Permanent-magnetic electric machine rotor magnet steel fixing structure

A permanent magnet motor, fixed structure technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve difficult second or even third dynamic balance test, fixed parts damage, poor craftsmanship, etc. problem, to achieve the effect of light weight, reduced machining accuracy and low machining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

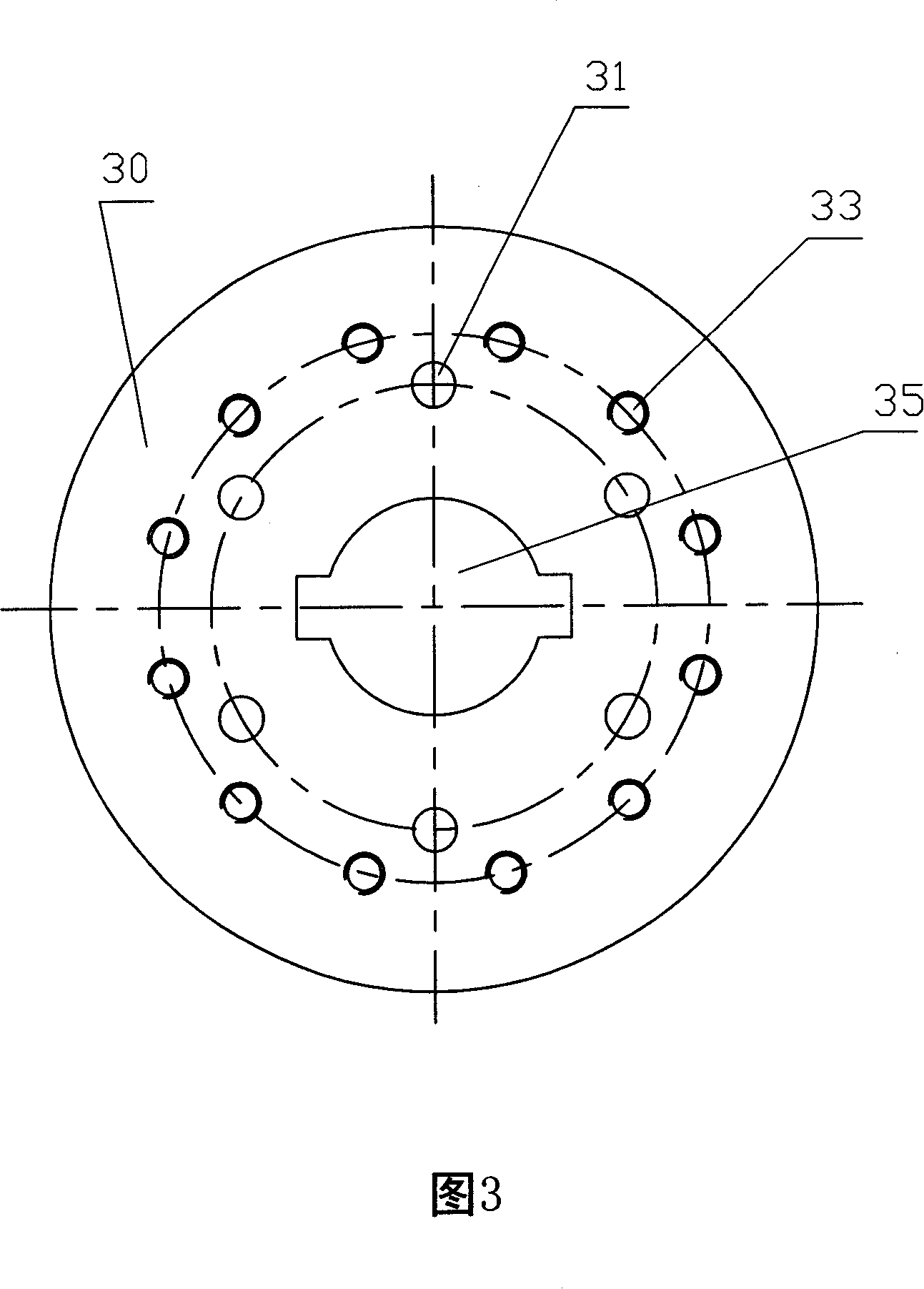

[0018] Please refer to FIG. 2 and FIG. 3 , the permanent magnet motor rotor magnetic steel fixing structure of the present invention is mainly composed of a rotating shaft 20 , a rotor core 80 , two magnetic steel pressure plates 30 , magnets 70 , and bolts 60 .

[0019] The two magnetic steel pressure plates 30 are respectively arranged on the two end surfaces of the rotor core 80. Since the length of the magnet 70 is consistent with the length of the rotor core 80, the magnetic steel pressure plates 30 are directly in contact with the two end surfaces of the rotor core 80 to form a rotor. Several magnetic steel sheets of the iron core 80 are superimposed on the axial direction of the rotating shaft 20, wherein each magnetic steel sheet is correspondingly provided with a locking hole (not shown), and the two magnetic steel pressing plates 30 are The position corresponding to the locking hole is provided with a through hole 31, and then the bolt 60 is passed through the locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com