Ring gear or flange processing method

A processing method and technology of a ring gear, which are applied to components with teeth, manufacturing tools, belts/chains/gears, etc., can solve the problems of wasting coal, electricity, and pollute the environment, and achieve low production costs, high work efficiency, and improved productivity. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

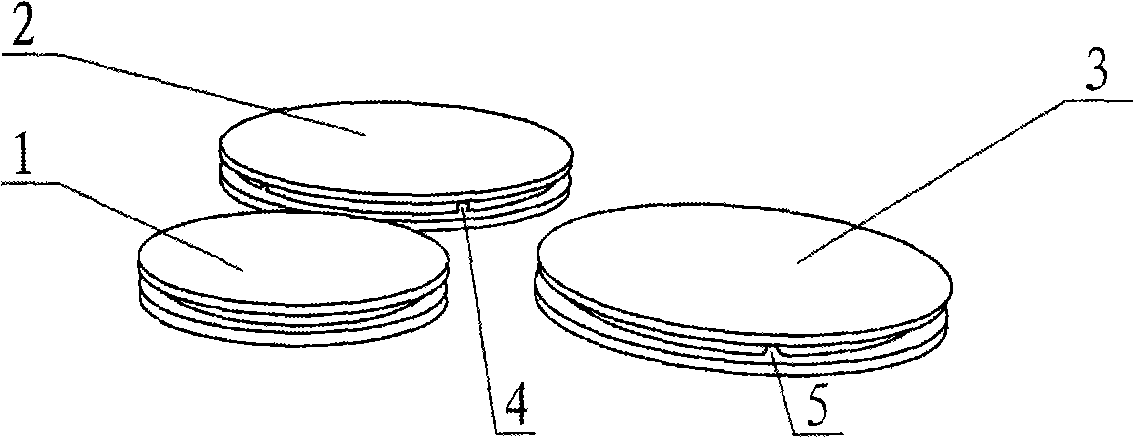

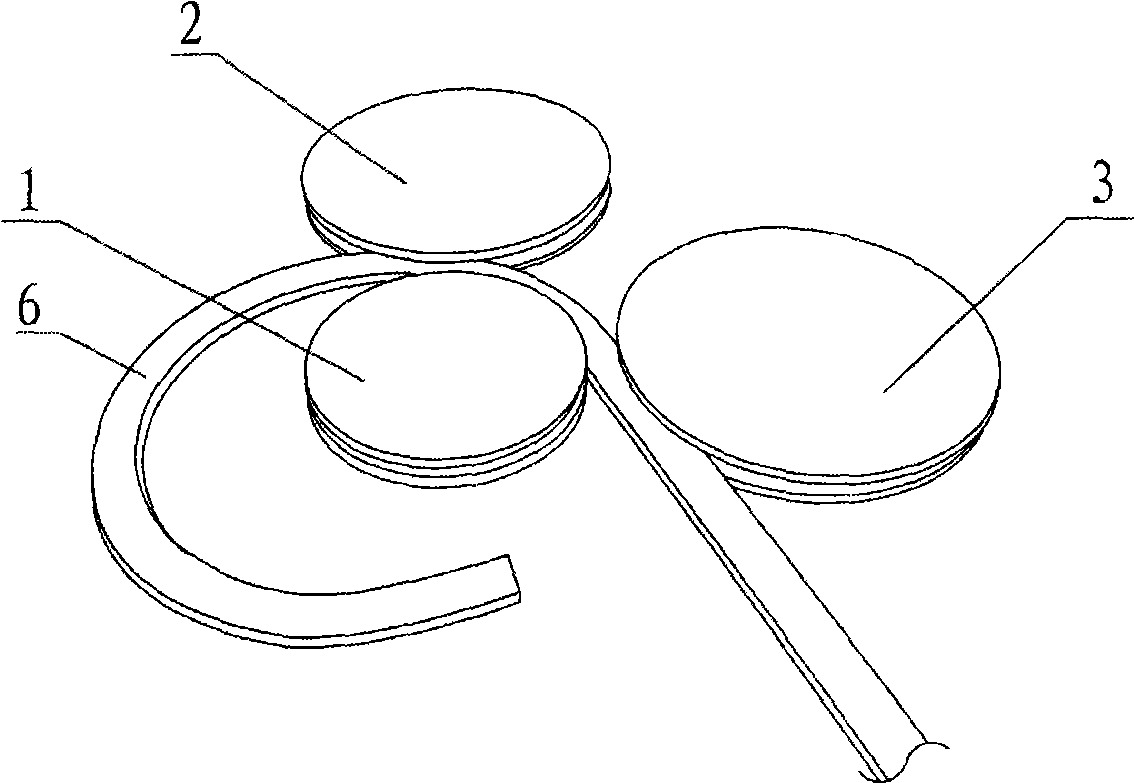

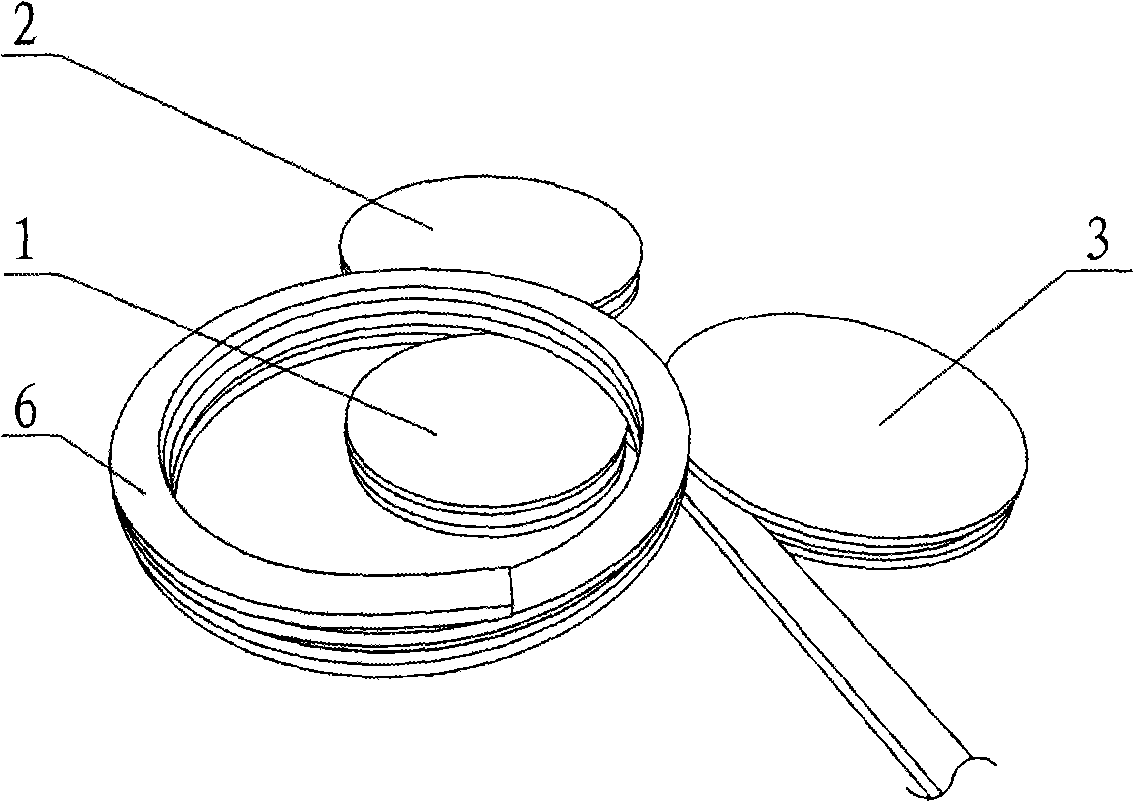

[0021] Embodiment 1: Place the square steel bar or flat steel bar 6 in the groove of the three wheels, extrude into a circular spiral shape, and after manual or mechanical cutting, form the arc square steel 9, and the arc square Put the steel 9 into the cold bending rolling machine for circular extrusion, make the two ends of the arc square steel 9 overlap together, then use the crowbar 7 to pry the overlapping ends to align, and then weld them together with a butt welder , and after being flattened with a hydraulic press, the welding residue and burrs on the welding port are polished with a grinding tool, thereby realizing the shape of the ring gear 8 or flange that can be further processed.

[0022] like Figure 8 As shown, on the basis of the shape of the ring gear 8 or the flange, lathe processing, gear hobbing, chamfering, high-frequency quenching, and tempering are performed sequentially to form the ring gear 8 or the flange.

Embodiment 2

[0023] Embodiment 2: the present invention comprises the square steel bar or flat steel bar 6 that ring gear 8 or flange are used, and realizes the required special equipment of this method and the ring gear processed into by square steel bar or flat steel bar 6 8 or flange shape, put the square steel bar or flat steel bar 6 into the grooves of the three wheels, extrude into a circular spiral shape, and after manual or mechanical cutting, form arc square steel 9, and then use Butt welding machine is welded together, and after being flattened by a hydraulic press, the welding residue and burrs on the welding port are polished with a grinding tool to form a ring gear shape that can be further processed. On the basis of the shape of the ring gear 8 or the shape of the flange, lathe processing, gear hobbing, chamfering, high-frequency quenching, and tempering are sequentially performed to form the finished ring gear 8 or flange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com