Millimeter wave rectangular-circular transition integrated corrugated horn antenna and processing method

A technology of rectangular transition and corrugated horn, which is applied in the microwave field, can solve the problems of processing technology and combination form, increase the complexity of the process, and prolong the processing time, so as to reduce the complexity of the process and the cost of man-hours, reduce weight and Volume, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The integrated corrugated horn antenna provided by the present invention will be described in detail below with reference to the drawings and embodiments.

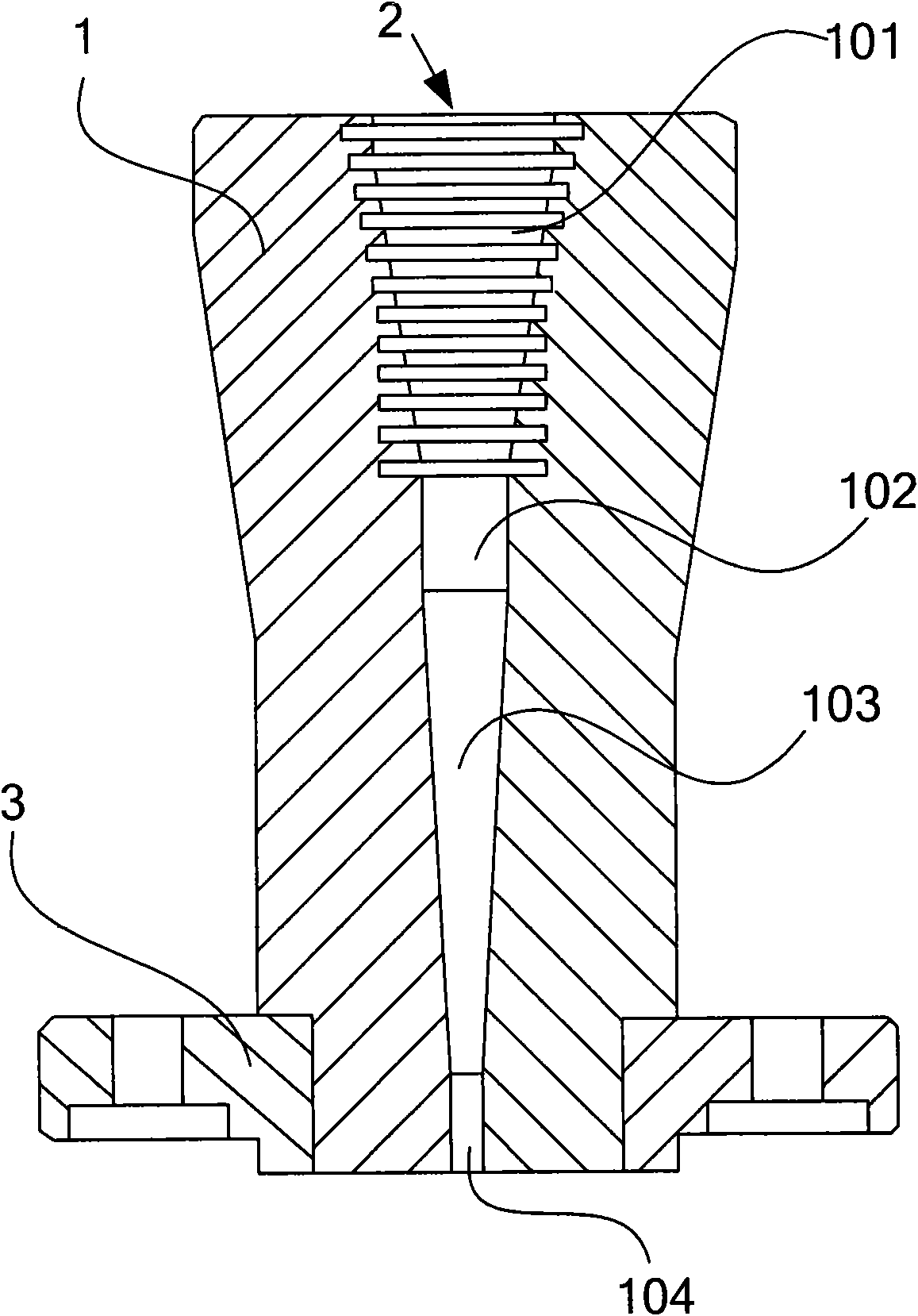

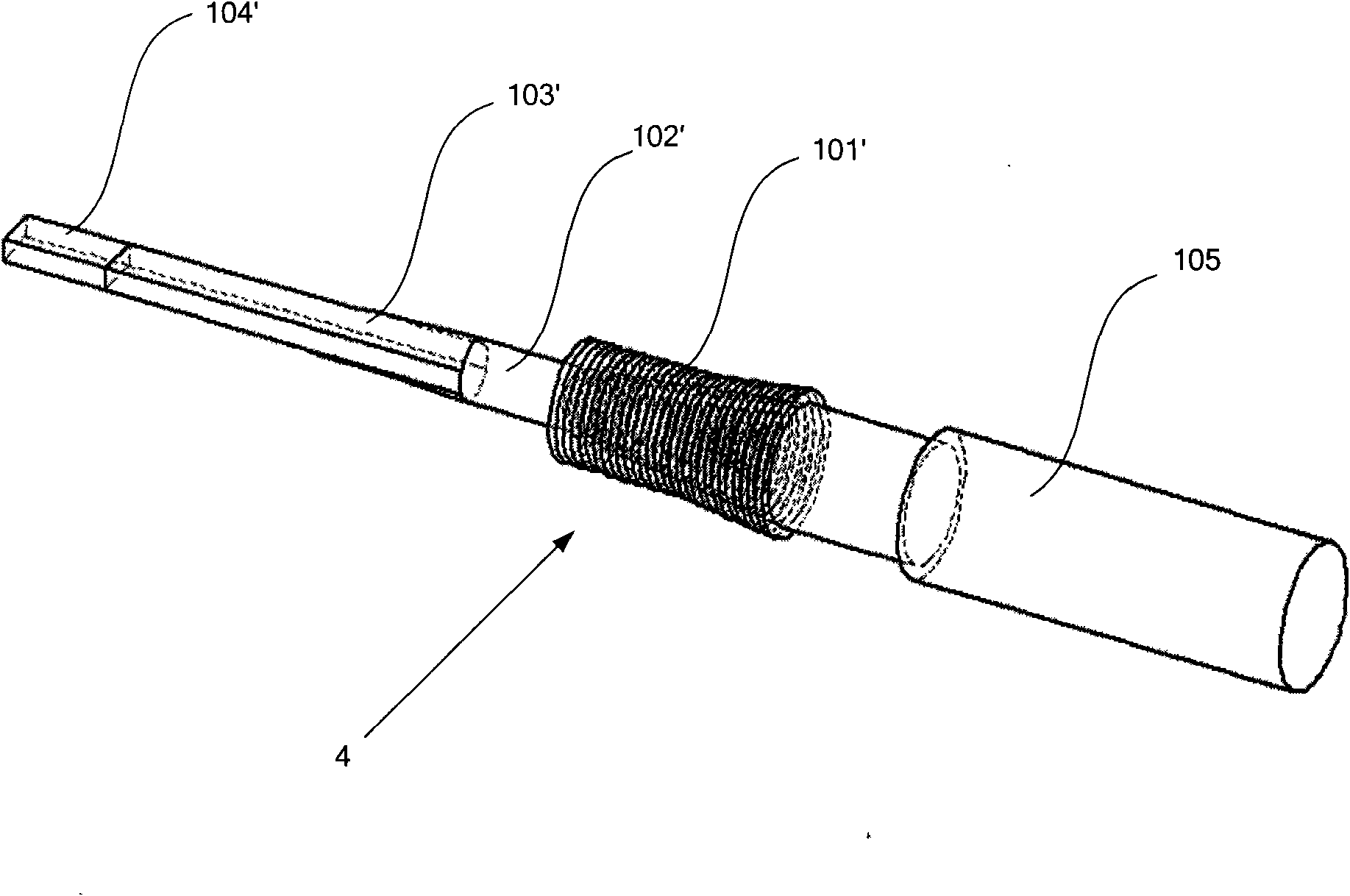

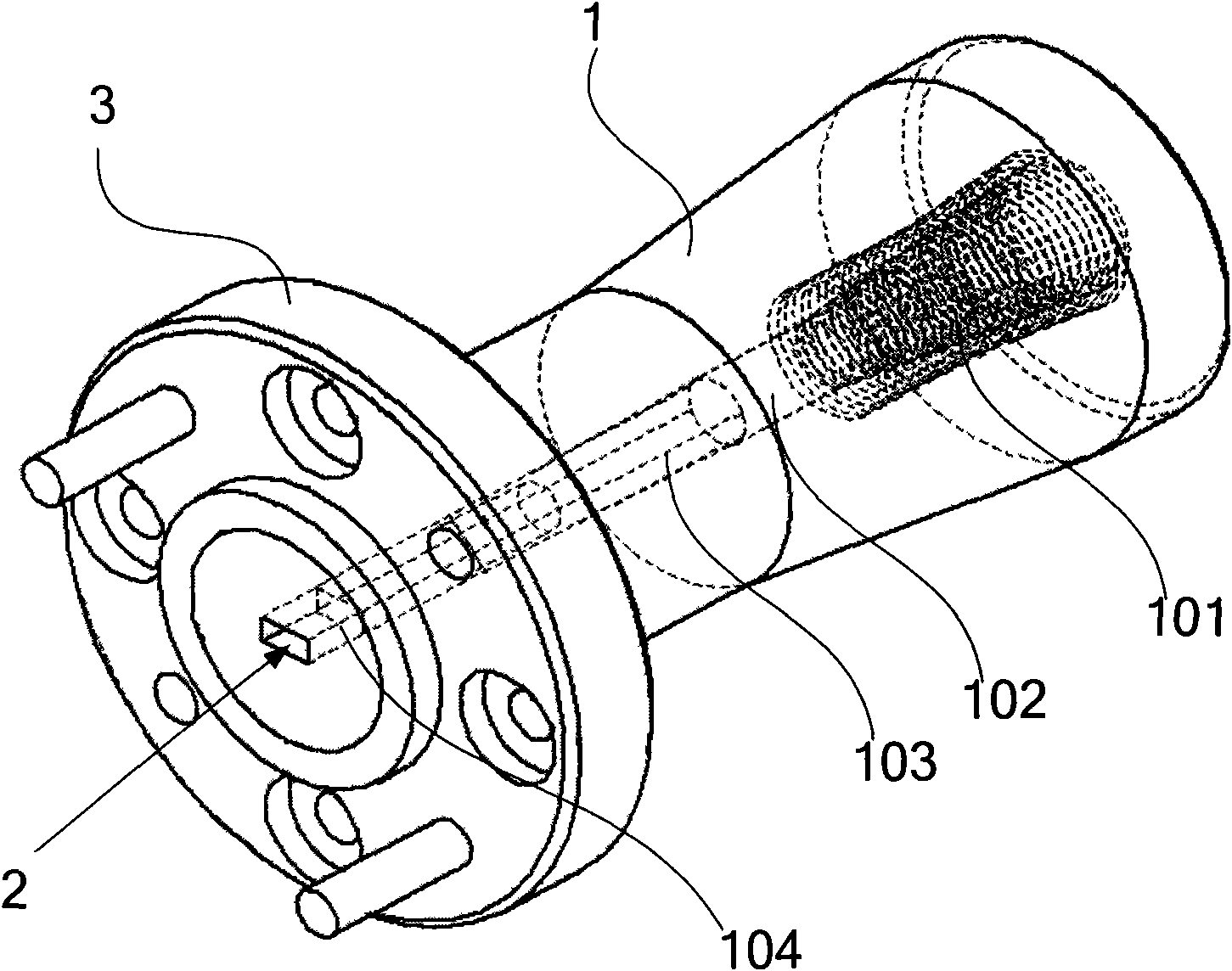

[0043] The present invention is a millimeter-wave rectangular-circle transition integrated corrugated horn antenna, such as figure 1 As shown, the integrated antenna has a shell 1 structure, and the shell 1 is formed by integral one-time electroforming, and the shell 1 is connected to the rectangular waveguide used for feeding power on other devices through the connecting part 3 .

[0044] Such as figure 1, the shell 1 is an integrated electroforming, which is an overall structure made of metal copper. There is an inner cavity 2 in the shell 1 that runs through the upper and lower ends of the shell 1. This integrated overall structure of the shell 1 ensures The continuity of the boundary of the inner cavity 2 conductors avoids the contact loss caused by the traditional way of using discrete components at the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com