Progressive slow piling steaming box

A progressive, steaming box technology, applied in the field of steaming boxes, can solve the problems of easily scalded fabrics, impermeability, small steaming area, etc., achieve small contact surface and friction, accelerate decomposition activity, and shorten stacking time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

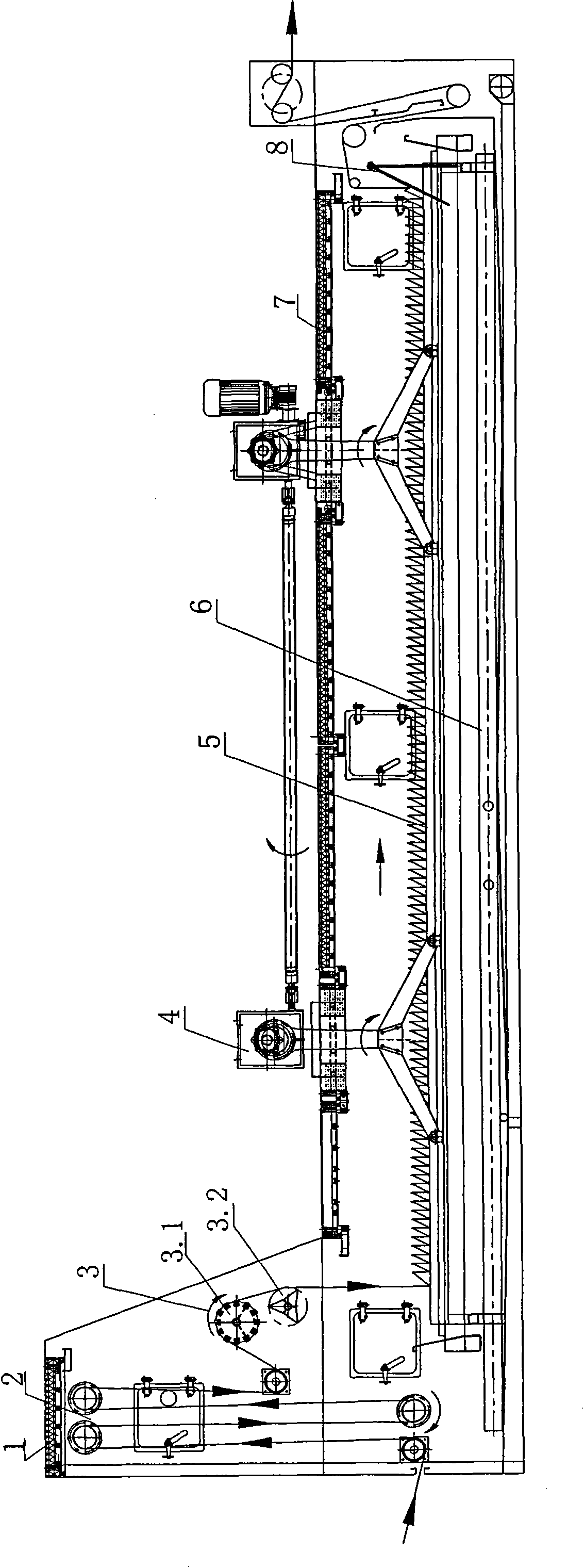

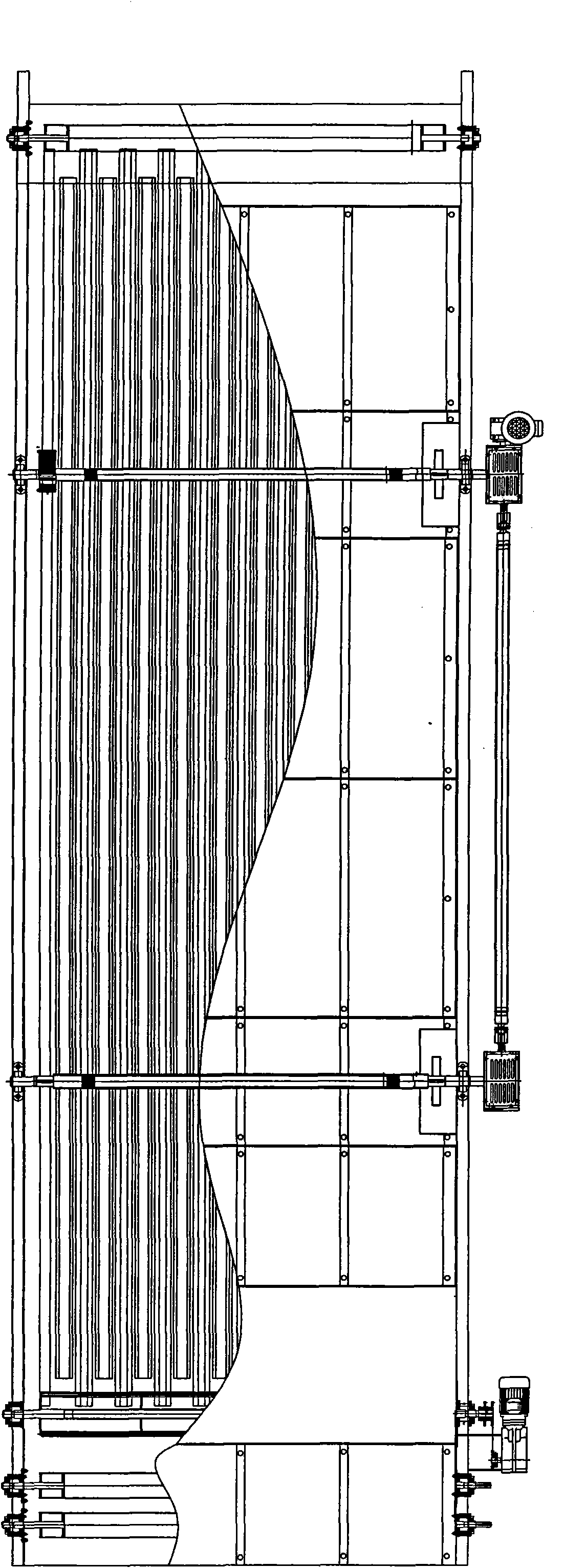

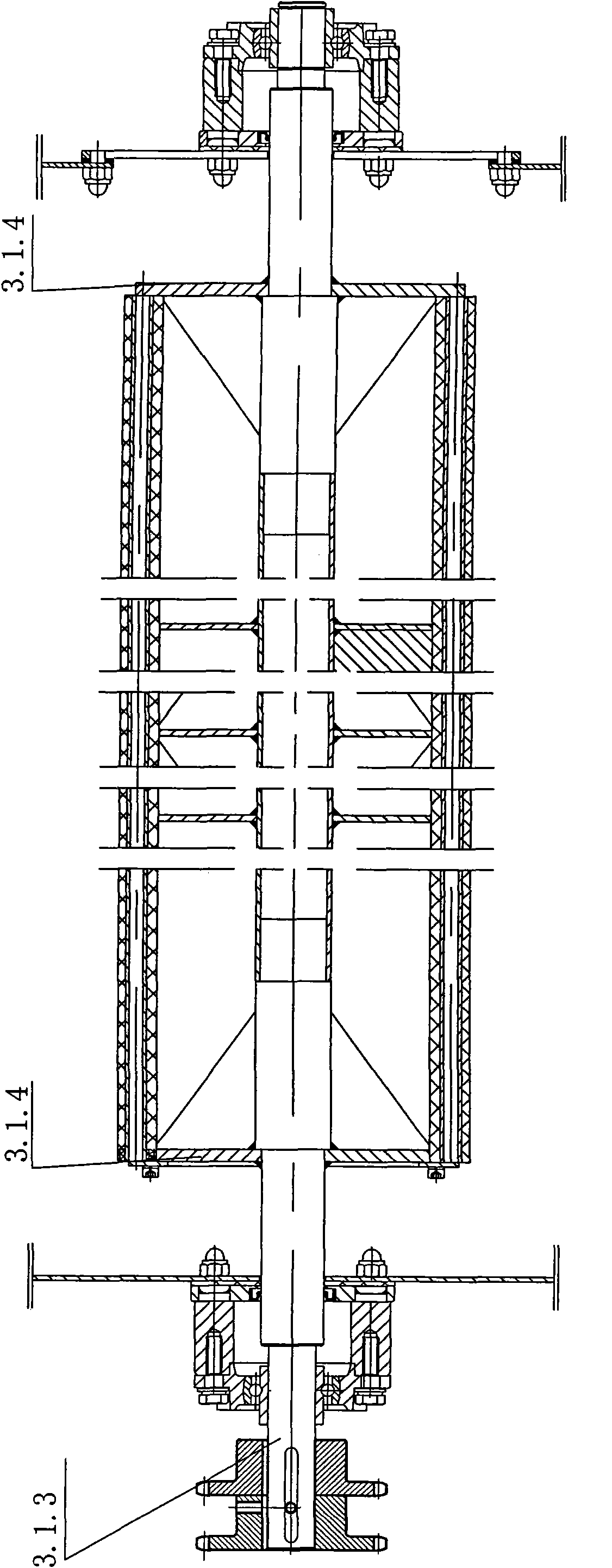

[0026] see Figure 1~2 , figure 1 It is a structural schematic diagram of the progressively stacked slow-moving steamer of the present invention. figure 2 for figure 1 top view. Depend on figure 1 and figure 2 It can be seen that the progressive stacking and slow-moving steaming box of the present invention includes a box body 1, a pre-steaming device 2, a cloth feeding and overfeeding device 3, a progressive slow-moving stacking device 4, a support basket 5, and a heating device 6 , heat preservation device 7 and cloth output control device 8, the pre-steaming device 2 is arranged at the head end of the box body 1 in the direction of cloth entry, the fabric pre-steamed by the pre-steaming device enters the cloth overfeeding device 3 from the pre-steaming device 2, and passes through The advance slow-moving stacking device 4 and the support basket 5 are arranged in the box body 1, and placed behind the cloth feeding and overfeeding device 3, the support basket 5 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com