Planar honeycomb tube truss construction method applied to profiling angle instrument

A construction method and a technology of an angle meter, which are applied in the processing of building materials, construction, building construction, etc., can solve problems such as inability to distinguish the left and right ends of steel pipes, and achieve improved assembly efficiency, simplified processing procedures, and good social and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

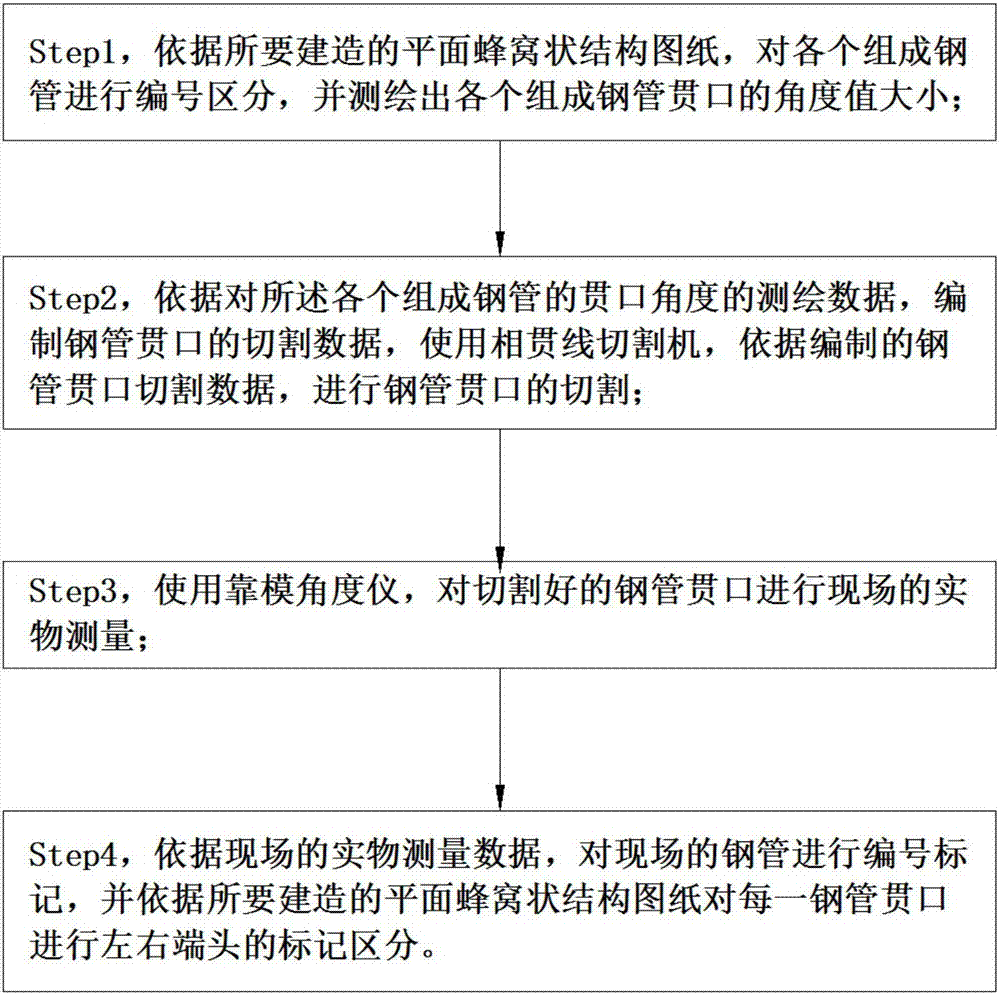

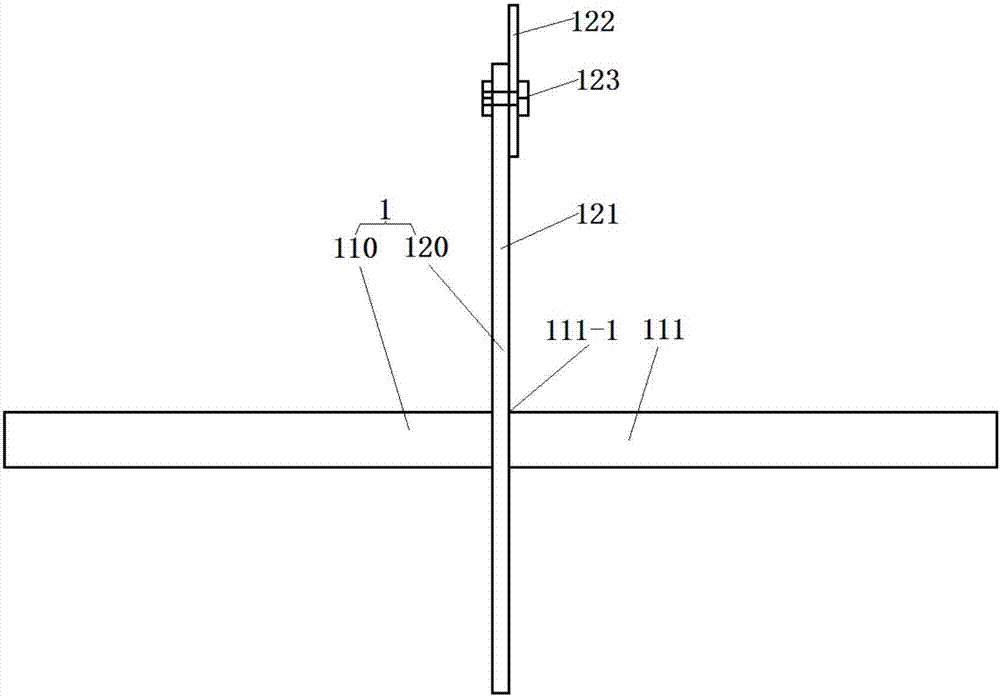

[0023] Please refer to Figure 1-Figure 2 , figure 1 Provide a kind of flow chart of the planar honeycomb pipe truss construction method of applying profiling angle instrument for the present invention; figure 2 A schematic structural view of the profiling angle meter is provided for the present invention.

[0024] Specifically, this embodiment provides a method for constructing a planar honeycomb pipe truss using a profiling angle meter, including the following steps:

[0025] Step1, according to the planar honeycomb structure drawing to be built, number and distinguish the various steel pipes formed, and measure and map the angle value of each formed steel pipe hole;

[0026] Step2, according to the surveying and mapping data of the angles of the steel pipes of the composition, the cutting data of the steel pipes are compiled, and the cutting data of the steel pipes are cut by using an intersecting line cutting machine according to the prepared steel pipes cutting data; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com