Self-cooling type air suspension air compressor with air storage function

A technology of air suspension and air compressor, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of bearing or shaft damage, failure to form dynamic pressure air film, carbon deposition, etc., and achieve the goal of improving efficiency and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] The self-cooling type air suspension compressor with gas storage function of the present invention, its preferred embodiment is:

[0014] Including combined compressor impeller, compressor volute, cooling turbine, heat pipe heat exchanger, DC brushless motor housing, compressor housing, DC brushless motor. The compressor impeller, cooling turbine, heat pipe heat exchanger, and air storage cavity are all installed at one end of the DC brushless motor. The DC brushless motor includes a stator, a rotor, and a rotor mandrel, and the rotor is coaxially connected with the combined compressor impeller and the cooling turbine through the rotor mandrel; the left side of the DC brushless motor is provided with a thrust bearing assembly, and the thrust bearing assembly includes The thrust bearing seat, the thrust disc, and a thrust bearing is arranged between the thrust bearing seat and the thrust disc. The thrust bearing is a foil type dynamic pressure gas thrust bearing. A rad...

specific Embodiment

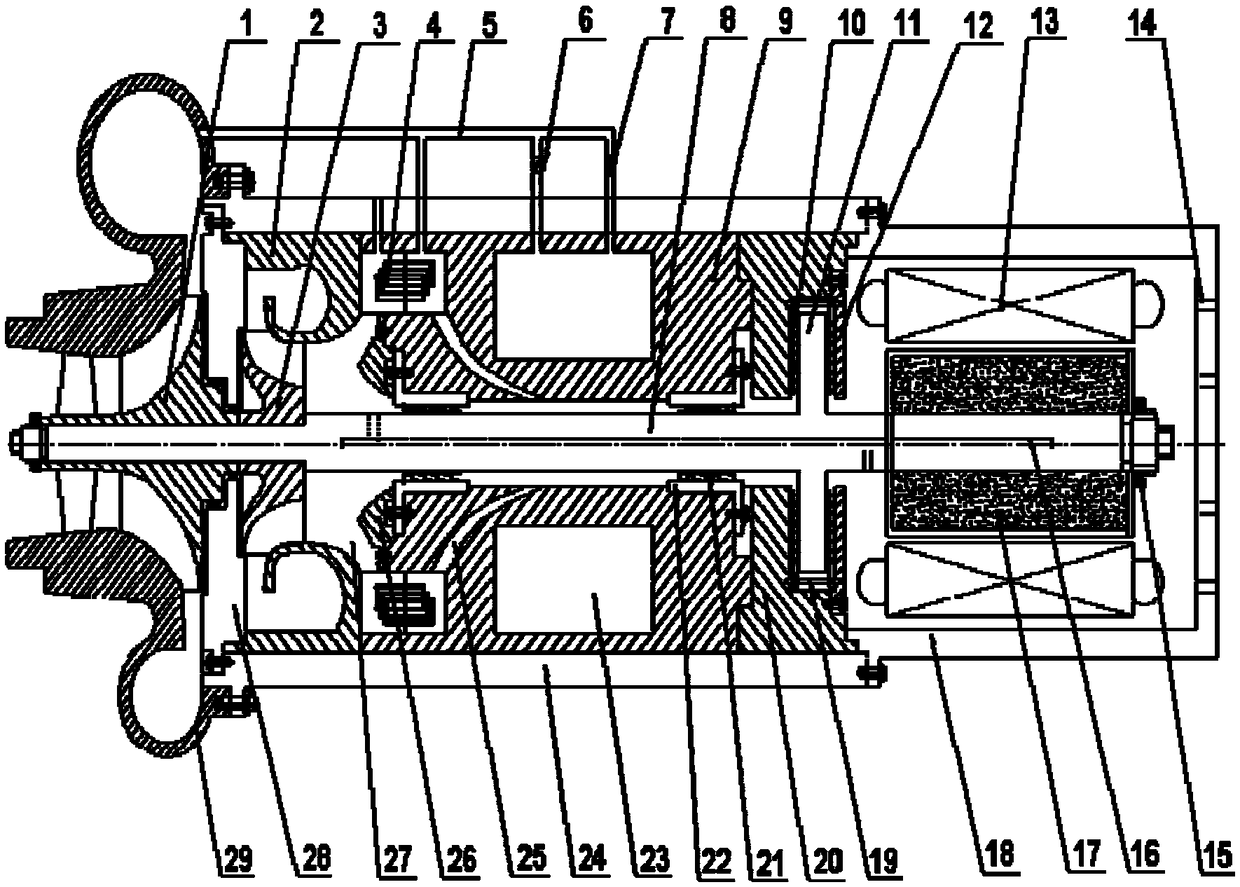

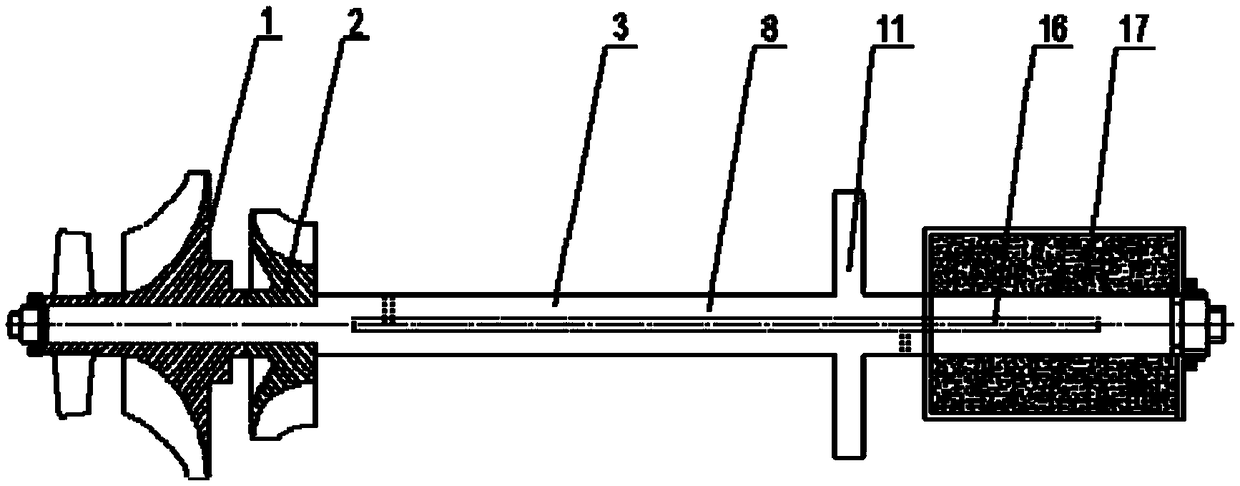

[0018] Such as figure 1 As shown, it includes combined compressor impeller 1, compressor volute 29, cooling turbine 3, heat pipe heat exchanger 4, air storage cavity 23, DC brushless motor housing 18, compressor housing 24, DC brushless motor . The compressor impeller, cooling turbine, heat pipe heat exchanger, and air storage cavity are all installed at one end of the DC brushless motor. The DC brushless motor includes a stator 13, a rotor 17, and a rotor mandrel 8, and the rotor is coaxially connected with the combined compressor impeller and the cooling turbine through the rotor mandrel; a thrust bearing assembly is arranged on the left side of the DC brushless motor, and the thrust The bearing assembly includes a thrust bearing seat and a thrust plate 11, and a thrust bearing 10 is arranged between the thrust bearing seat and the thrust plate. The thrust bearing is a foil type dynamic pressure gas thrust bearing. A radial bearing assembly is arranged inside the compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com