Environment-friendly type modified master batch and preparation method thereof

A modified masterbatch and environmentally friendly technology, which is applied in the field of processing plastic products, can solve the problems of affecting the quality of plastic products and the decline of mechanical properties of plastic products, and achieve the effects of maintaining physical and mechanical properties, improving mechanical properties, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Environmentally friendly modified masterbatch, including the following components, in parts by weight:

[0044] 3000 mesh ground calcium carbonate (CaCO 3 ) 61Kg

[0045] Linear Low Density Polyethylene (LLDPE) 17Kg

[0046] Polyethylene wax 2Kg

[0047] Coordination type titanate coupling agent (TIO 3 (OR) 2 ) 1Kg

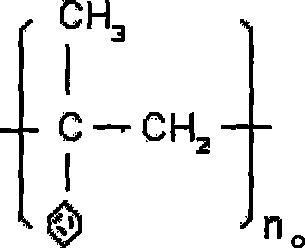

[0048] α-Methylstyrene 1Kg

[0049] Composite wax (PEW) 1Kg

[0050] Zinc stearate ([CH 3 (CH 2 ) 16 COO] 2 Zn) 1Kg

[0051] Calcium Stearate (C 36 h 70 CaO 4 ) 0.5Kg

[0052] Poly-alpha-methylstyrene 0.6Kg

[0053] Tricresyl Phosphate 0.8Kg

[0054] The preparation method is as follows: put the above-mentioned heavy calcium carbonate into a high-speed mixer and stir and mix for 15 minutes, add coordination type titanate coupling agent and diluent and stir and mix for 5 minutes, then add other small materials and stir and mix for 1 minute, Make a mixture; put the mixture into a co-rotating twin-screw granulator for granulation, heat cuttin...

Embodiment 2

[0056] Environmentally friendly modified masterbatch, including the following components, in parts by weight:

[0057] 3000 mesh ground calcium carbonate (CaCO 3 ) 67Kg

[0058] Linear Low Density Polyethylene (LLDPE) 23Kg

[0059] Polyethylene wax 4Kg

[0060] Coordination type titanate coupling agent (TIO 3 (OR) 2 ) 2Kg

[0061] α-Methylstyrene 2Kg

[0062] Composite wax (PEW) 2Kg

[0063] Zinc stearate ([CH 3 (CH 2 ) 16 COO] 2 Zn) 2Kg

[0064] Calcium Stearate (C 36 h 70 CaO 4 ) 1Kg

[0065] Poly-alpha-methylstyrene 0.5Kg

[0066] Tricresyl Phosphate 0.7Kg

[0067] The preparation method is as follows: put 3000 mesh heavy calcium carbonate into a high-speed mixer and stir for 15 minutes, add coordination type titanate coupling agent and diluent and stir for 8 minutes, then add other small materials and stir for 2 minutes , to make a mixture; put the mixture into a co-rotating twin-screw granulator for granulation, heat cutting, cooling and packaging, and t...

Embodiment 3

[0069] Environmentally friendly modified masterbatch, including the following components, in parts by weight:

[0070] 3000 mesh ground calcium carbonate (CaCO 3 ) 69Kg

[0071] Linear Low Density Polyethylene (LLDPE) 25Kg

[0072] Polyethylene wax 4.5Kg

[0073] Coordination type titanate coupling agent (TIO 3 (OR) 2 ) 2.5Kg

[0074] α-Methylstyrene 2.5Kg

[0075] Composite wax (PEW) 2.5Kg

[0076] Zinc stearate ([CH 3 (CH 2 ) 16 COO] 2 Zn) 2.5Kg

[0077] Calcium Stearate (C 36 h 70 CaO 4 ) 1.5Kg

[0078] Poly-alpha-methylstyrene 0.3Kg

[0079] Tricresyl Phosphate 0.3Kg

[0080] The preparation method is as follows: put 3000 mesh heavy calcium carbonate into a high-speed mixer and stir for 15 minutes, add coordination type titanate coupling agent and diluent and stir for 10 minutes, then add other small materials and stir for 3 minutes , to make a mixture; put the mixture into a co-rotating twin-screw granulator for granulation, heat cutting, cooling and pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com