is an alkali-free glass fiber with a diameter of 20 μm;

[0055] The high melt strength polypropylene is a polypropylene resin having 0.15 long-chain branches per 1000 carbon atoms and a polydispersity coefficient of 10;

[0056] The compatibilizer is cyclic anhydride grafted polypropylene (PP-g-MAH);

[0057]The ethylene-propylene block copolymer is an ethylene-propylene block copolymer elastomer with an ethylene segment content of 20%;

[0058] The other additives described are flow modifier PE wax.

[0059] The preparation method of the low-floating glass fiber reinforced polypropylene material comprises the following specific steps: producing by melt extrusion and blending process, and the screw rod is divided into 10 hea...

Embodiment 3

[0063] Described a kind of low float glass fiber reinforced polypropylene material, it comprises following composition:

[0064]

[0065] The polypropylene is selected from the 1:1 mixture of SK BX3800 (syndiotactic polypropylene) and Yangzi Petrochemical S700 (isotactic polypropylene) in South Korea;

[0066] The glass fiber is an alkali-free glass fiber with a diameter of 12 μm;

[0067] The high melt strength polypropylene is a polypropylene resin having 0.1 long-chain branches per 1000 carbon atoms and a polydispersity coefficient of 8;

[0068] The compatibilizer is cyclic anhydride grafted polypropylene (PP-g-MAH);

[0069] The ethylene-propylene block copolymer is an ethylene-propylene block copolymer elastomer with an ethylene segment content of 18%;

[0070] The other additives described are flow modifier PE wax;

[0071] The preparation method of the low-floating glass fiber reinforced polypropylene material comprises the following specific steps: producing by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com