Multifunctional efficient rice husking machine

A rice milling machine, multi-functional technology, applied in the fields of application, agriculture, grain processing, etc., can solve the problems of poor rice bran separation, short rice milling time, economic loss, etc., achieve sufficient and uniform milling, and enhance rice milling effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

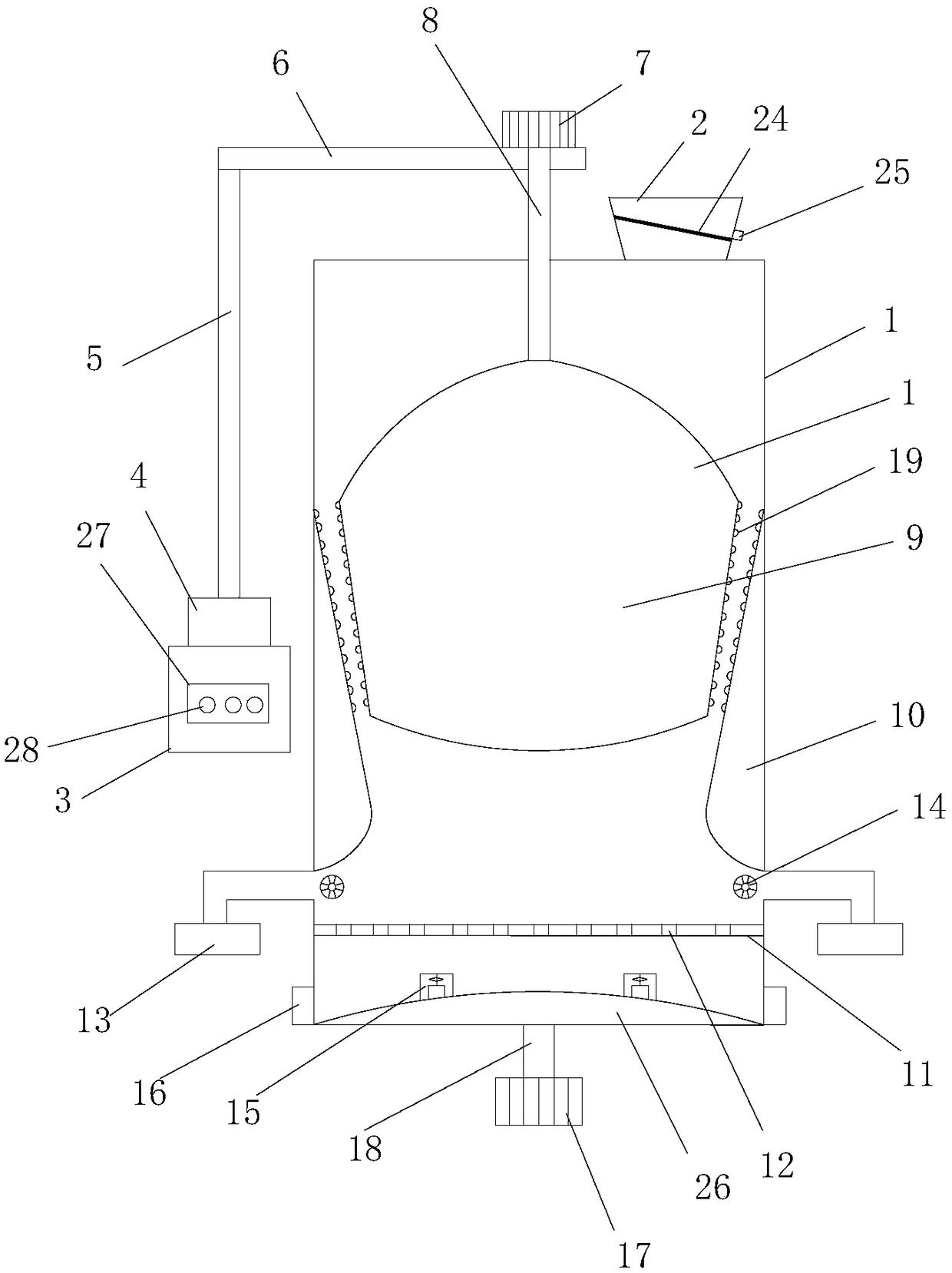

[0028] see figure 1 , the multifunctional high-efficiency rice milling machine of the present embodiment comprises a rice milling machine body 1, a feed hopper 2, a control box 3, and a hydraulic cylinder 4. The hydraulic cylinder 4 is arranged above the control box 3, and the top of the hydraulic cylinder 4 is connected with Telescopic rod 5, the upper end of telescopic rod 5 is connected with platform board 6, and the first motor 7 is arranged on the platform board 6, and the first rotating shaft 8 is arranged below the first motor 7, and the upper end of first rotating shaft 8 runs through described platform board 6 and Connected to the output end of the first motor 7, the lower end of the first rotating shaft 8 extends into the rice mill body 1, the rice mill body 1 is provided with a milling cone 9, and the top of the milling cone 9 is connected to the second milling cone 9 through the first rotating shaft 8 A motor 7, the rice mill body 1 inner wall is provided with the ...

Embodiment 2

[0035] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that the support plate 11 is prepared from a modified epoxy resin material, and the modified epoxy resin material includes the following raw materials in parts by weight: 40 parts of epoxy resin, di 22 parts of cumene, 16 parts of styrene, 8 parts of toughening additives, 5 parts of titanium carbide, 5 parts of nano-tin oxide, 4 parts of glass fiber, 6 parts of nano-titanium dioxide, 4.7 parts of polyphenylene sulfide, 2.5 parts of magnesium oxide , 2 parts of silane coupling agent KH-550, 0.6 parts of silicone leveling agent, 0.2 parts of nano zinc oxide.

[0036] Compared with the traditional modified epoxy resin, the modified epoxy resin material has significantly improved lubricity, high temperature resistance, corrosion resistance, and machinability, so that the milled rice grains quickly enter the drying box along the passing hole, and It is less affected by the long-term heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com