Compensation method of grinder rigidity based on negative flexibility principle

A compensation method and negative flexibility technology, which is applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve elastic deformation, insufficient rigidity of grinding machine, and inability to accurately control grinding consumption, etc. problems, to achieve the effect of improving processing efficiency, improving surface processing quality and processing efficiency, and ensuring grinding depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

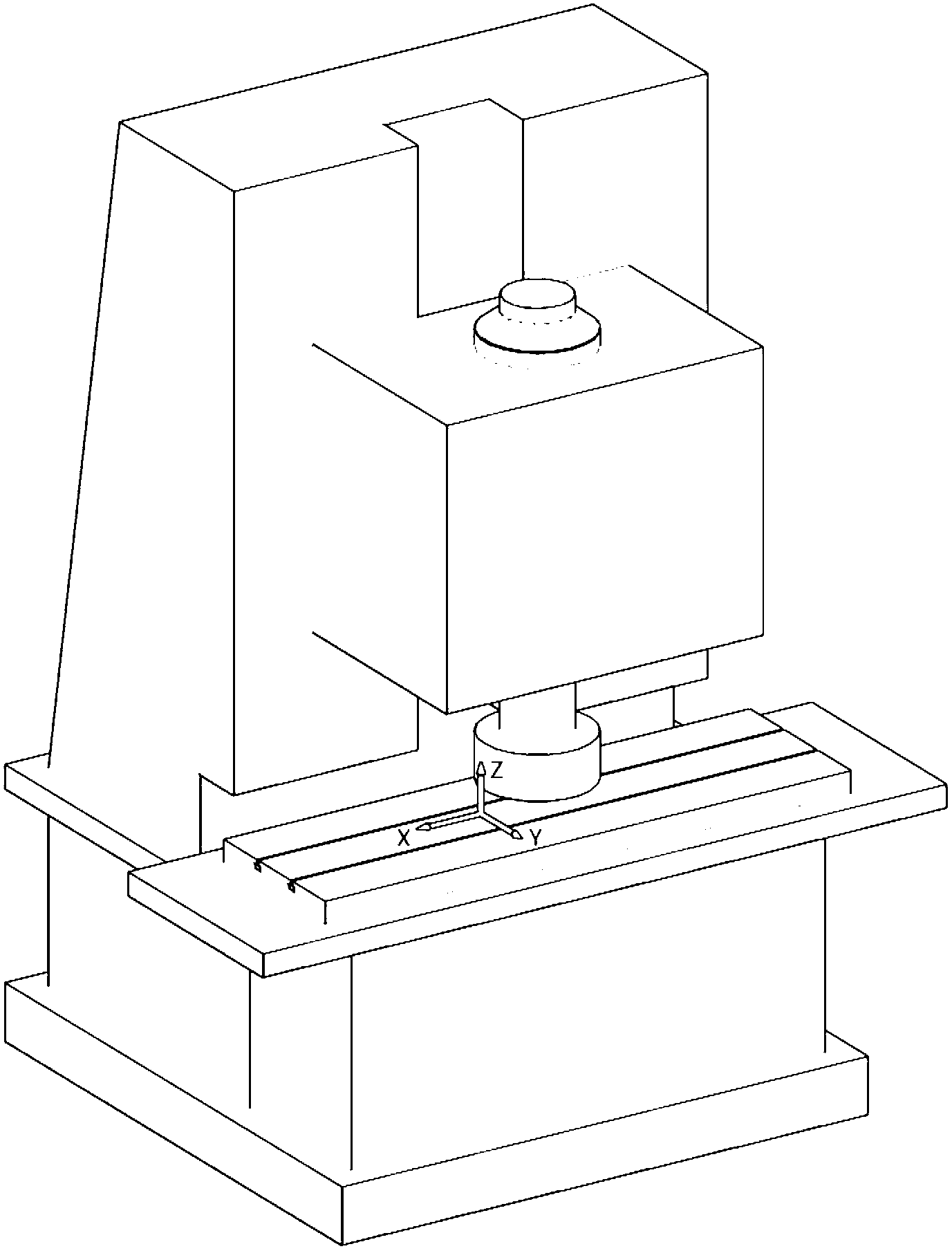

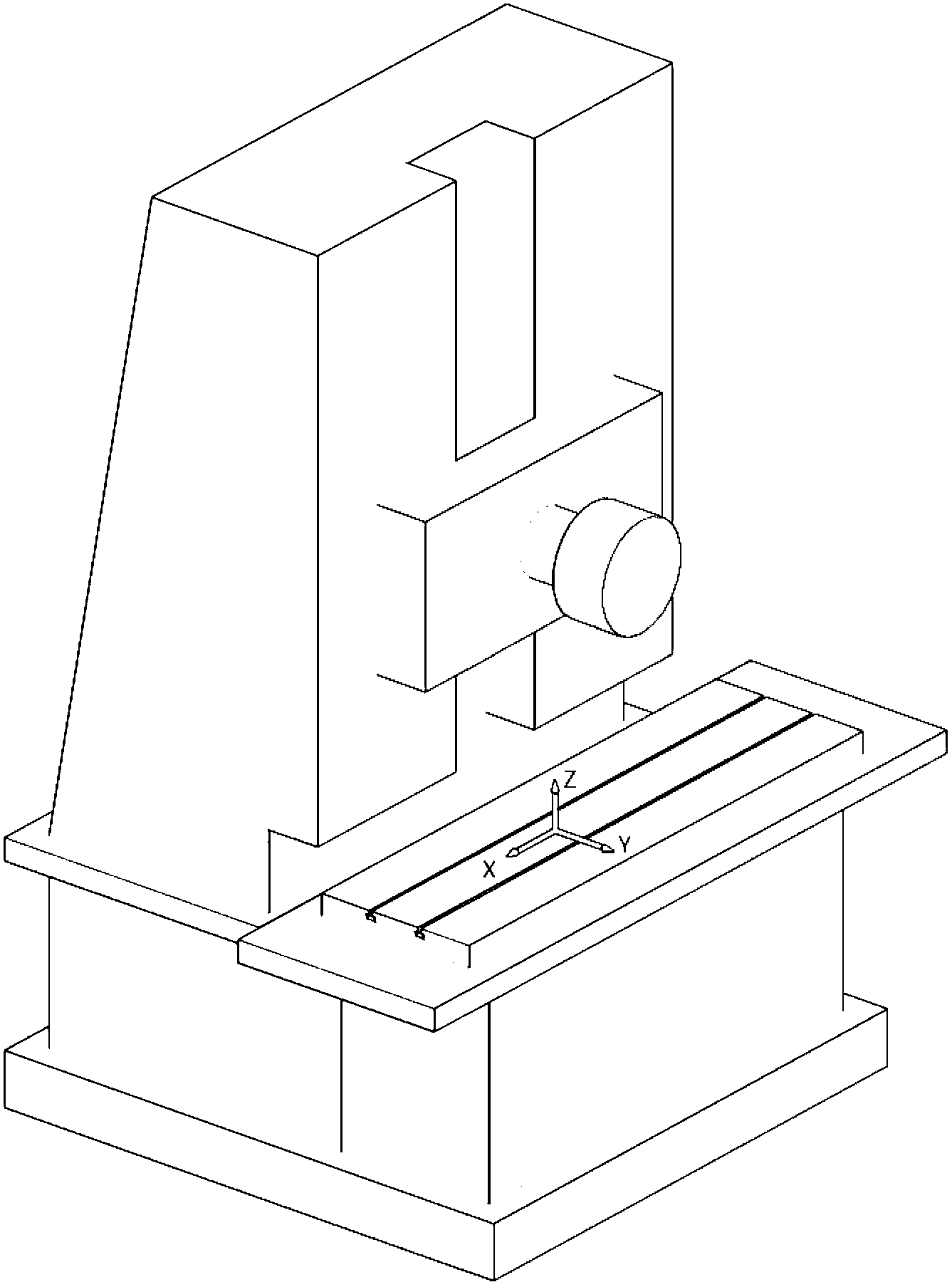

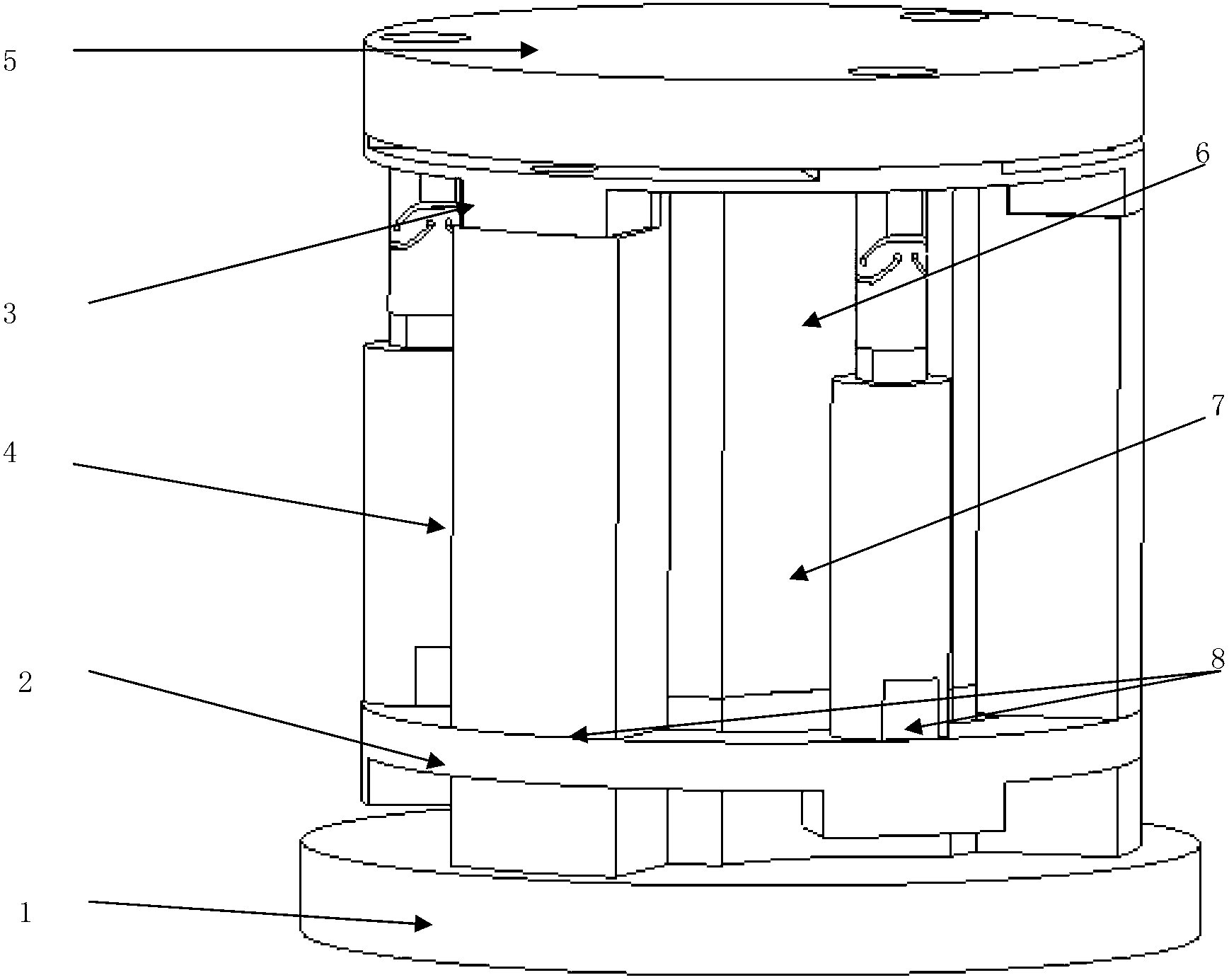

[0029] The invention relates to a grinding machine stiffness compensation method based on the principle of negative flexibility. Before this method is implemented, it is first necessary to establish a stiffness compensation coordinate system. The definitions of the grinding plane XY plane and normal direction of vertical surface grinder and horizontal surface grinder are as follows: figure 1 and figure 2 Shown in the OXYZ coordinate system. The main elastic deformation errors that affect the quality of the grinding surface are the elastic deformation in the Z direction and the angular deformation around the X and Y axes, so for the present invention, such as image 3 and Figure 4 The negative compliance controllable table is shown to realize the compensation of the grinding machine stiffness. The workbench used ( image 3 ) The overall size is Φ130×145mm 3 , the parameters of the piezoelectric ceramic driver (7) are: maximum thrust 3000N, axial stiffness 200N / μm. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com