Instrument break valve with lower valve stem non-rotation sealing structure

A technology of stop valve and valve stem, which is applied in the direction of valve shell structure, shaft seal, valve operation/release device, etc. It can solve the problems of small friction coefficient, easy wear, large friction force and friction coefficient, etc., and achieve friction and Small amount of frictional movement, long life, and excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

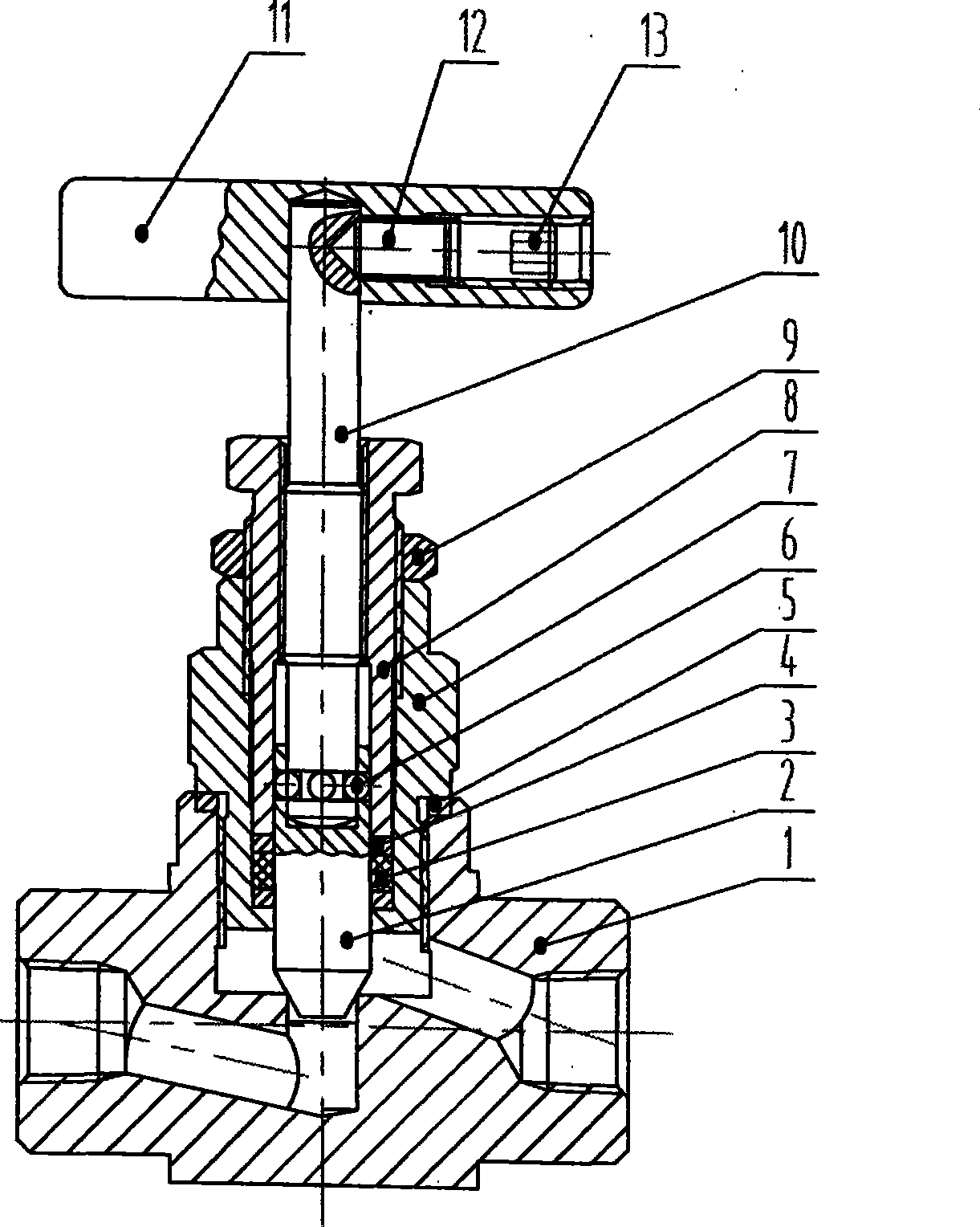

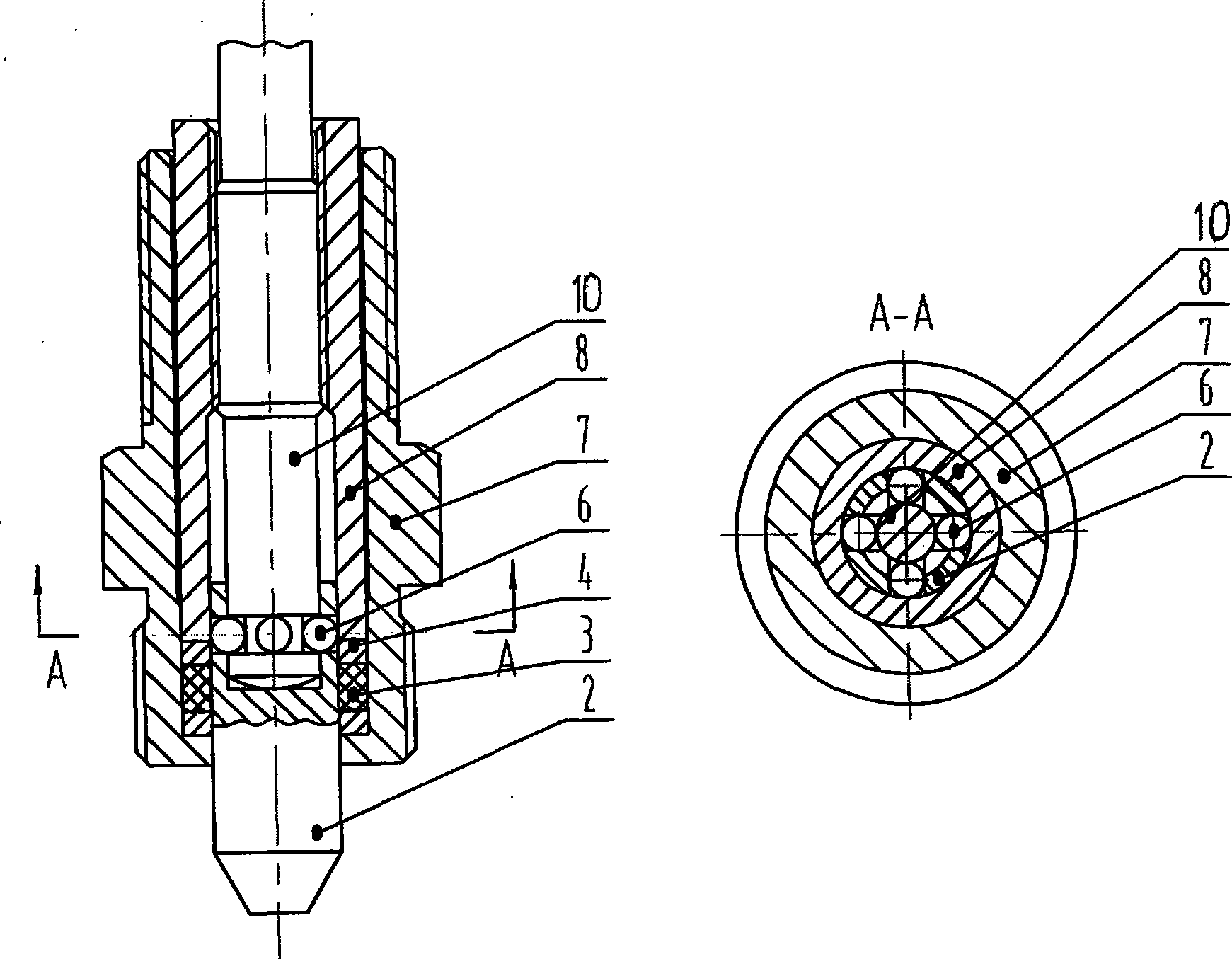

[0015] An instrument globe valve with a non-rotating and sealed structure of the lower valve stem, which consists of a valve body (1), a valve cover (7), a lower valve stem (2), a packing (3), a threaded guide sleeve (8), an upper valve stem ( 10) and other components, such as figure 1 shown. Its characteristics are: one end of the lower valve stem (2) is a valve core, the other end is a hole, the bottom of the hole is a plane, and 3 to 6 small holes are evenly distributed on the corresponding positions of its circumference; the lower part of the upper valve stem (10) The end face is arc-shaped, and it is inserted into the hole of the lower valve stem (2), so that the arc end face is in contact with the bottom plane of the hole, which is not only conducive to the uniform distribution of the force in the center of the lower valve stem (2), but also help...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com