Boat hull strake design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

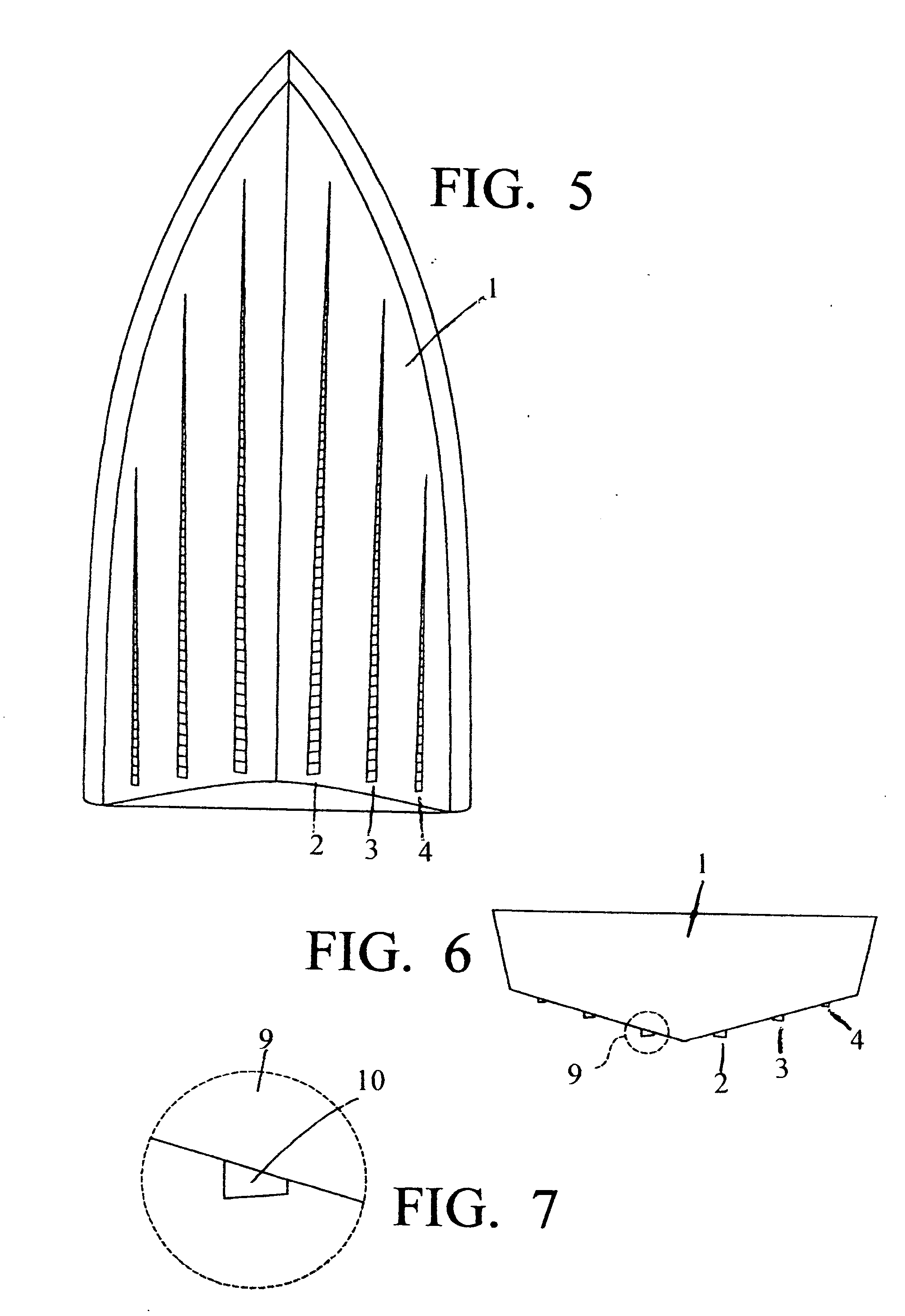

[0016]FIGS. 1A-1C illustrate a conventional design of a boat showing The bottom of a boat, a rear view and a side view.

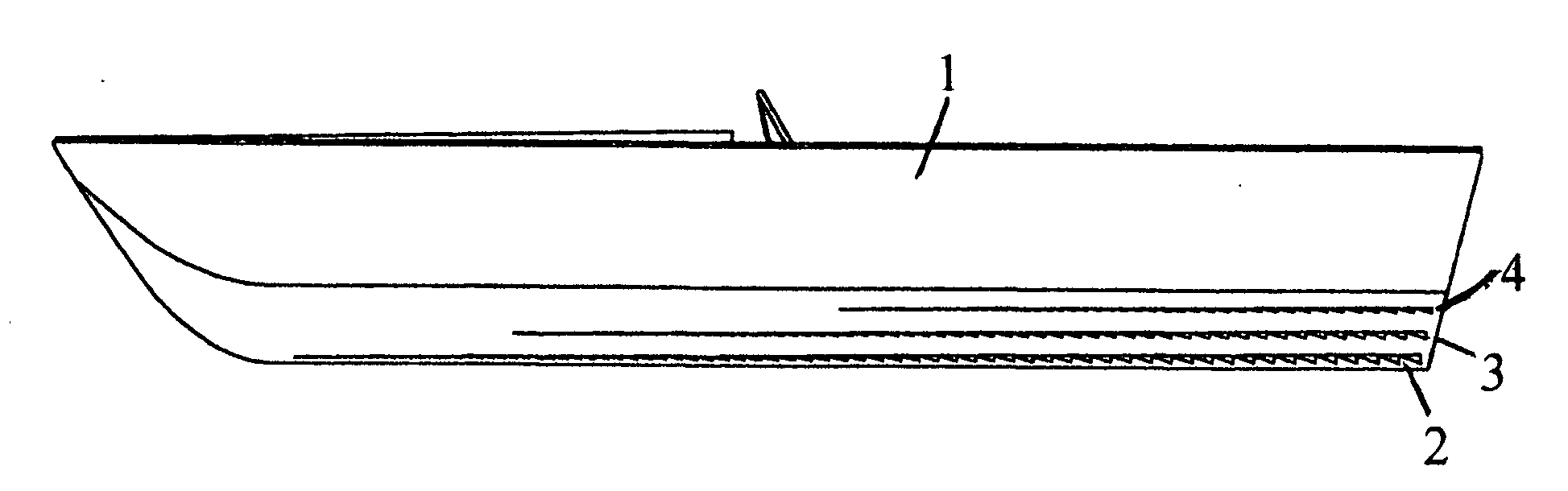

[0017]FIG. 1 illustrates a side view of a boat having several strakes attached to the bottom from the keel shown at 2, the side of the boat hull 3 and further up the side shown at 4. These strake series are space apart from each in a horizontal manner and they can be of different lengths.

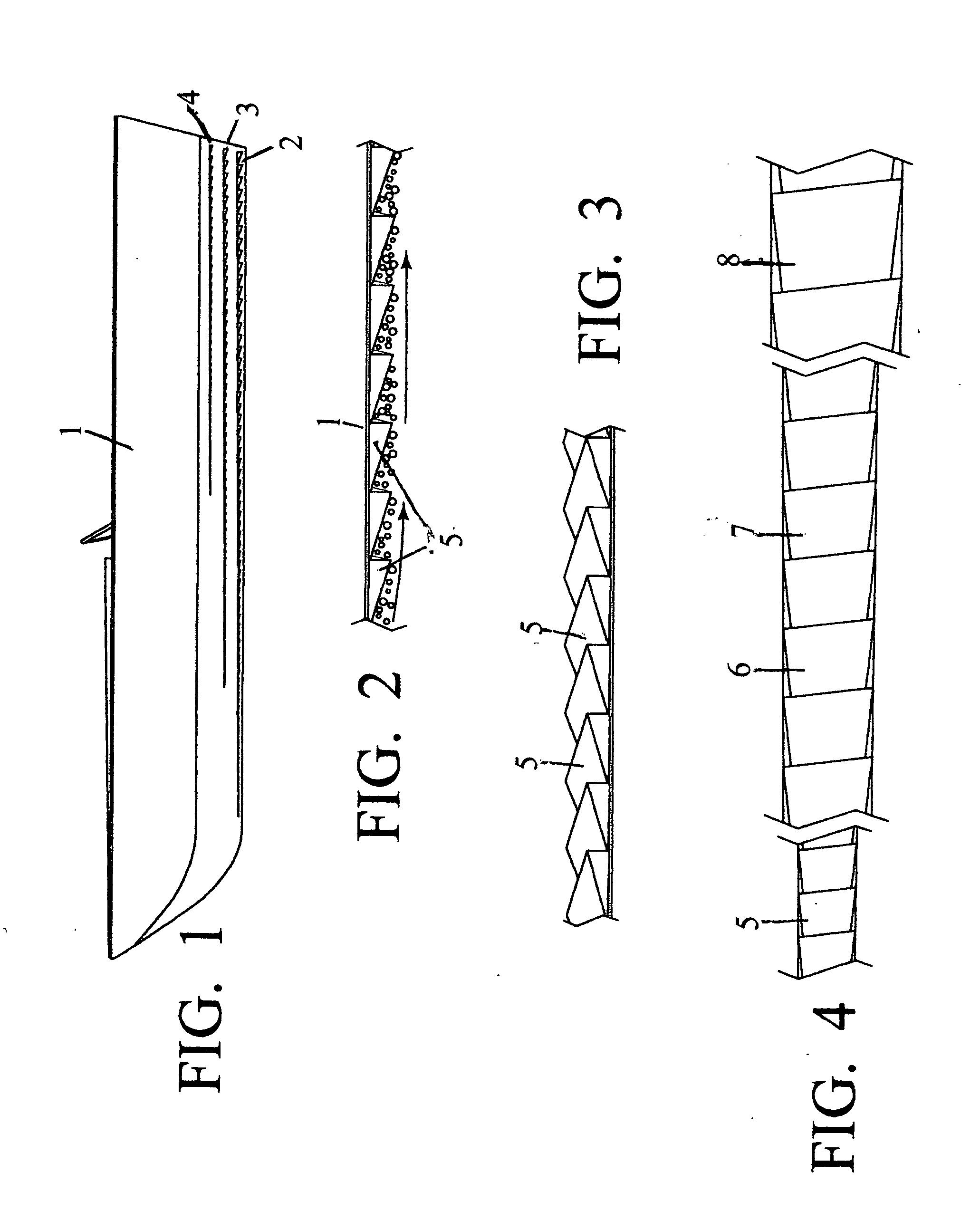

[0018]FIG. 2 shows how the individual strakes 5 create a a stream of bubbles 5. The individual strakes are slanted upwardly as seen from the direction of the travel of the boat. This slant is especially constructed because , once the water flow passes over the strakes, it creates somewhat of a venturi effect which aids in the creation of the bubbles which is the basic aim of the inventive concept.

[0019]FIG. 3 is a perspective view of a line of strakes where the slant of the individual strakes can be observed. The individual strakes are also canted relative to the hull of the boat or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com