Carbon material coated lead powder composite material and its application

A technology of carbon material coating and composite materials, which is applied in the direction of hybrid capacitor electrodes, electrical components, battery electrodes, etc., can solve the problems that carbon materials cannot be mixed evenly, the mechanical strength of the plates is not enough, and the uniformity is not good. Suppresses the occurrence of lead sulfate, improves capacitance and battery performance, and prolongs life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

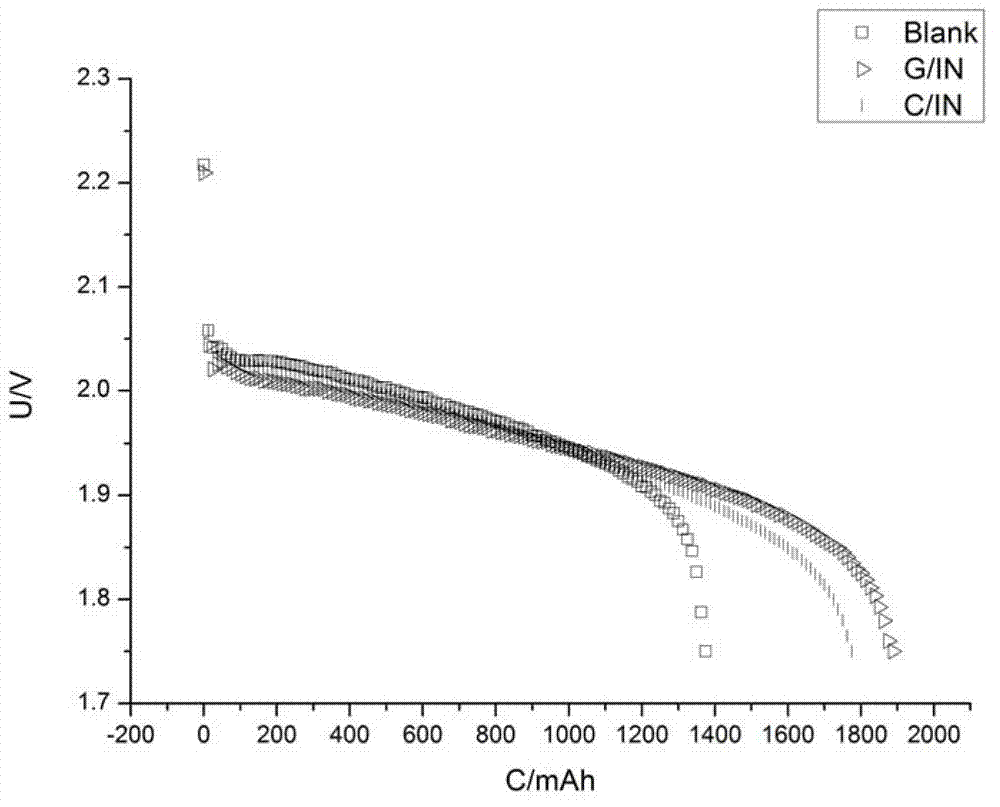

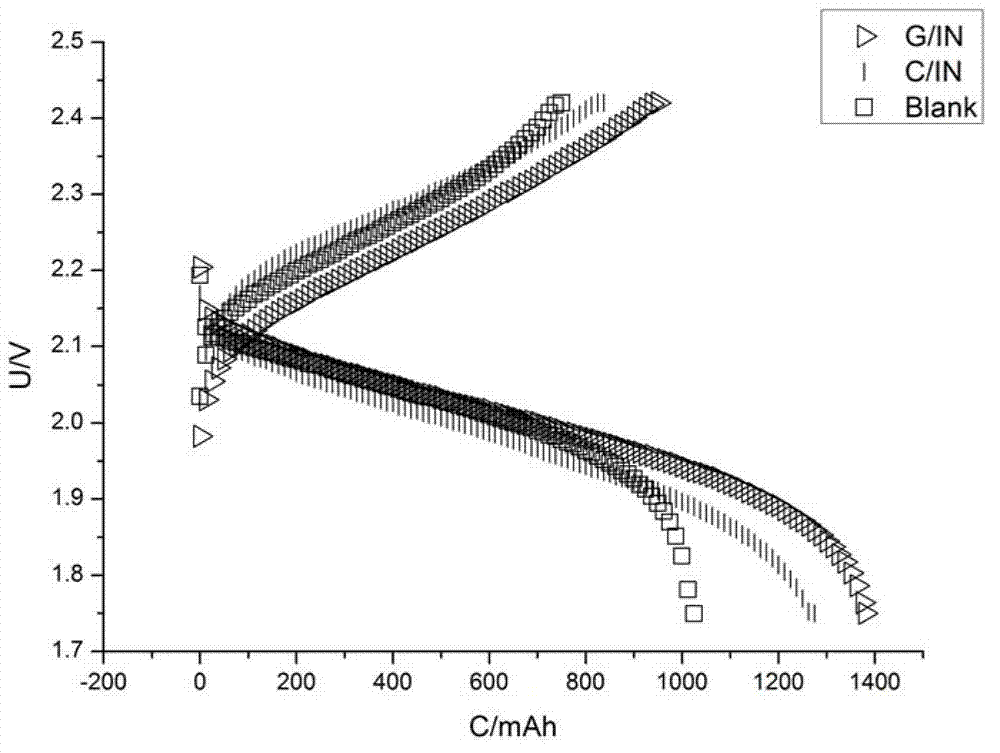

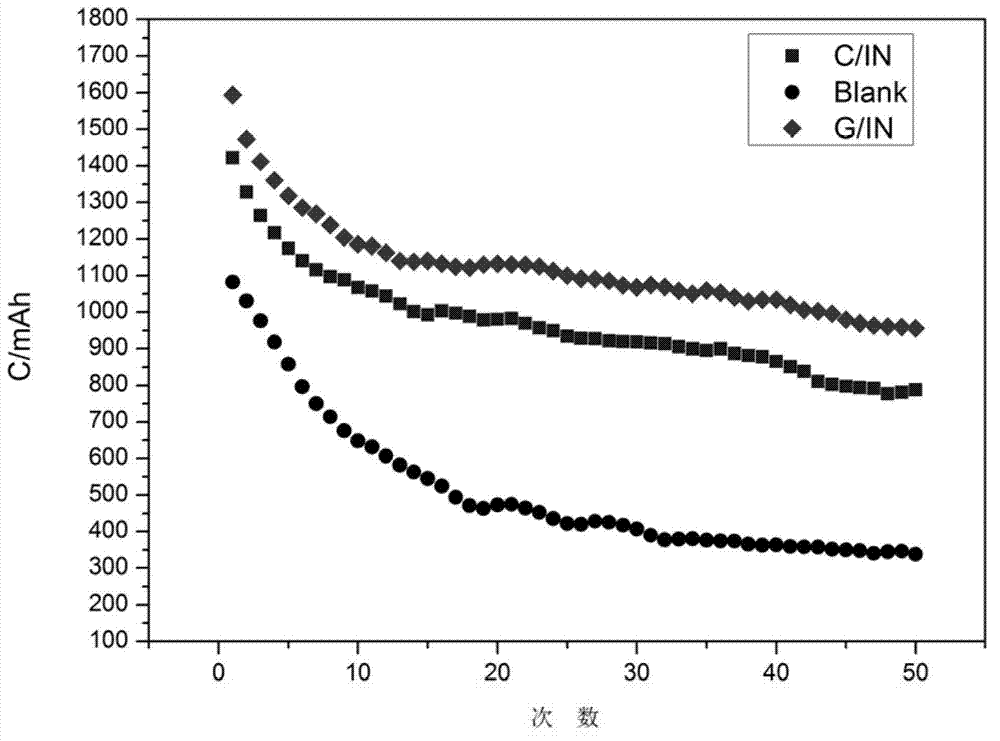

Embodiment 1

[0044] Take 2g of graphite, 1.5g of glucose and 0.01g of indium oxide, add 30ml of deionized water and 40ml of alcohol, stir evenly, then add 40g of lead powder, ultrasonically disperse for 30min, then move to a water bath at 80°C for heating Stir until the water and alcohol in the solution are evaporated, take out the graphite and glucose-coated lead powder, grind them, put them into a tube furnace, and carry out carbonization at 200°C for 2 hours under a nitrogen atmosphere to obtain graphite-coated lead powder composite material.

[0045] Make a lead-carbon super battery according to the weight ratio of the following materials: graphite-coated lead powder composite material 99, short fiber 0.2, barium sulfate 0.3, conductive graphite 0.5, after mixing evenly, add the total mass of the above raw materials 18%, 1.15g / ml Sulfuric acid and deionized water with 12% of the total mass of the above raw materials are mixed at 50°C. After the plate is coated, it is cured at 50°C and ...

Embodiment 2

[0047] Take 4g of glucose and 0.01g of indium oxide, add 30ml of deionized water and 40ml of alcohol, stir well, then add 40g of lead powder, ultrasonically disperse for 30min, move to a water bath at 80°C, heat and stir until steaming Dry the water and alcohol in the solution, take out the glucose-coated lead powder, grind it, put it into a tube furnace, and carry out carbonization at 200°C for 2 hours under a nitrogen atmosphere to obtain a carbon-coated lead powder composite material.

[0048] Make a lead-carbon super battery according to the weight ratio of the following materials: carbon-coated lead powder composite material 99%, short fiber 0.2, barium sulfate 0.3, conductive graphite 0.5, after mixing evenly, add the total mass of the above raw materials 18%, 1.15g / ml Sulfuric acid and deionized water with 12% of the total mass of the above raw materials are mixed at 50°C. After the plate is coated, it is cured at 50°C and relative humidity of 90-98% for 24 hours, and th...

Embodiment 3

[0050] Take 2g of graphite, 1.5g of glucose and 0.02g of indium oxide, add 40ml of deionized water and 60ml of alcohol, stir evenly, then add 50g of lead powder, ultrasonically disperse for 30min, then move to a water bath at 80°C for heating Stir until the water and alcohol in the solution are evaporated, take out the graphite and glucose-coated lead powder, grind them, put them into a tube furnace, and carry out carbonization at 200°C for 5 hours under a nitrogen atmosphere to obtain graphite-coated lead powder composite material.

[0051] Make a lead-carbon super battery according to the weight ratio of the following materials: graphite-coated lead powder composite material 99, short fiber 0.2, barium sulfate 0.3, conductive graphite 0.5, after mixing evenly, add the total mass of the above raw materials 18%, 1.15g / ml Sulfuric acid and deionized water with 12% of the total mass of the above raw materials are mixed at 50°C. After the plate is coated, it is cured at 50°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com