Drilling machine with deflection mechanism and using method thereof

A deflecting mechanism and drilling rig technology, applied in drilling equipment and methods, drilling equipment, directional drilling, etc., can solve the problems of poor stability, complex structure, easy wear at the rotation of the pin shaft, etc., to achieve low friction and improve safety. , The effect of sliding accuracy guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

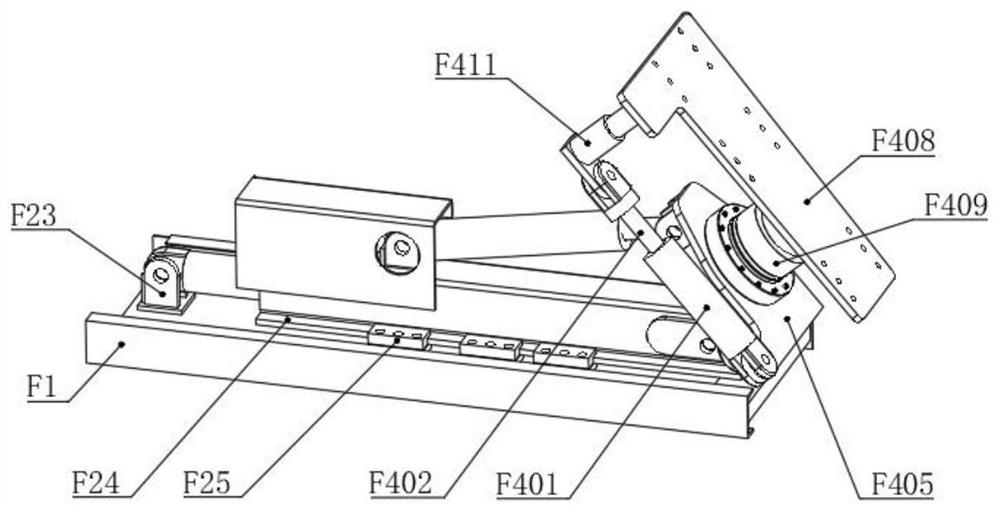

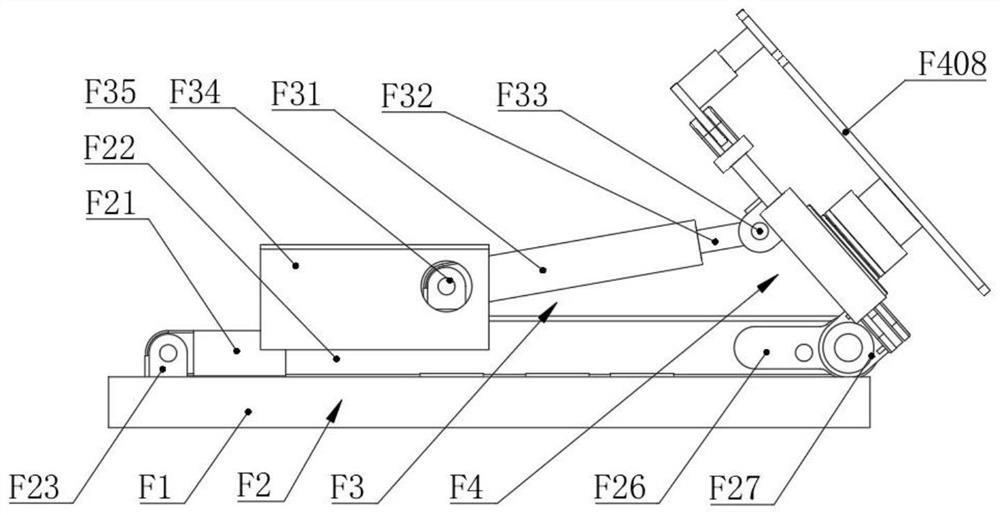

[0076] Such as Figure 1-10 As shown, a drilling rig with a deflection mechanism includes two slider devices A, a double-row chain guide rail device B, a lifting arm device C, a guide sleeve device D, a power head device E and a deflection device F;

[0077] The deflection device F includes a base F1, a first sliding unit F2, an angle adjustment unit F3, a deflection unit F4 and a transport unit F5;

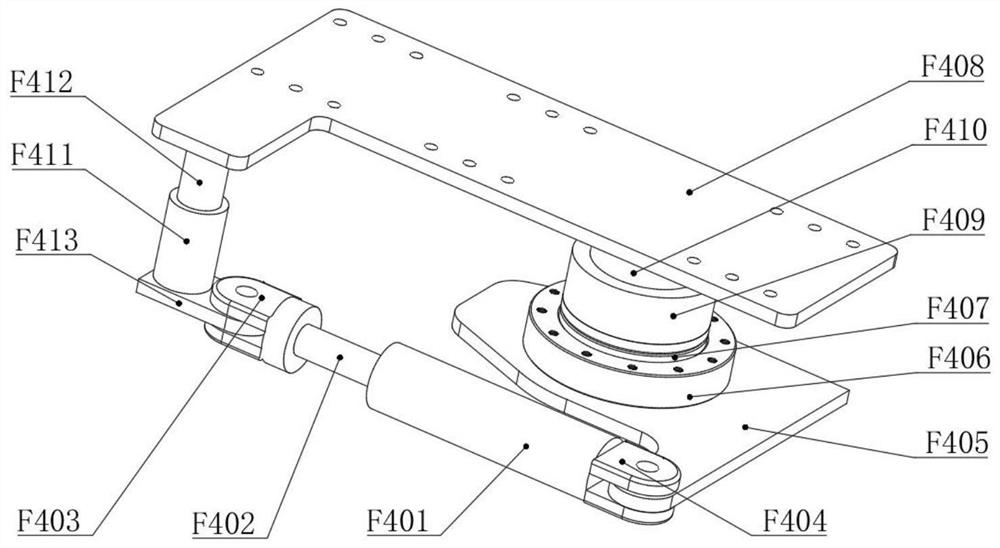

[0078] The deflection unit F4 includes a third hydraulic cylinder F401, a third telescopic rod F402, a swivel seat F405, a bearing seat F406, a slewing support bearing F407 and a drill arm support seat F408. One end of the third telescopic rod F402 is inside the third hydraulic cylinder F401 and connected with it Flexible connection, the swivel seat F405 and the drill arm support seat F408 are both L-shaped flat plates, the outside of the third hydraulic cylinder F401 is movably connected with one end of the swivel seat F405, and the free end of the third telescopic rod F402 is mov...

Embodiment 2

[0093] Such as Figure 1-10 As shown, a drilling rig with a deflection mechanism includes two slider devices A, a double-row chain guide rail device B, a lifting arm device C, a guide sleeve device D, a power head device E and a deflection device F;

[0094] The deflection device F includes a base F1, a first sliding unit F2, an angle adjustment unit F3, a deflection unit F4 and a transport unit F5;

[0095] The first sliding unit F2 is arranged on the upper part of the base F1, the first sliding unit F2 is connected with the lower part of the rotating seat F405, and the first sliding unit F2 and the deflection unit F4 perform synchronous movement;

[0096] The angle adjustment unit F3 is installed on the upper part of the first sliding unit F2, the first sliding unit F2 drives the angle adjustment unit F3 to perform synchronous movement, one end of the angle adjustment unit F3 is connected to the lower part of the rotating seat F405, and the angle adjustment unit F3 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com