Command point shaping, compressing and interpolating method suitable for numerical control device

A technology of numerical control device and command point, which is applied in the field of numerical control machining of complex profiles, and can solve the problems of inability to meet the high-speed and high-precision machining requirements of complex profiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

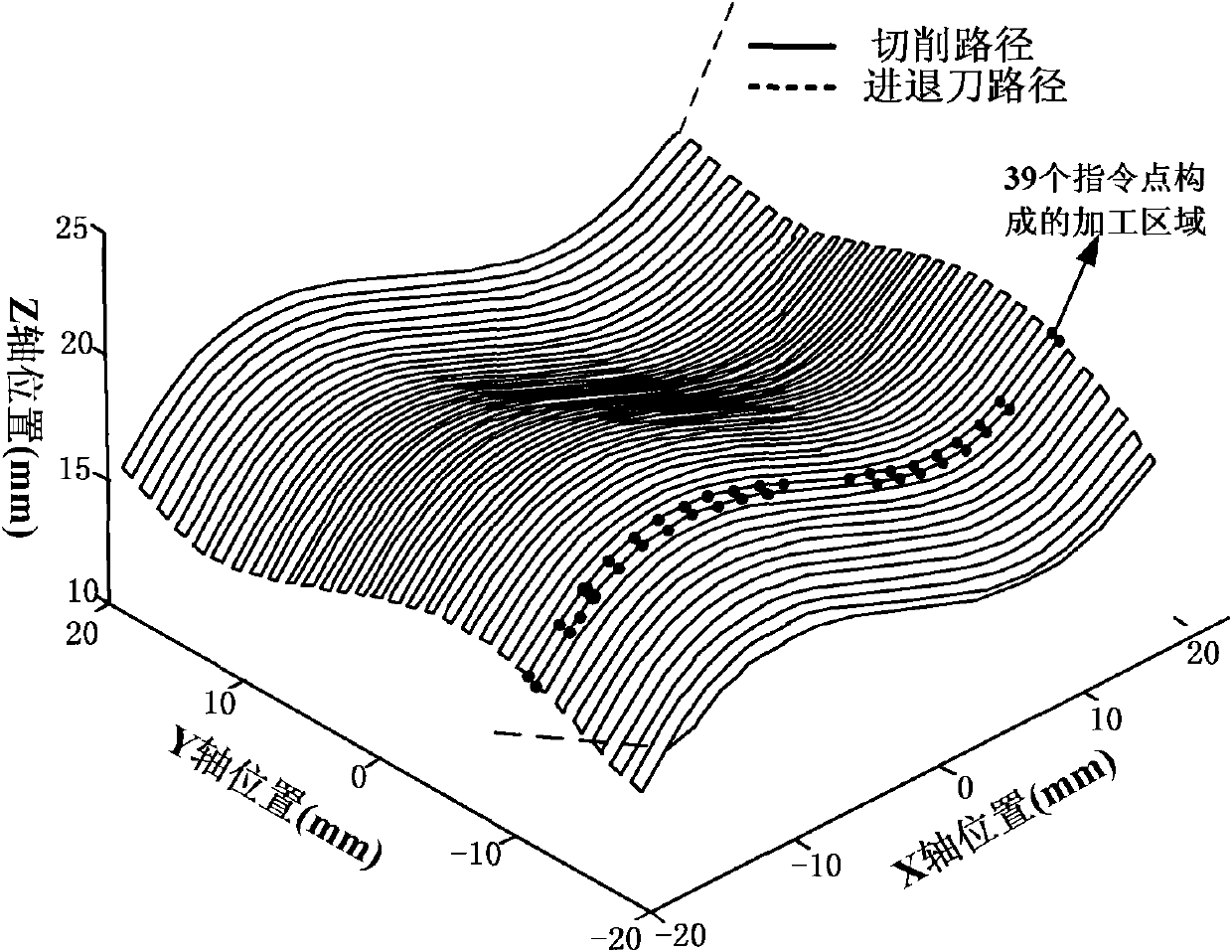

[0063] Such as image 3 As shown, the present invention is applicable to the command point shaping compression interpolation method of the numerical control device, comprising the following steps:

[0064] Recognition of continuous micro-segment processing area: According to the read-in NC processing program, judge whether any three adjacent instruction points on the surface to be processed meet the continuous processing conditions;

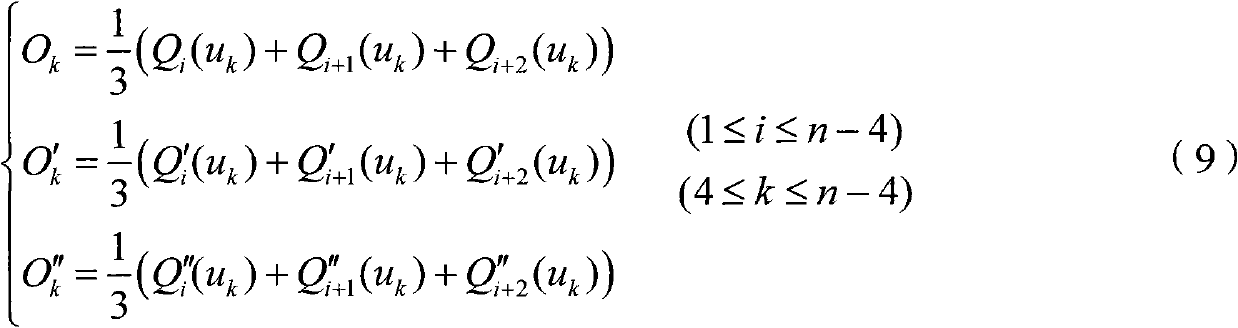

[0065] Estimation of interpolation points: When any three adjacent instruction points on the surface to be processed meet the continuous processing conditions, through the middle point of each adjacent three instruction points, the distance between the interpolation and the middle point is set for the tolerance of the numerical control device and is consistent with the For arcs with tangent line segments between a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com