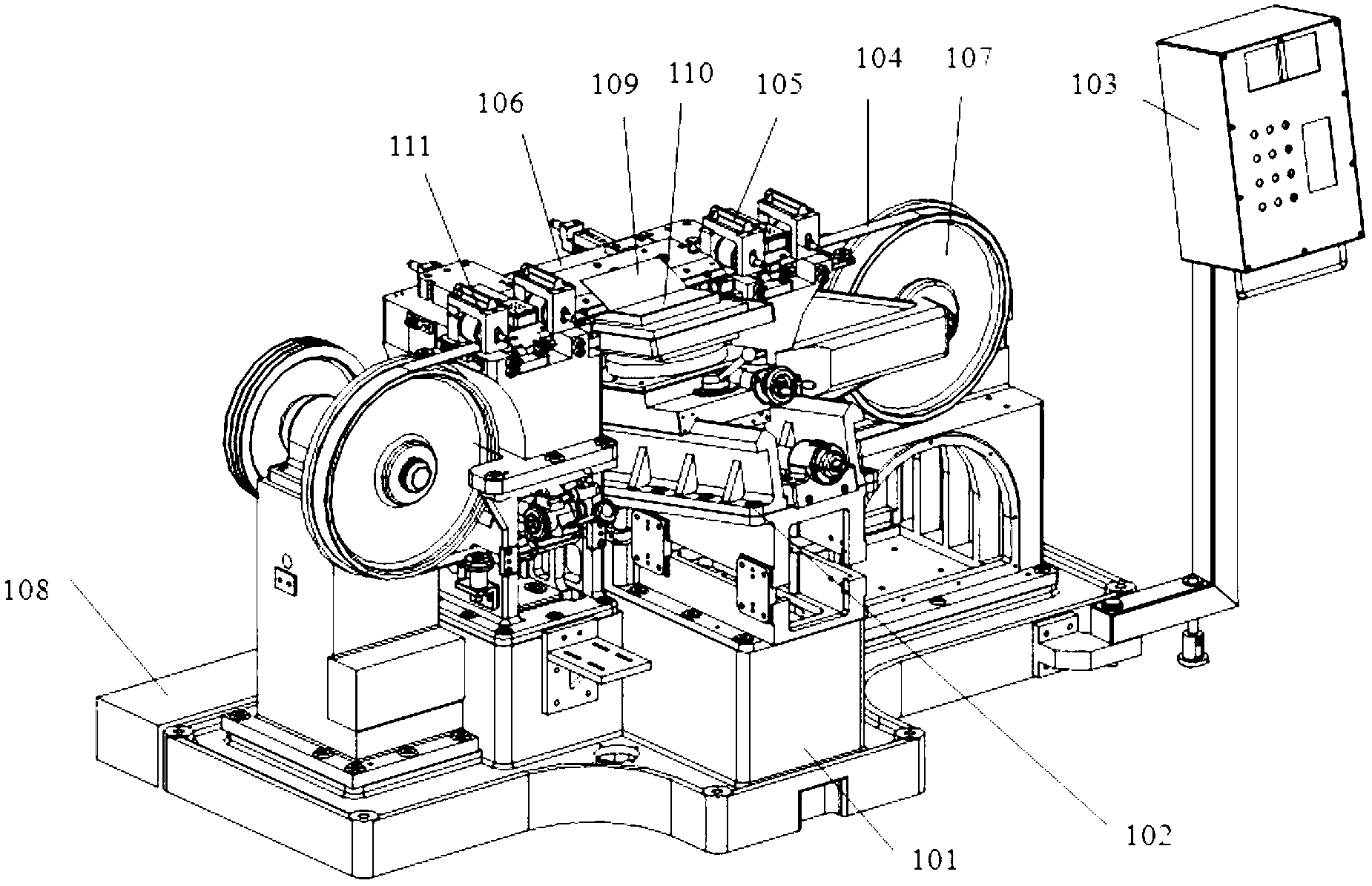

Slicing machine and method for processing flexible non-metal slice with high-precision thickness and wide format

A non-metallic, high-precision technology, applied in metal processing, thin material processing, object supply, etc., can solve the problems of easy deformation, inability to realize soft non-metallic sheet processing, and large influence on the thickness and dimension accuracy of processed sheets, and achieve high thickness Effect of Dimensional Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] A method for processing large-format soft non-metallic thin slices with high-precision thickness, when the above-mentioned slicer is used for processing, includes the following steps:

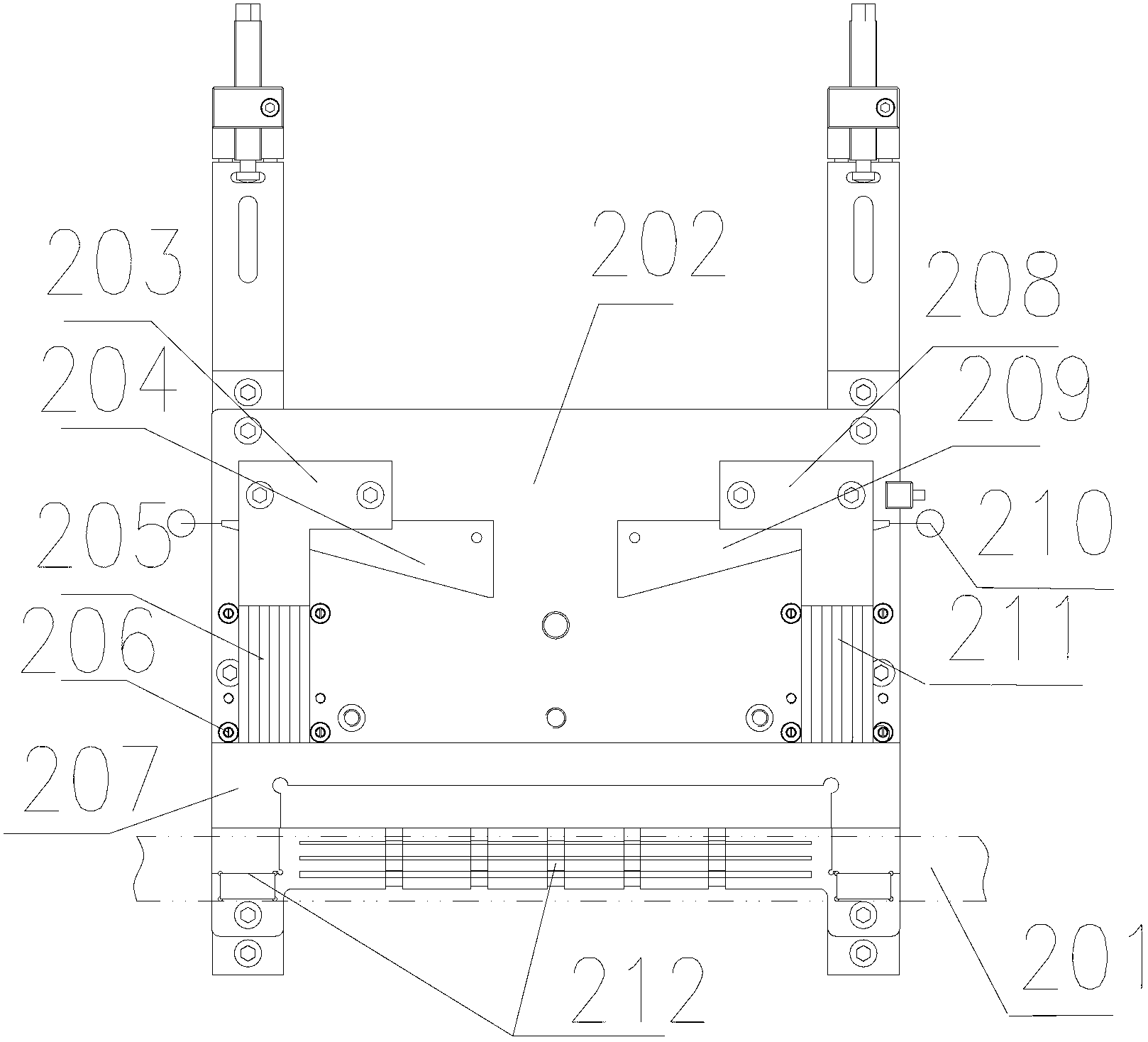

[0057] 1) Adjust the plane inlaid with cemented carbide in the platen, the upper edge of the guide slope of the backing plate in the press knife guide device, and the tops of the two wheels in the belt knife drive device are all in a horizontal plane with a small error;

[0058] 2) Adjust the angle between the feeding direction of the workpiece and the smooth plane inlaid with cemented carbide on the table to be greater than the slope angle at the lower part of the front end of the table to ensure that the slope at the lower front of the table will not hinder the feeding movement of the soft non-metallic blank;

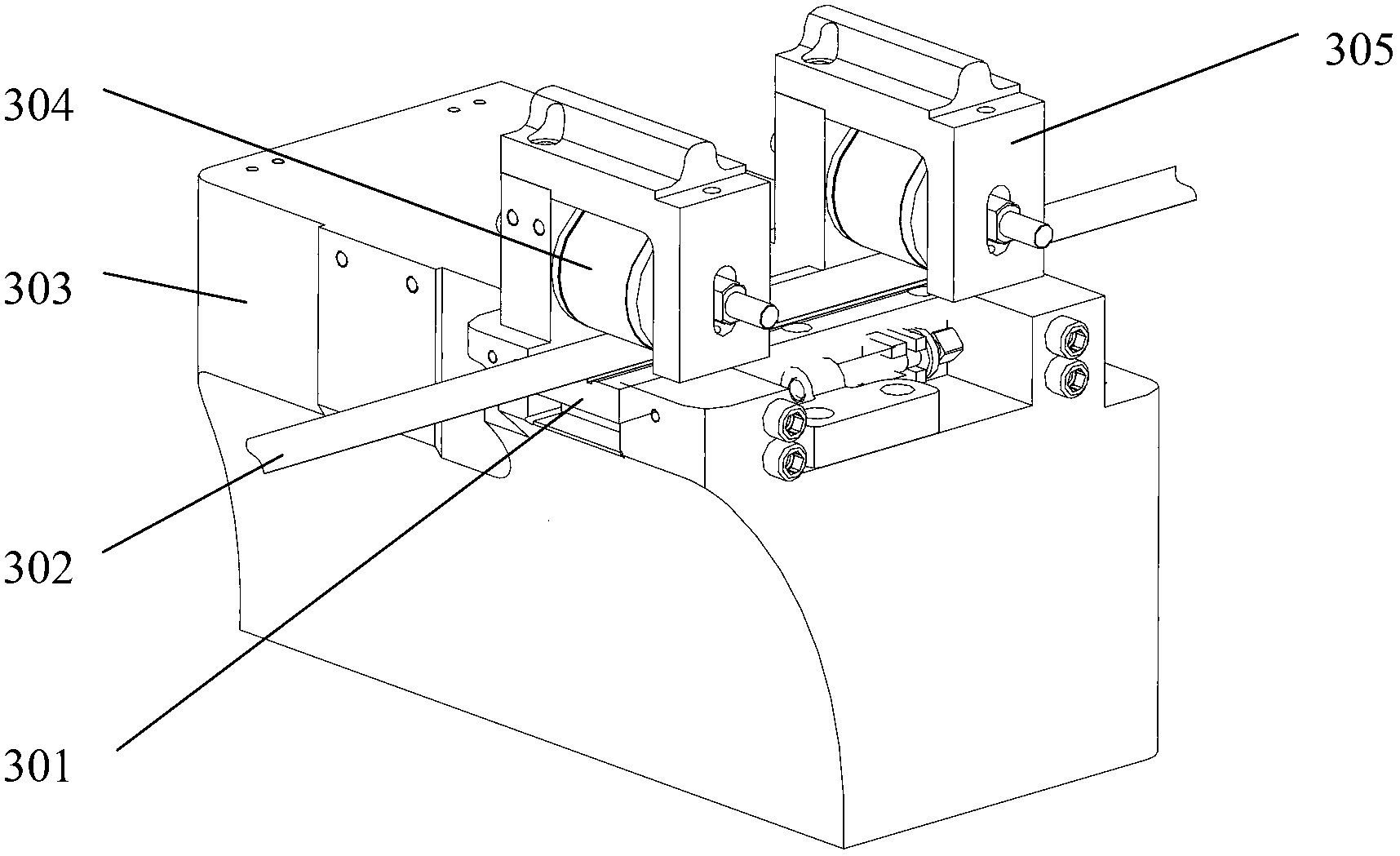

[0059] 3) Sharpen the belt knife so that the angle of the belt knife edge is smaller than the angle between the feeding direction of the workpiece and the smooth surface of the tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com