Method for increasing jetting gluing quality and gluing device

A technology of dispensing device and spray point, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problem of difficulty in spraying high-viscosity glue, and achieves solving the problem of spraying difficulty, improving efficiency, Low friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

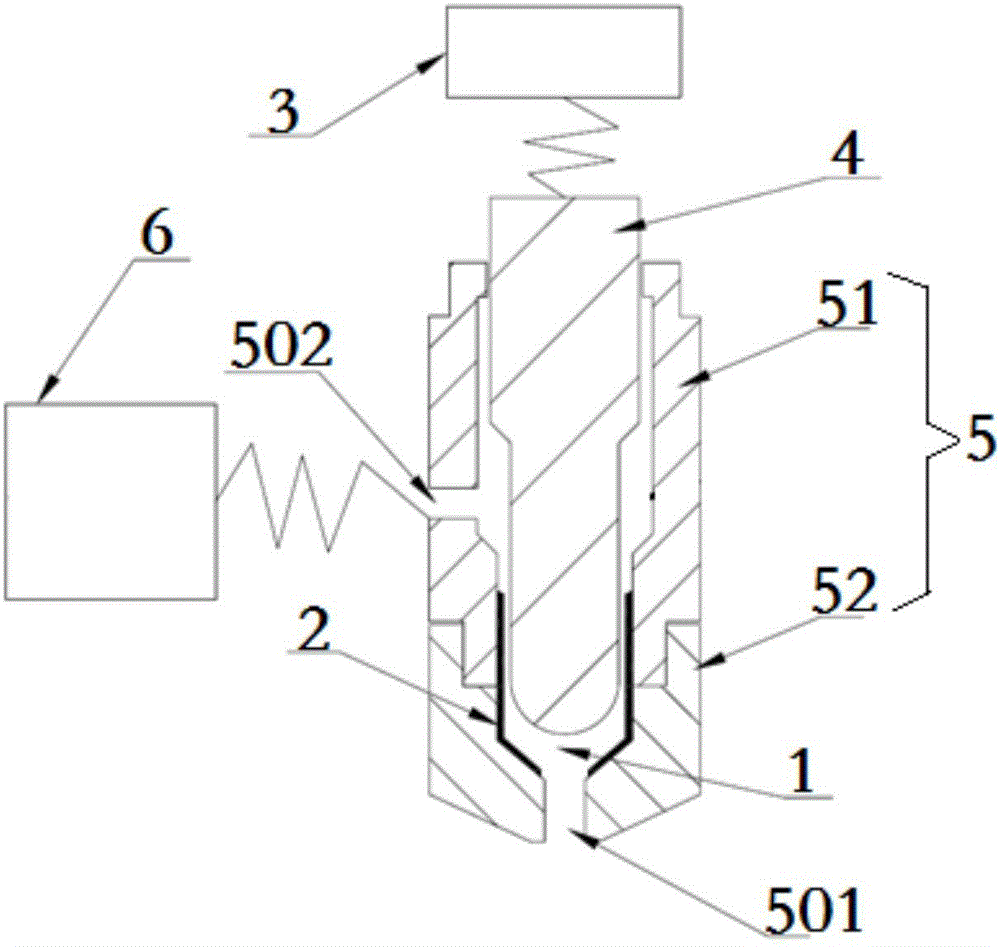

[0036] The core of the present invention is to provide a method and a dispensing device for improving the quality of jet dispensing. High-viscosity glue is more likely to be ejected at a high speed and in a stable state, which solves the difficult problem of high-viscosity glue injection in the current technology, and improves the Improve the quality of dispensing and molding, while improving the efficiency of jet dispensing.

[0037] In order for those skilled in the art to better understand the technical solution of the present invention, the method for improving the quality of jet dispensing and the dispensing device of the present application will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

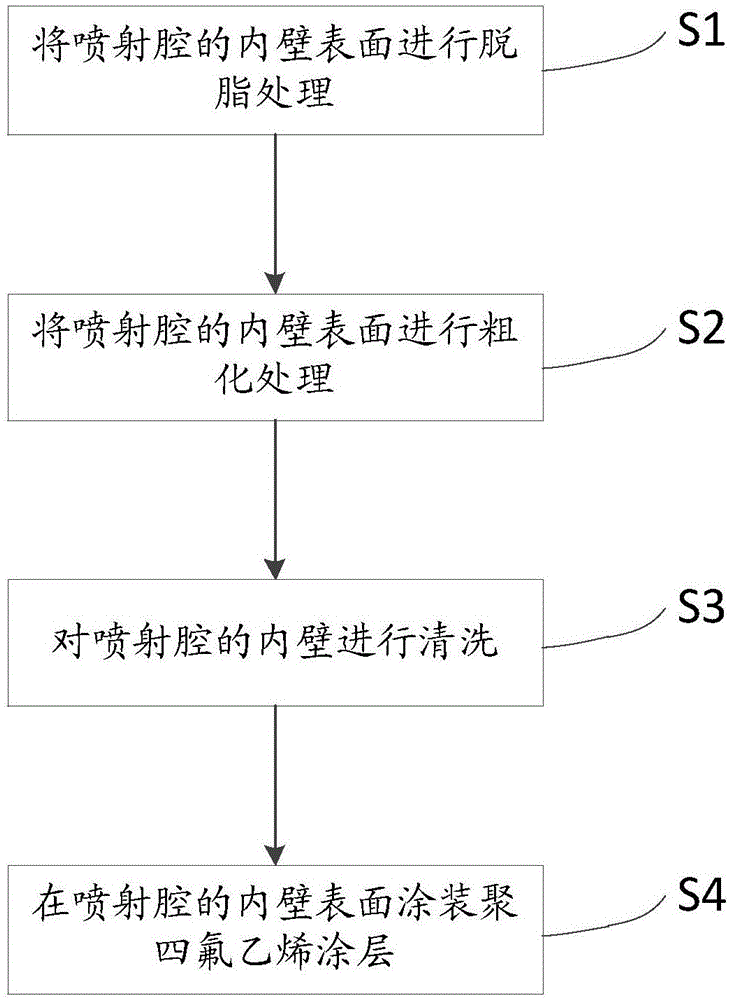

[0038] Such as figure 1 Shown is a specific flow chart of the method for improving the quality of jet dispensing in the present invention. The invention provides a method for improving the quality of jet dispensing, which incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com