Halogen-free flame-retardant polyamide resin composition and preparation method thereof

A technology for flame-retardant polyamide and resin composition, which is applied in the field of halogen-free flame-retardant polyamide resin composition and its preparation, can solve the problem of low mechanical properties of the polyamide resin composition, large amount of inorganic flame retardant added, and adverse effects. problems such as the life of electrical products, to achieve the effect of reducing the effective melt viscosity, reducing the processing temperature, and improving the yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

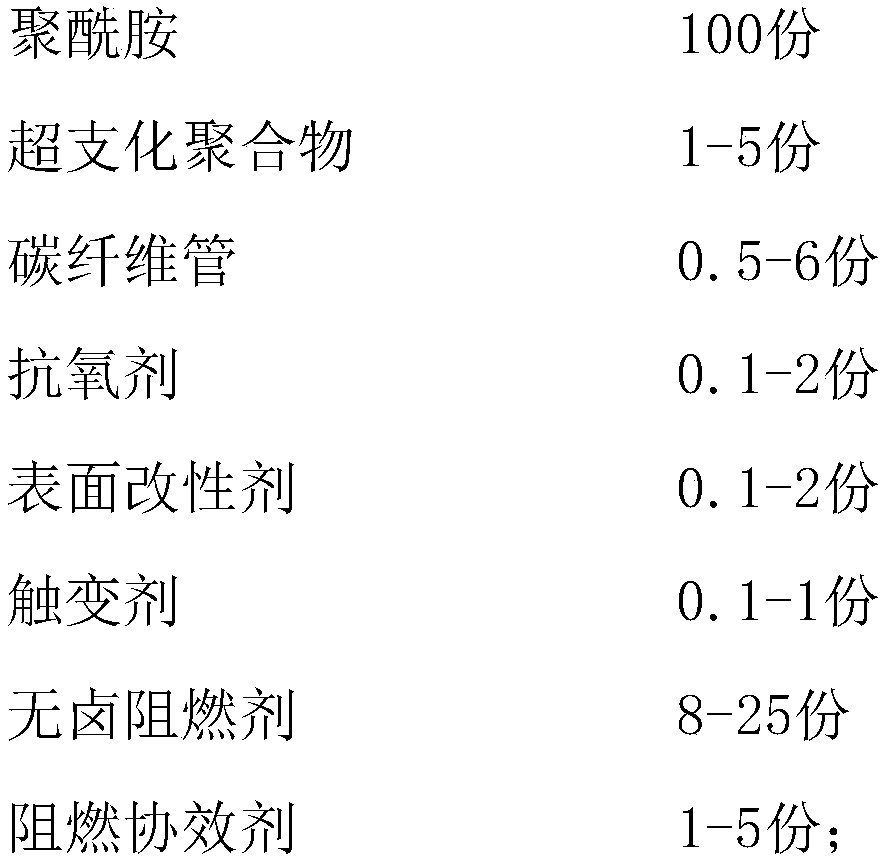

[0042] A halogen-free flame-retardant polyamide resin composition prepared from the following raw materials:

[0043]

[0044] Wherein, the hyperbranched polymer is an amino-terminated hyperbranched polyamide.

[0045] The polyamide is a PA6 / PA66 / PA6T ternary copolymerization material, and the PA6 / PA66 / PA6T ternary copolymerization material is prepared by melt copolymerization of caprolactam, hexamethylene adipate and hexamethylene p-benzoamide, wherein The mass ratio of caprolactam, hexamethylene adipate and hexamethylene p-benzoyl is 5:2:1.

[0046] The carbon fiber tube is a modified multi-wall carbon fiber tube, the diameter of the multi-wall carbon fiber tube is 15-40nm, and the length is 0.2-2μm. The specific modification step is: after passivating the multi-wall carbon fiber tube with concentrated sulfuric acid, The taurine is grafted onto the surface of the multi-wall carbon fiber tube under gamma ray irradiation to obtain the modified multi-wall carbon fiber tube....

Embodiment 2

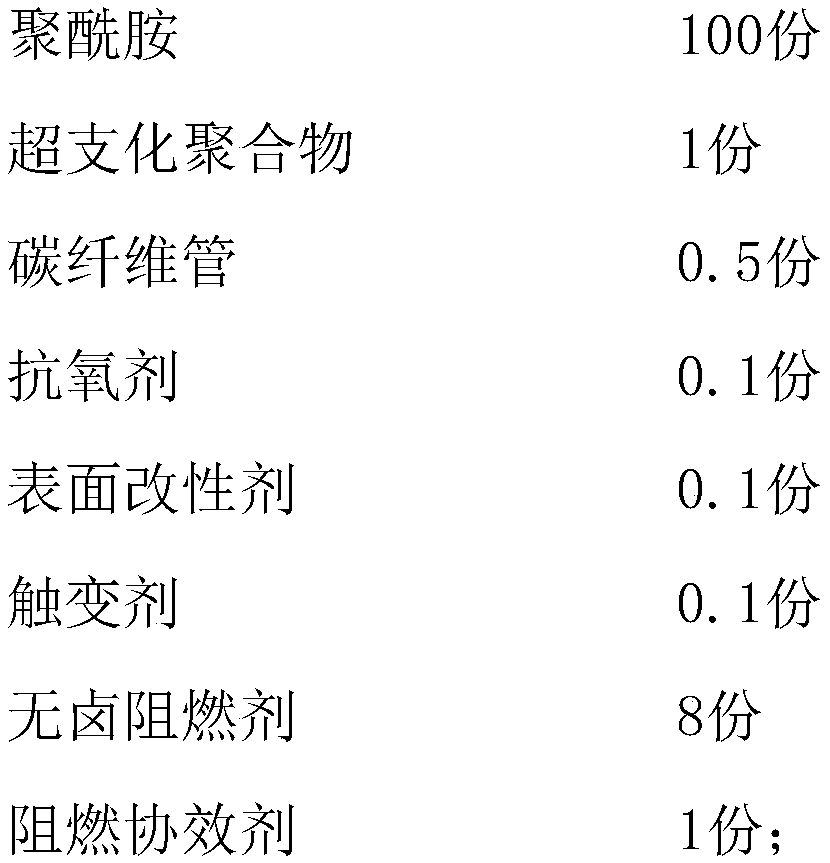

[0063] A halogen-free flame-retardant polyamide resin composition prepared from the following raw materials:

[0064]

[0065]

[0066] Wherein, the hyperbranched polymer is an amino-terminated hyperbranched polyamide.

[0067] The polyamide is a PA6 / PA66 / PA6T ternary copolymerization material, and the PA6 / PA66 / PA6T ternary copolymerization material is prepared by melt copolymerization of caprolactam, hexamethylene adipate and hexamethylene p-benzoamide, wherein The mass ratio of caprolactam, hexamethylene adipate and hexamethylene p-benzoyl is 7:4:1.

[0068] The carbon fiber tube is a modified multi-wall carbon fiber tube, the diameter of the multi-wall carbon fiber tube is 15-40nm, and the length is 0.2-2μm. The specific modification step is: after passivating the multi-wall carbon fiber tube with concentrated sulfuric acid, The taurine is grafted onto the surface of the multi-wall carbon fiber tube under gamma ray irradiation to obtain the modified multi-wall carbon...

Embodiment 3

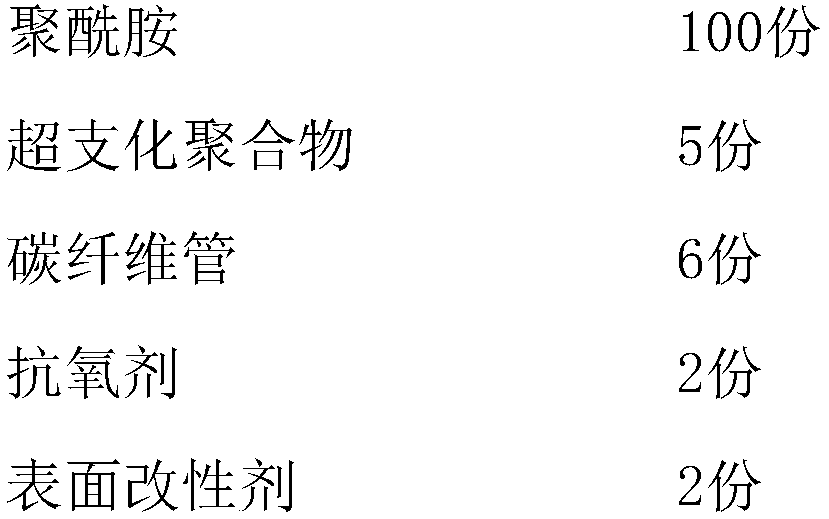

[0085] A halogen-free flame-retardant polyamide resin composition prepared from the following raw materials:

[0086]

[0087] Wherein, the hyperbranched polymer is an amino-terminated hyperbranched polyamide.

[0088] The polyamide is a PA6 / PA66 / PA6T ternary copolymerization material, and the PA6 / PA66 / PA6T ternary copolymerization material is prepared by melt copolymerization of caprolactam, hexamethylene adipate and hexamethylene p-benzoamide, wherein The mass ratio of caprolactam, hexamethylene adipate and hexamethylene p-benzoyl is 6:3:1.

[0089] The carbon fiber tube is a modified multi-wall carbon fiber tube, the diameter of the multi-wall carbon fiber tube is 15-40nm, and the length is 0.2-2μm. The specific modification step is: after passivating the multi-wall carbon fiber tube with concentrated sulfuric acid, The taurine is grafted onto the surface of the multi-wall carbon fiber tube under gamma ray irradiation to obtain the modified multi-wall carbon fiber tube....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com