Automatic monitoring method for high-speed milling cutter abrasion

A technology for tool wear and automatic monitoring, which is used in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc. problems, to achieve the effect of predicting tool life, facilitating tool compensation and calibration, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

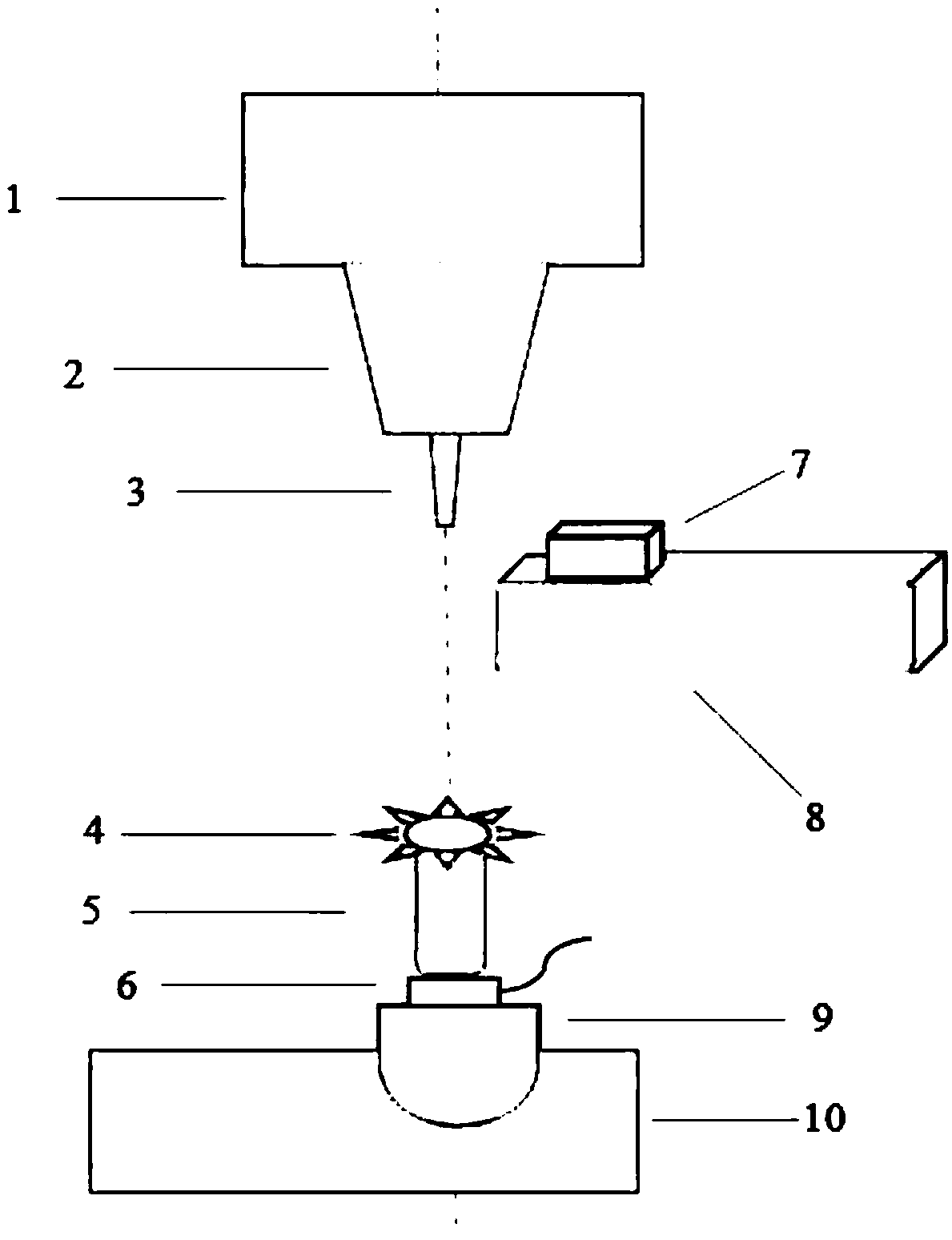

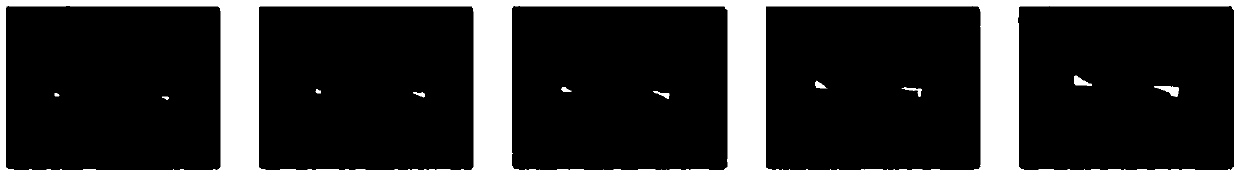

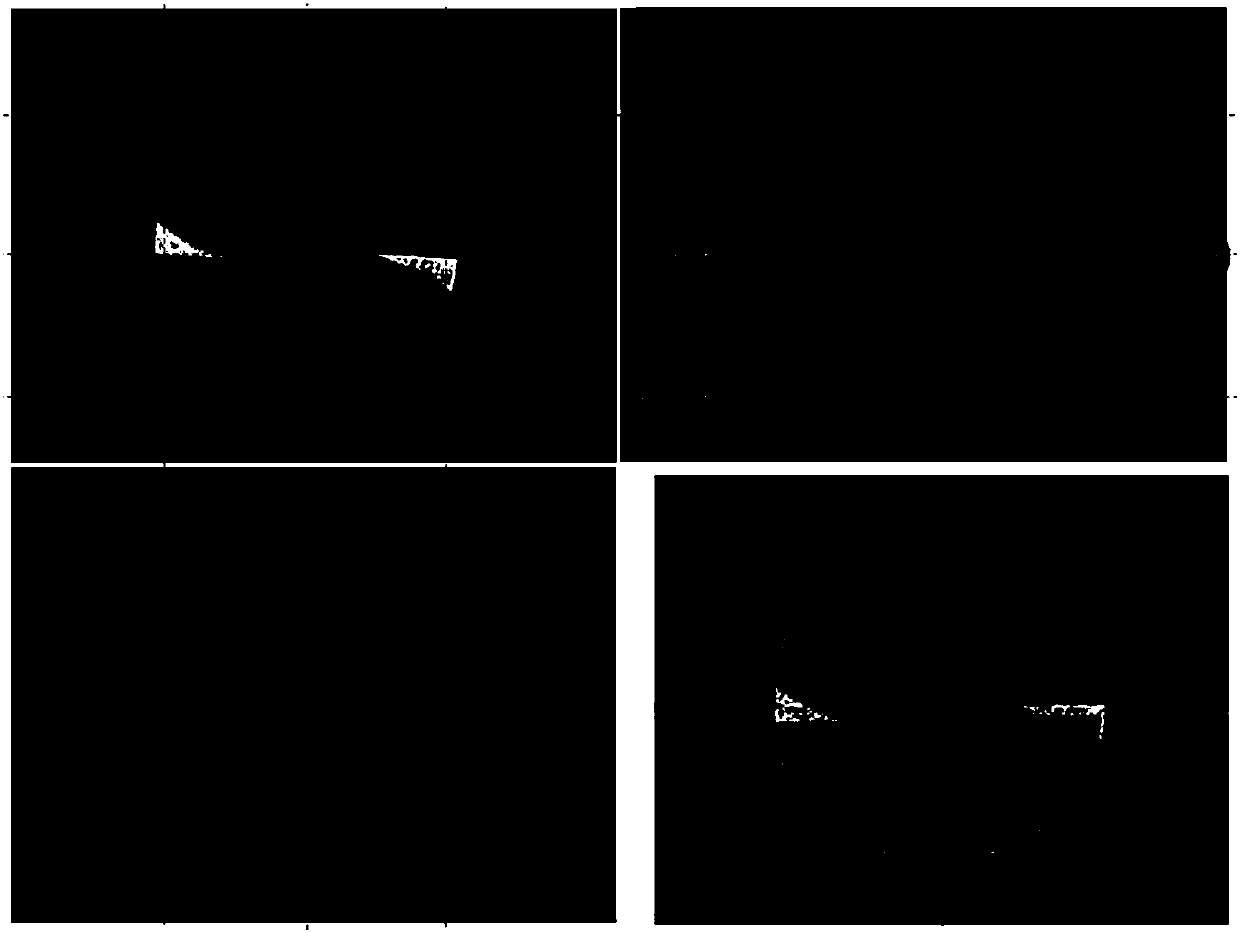

[0018] Depend on Figure 1-Figure 6 An automatic monitoring method for high-speed milling tool wear is shown. The imaging device faces the end of the working end of the tool 3 during the processing interval and collects images multiple times, and obtains multiple images. The processing interval is set by the program, which means In the processing program, multiple intervals are artificially added to take pictures; the tool 3 is a milling cutter of a CNC milling machine, preferably a micro-milling cutter, and the gray mean square error is performed on the central area of each image collected in real time in the processing gap. Statistically, the central region includes the area where the cutter is located, and the image with the largest mean square error is selected as the target image, and the central region of each image is preferably the central region; the target image is the image of the front projection of the cutter 3 ends, and there are For the white area formed by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com