Universal grinding device

A grinding device and universal technology, which is applied in the field of grinding machines, can solve the problems of not being able to meet the requirements of inner hole processing accuracy, and it is difficult to achieve the accuracy, and achieve the effect of improving the processing progress and ensuring the grinding depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

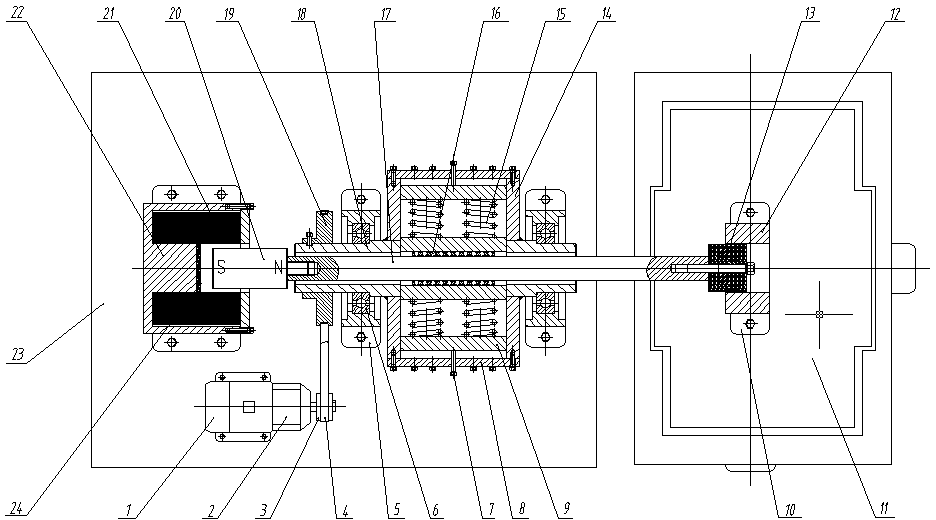

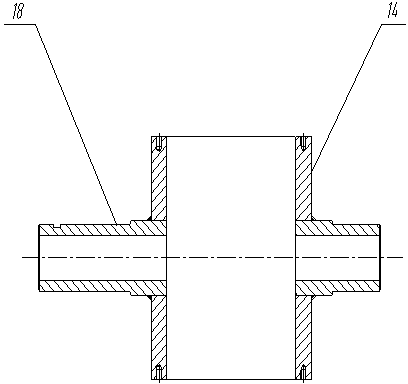

[0022] A kind of universal grinding device involved in the present invention is provided with a grinding shaft 17, one end of the grinding shaft 17 is provided with a grinding head 13, and the other end is provided with a magnetic block 20, and the magnetic block 20 and the grinding head 13 are all composed of bolts and grinding shafts. 17 connections.

[0023] The left end of the magnetic block 20 is an S pole, and the right end is an N pole, inserted inside the electromagnetic coil group 21, the electromagnetic coil group 21 is installed in the electromagnetic coil seat 22, and the contact end surface of the electromagnetic coil seat 22 and the magnetic block 20 is installed with an anti-shock silicone rubber 24 , to prevent the grinding shaft 17 and the electromagnetic coil seat 22 from colliding.

[0024] An organic casing is arranged outside the grinding shaft 17, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com