Grinding polishing method based on magnetic rheology effect and its polishing device

A technology of magnetorheological effect and magnetorheological fluid, which is applied in the direction of polishing compositions containing abrasives, grinding/polishing equipment, polishing compositions, etc., can solve the problem that the residence time of the movement speed of free abrasive particles cannot be effectively controlled and affects Accuracy and efficiency of ultra-smooth surface grinding, detachment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

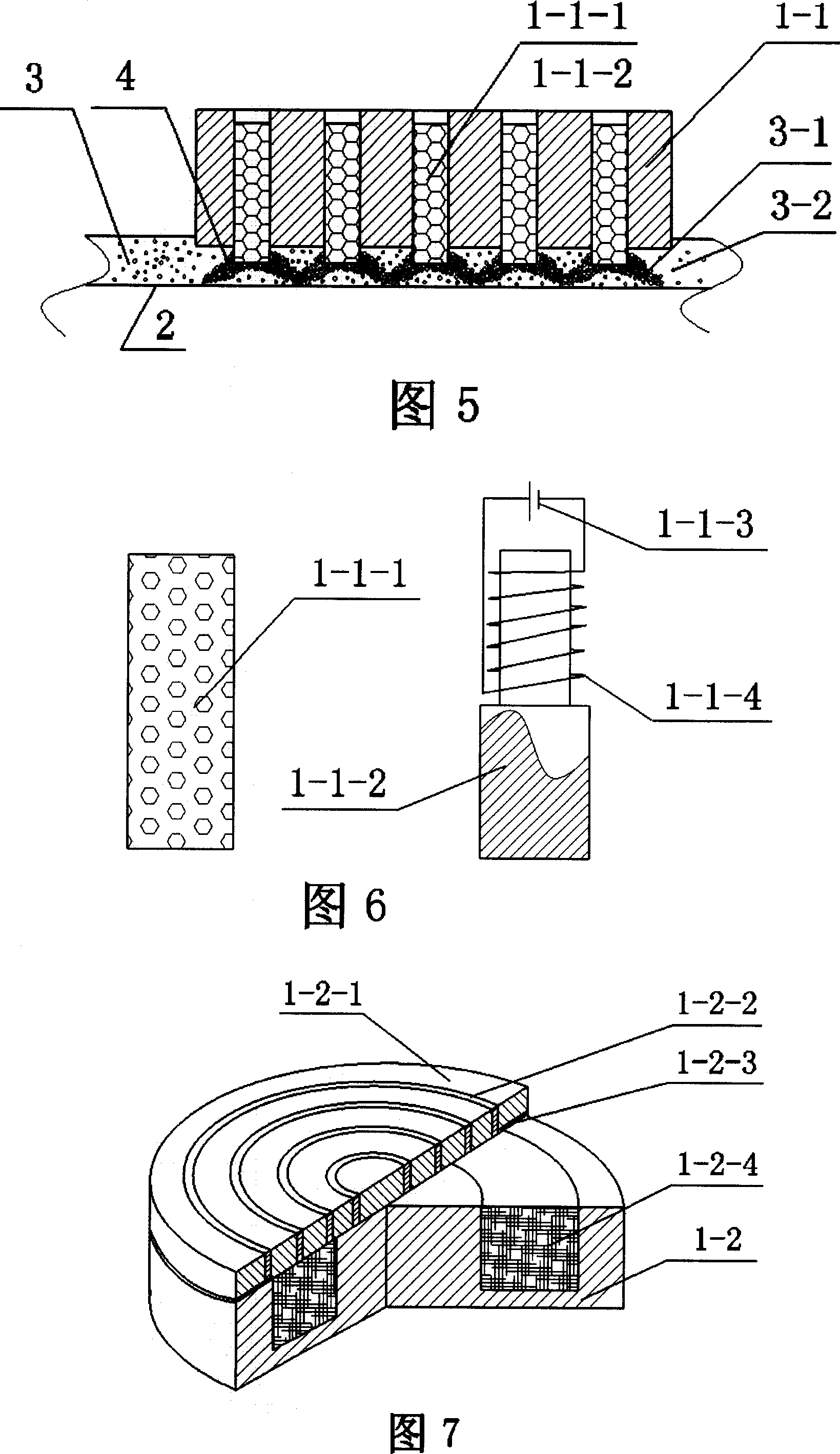

[0059] Fig. 10 shows the concrete structure that the present invention is used for ultra-smooth plane grinding and polishing processing, by array type magnetic plane grinding tool 1-1 or distributed magnetic plane grinding tool 1-2, conductive copper ring slider assembly 9, DC power supply 1-1-3, etc. constitute a macro plane grinding tool, the grinding tool is connected with the grinding disc spindle 10 of the machine tool, the grinding tool spindle motor 12 realizes the rotary motion of the plane grinding tool through the grinding tool spindle transmission mechanism 11, and is installed on the body stand The X-direction feeding system 13 and the Z-direction feeding system 14 of the grinding tool on the 8 can realize the X-direction and Z-direction feeding of the magnetic plane grinding tool 1-1. The workpiece 2-1 with a flat processing surface is installed on the rotary table 5, the rotary table 5 is connected with the rotary table spindle 6, the rotary table spindle motor an...

Embodiment 2

[0061] Fig. 11 has shown the concrete structure that the present invention is used for ultra-smooth curved surface grinding and polishing processing, curved surface magnetic grinding tool 1-3 can realize rotation under the drive of grinding tool spindle motor 12, and processing surface is the workpiece 2- of non-axisymmetric curved surface 3 Installed on the workbench 5 with 3-axis numerical control interpolation movement, the X-direction feed system 13, Z-direction feed system 14 and Y-direction feed system 16 realize the curved surface magnetic grinding tool under the control of the numerical control system 17 1- 3 and the interpolation movement between the workpiece 2-3 whose processing surface is a non-axisymmetric curved surface, the computer 18 transmits the processing data to the numerical control system 17, and the grinding and polishing liquid nozzle 15 is filled with the grinding and polishing liquid (the magnetorheological fluid is mixed with the abrasive material) L...

Embodiment 3

[0063] The present invention can also grind and polish a convex curved surface or a curved surface with a combination of convex and concave, and its implementation process is similar to the above process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com