Feeding device

A technology of feeding device and force applying device, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of low efficiency of feeding device, achieve the effect of improving work efficiency and speeding up processing progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

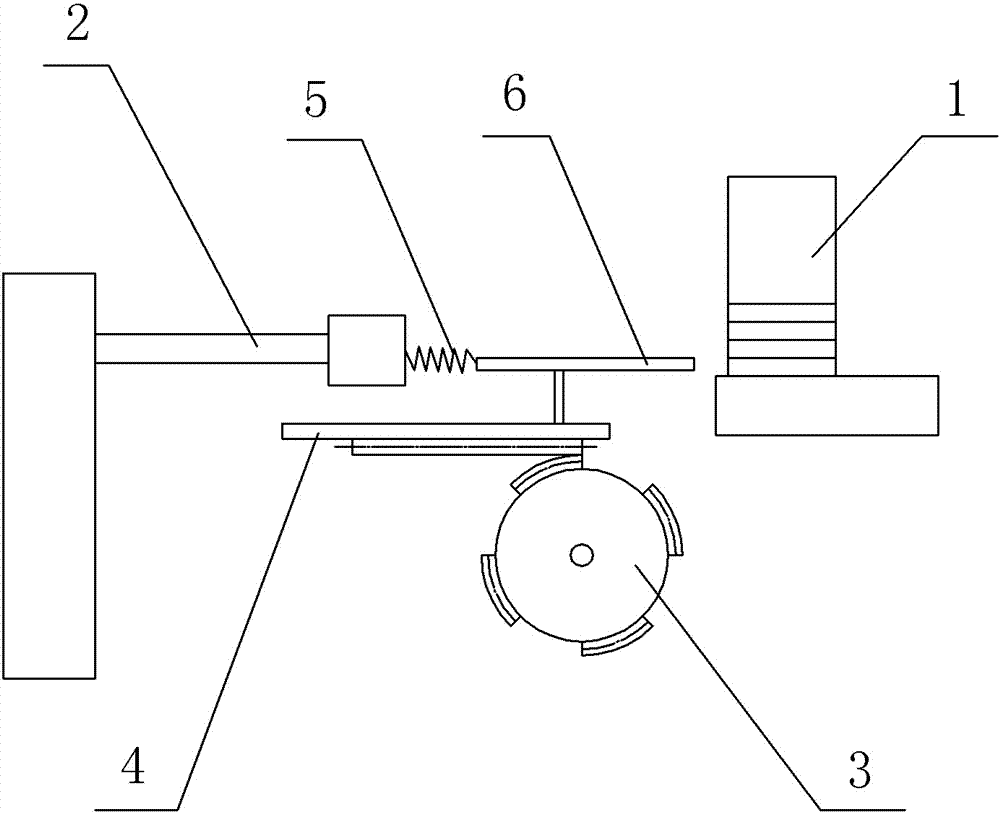

[0010] Such as figure 1 As shown, a feeding device in this embodiment includes a push rod 1, a base 2, a toothless gear 3 as a force applying device, a transmission rod 4 with a rack, and a feeding box 6 containing materials, wherein, There are multiple tooth-missing segments evenly distributed on the tooth-missing gear 3, the tooth-missing gear 3 is driven by a motor, the tooth-missing gear 3 meshes with the rack on the transmission rod 4, the transmission rod 4 is connected with the push rod 1, and the push rod 1 is reset The spring 5 is connected to the base 2 . The push rod 1 needs to reciprocate left and right to realize the delivery of the material in the feeding box 6 .

[0011] When working, the tooth-missing gear 3 rotates under the drive of the motor. When the gear segment meshes with the toothed segment, the gear 3 pushes the push rod 1 to feed through the transmission rod 4; when it enters the tooth-missing segment, the gear 3 does not contact the rack. The push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com