Ball screw and belt stepless variable speed devcie with same

A technology of belt-type continuously variable speed and ball screw, which is applied in the direction of transmission, friction transmission, transmission control, etc., can solve the problems that hinder the light weight and compactness of CVT, and the difficulty of optimal design, so as to achieve the purpose of suppressing lubricant The effect of scattering, increasing the effective length, and shortening the total length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

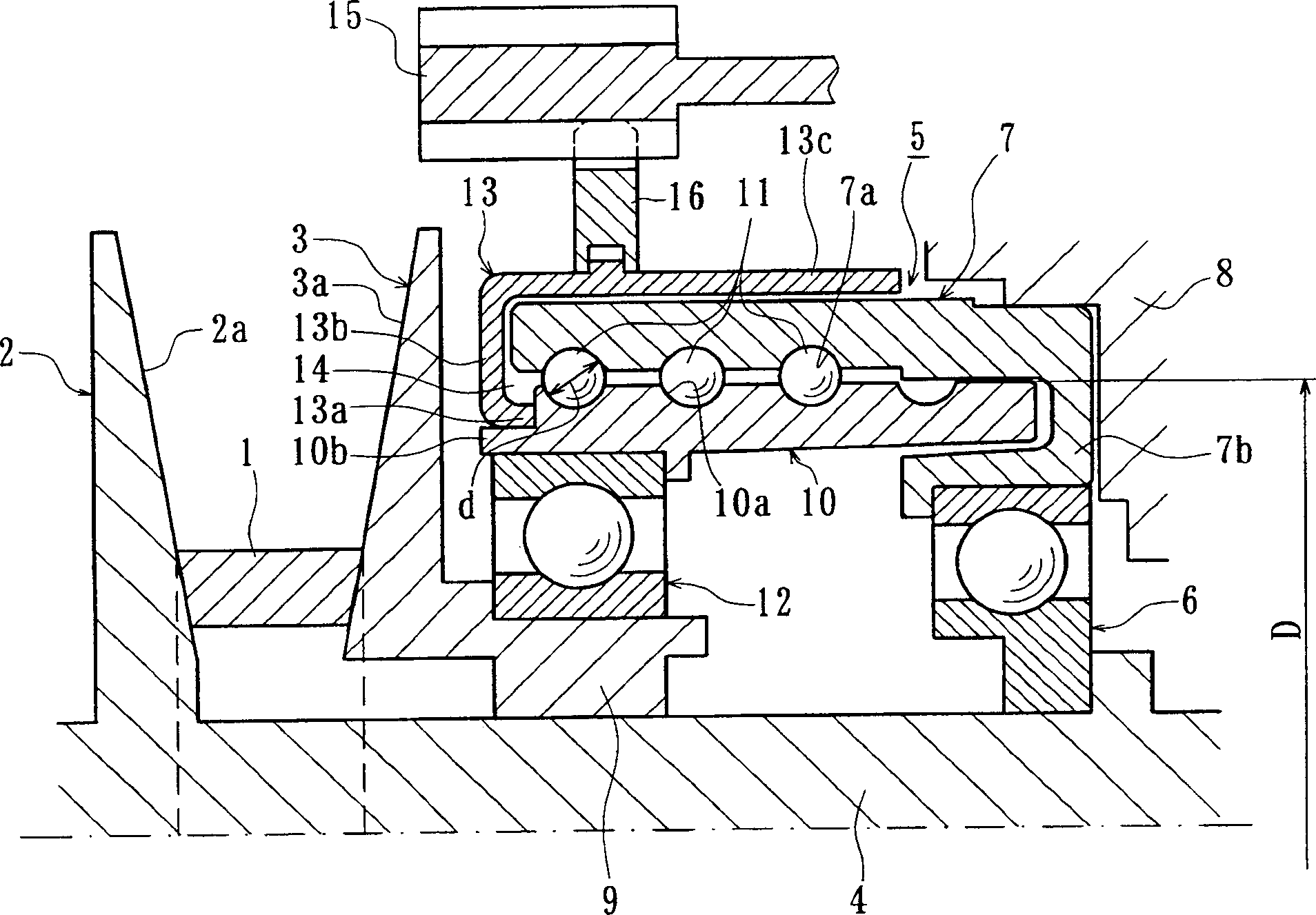

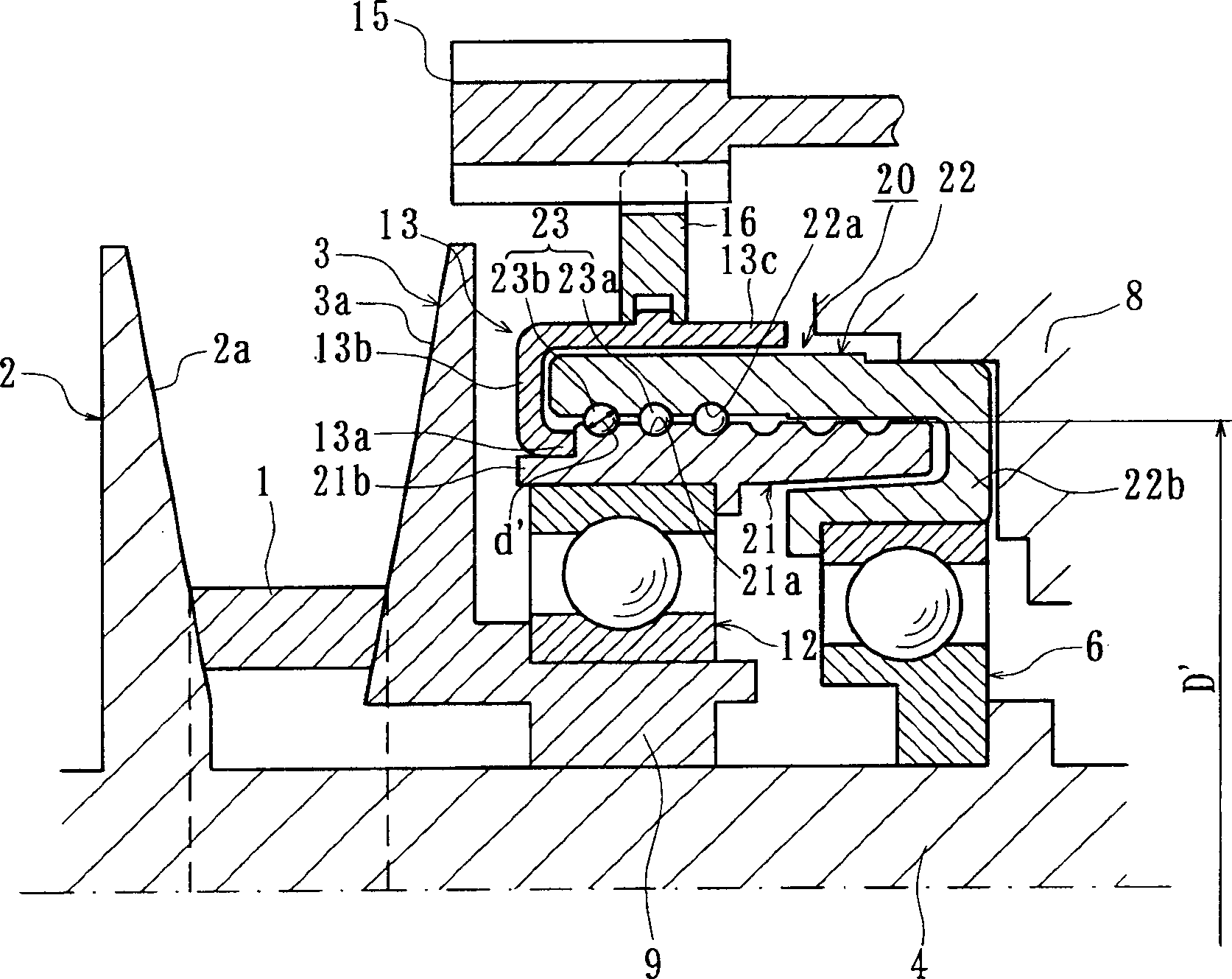

[0034] Below, according to Figure 1 ~ Figure 4 Embodiments of the present invention will be described in detail. figure 1 It is a longitudinal sectional view showing a CVT having a ball screw of the present invention.

[0035] In this CVT, a fixed pulley 2 and a movable pulley 3 around which a transmission belt 1 is wound are attached to a rotary shaft 4 so that respective belt receiving surfaces 2a, 3a face each other. By moving the movable pulley 3 linearly in the axial direction by the ball screw 5, the winding diameter of the conveyor belt 1 is continuously changed. Here, a structure in which the fixed pulley 2 and the rotary shaft 4 are integrally formed is exemplified, but a cylindrical portion extending toward the movable pulley 3 side on the fixed pulley 2 may be provided and fitted on the rotary shaft 4 .

[0036] The nut 7 integrally has a connecting portion 7b having a U-shaped cross section. The connection portion 7 b covers one end of the screw shaft 10 , res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com