Multi-functional all-in-one automatic drilling and tapping machine tool

A multi-functional and automatic technology, which is applied to the parts of boring machine/drilling machine, thread cutting machine, boring/drilling, etc., can solve the problems of low yield rate of micro-hole drilling, high labor intensity of workers, difficult automatic processing, etc., to achieve Simplified structure, low cost and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

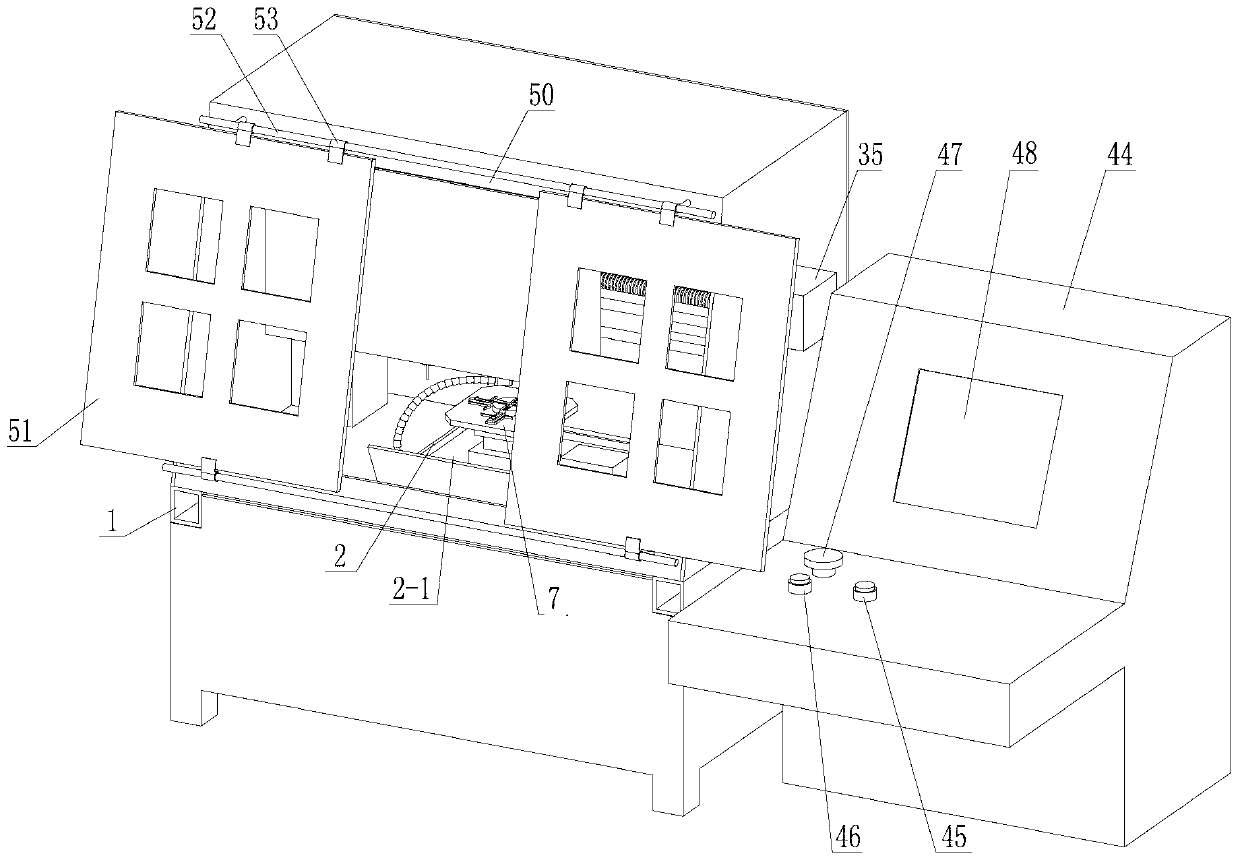

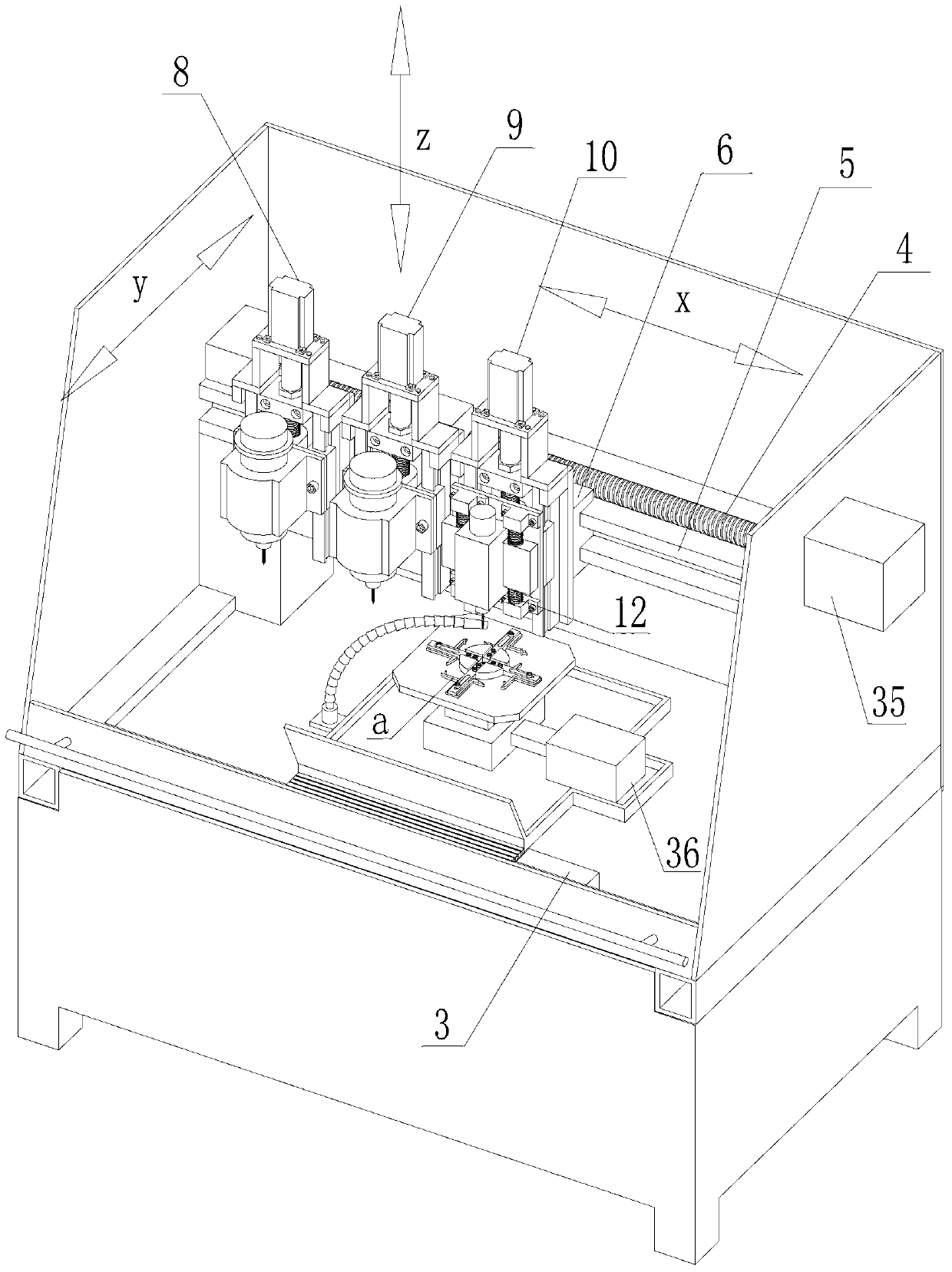

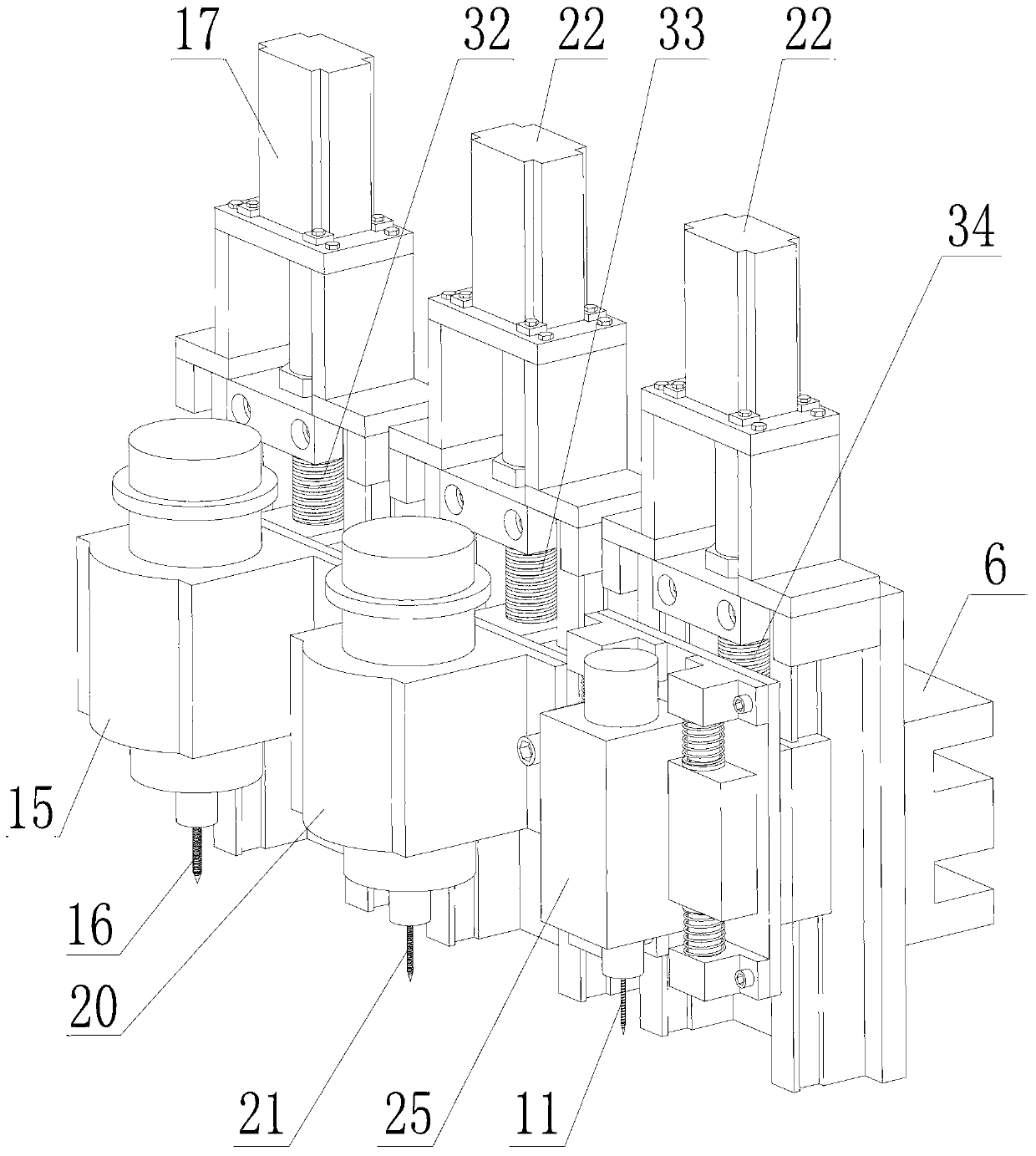

[0031] Referring to the accompanying drawings: the multi-functional integrated automatic drilling and tapping machine tool in this embodiment includes a frame 1, on which a workbench 2 is arranged, and the workbench 2 is controlled by a Y-axis servo motor 3 in the Y-axis direction The moving workbench 2, the frame 1 above the workbench 2 is provided with an X-axis oriented drive screw 4, an X-axis servo motor 35 that drives the drive screw 4 to rotate, and a horizontal axis parallel to the drive screw 4. The guide rail 5 and the transverse guide rail 5 are provided with a main slide seat 6 slidingly matched with the transverse guide rail 5. The main slide seat 6 is driven by the driving screw 4. The worktable 2 is provided with a multi-workpiece fixture mechanism 7. A pre-drilling mechanism 8, a drilling mechanism 9, and a tapping mechanism 10 corresponding to the position ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com