High-pressure resistant three-valve group

A three-valve, high-pressure-resistant technology, used in lift valves, valve details, multi-way valves, etc., can solve the problems affecting the service life and pressure sealing performance of the valve, the operation cannot be carried out continuously, and the valve is damaged by high pressure scouring. Good strength, easy operation, and the effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

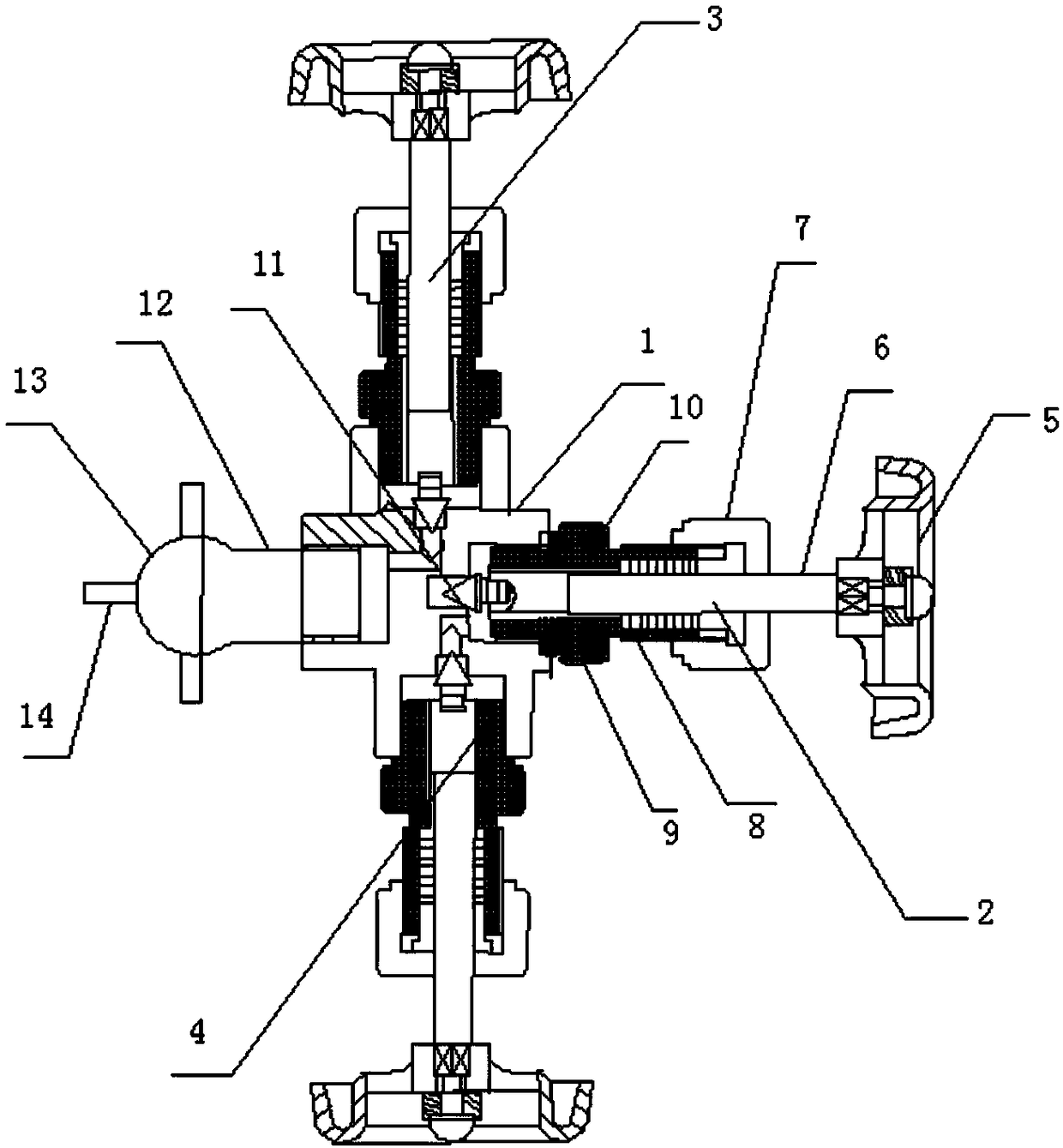

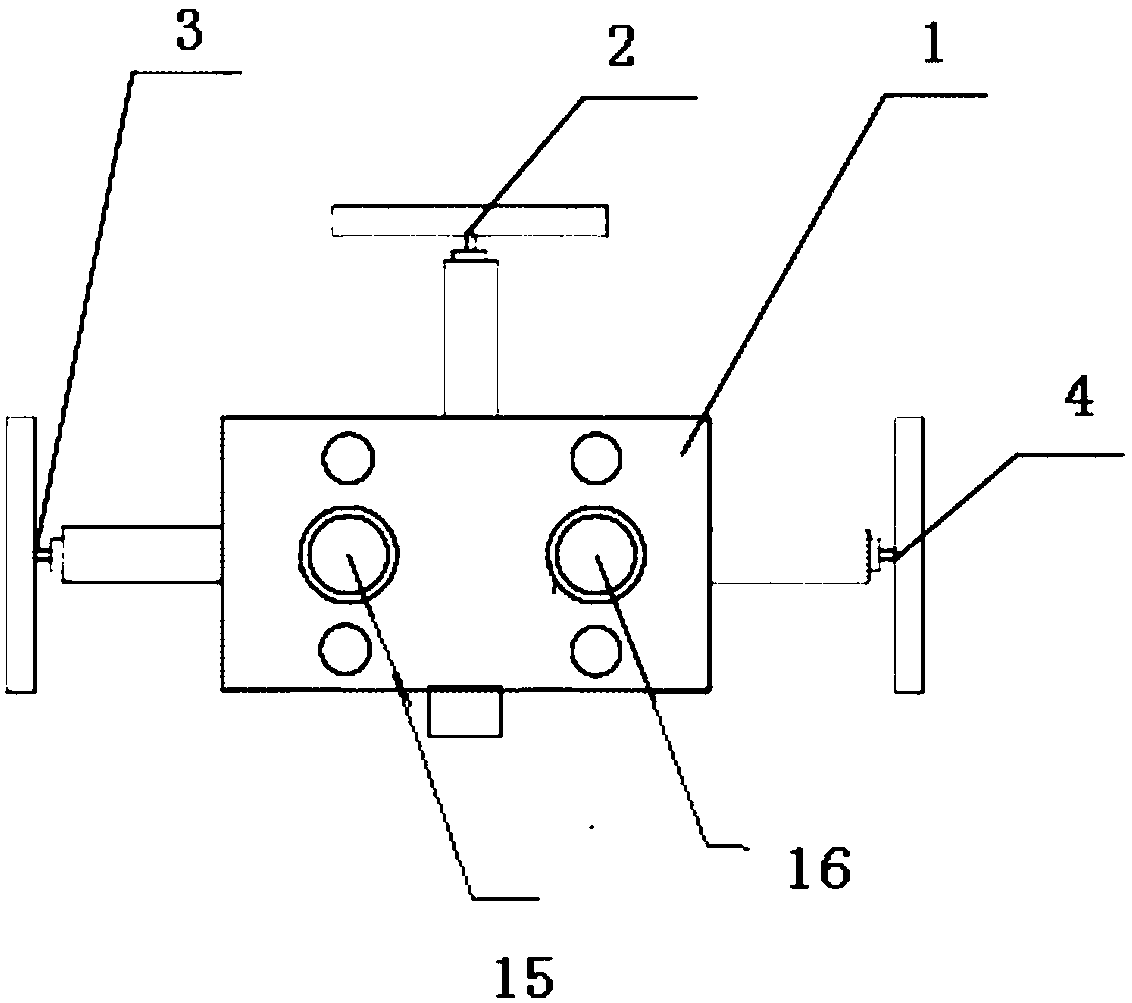

[0017] This embodiment provides a high-pressure three-valve group, such as Figure 1-2 Shown: including valve body 1, first control valve 2, second control valve 3 and third control valve 4, the first control valve is the main cut-off valve, the second control valve is the pressure relief valve, and the third control valve is the balance valve Valve, the valve body is a cuboid structure, the control valve connection port is provided in the middle of any three of the four sides of the valve body, and the medium inlet is provided on the end of the remaining side, the first control valve, the second control valve and the second control valve. The three control valves are respectively installed on the connection ports provided on the side of the valve body, and are used to control the cut-off or communication of each flow channel in the valve body. The second control valve and the third control valve are on the same axis, and the axis of the first control valve is perpendicular to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com