ATH (alumina trihydrate)/graphene-synergized flame-retardant EVA (ethylene-vinyl acetate copolymer) and preparation method thereof

A technology of synergistic flame retardant and graphene, applied in the field of flame retardant EVA materials, can solve the problems of composite material processing performance and mechanical properties, and achieve the effects of improving mechanical properties, improving dispersibility, and enhancing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

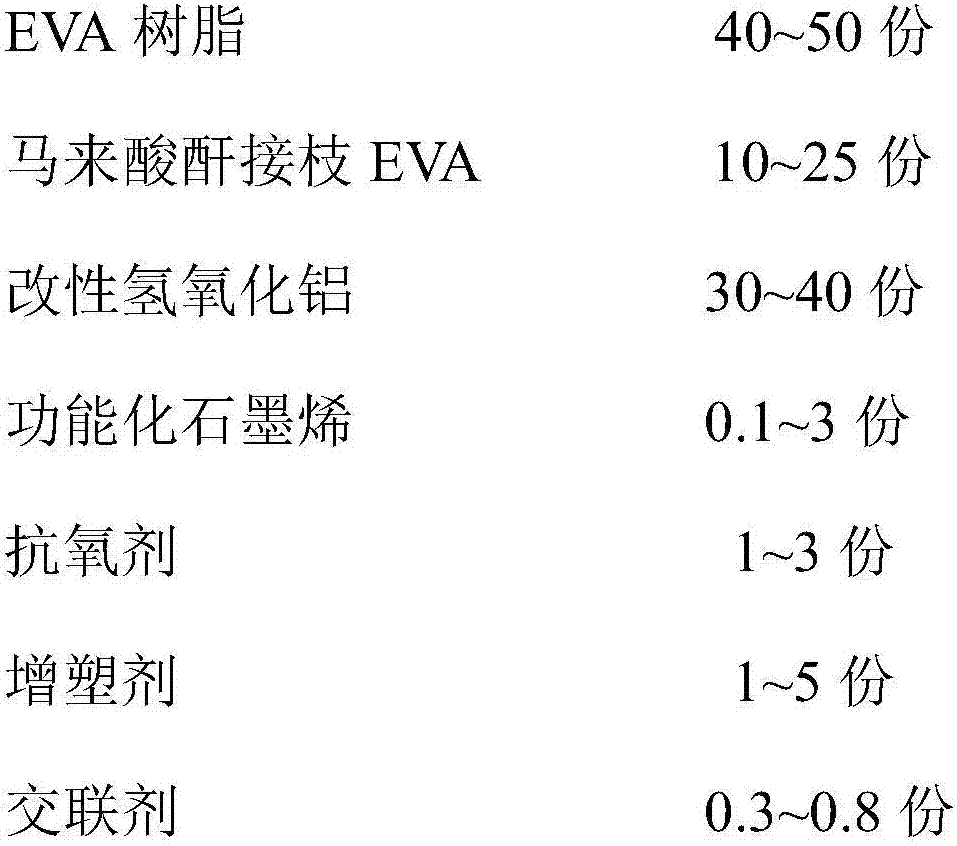

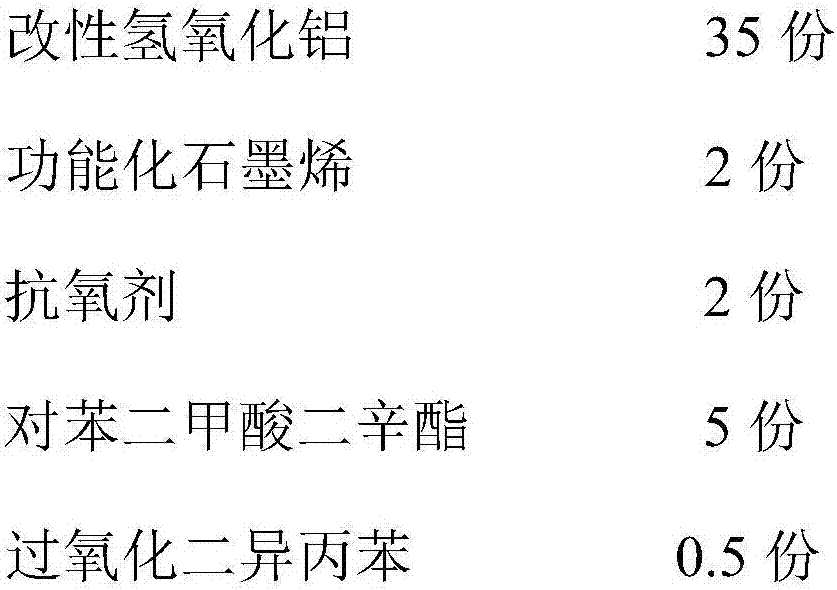

[0025] A kind of ATH / graphene synergistic flame retardant EVA material, its composition is calculated as follows in parts by weight:

[0026]

[0027]

[0028] The VA content in the described EVA resin is 25%.

[0029] The grafting rate of the maleic anhydride grafted EVA is 1.5%.

[0030] The modified aluminum hydroxide is prepared by the following method: dry the aluminum hydroxide at 110°C for 5-10 hours, then add distilled water to obtain the material, the mass ratio of aluminum hydroxide to distilled water is 3:2; then put the material into a constant temperature Heat to 50°C in a water bath, stir at a constant temperature, and the stirring speed is 4500r / min; then add titanate coupling agent and continue stirring at 4000r / min for 2h, the amount of titanate coupling agent added is 10% of the mass of aluminum hydroxide %, after emulsification, suction filtration, drying at 110°C for 5 hours, grinding and sieving to obtain modified aluminum hydroxide with a particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com