Patents

Literature

37results about How to "Limit axial movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

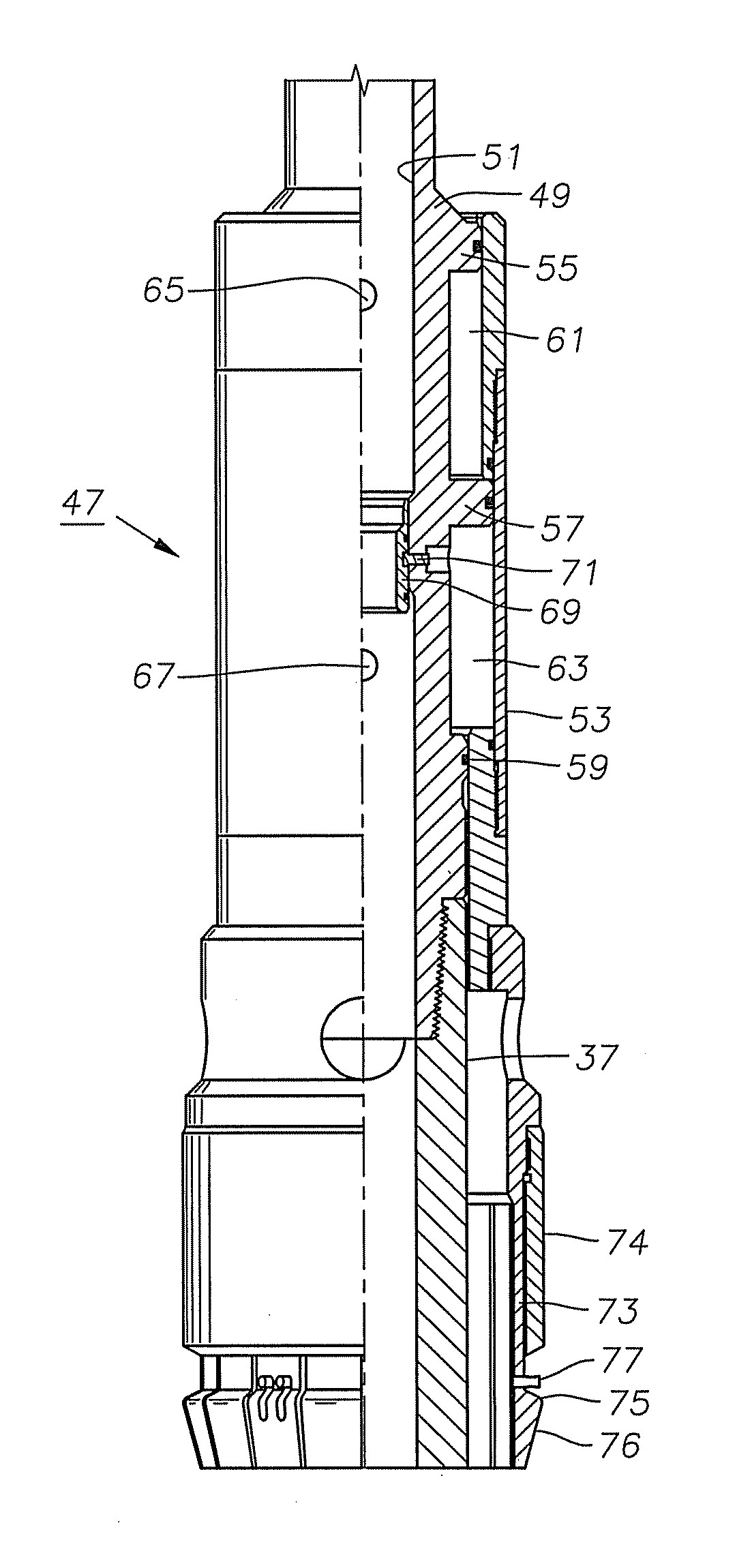

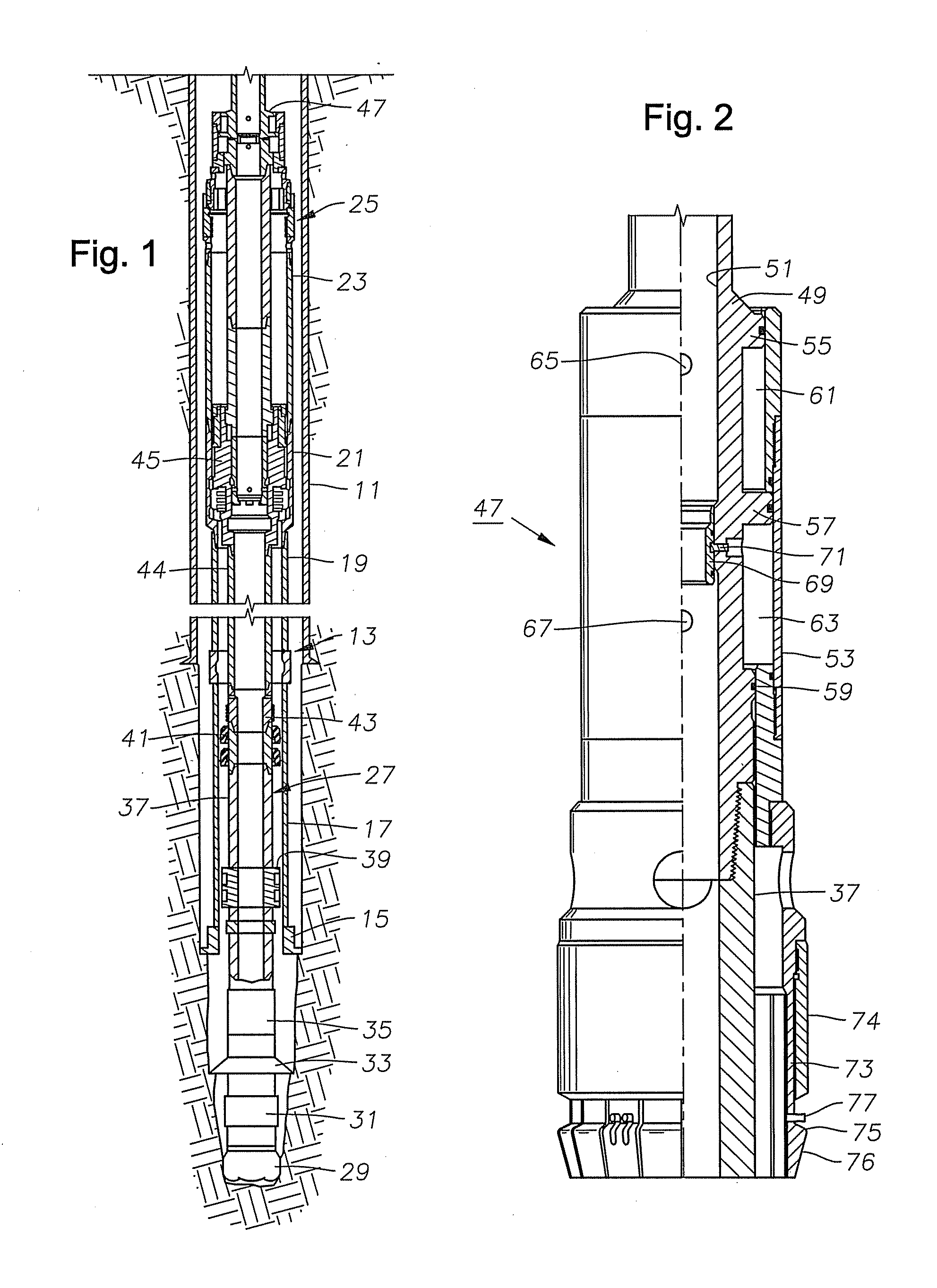

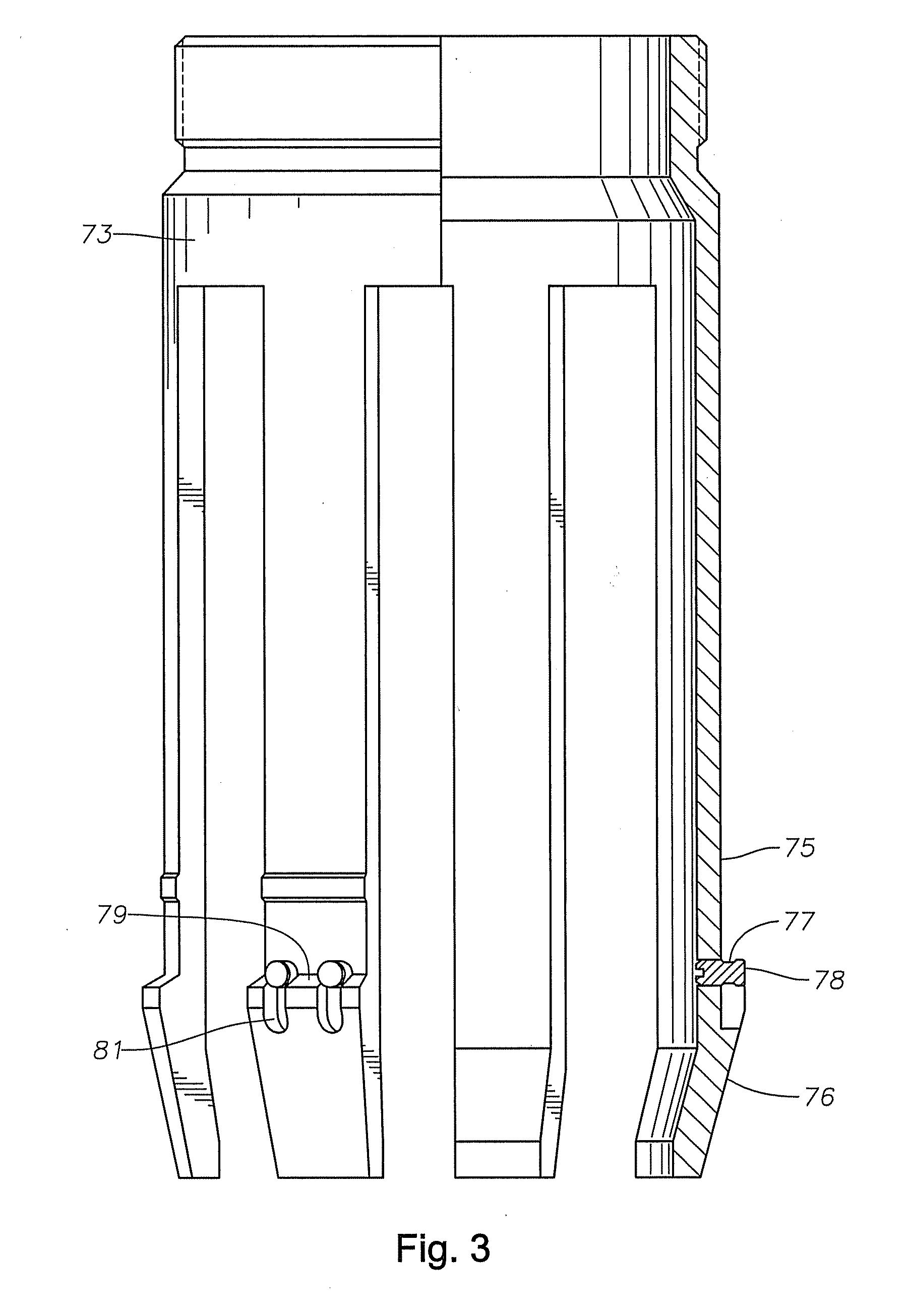

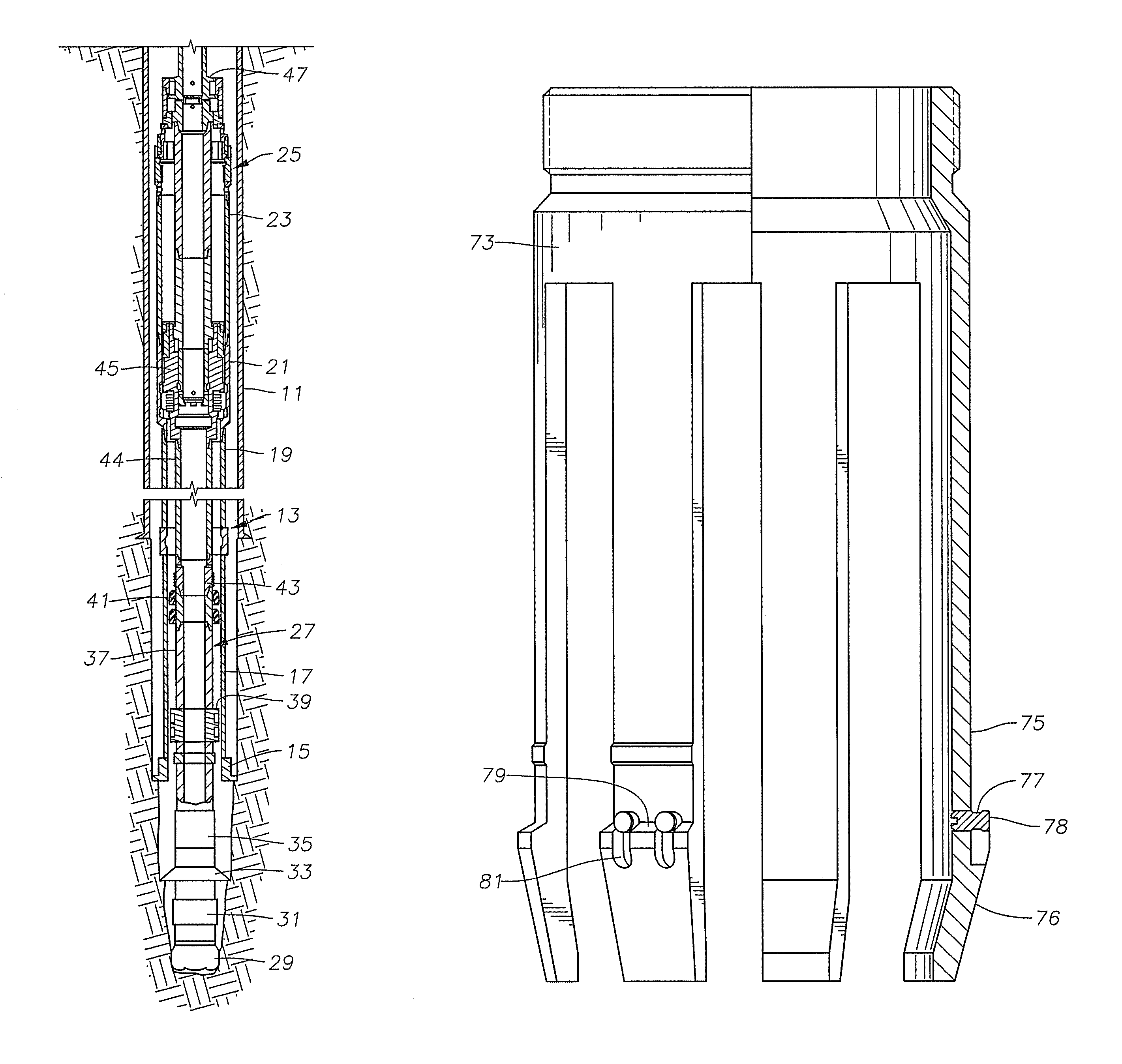

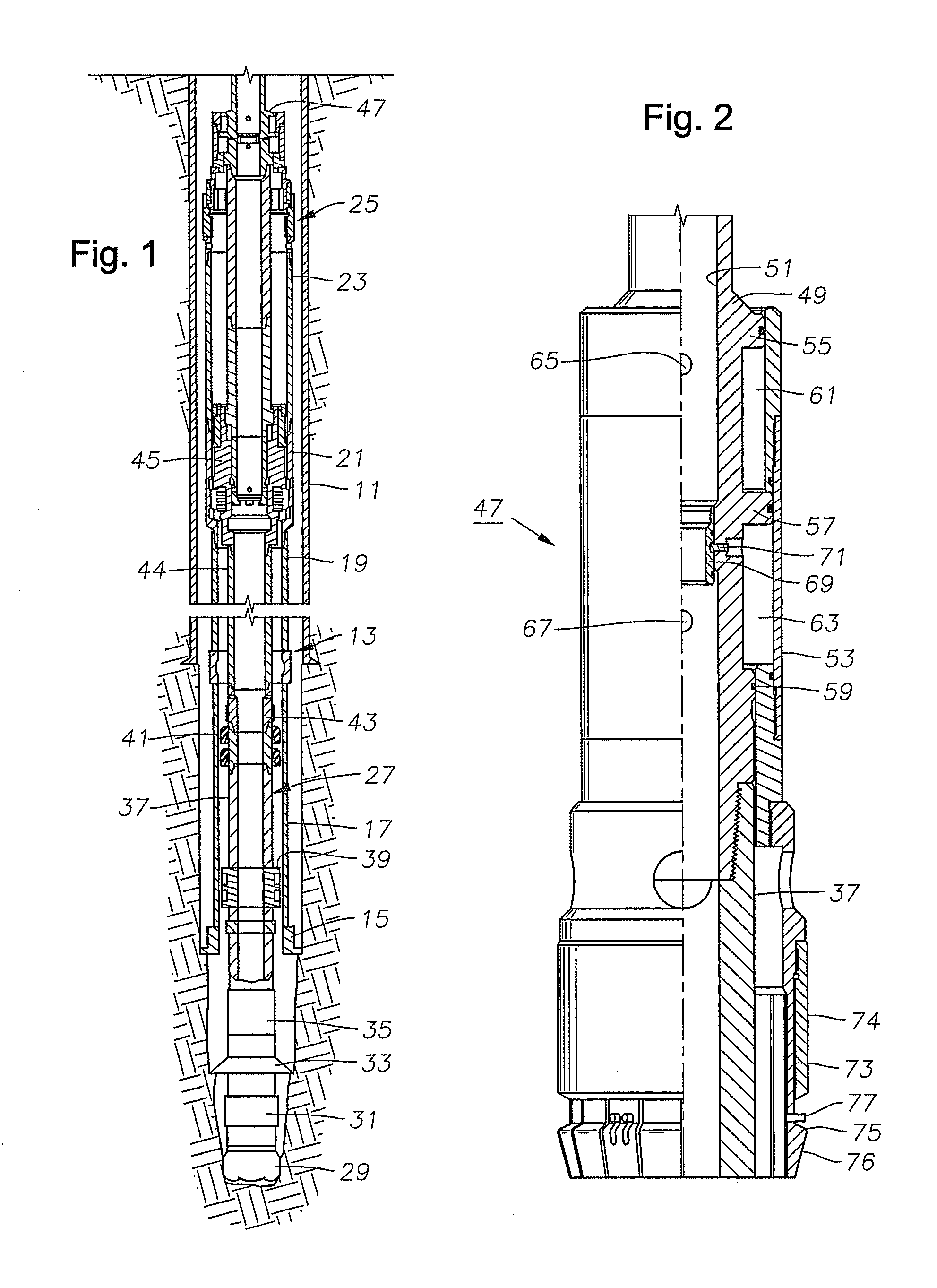

Well Tool with Shearable Collet

A running tool for well drilling operations is carried by a running string into and out of a wellbore. A collet is carried by the running tool, the collet having fingers with a radially expanded position arranged to latch against a wellbore shoulder in the wellbore. The fingers are resiliently and radially contractible. A shear element is carried by the collet, the shear element preventing the fingers from radially contracting to unlatch the running tool while the shear element is intact. If a selected axial force is applied against the shear element, it shears, freeing the collet fingers to retract. The collet may be part of a tool to set and release a liner hanger from engagement with a string of casing.

Owner:SCHLUMBERGER TECH CORP

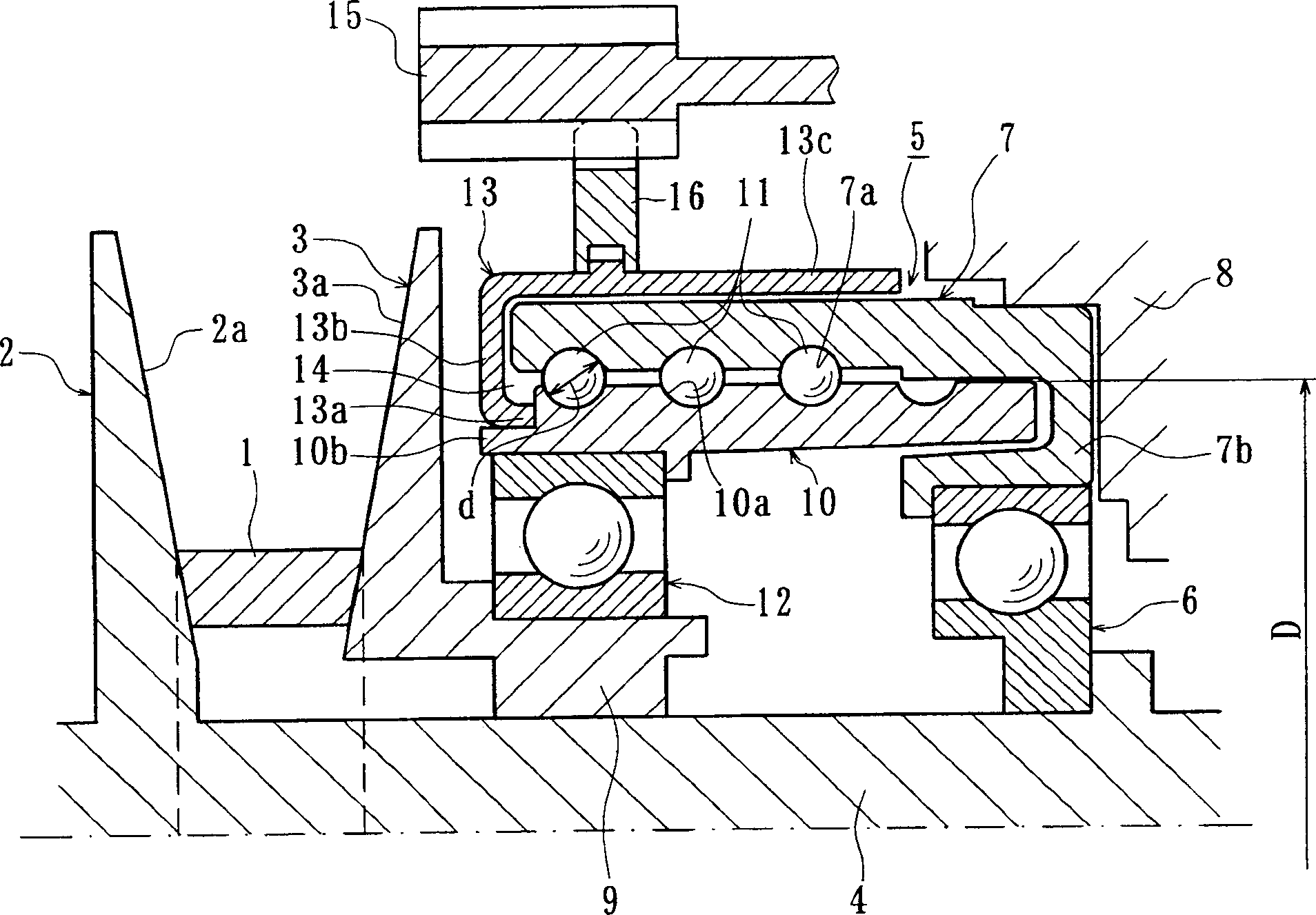

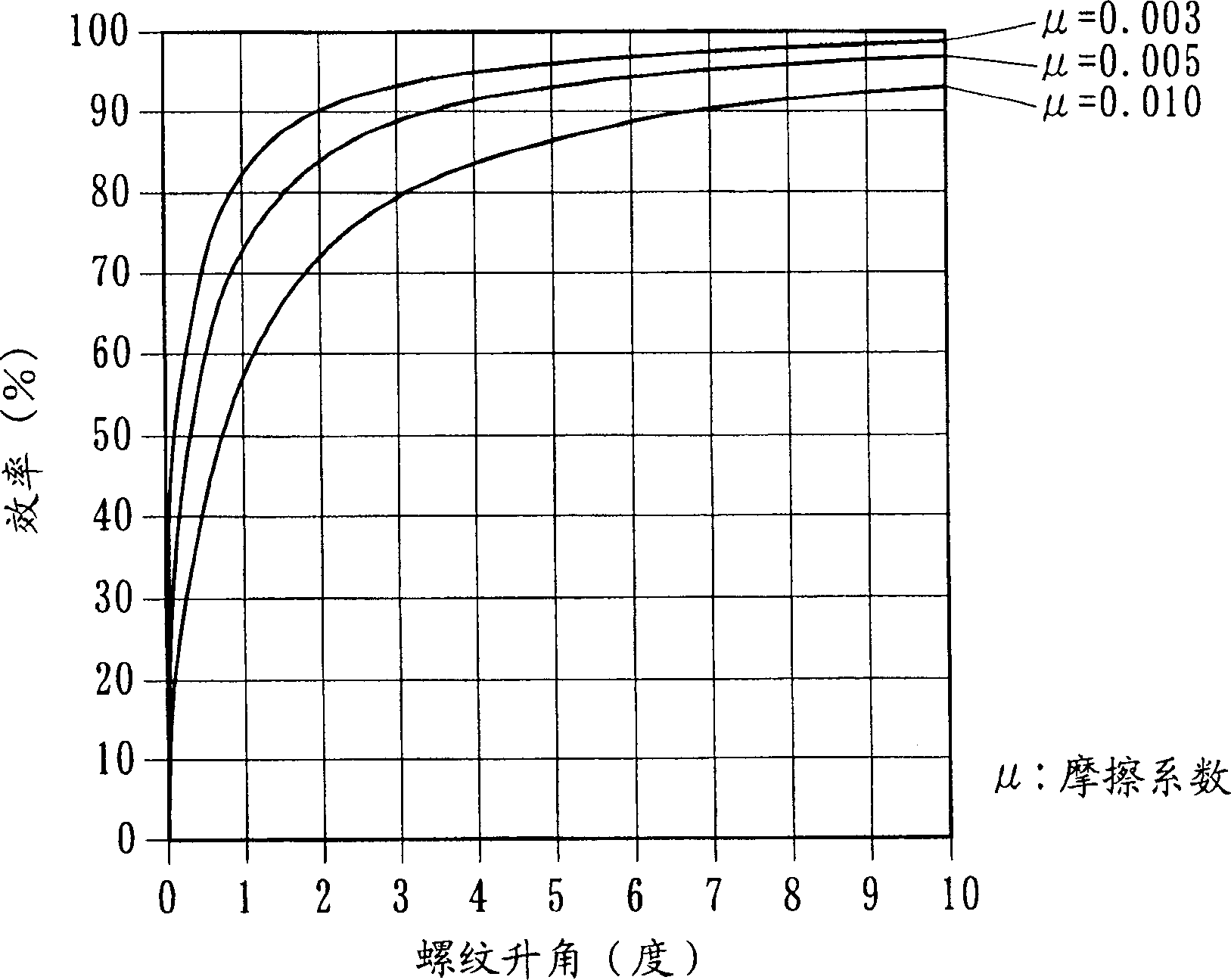

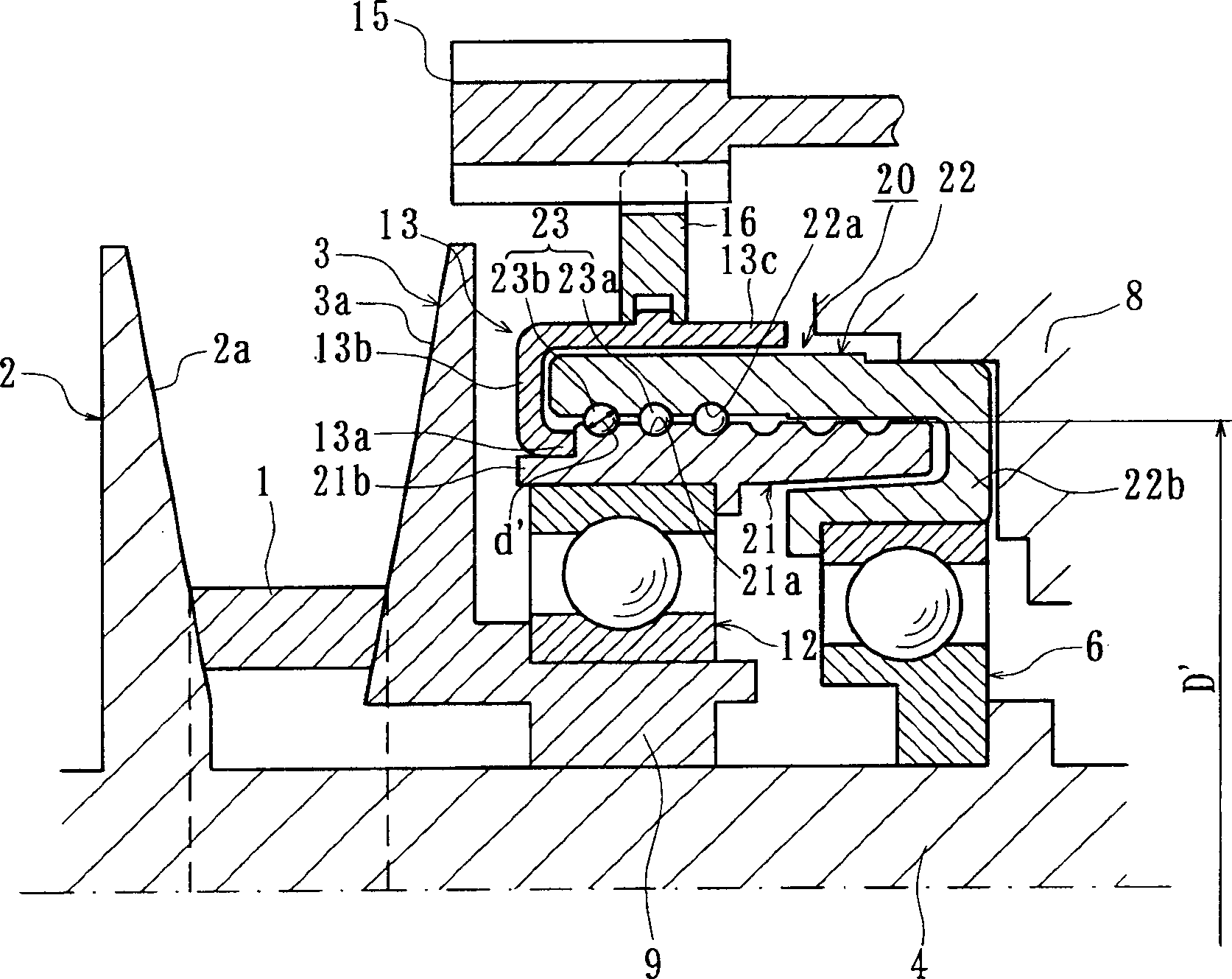

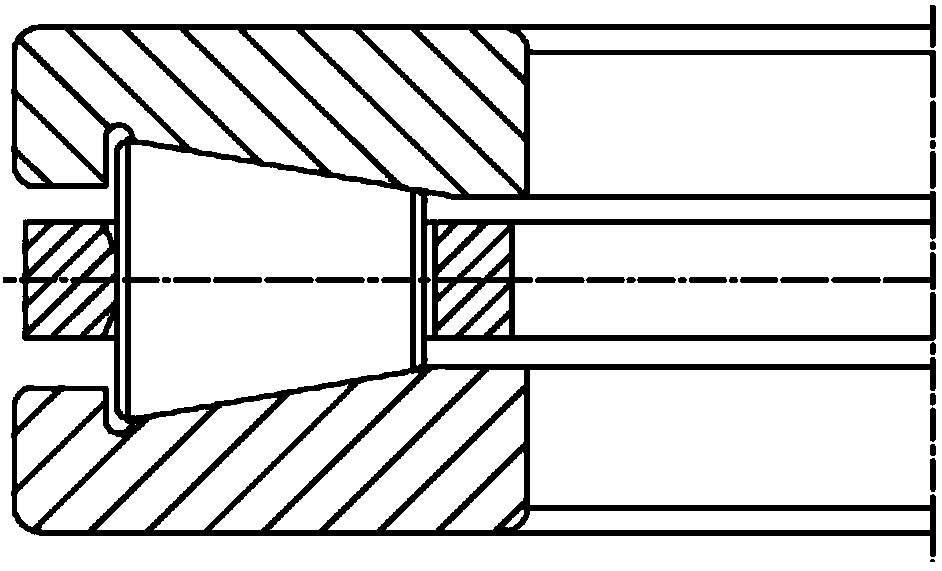

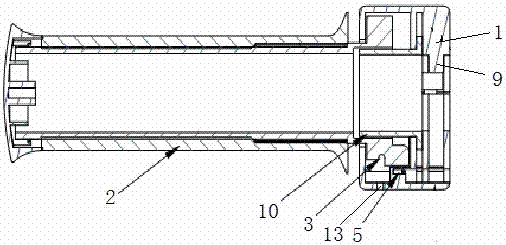

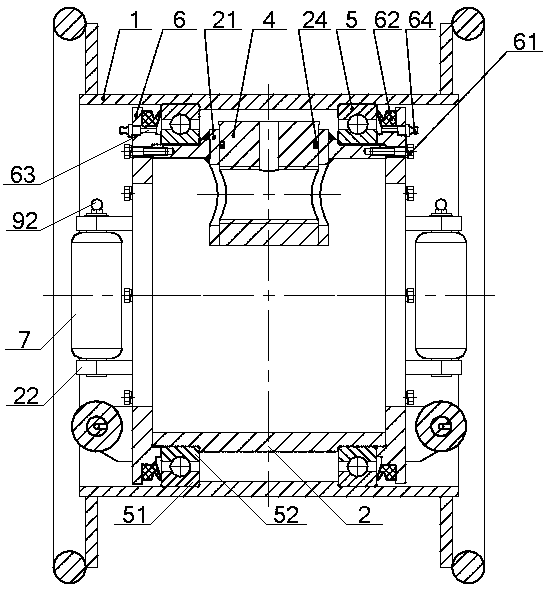

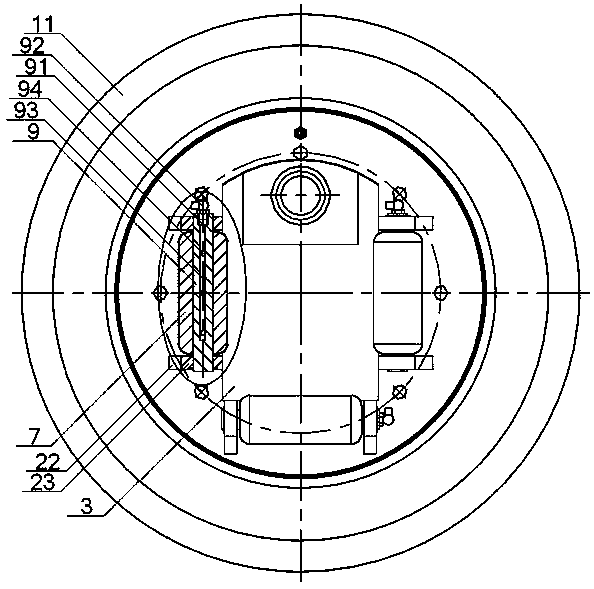

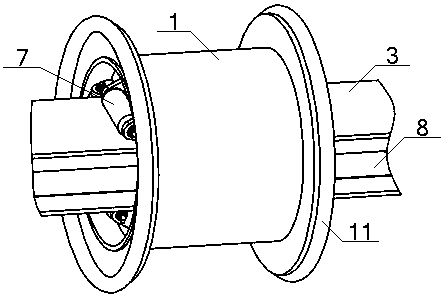

Ball screw and belt stepless variable speed devcie with same

InactiveCN1420293AShorten the overall lengthEliminate relative slidingGearing controlBearing componentsBall screwPulley

There are provided a ball screw enabling the reduction of weight and size of a CVT without reduction of the transmission efficiency as well as a CVT in which the ball screw is incorporated. A CVT of the present invention comprises an axially immovable pulley half 2 and axially movable pulley half 3 both mounted on a rotary shaft 4, and the axially movable pulley half 3 being moved by a ball screw 20 so as to infinitely vary the belt wrapping radius and thus the transmission speed, and is characterized in that a nut 22 forming one part of the ball screw 20 is immovably secured both in axial and rotational directions, a screw shaft 21 forming the other part of the ball screw 20 is movable both in axial and rotational directions and connected to the axially movable pulley half 3, and the axially movable pulley half 3 is axially moved by rotating the screw shaft 21.

Owner:NTN CORP

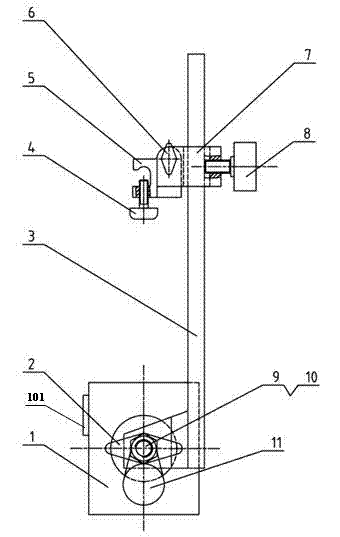

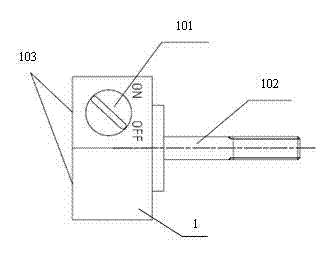

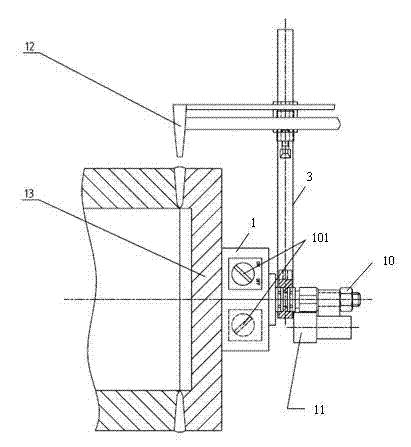

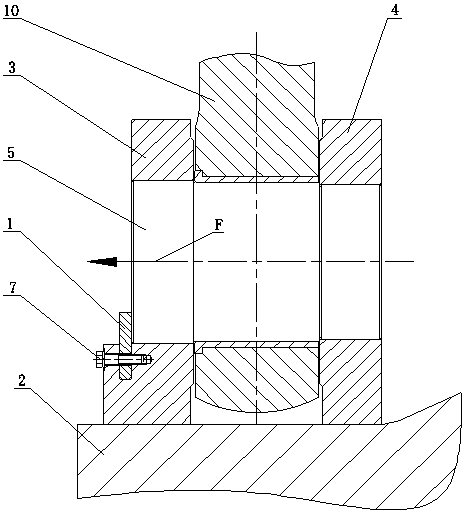

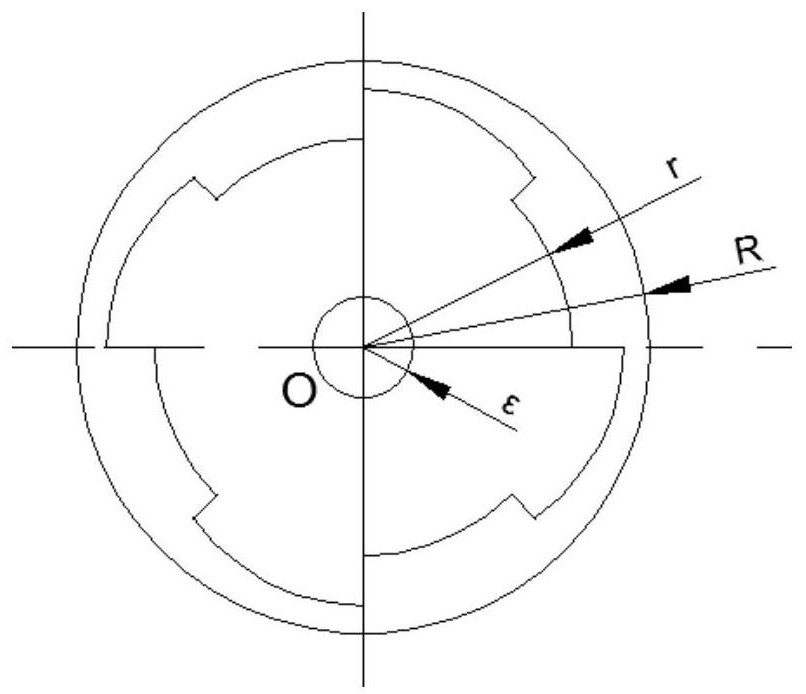

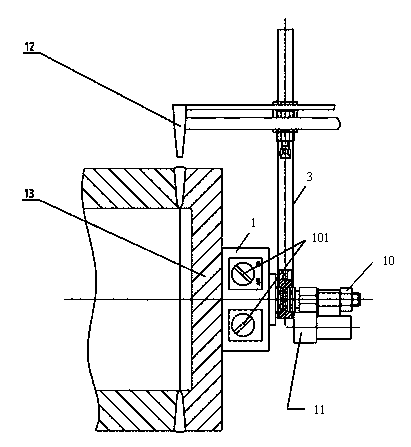

Gas cutting guiding device

ActiveCN102390000ALow manufacturing costPracticalWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCutting guide

The invention relates to a gas cutting guiding device which comprises a clamping locating mechanism and a speed-changeable transmission mechanism. The clamping locating mechanism comprises an end cover connection guiding mechanism and a gas cutting gun mounting locating mechanism, wherein the end cover connection guiding mechanism comprises a magnetic block and a guiding block, the magnetic block is fixedly arranged on the end surface of a pipe end cover, a threaded core shaft is arranged at the center of the end surface of the magnetic block, the guiding block is arranged on the threaded core shaft in a through manner and can rotate around the threaded core shaft. The speed-changeable transmission mechanism is arranged on the threaded core shaft of the magnetic block. The gas cutting gun mounting locating mechanism is arranged on the guiding block and comprises a locating block and a clamping device, wherein the locating block is arranged on the guiding block and can slide up and down along the guiding block, and the clamping block is connected with the locating block and can rotate around the locating block. The gas cutting guiding device disclosed by the invention can provide the gas cutting guiding for the pipe end covers with different diameters, and limits the axial drifting of a gas cutting gun and modifies the gas cutting end surface formation of pipes in an operation process of gas cutting the end cover; in addition, the universality is strong, the work efficiency is improved, and the large-scale investment and application of workshops is convenient.

Owner:SHANGHAI BOILER WORKS

Well tool with shearable collet

A running tool for well drilling operations is carried by a running string into and out of a wellbore. A collet is carried by the running tool, the collet having fingers with a radially expanded position arranged to latch against a wellbore shoulder in the wellbore. The fingers are resiliently and radially contractible. A shear element is carried by the collet, the shear element preventing the fingers from radially contracting to unlatch the running tool while the shear element is intact. If a selected axial force is applied against the shear element, it shears, freeing the collet fingers to retract. The collet may be part of a tool to set and release a liner hanger from engagement with a string of casing.

Owner:SCHLUMBERGER TECH CORP

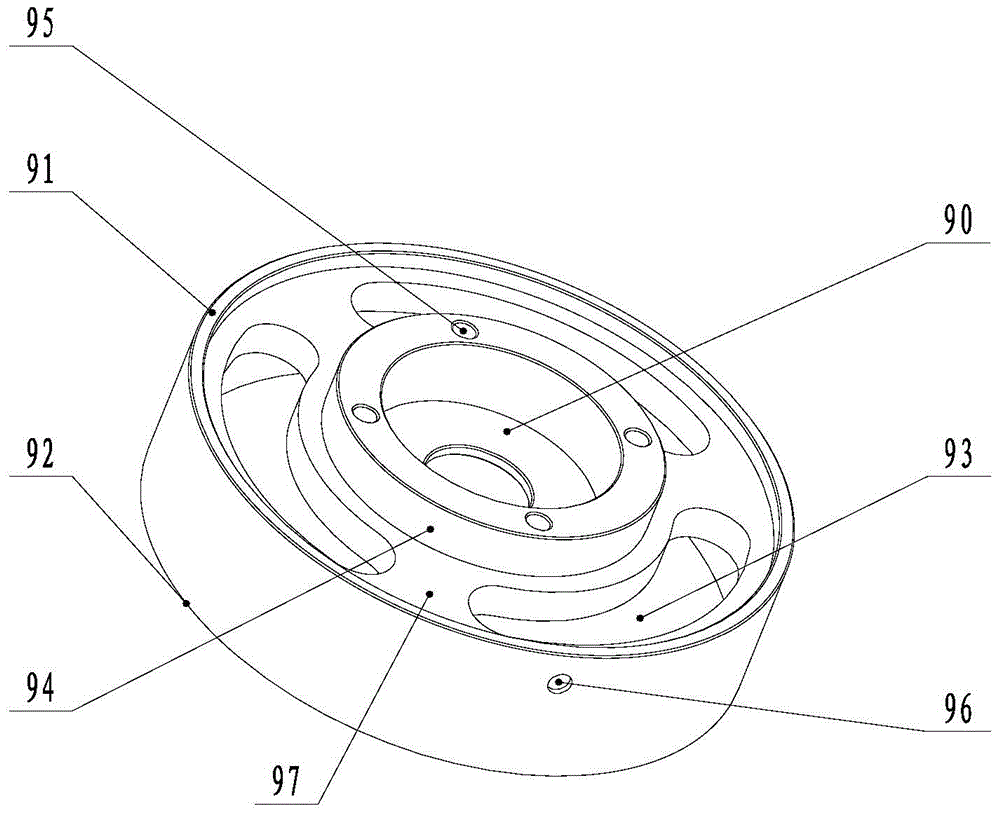

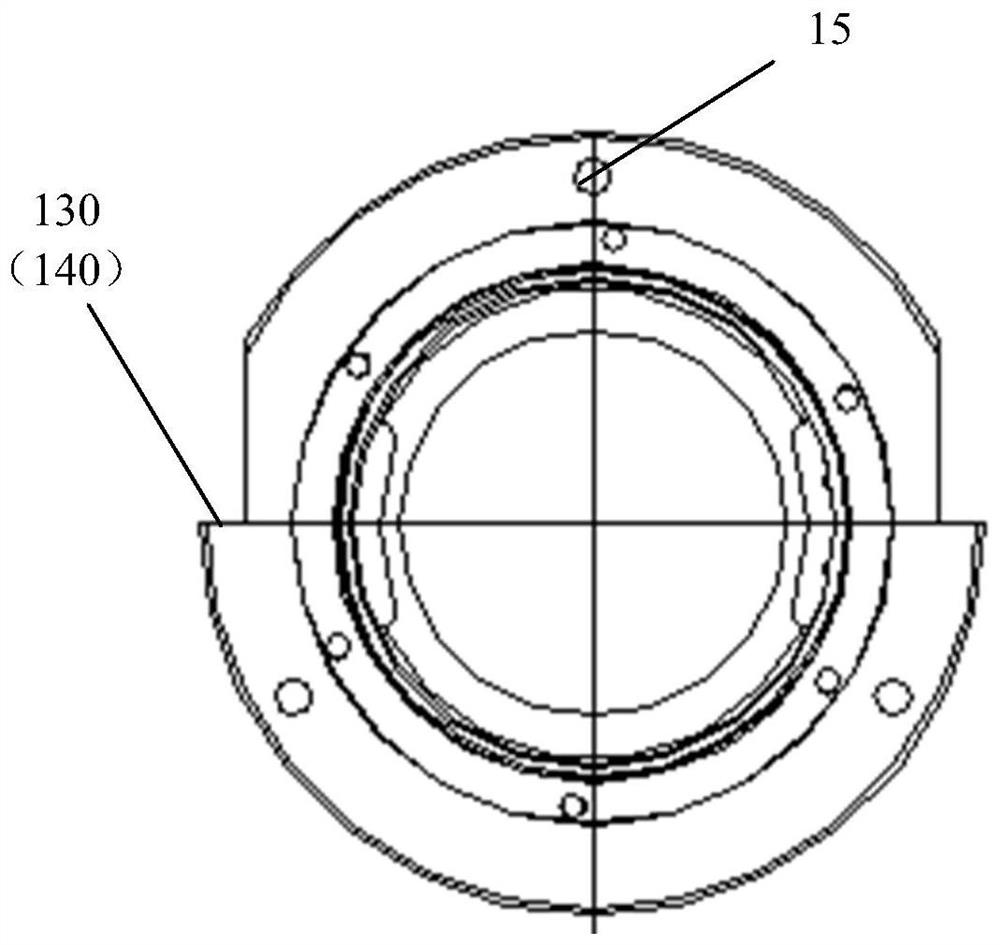

Vacuum scroll compressor

InactiveCN104405637AReduce coefficient of frictionReduce frictionRotary piston pumpsRotary piston liquid enginesMechanical engineeringCrankshaft

The invention relates to a vacuum scroll compressor, in particular to a vacuum scroll compressor which doesn't use a cross ring to limit rotation of a removable scroll pan. The vacuum scroll compressor comprises the removable scroll pan and a crankshaft penetrating through the base, wherein the crankshaft comprises a front crankshaft section and a rear crankshaft section, the front crankshaft section has preset crankshaft eccentricity relative to the rear crankshaft section, the removable scroll pan is mounted at the front end of the crankshaft and connected with the base through an eccentric shaft, and the eccentricity and the rotation angle vector of an eccentric shaft section connected with the removable scroll pan relative to the eccentric shaft section connected with the base are equal to the preset crankshaft eccentricity and the rotation angle vector of the front crankshaft section relative to the rear crankshaft section. According to the vacuum scroll compressor, equipment vibration and noise are reduced, and the service life is prolonged.

Owner:淄博昊驰泵业有限公司

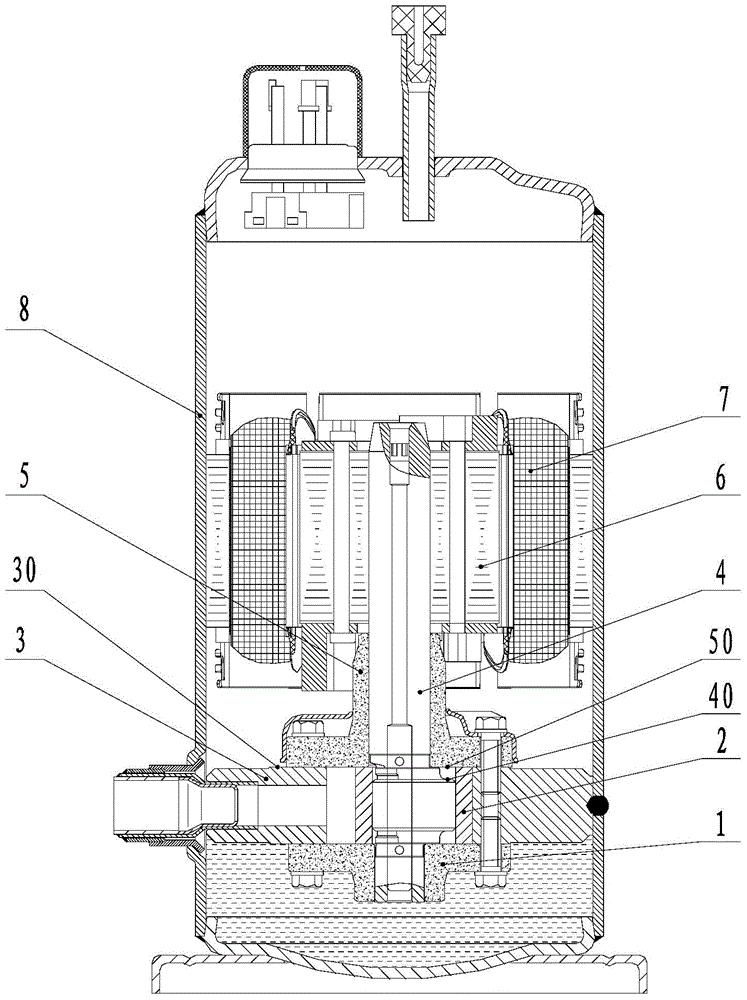

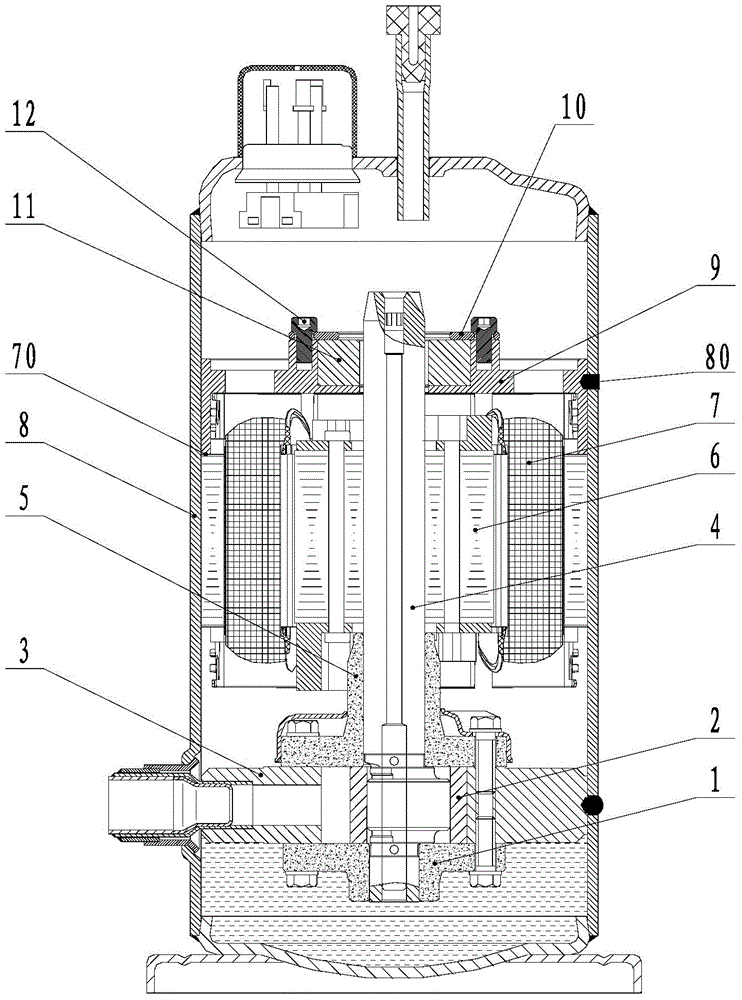

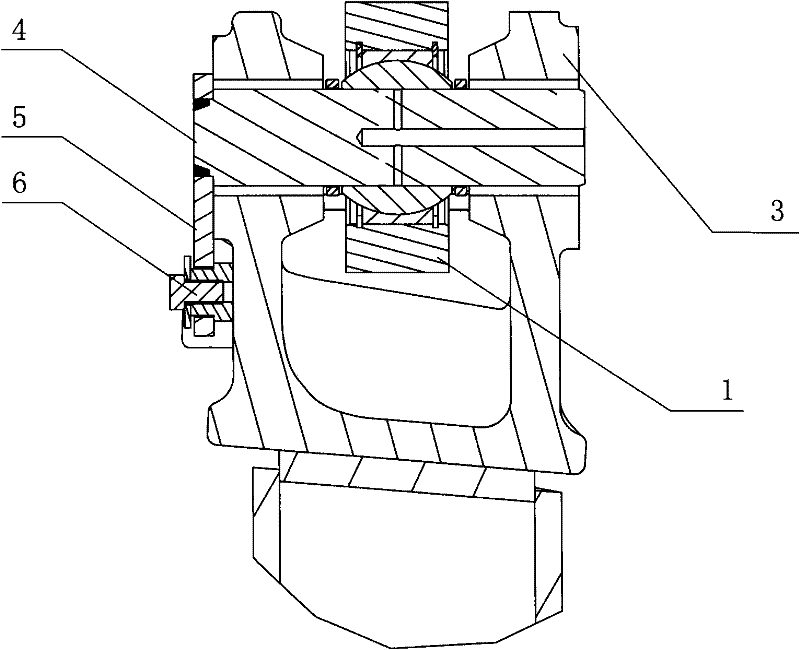

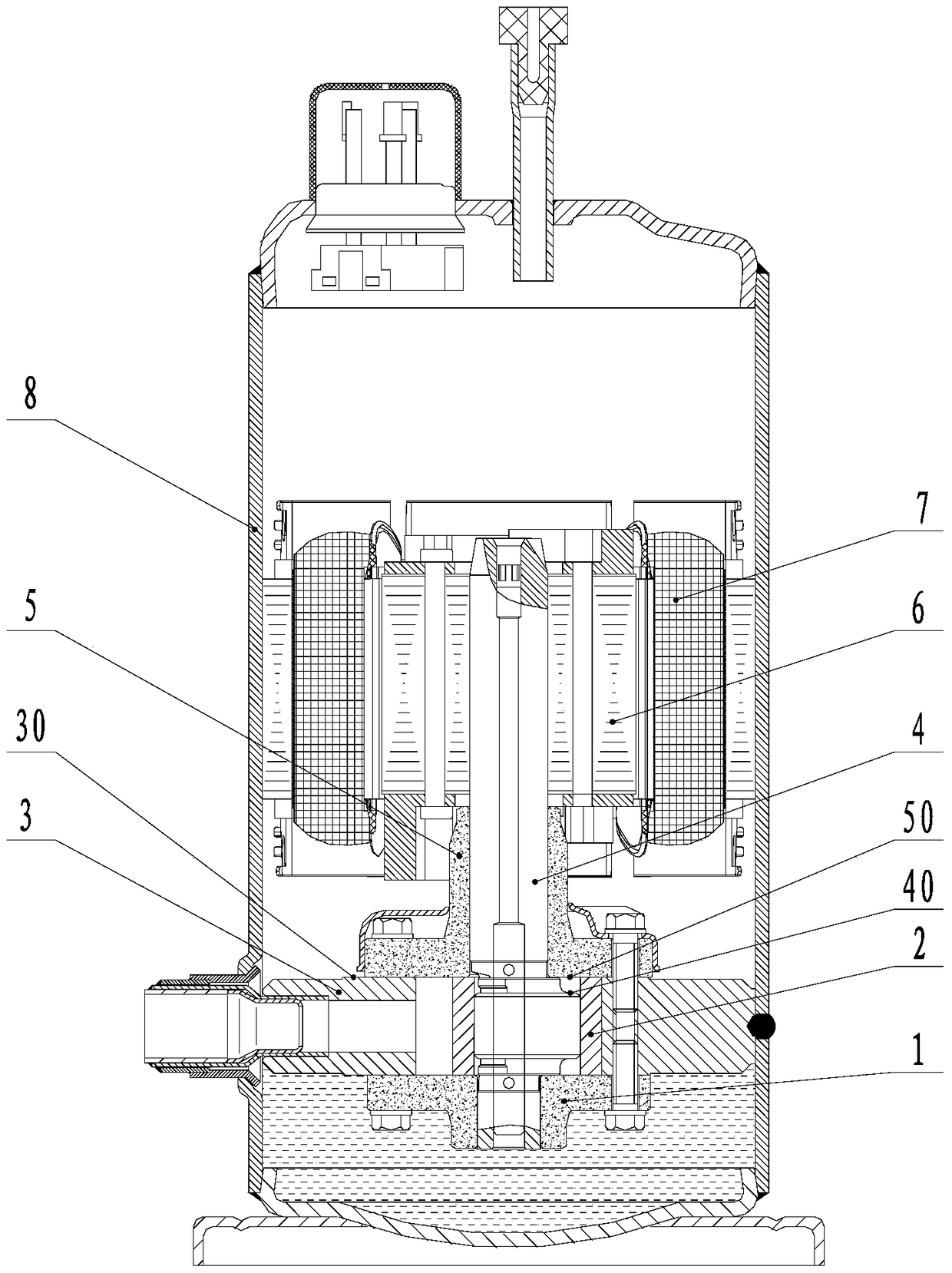

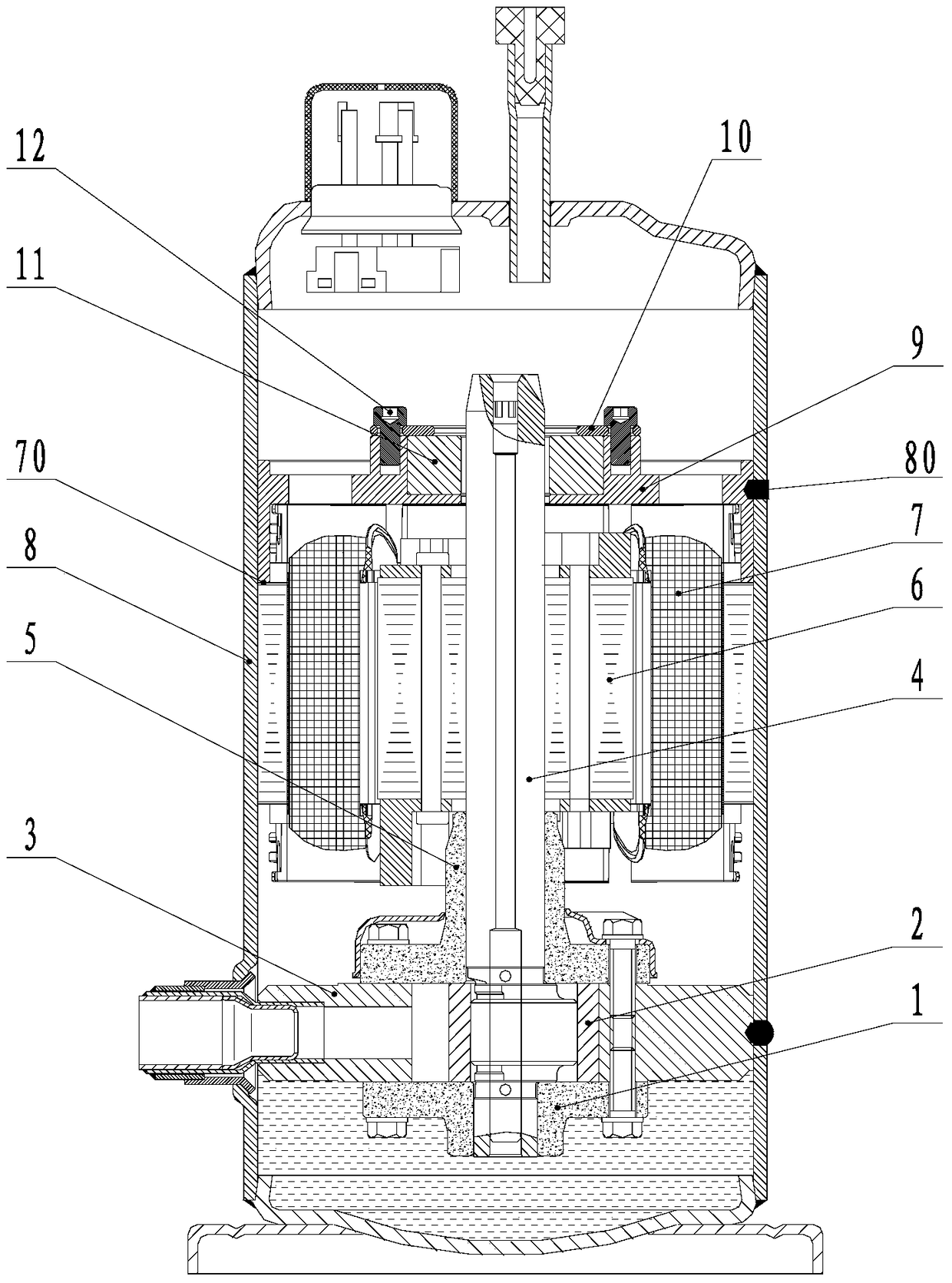

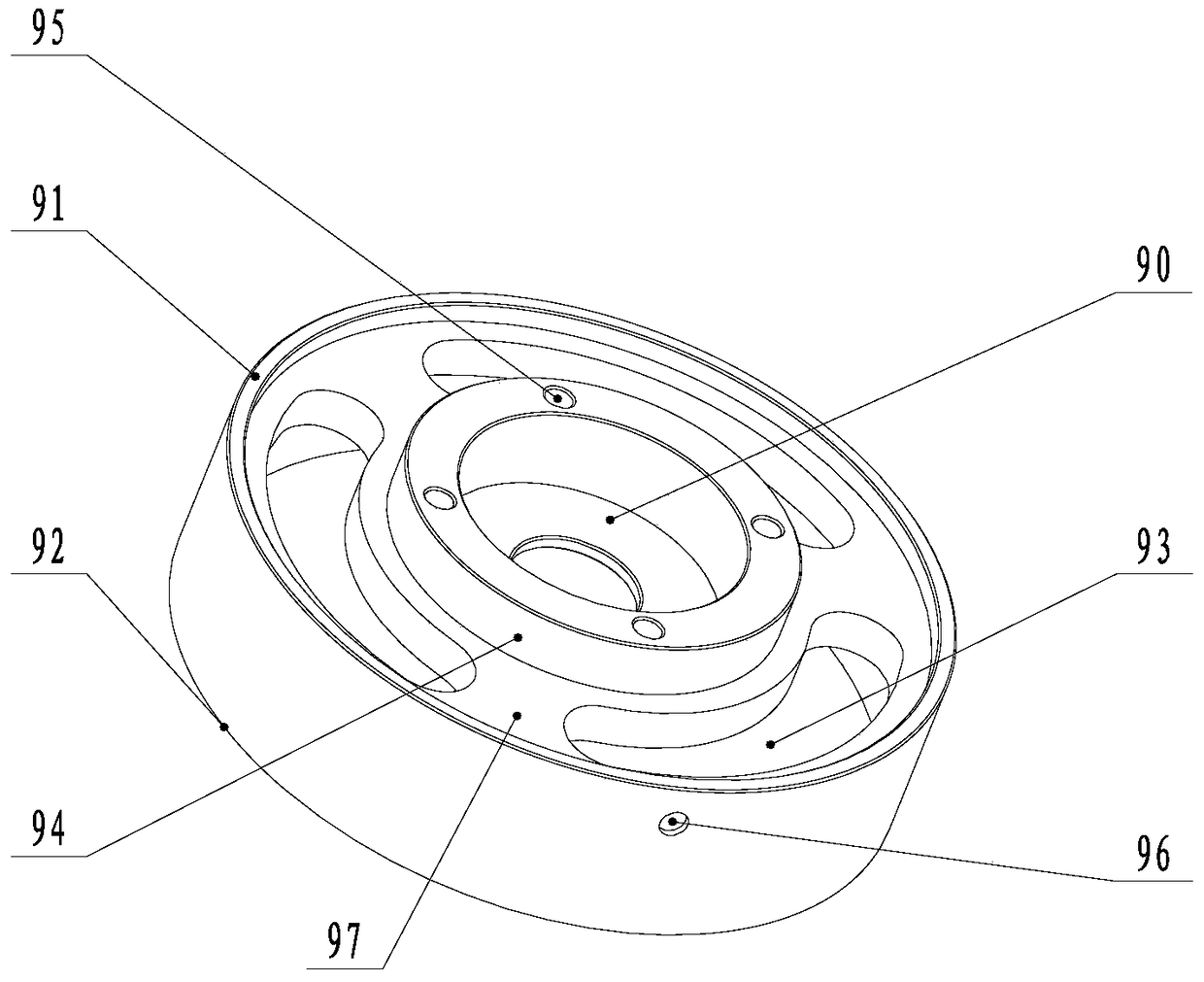

Compressor and air conditioner

ActiveCN106151042AEliminate periodic noise vibration problemsGuaranteed coaxialityRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention provides a compressor which comprises a motor and a crankshaft. The motor and the crankshaft are arranged in the shell. An axial moving limiting device is arranged at the tail end of the crankshaft and comprises a supporting seat, a bearing and a pressing plate. The supporting seat is inlaid in the shell. The bearing is arranged on the supporting seat. The supporting seat is arranged on the crankshaft in a sleeving manner through the bearing. The pressing plate is fixedly arranged on the supporting seat. The pressing plate is used for limiting the axial movement of the bearing. The invention further relates to an air conditioner. According to the compressor and the air conditioner, the axial moving limiting device is arranged at the tail end of the crankshaft of the compressor, the problem of axial moving of the crankshaft is effectively solved through the bearing and the pressing plate of the axial moving limiting device, the problem of periodical noise vibration of the compressor under some conditions is solved, the axial moving limiting device is simple in structure, convenient to install and high in universality, the problems of radial deflection and eccentricity of the crankshaft are effectively solved, and the coaxility of the whole compressor is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

Low-frictional-loss thrust conical roller bearing

ActiveCN107830049AReduce frictionIncrease frictionRoller bearingsBearing componentsClassical mechanicsStructural engineering

A low-frictional-loss thrust conical roller bearing comprises an upper ferrule, a lower ferrule, a conical roller and a holder. The geometrical parameters of the conical roller and the ferrules meet the pure rolling geometrical conditions and the axial sliding self-locking physical conditions of the roller. The large end face of the conical roller makes contact with the top face of a frame-shapedpocket of the holder, and the large end of the conical roller does not make contact with the stop edges of the upper ferrule and the lower ferrule. The low-frictional-loss thrust conical roller bearing has the beneficial effects that a sliding state of a rolling belt between the rolling body and a rolling way is changed into a pure rolling state, the large end of the conical roller does not make contact with the stop edges of the upper ferrule and the lower ferrule, thus the situation that the large end of the roller makes contact with the stop edges of the ferrules, and therefore sliding friction occurs is avoided, friction between the large end of the roller and the holder is reduced to the largest extent, and the friction and lubricating conditions between the holder and the large end of the conical roller are improved to the greatest extent; and meanwhile, the contacting strength of the contacting position of the large end of the roller and the holder is ensured, the efficiency ofthe bearing is improved, and the fatigue life of the bearing is prolonged.

Owner:DALIAN JIAOTONG UNIVERSITY

Slurry-rotating-type turbine runner connecting rod pin limiting device

InactiveCN108119286ALimit axial movementEliminate potential safety hazardsEngine fuctionsHydro energy generationAxial displacementEngineering

The invention discloses a slurry-rotating-type turbine runner connecting rod pin limiting device. The slurry-rotating-type turbine runner connecting rod pin limiting device comprises a limiting part,an outer lug and an inner lug, wherein the outer lug and the inner lug are fixed to a turbine runner relay cylinder, connecting rod pins are assembled in pin holes of the outer lug and the inner lug,a clamping groove is formed in the outer lug, the lower portion of the limiting part is arranged in the clamping groove, the upper portion of the limiting part blocks the lower areas of the outer endfaces of the connecting rod pins, the limiting part is limited in the clamping groove through the connecting part and does not fall off, axial displacement force of the connecting rod pins is totallyborne by the limiting part and the clamping groove, and the connecting part does not bear the axial displacement force of the connecting rod pins. By means of the slurry-rotating-type runner connecting rod pin limiting device, the limiting part which is used for limiting axial displacement of the connecting rod pins is limited in the clamping groove through the connecting part, so that the axial displacement force in the working process of the connecting rod pins is completely borne by the limiting part and the clamping groove, the connecting part only achieves the effect of fixing the limiting part and does not bear the axial displacement force of the connecting rod pins, and the working safety and reliability of a slurry-rotating-type turbine runner are guaranteed.

Owner:DONGFANG ELECTRIC MACHINERY

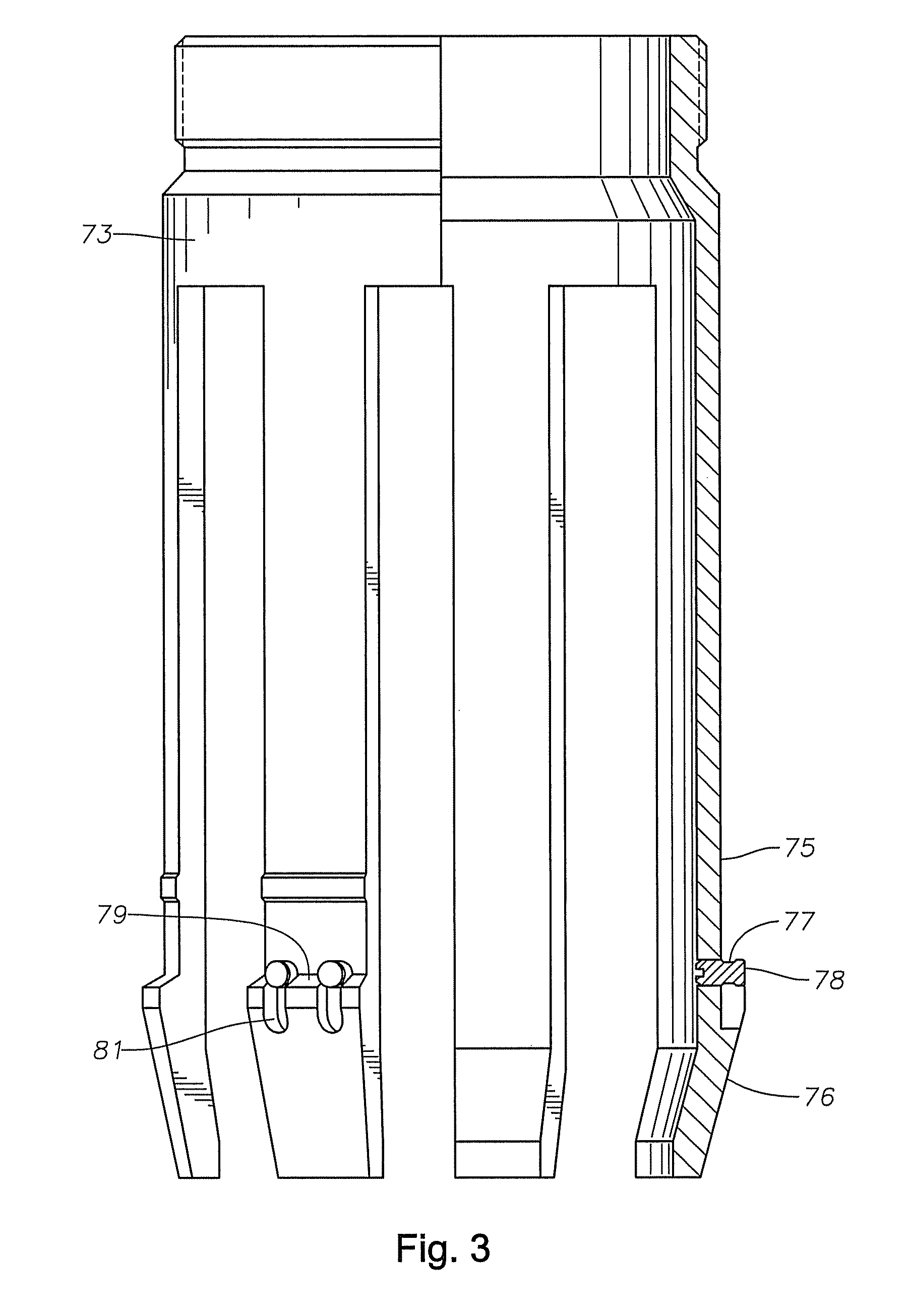

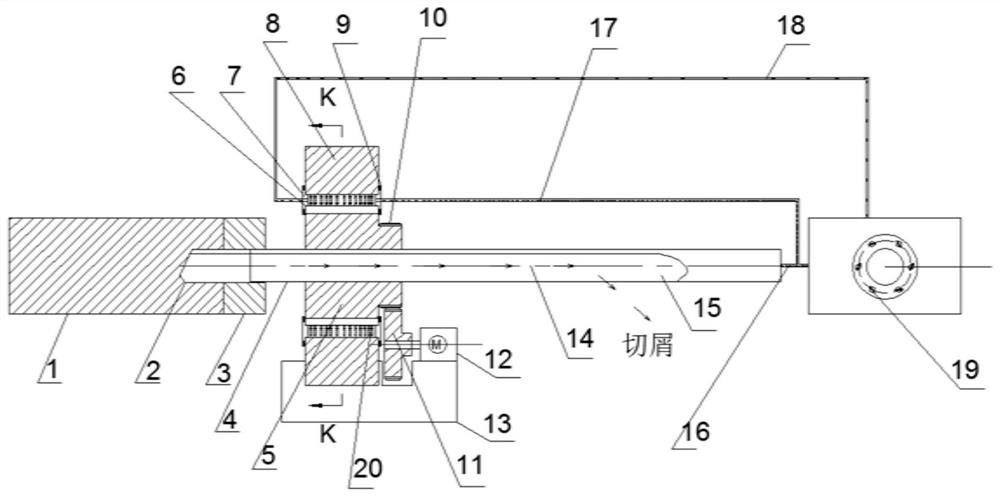

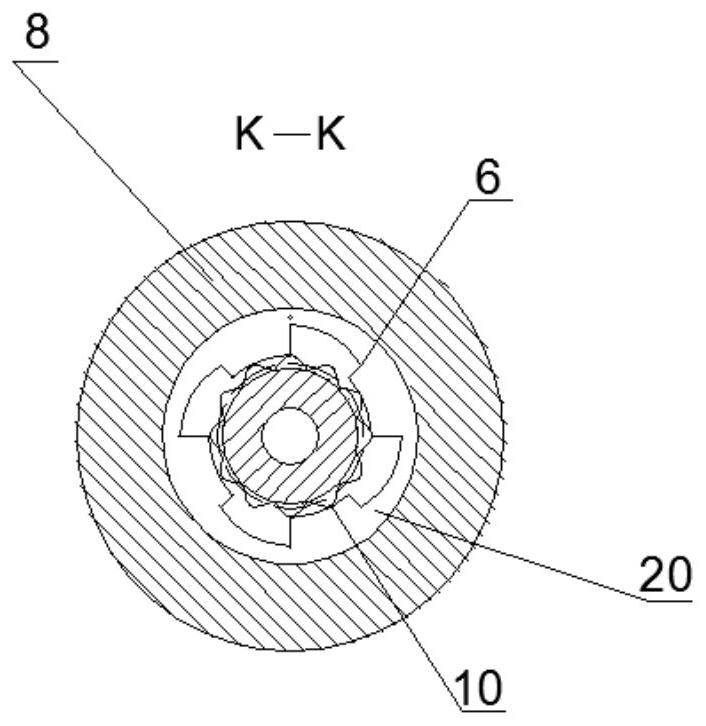

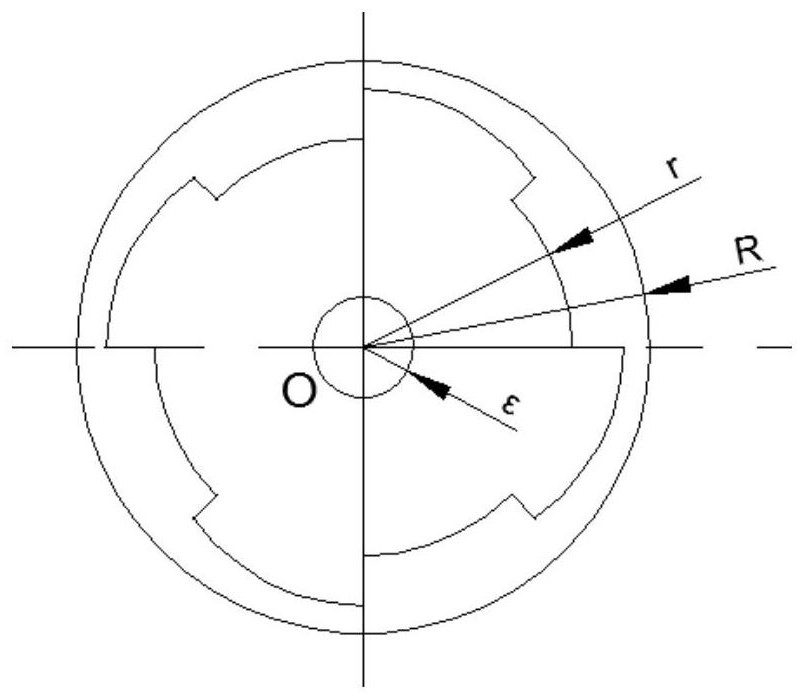

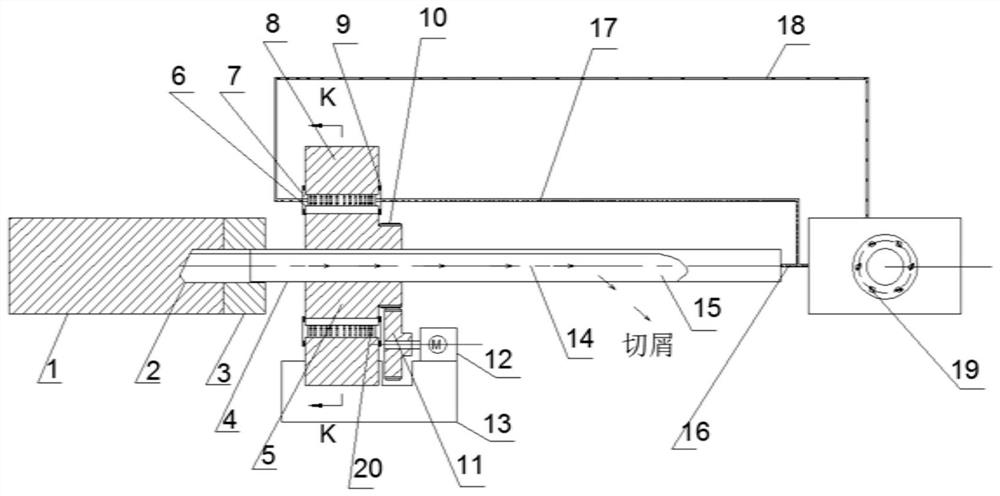

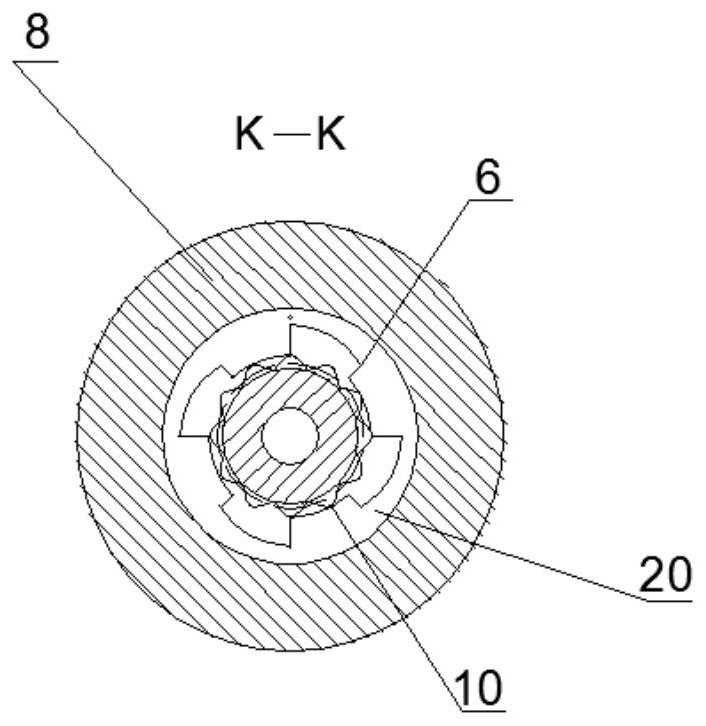

A hydraulic-based self-correction system for small and medium diameter deep hole machining

ActiveCN112077362BSelf-correctingIncrease stiffnessBoring/drilling componentsBoring/drilling machinesEngineeringShear flow

The invention is applied to the field of small and medium diameter deep hole processing, and in particular relates to a hydraulically-based self-correcting system for small and medium diameter deep hole processing. Including inner rotary body, outer rotary body and driving mechanism; the inner rotary body is sleeved on the outer periphery of the drill pipe and fixed relative to the drill pipe; cutting fluid is filled between the inner rotary body and the outer rotary body so that the inner rotary body and the outer rotary body A flow channel is formed between the bodies, and the flow channel includes a plurality of wedge-shaped flow channels uniformly distributed in the circumferential direction. When the driving mechanism drives the inner rotary body to rotate, the cutting fluid enters the small end from the large end of the wedge-shaped flow channel, and the superposition of pressure flow and shear flow generates Oil film pressure realizes self-centering and self-correction of drill pipe. The present invention forms a wedge-shaped flow space between the wedge-shaped entity and the outer sleeve. Under normal conditions, the oil film pressure in the wedge-shaped space provides a circumferentially symmetrical self-centering force; when the drill pipe is deflected, the wedge-shaped space will generate oil film pressure, that is, self-correction The drill pipe can be "pushed back" to the correct axis by using the self-correcting force, so as to realize the self-correction of the axis deviation.

Owner:NANJING UNIV OF SCI & TECH

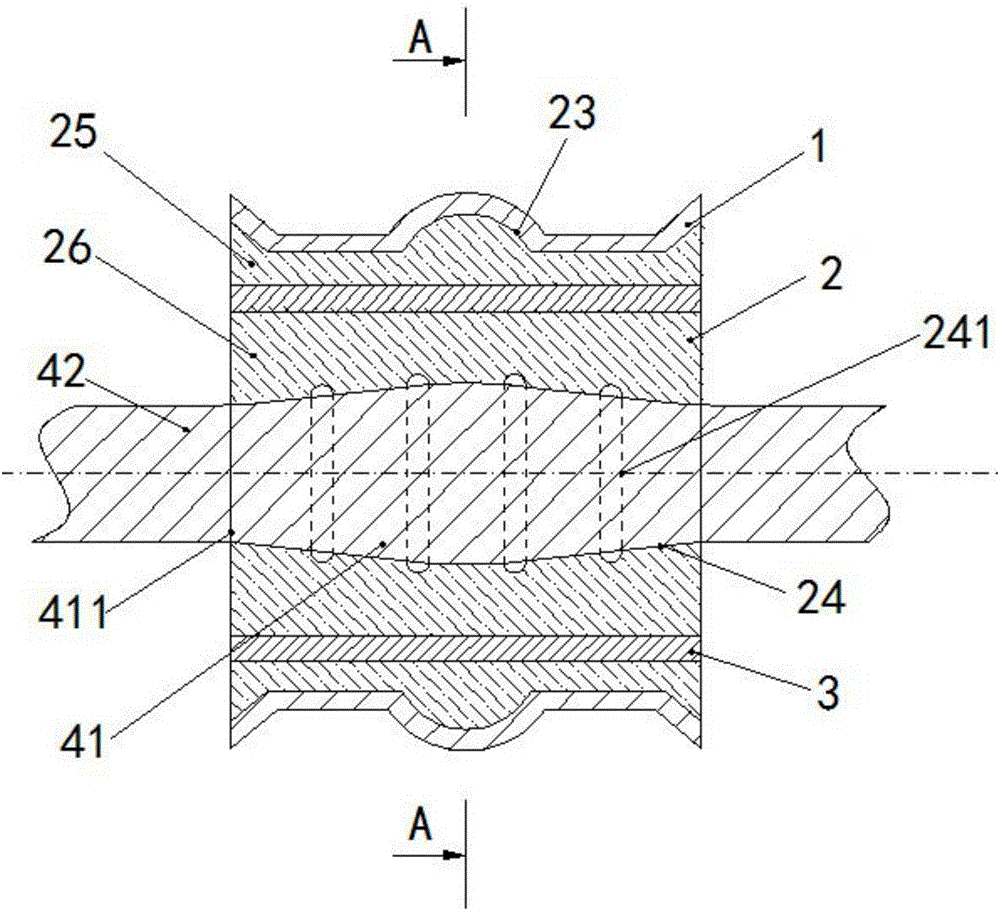

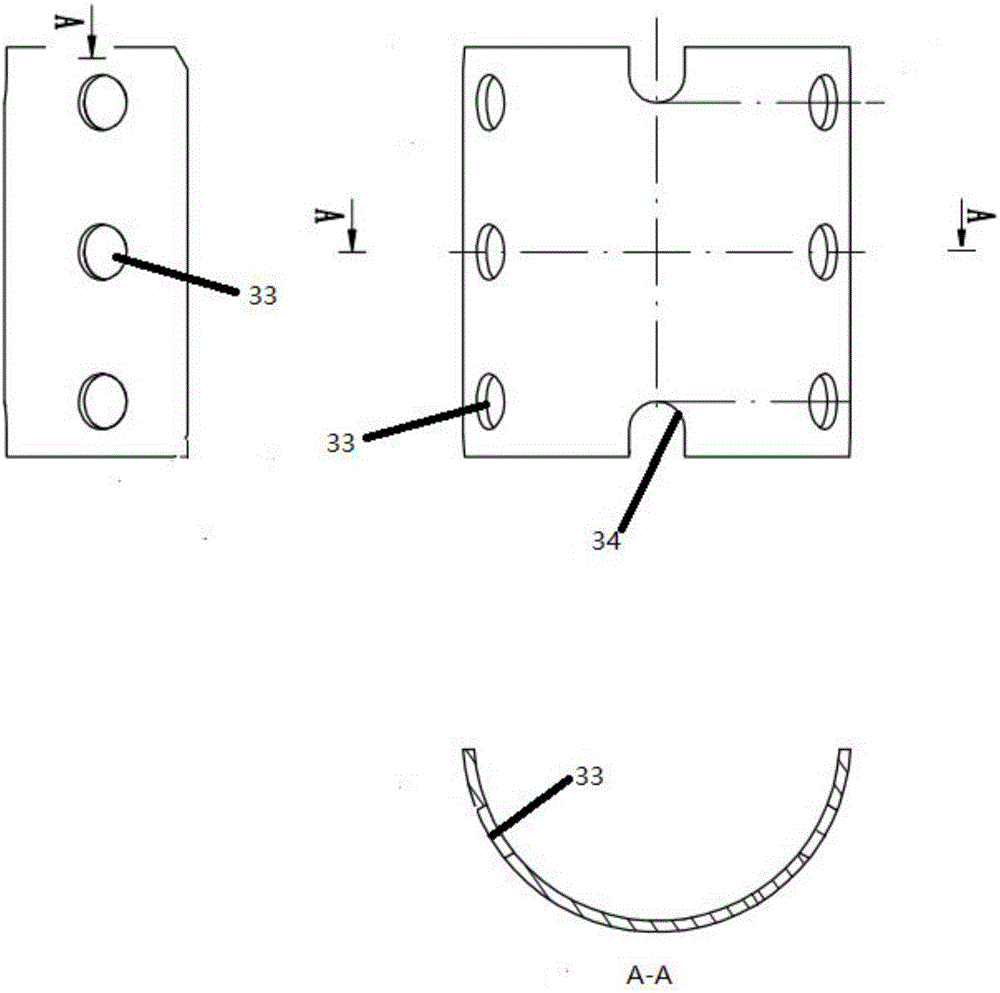

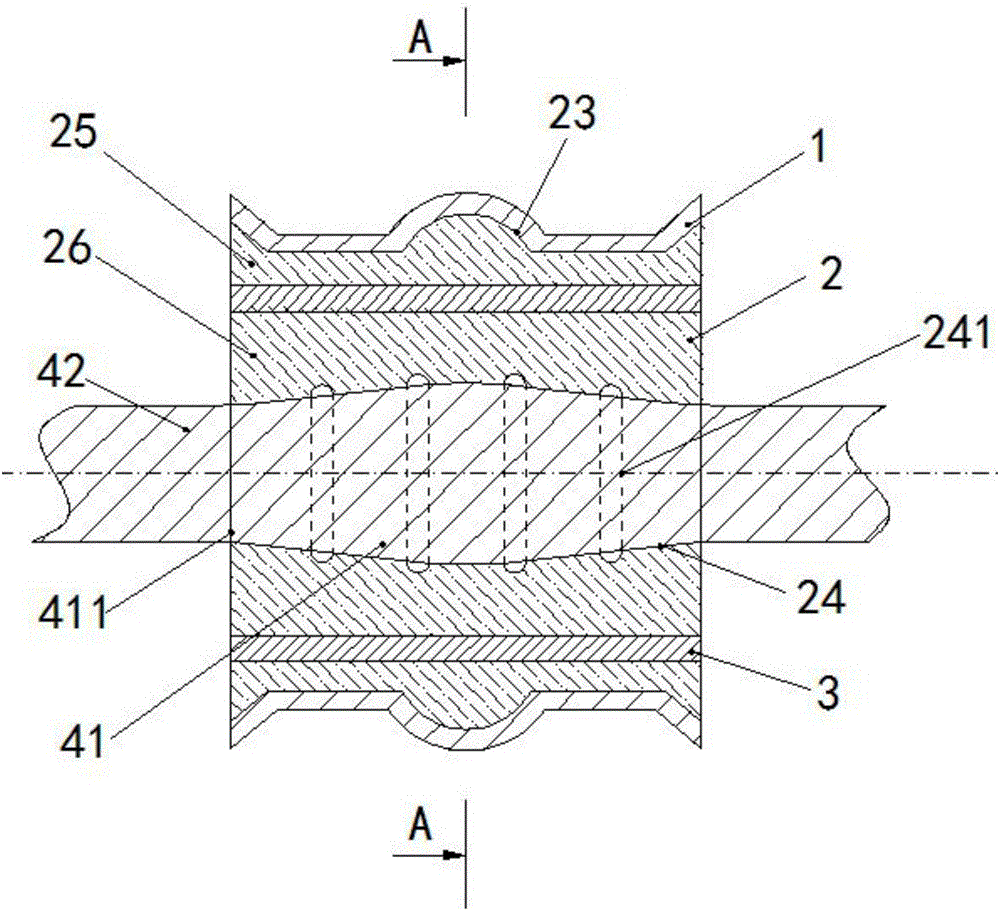

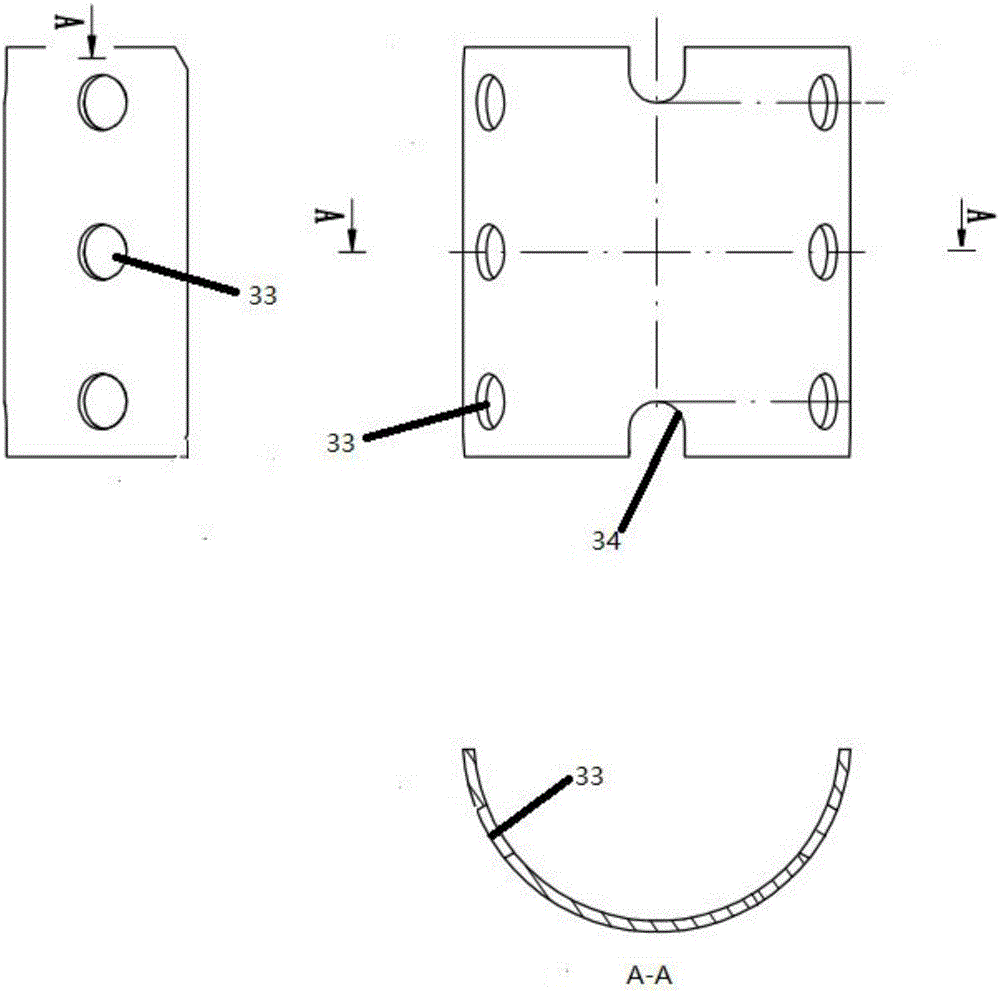

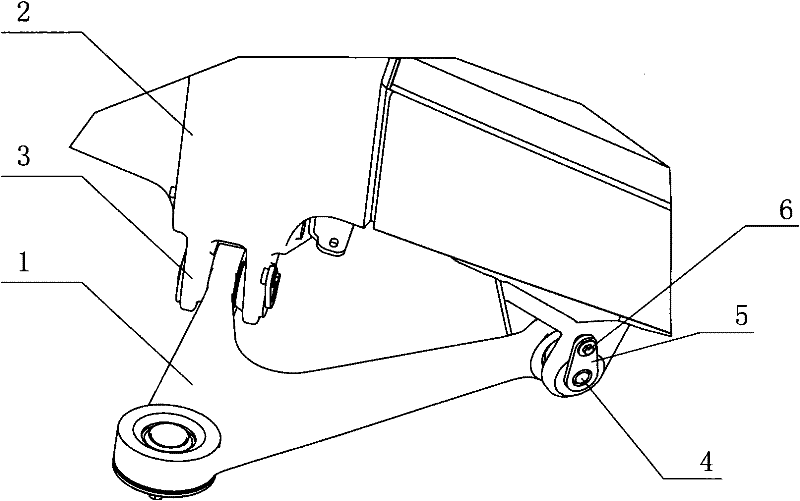

High-strength transverse stabilizer bar lining capable of preventing axial movement

InactiveCN106218347AAverage external forceExtended service lifeInterconnection systemsHigh intensityEngineering

A high-strength transverse stabilizer bar lining capable of preventing axial movement comprises a fixing support, a lining body and a framework. Lining protruding ribs are arranged on the surface of the lining body. Annular grooves are evenly formed in the wall of a lining inner hole. The framework is embedded inside the lining body. The fixing support is matched with the outer surface of the lining body. A part, matched with the stabilizer bar lining, of a transverse stabilizer bar is a stabilizer bar matching part. The diameter of the middle of the stabilizer bar matching part is the largest, and the diameter of the stabilizer bar matching part is gradually decreased from the middle to the two sides. The lining body is made by machining materials including natural rubber, 26-type fluororubber, chlorinated butyl rubber, polyisoprene and the like. According to the high-strength transverse stabilizer bar lining capable of preventing axial movement, the stabilizer bar and the stabilizer bar lining have sufficient axial stiffness, axial movement of the stabilizer bar lining is limited accordingly, abrasion of the rubber material of the lining inner hole is reduced, and abnormal noise generated between the stabilizer bar and the stabilizer bar lining in the driving process of an automobile is eliminated.

Owner:安徽东升精密铸钢件有限公司

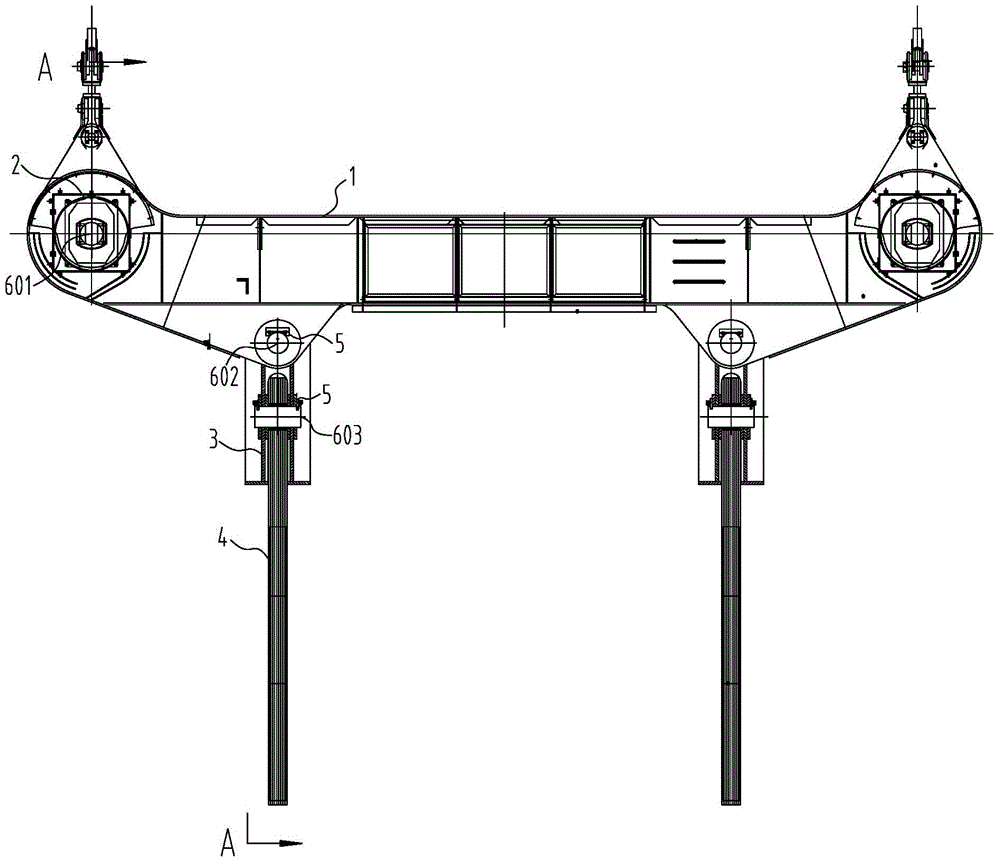

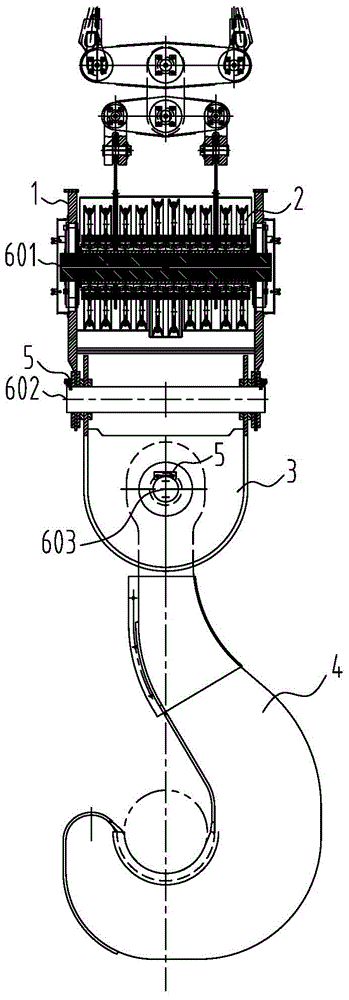

Metallurgical bridge crane

InactiveCN105197802APlay the role of axial limitLimit axial movementTrolley cranesSafety gearEngineeringPulley

The invention discloses a metallurgical bridge crane. The metallurgical bridge crane comprises a cross beam, movable pulley blocks, lifting forks, lifting hooks and a plurality of pin shafts used for hinging two parts. The two parts comprise the first part and the second part which is at least partially located inside the first part so as to be hinged to the first part through the pin shafts. The two ends of each pin shaft extend out of the first part. Grooves are formed in the positions, close to the two ends, of each pin shaft. Baffles used for preventing the pin shafts from being disengaged from the two parts are inserted in the grooves, and the baffles are fixed to the first part. Indicating rods are fixedly arranged at the ends of the pin shafts. By the adoption of the metallurgical bridge crane, the parts can be prevented from being disengaged, and safety accidents are avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

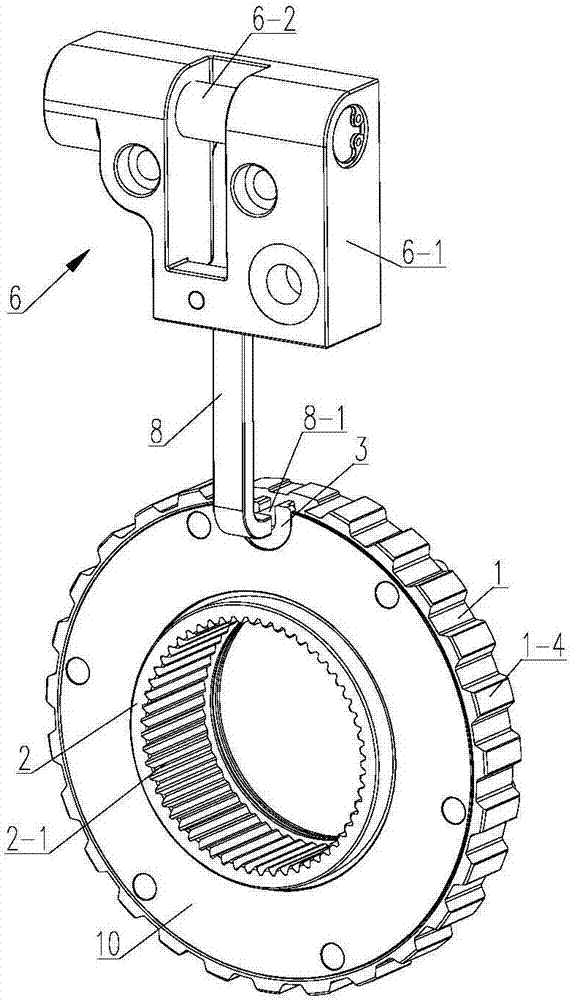

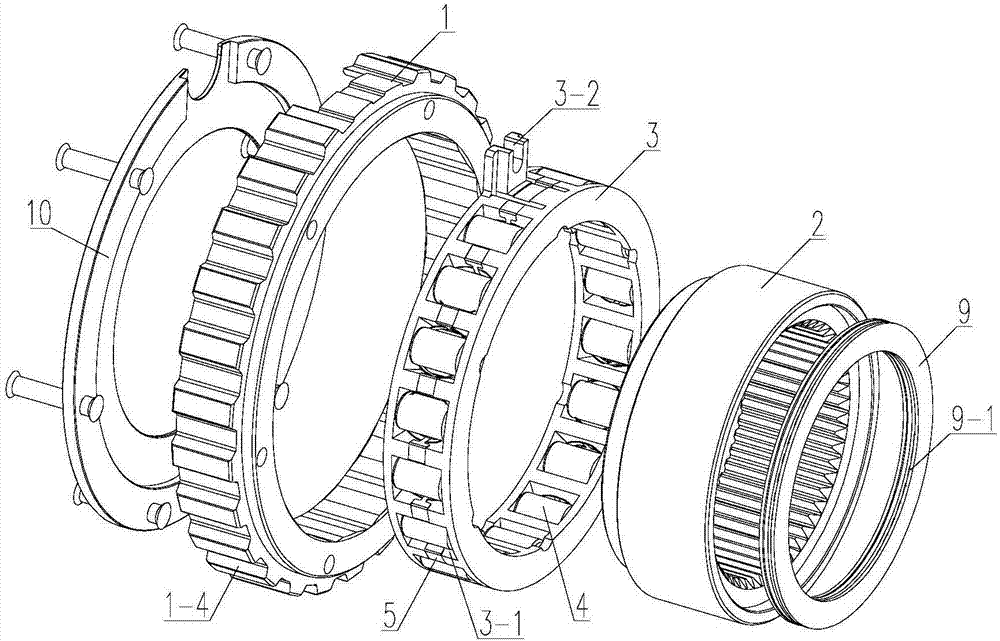

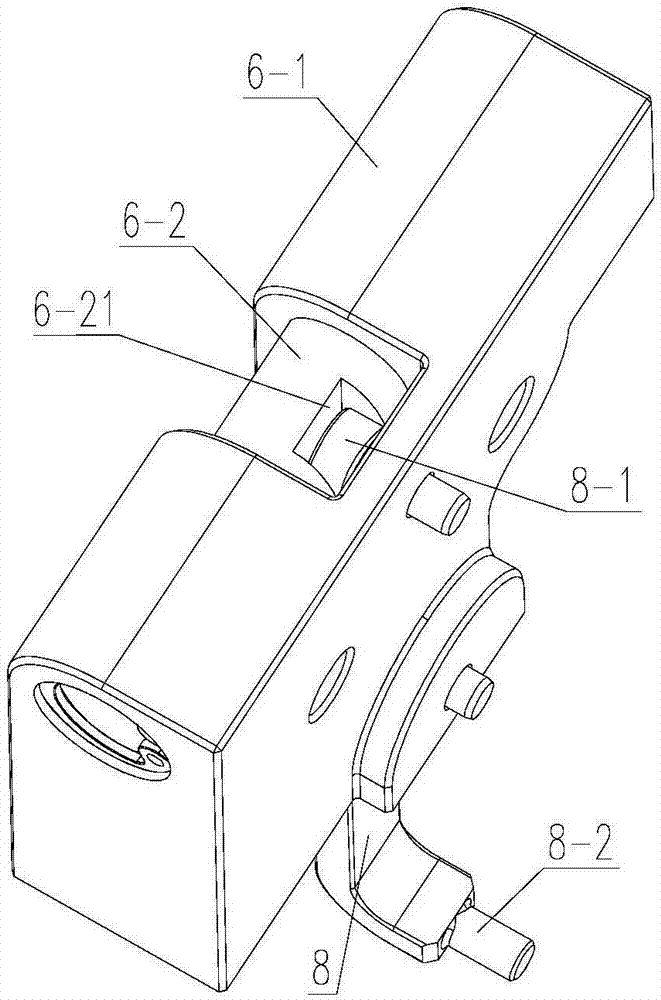

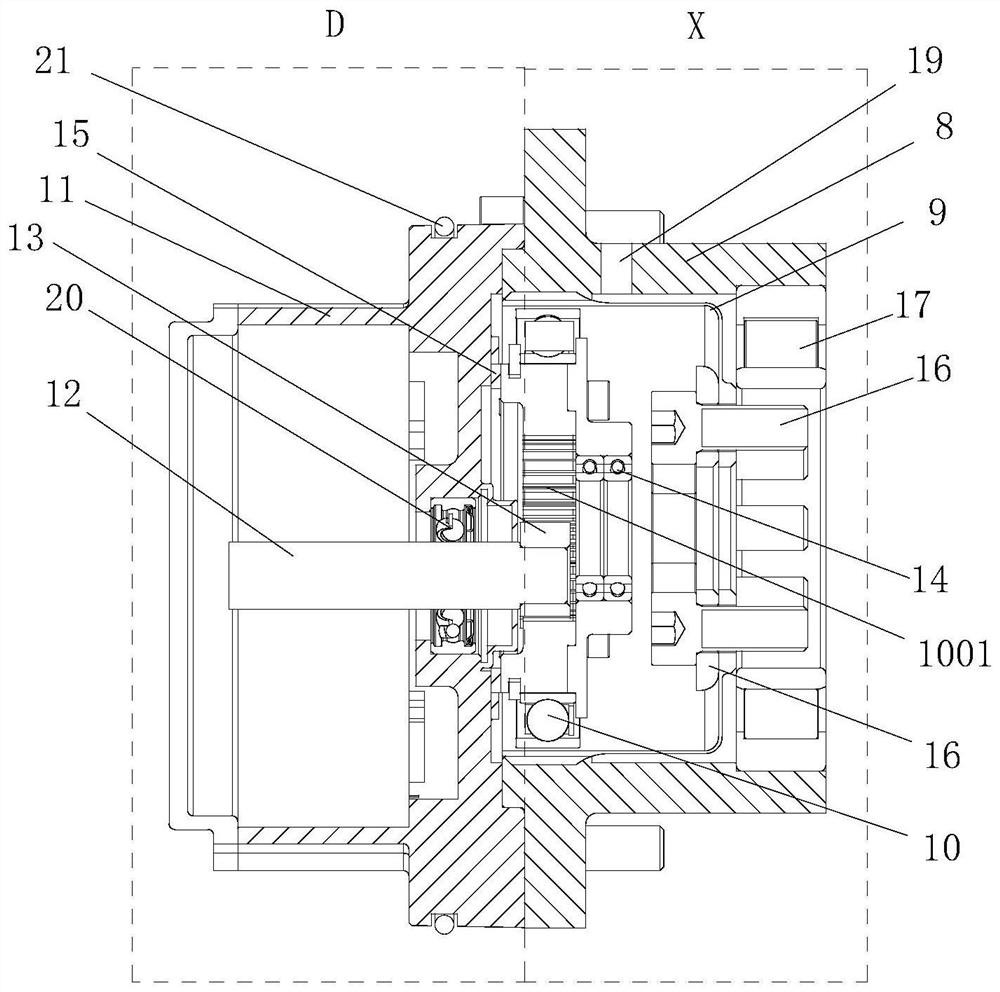

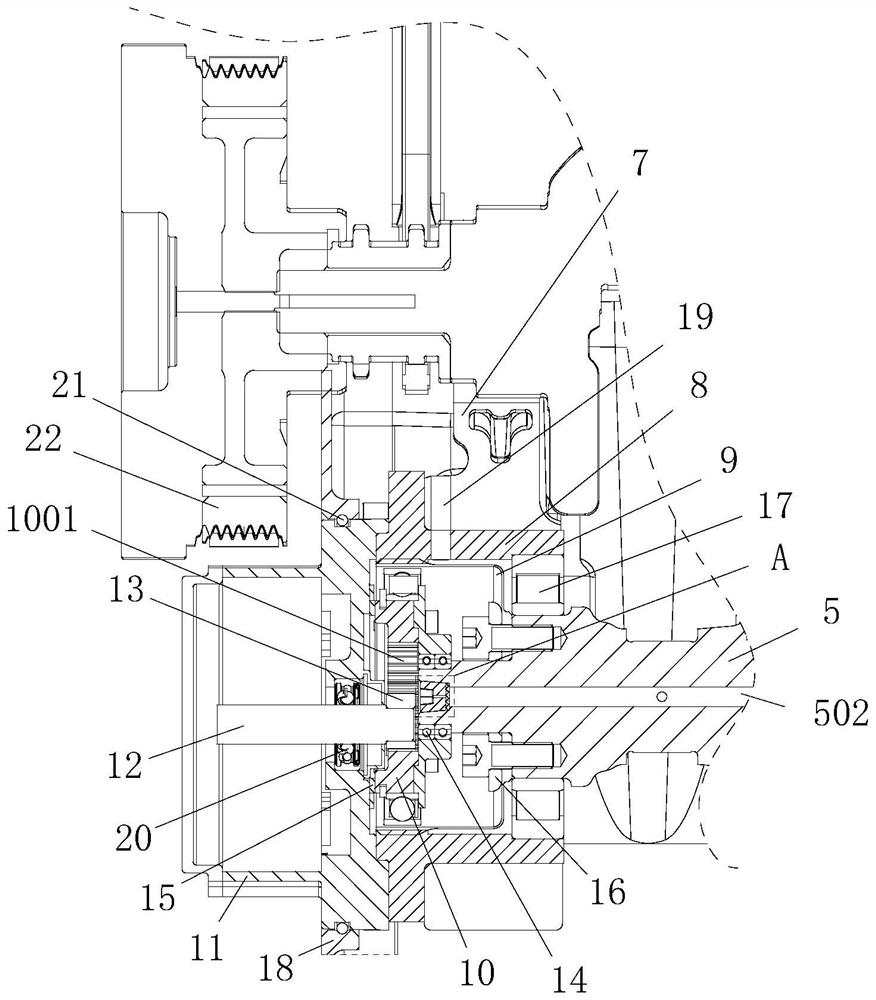

Multi-mode clutch

PendingCN107542808ARealize free switchingLimit axial movementFluid actuated clutchesInterengaging clutchesEngineeringActuator

The invention relates to the technical field of clutches, in particular to a multi-mode clutch. The multi-mode clutch comprises a clutch body and an execution mechanism, wherein the clutch body comprises an outer ring and an inner ring which are arranged coaxially; a control ring is arranged between the outer ring and the inner ring; a plurality of windows are arranged on the outer circumferentialsurface of the control ring in the circumferential direction in a penetrating manner; rollers are all arranged in windows; an inner circle wall of the outer ring is provided with a plurality of die cavities corresponding to the rollers one by one; a distance from a middle part of the cavity bottom of each die cavity to an outer circle wall of the inner ring is larger than the diameter of each roller; the left side surfaces of the die cavities are gradually inclined toward the inner ring from the cavity bottoms to the left side surface direction; and the right side surfaces of the die cavitiesare gradually inclined toward the inner ring from the cavity bottoms to the right side surface direction. According to the multi-mode clutch disclosed by the invention, along with rotation of the control ring, the rollers positioned on the control ring are respectively positioned in three different working positions in the die cavities so as to realize that the clutch has three working modes; andthrough the execution mechanism, the control ring is driven to rotate by a driving lever, so that free switch of the three working modes of the clutch can be realized.

Owner:JIANG SU NAN FANG BEARING CO LTD

Anti-axial-disengaging deformation-resistant transverse stabilizer bar bush

InactiveCN106274346AImprove axial stiffnessExtended service lifeInterconnection systemsButadiene-styrene rubberEngineering

The invention discloses an anti-axial-disengaging deformation-resistant transverse stabilizer bar bush. The anti-axial-disengaging deformation-resistant transverse stabilizer bar bush comprises a fixing support, a bush body and a framework. A bush convex rib is arranged on the surface of the bush body, annular grooves are evenly formed in the inner hole wall of the bush, and the framework is embedded into the bush body; the fixing support is matched with the outer surface of the bush body; a stabilizer bar matching part is the part, matched with the stabilizer bar bush, on a transverse stabilizer bar, and the diameter of the stabilizer bar matching part is gradually reduced from the middle to the two edges. The bush body is prepared from materials such as natural rubber, butadiene styrene rubber, butadiene rubber, copolymerization-type epichlorohydrin rubber and ethylene-vinyl acetate rubber in a processed mode. By means of the anti-axial-disengaging deformation-resistant transverse stabilizer bar bush, the stabilizer bar and the stabilizer bar bush have the enough axial rigidity, axial disengaging of the stabilizer bar bush is limited accordingly, and abrasion of the bush inner-hole rubber material is reduced, and an abnormal sound generated between the stabilizer bar and the stabilizer bar bush in the traveling process of an automobile is eliminated.

Owner:安徽东升精密铸钢件有限公司

Anti-axial-disengaging wear-resistant transverse stabilizer bar bush

InactiveCN106274347AAverage external forceExtended service lifeInterconnection systemsRubber materialWear resistant

The invention discloses an anti-axial-disengaging wear-resistant transverse stabilizer bar bush. The anti-axial-disengaging wear-resistant transverse stabilizer bar bush comprises a fixing support, a bush body and a framework. A bush convex rib is arranged on the surface of the bush body, annular grooves are evenly formed in the inner hole wall of the bush, and the framework is embedded into the bush body; the fixing support is matched with the outer surface of the bush body; a stabilizer bar matching part is the part, matched with the stabilizer bar bush, on a transverse stabilizer bar, and the diameter of the stabilizer bar matching part is gradually reduced from the middle to the two edges. The bush body is prepared from materials such as natural rubber, butadiene styrene rubber, butadiene rubber, copolymerization-type epichlorohydrin rubber and ethylene-vinyl acetate rubber in a processed mode. By means of the anti-axial-disengaging wear-resistant transverse stabilizer bar bush, the stabilizer bar and the stabilizer bar bush have the enough axial rigidity, axial disengaging of the stabilizer bar bush is limited accordingly, and abrasion of the bush inner-hole rubber material is reduced, and an abnormal sound generated between the stabilizer bar and the stabilizer bar bush in the traveling process of an automobile is eliminated.

Owner:安徽东升精密铸钢件有限公司

Self-deviation-rectifying system for small-and-medium-diameter deep hole processing based on hydraulic pressure

ActiveCN112077362ASelf-correctingIncrease stiffnessBoring/drilling componentsBoring/drilling machinesEngineeringShear flow

The invention belongs to the field of small-and-medium-diameter deep hole processing, and particularly relates to a self-deviation-rectifying system for small-and-medium-diameter deep hole processingbased on the hydraulic pressure. The self-deviation-rectifying system comprises an inner rotation body, an outer rotation body and a driving mechanism; the inner rotation body is arranged on the periphery of a drill rod in a sleeving mode and is fixed relative to the drill rod; the position between the inner rotation body and the outer rotation body is filled with cutting liquid, so that a flow channel is formed between the inner rotation body and the outer rotation body, the flow channel comprises a plurality of wedge-shaped flow channels which are evenly distributed in the circumferential direction, and when the driving mechanism drives the inner rotation body to rotate, the cutting fluid enters the small ends from the large ends of the wedge-shaped flow channels; and a pressure flow anda shear flow are superposed to generate oil film pressure to realize self-centering and self-deviation-rectifying of the drill rod. A wedge-shaped flowing space is formed between a wedge-shaped solidbody and an outer sleeve, and in a normal state, oil film pressure of the wedge-shaped space provides circumferentially-symmetrical self-centering force; and when the drill rod deflects, the wedge-shaped space generates the oil film pressure, namely self-deviation-rectifying force, the drill rod can be 'pushed back' to the correct axis through the self-deviation-rectifying force, and self-correcting of axis deflection is achieved.

Owner:NANJING UNIV OF SCI & TECH

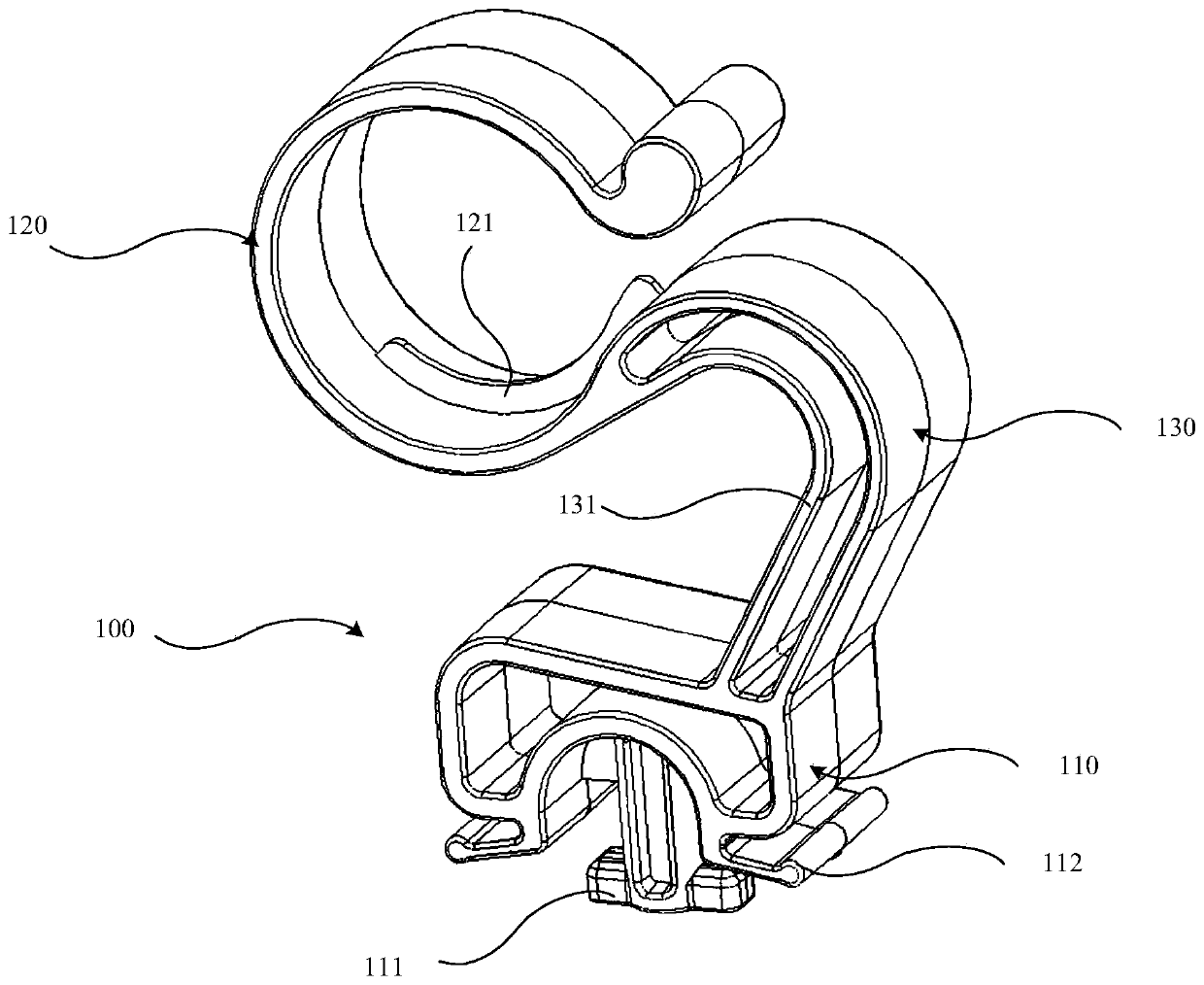

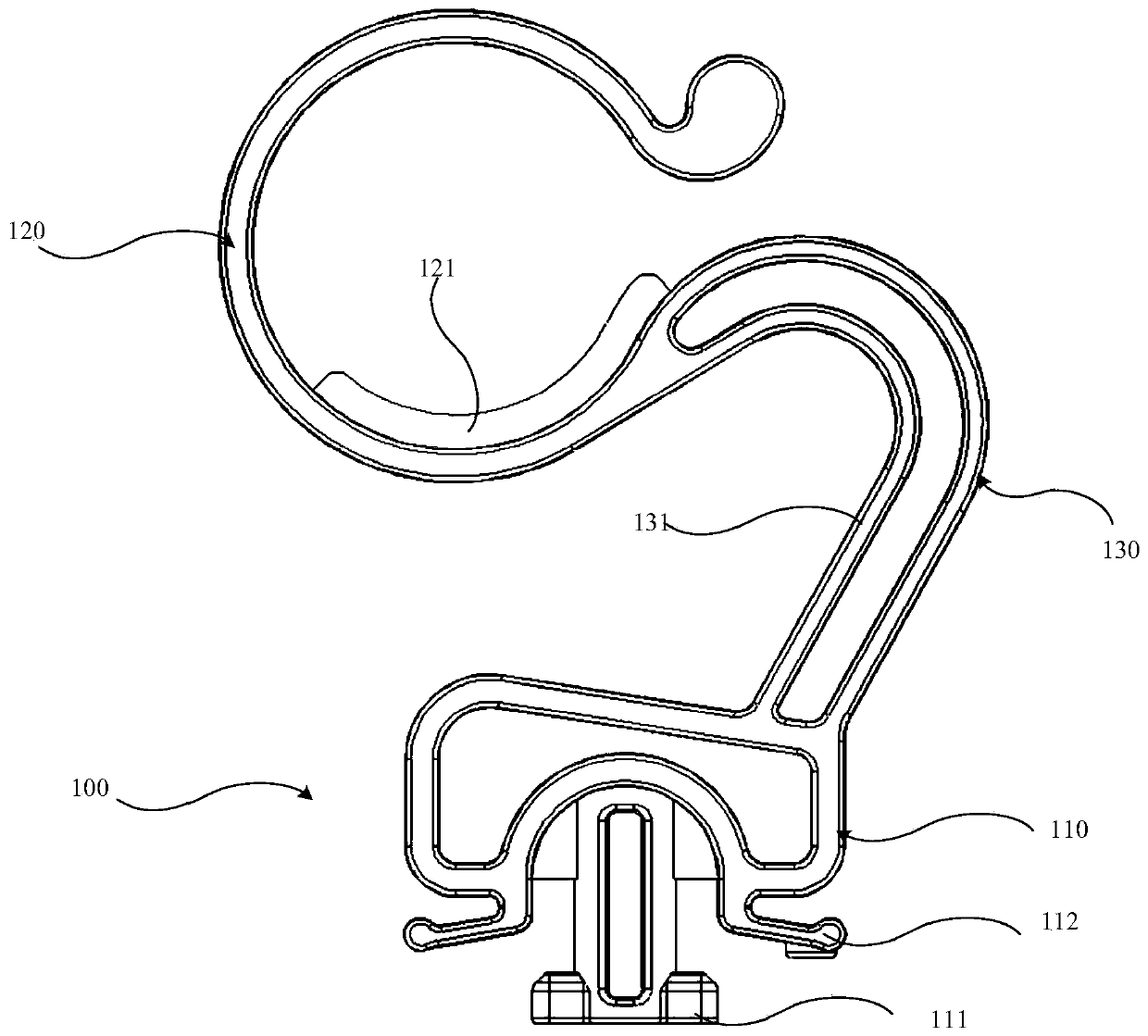

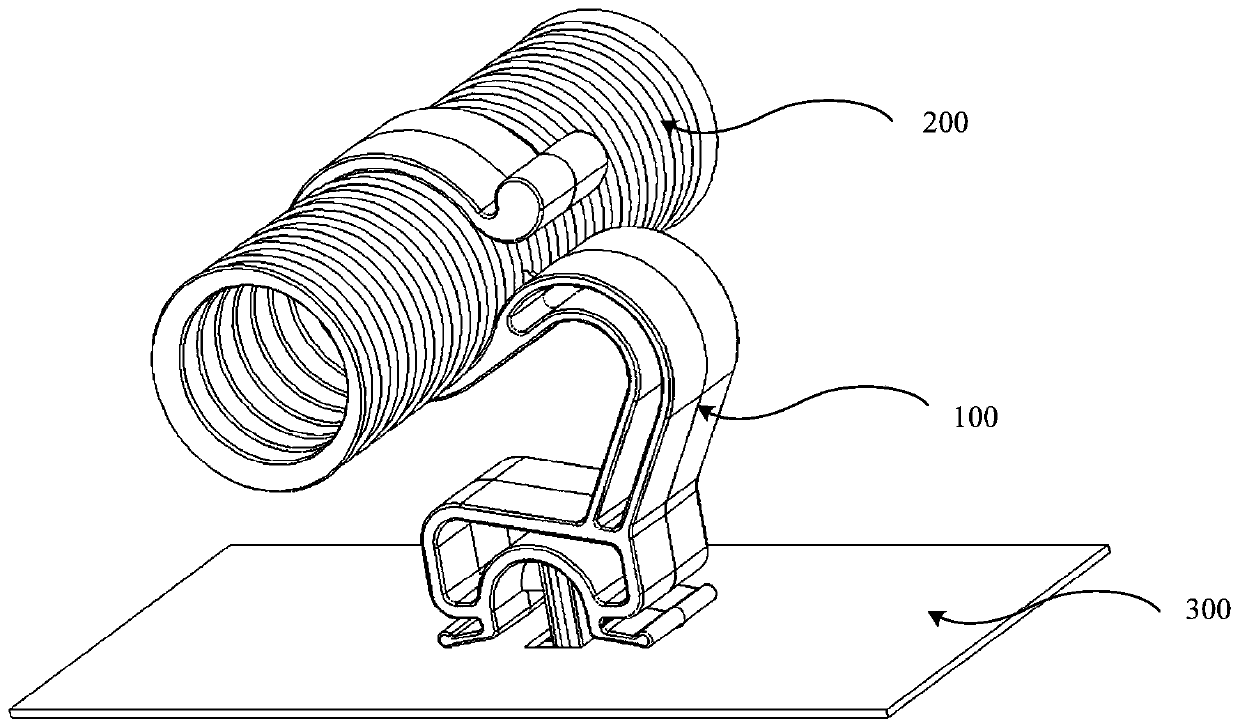

Inner drainage pipe fixing bracket and washing machine

PendingCN110528231AAchieve circumferential fixationAvoid swingingOther washing machinesTextiles and paperPulp and paper industry

The invention relates to the technical field of washing machines, in particular to an inner drainage pipe fixing bracket and a washing machine, and aims at solving the problem of a poor fixing effectwhen a locking belt is adopted for fixing an inner drainage pipe. The provided inner drainage pipe fixing bracket is used for fixing the inner drainage pipe of the washing machine, and comprises a bracket body, wherein a base of the bracket body is detachably connected with a bottom plate of the washing machine, and the top end of the bracket body is provided with a clamping piece; the clamping piece sleeves the inner drainage pipe, and the inner side wall of the clamping piece is also provided with a clamping part used for cooperating with a bulge or groove of the inner drainage pipe.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Connecting assembly of mine self-discharging vehicle front suspension frame guide mechanism and vehicle frame

InactiveCN101870237BLimit axial movementAvoid wear and tearPivoted suspension armsVehicle frameEngineering

The invention discloses a mine self-discharging vehicle front suspension frame guide mechanism and a connecting assembly of a vehicle frame. The guide mechanism comprises an A-shaped arm. The invention is characterized in that an A-shaped arm installing seat is arranged in the vehicle frame, the A-shaped arm is respectively provided with installing holes corresponding to both ends of the A-shapedarm installing seat, joint bearings are respectively arranged in the installing holes, the installing holes and the A-shaped arm installing seat are respectively connected through connecting shafts, one end of the connecting shafts is matched with the inner rings of the joint bearings, the other end of the connecting shafts is provided with eccentric convex plate, eccentric grooves matched with the eccentric convex plate are arranged on the inner side of the A-shaped arm installing seat, the center of the connecting shaft is provided with a screw hole, and an installing screw is in arrangement matched with the screw hole. The invention is provided with the connecting shafts, the A-shaped arm and the vehicle frame are connected through the connecting shafts, screw bolts are arranged in inner holes of the connecting shafts for limiting the axial movement of the connecting shafts, the eccentric structures limit the relative rotation of the connecting shafts and the installing holes, the abrasion generated by the connecting shafts because of the movement can be prevented, and in addition, the coaxiality requirement during the installation can be met.

Owner:SANY HEAVY EQUIP

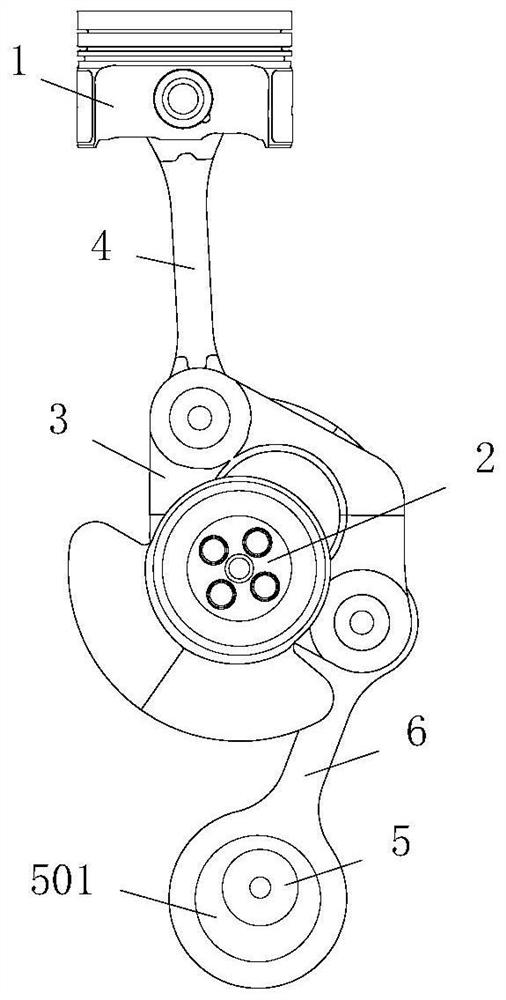

Assembly method of variable compression ratio drive structure

ActiveCN113294239BReliable settingsSimplify the assembly processAssembly machinesMachines/enginesReduction driveElectric machinery

The invention provides an assembly method of a variable compression ratio drive structure, the variable compression ratio drive structure drives the eccentric shaft in the variable compression ratio mechanism to rotate, and includes a harmonic reducer fixed on the engine block unit, and the motor unit fixed on the rigid wheel in the harmonic reducer unit, the assembly method includes first installing the rigid wheel, flexible wheel and eccentric shaft, and then installing them into the engine block, Then install the wave generator, the timing cover and the motor unit, and complete the sealing between the motor unit and the timing cover with the installation of the motor unit. The assembling method of the invention can realize the assembling of the variable compression ratio driving structure, and the assembling is relatively simple, can improve the assembling precision, and is beneficial to the reliable setting of the driving structure.

Owner:GREAT WALL MOTOR CO LTD

Gas cutting guiding device

ActiveCN102390000BLimit axial movementEasy to shapeWelding/cutting auxillary devicesAuxillary welding devicesTorchEngineering

Owner:SHANGHAI BOILER WORKS

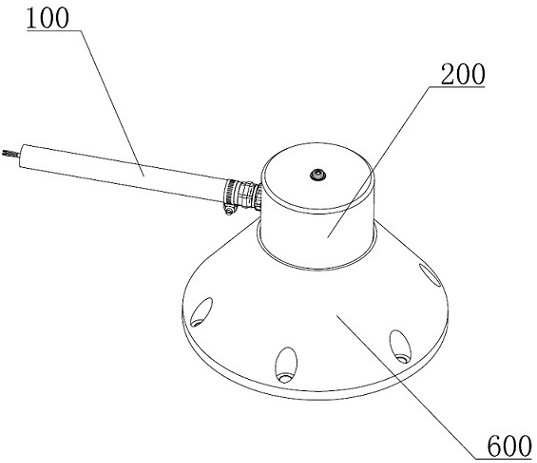

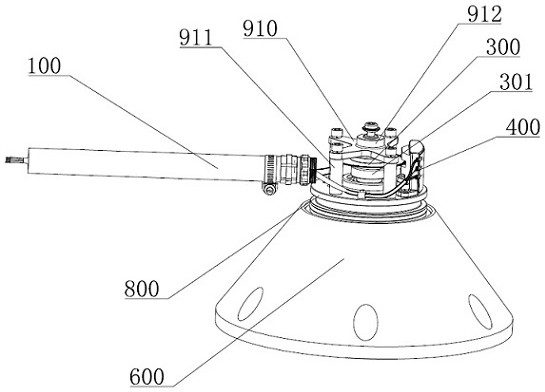

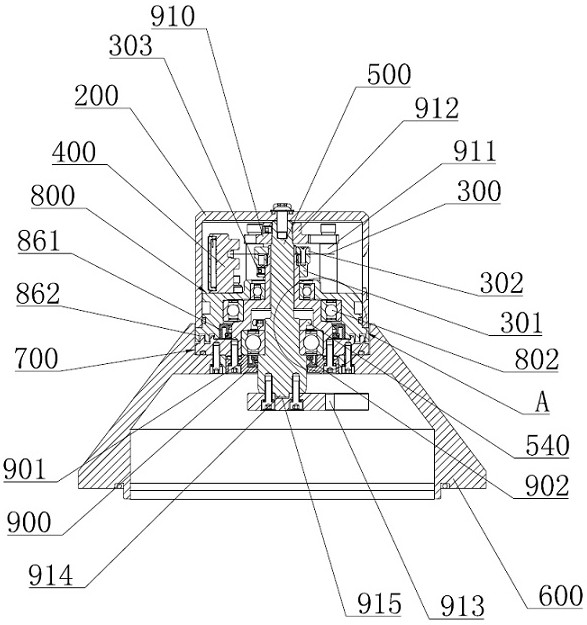

Photoelectric rotating speed sensor

ActiveCN114778881ALimit axial movementHigh rotation accuracySpeed/acceleration/shock instrument detailsDevices using optical meansGratingControl system

The invention provides a photoelectric rotating speed sensor, which comprises a connecting cable, an outer cover, a grating and a photoelectric module matched with the grating, and is characterized by further comprising a fixed shaft and a transmission disc, the transmission disc is fixed with a wheel, one end, close to the wheel, of the fixed shaft is fixed with an axle end, and the other end of the fixed shaft penetrates through the transmission disc and is rotationally connected with the transmission disc; the grating is arranged on the fixed shaft in a penetrating mode, the grating is rotationally connected with the fixed shaft, a rotating assembly is arranged between the transmission disc and the grating, so that when the transmission disc rotates, the grating can be driven to rotate, the transmission disc is covered with the outer cover, the outer cover is connected with the fixed shaft, and the photoelectric module is arranged in the outer cover. And a rotating assembly is arranged between the driving disc and the grating, so that when the wheel rotates, the driving disc drives the grating to rotate, a frequency signal proportional to the rotating speed of the wheel is generated and provided for a control system, and the device is suitable for rail transit vehicles with fixed axles and rotating wheels in the running process.

Owner:NINGBO CRRC TIMES TRANSDUCER TECH CO LTD

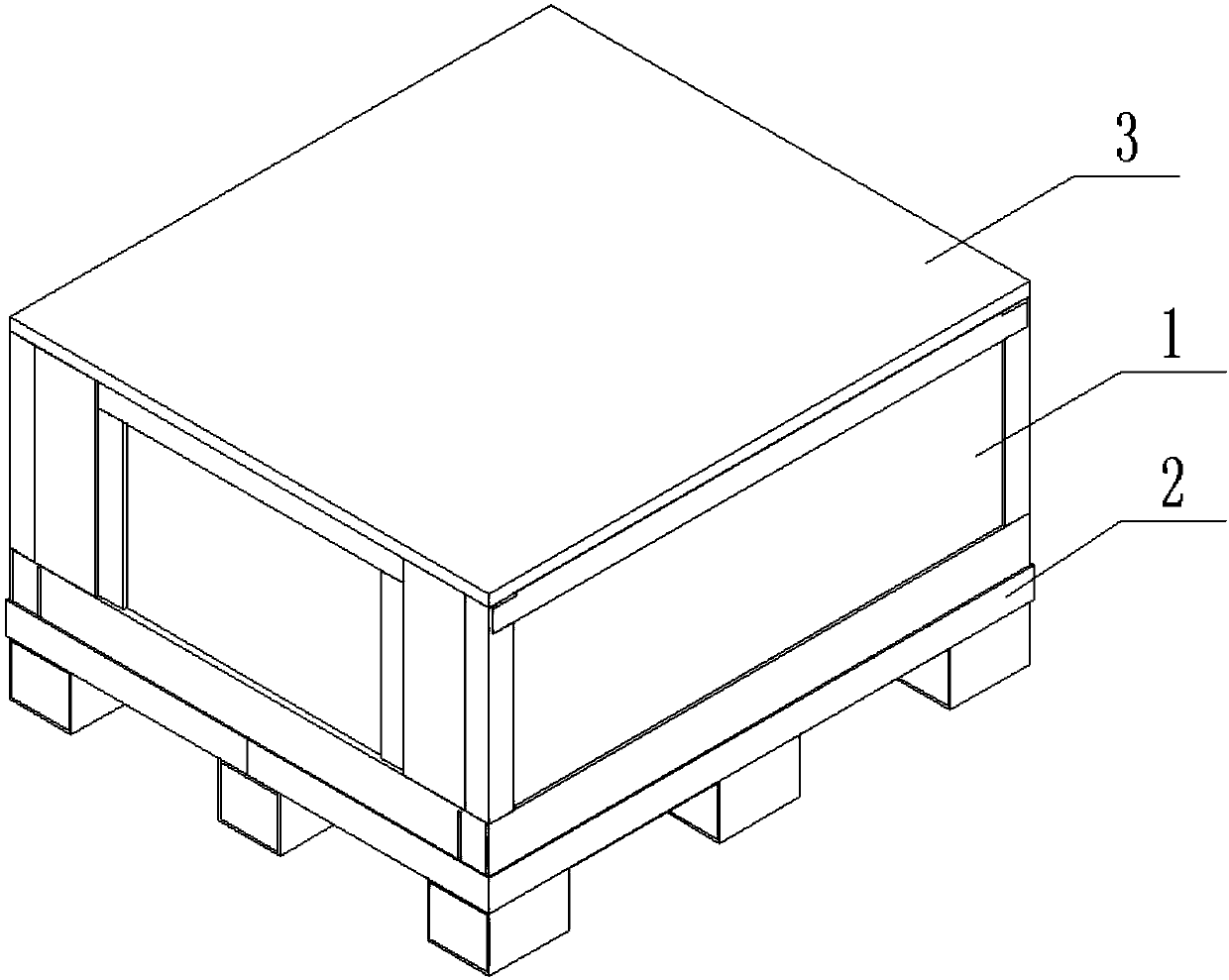

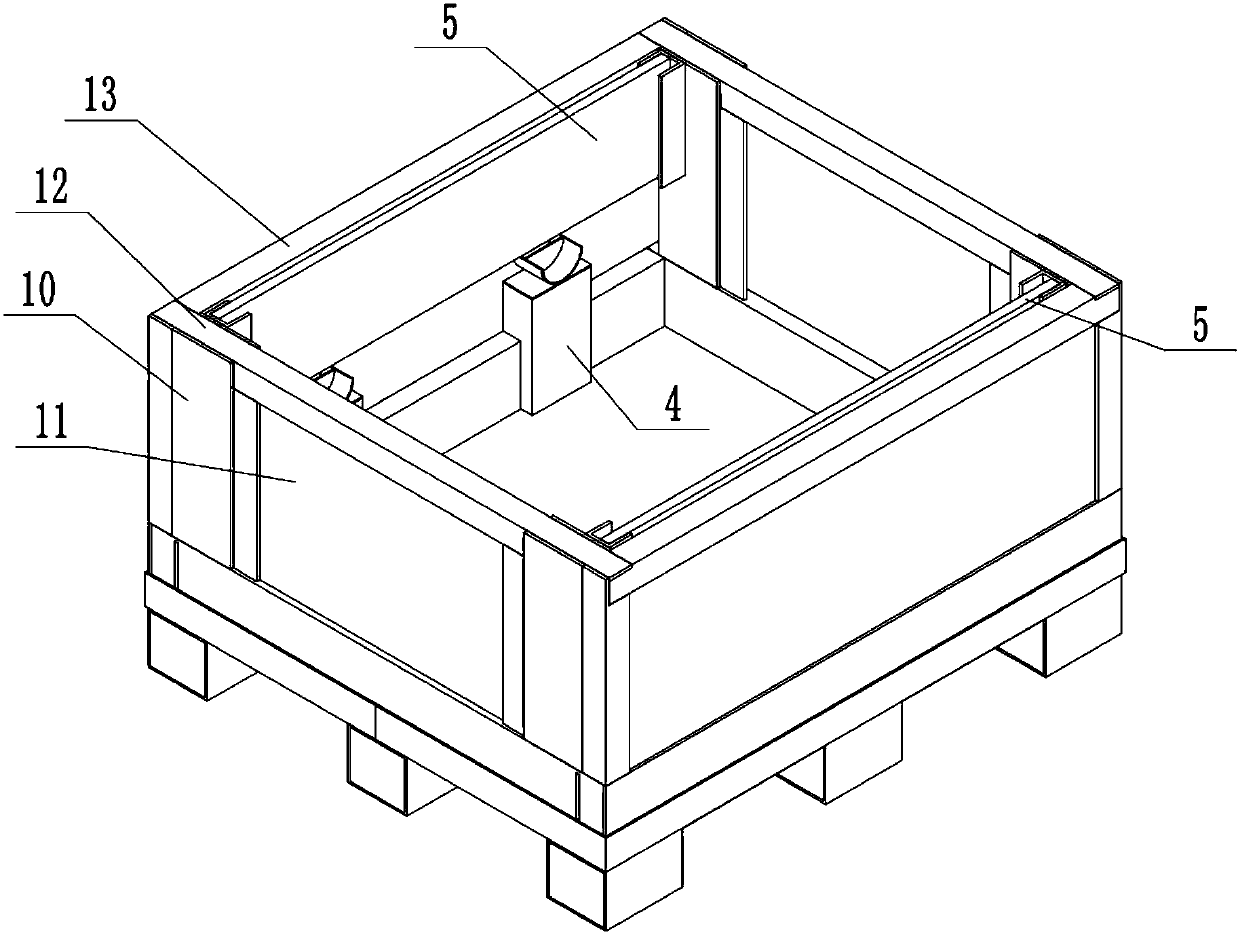

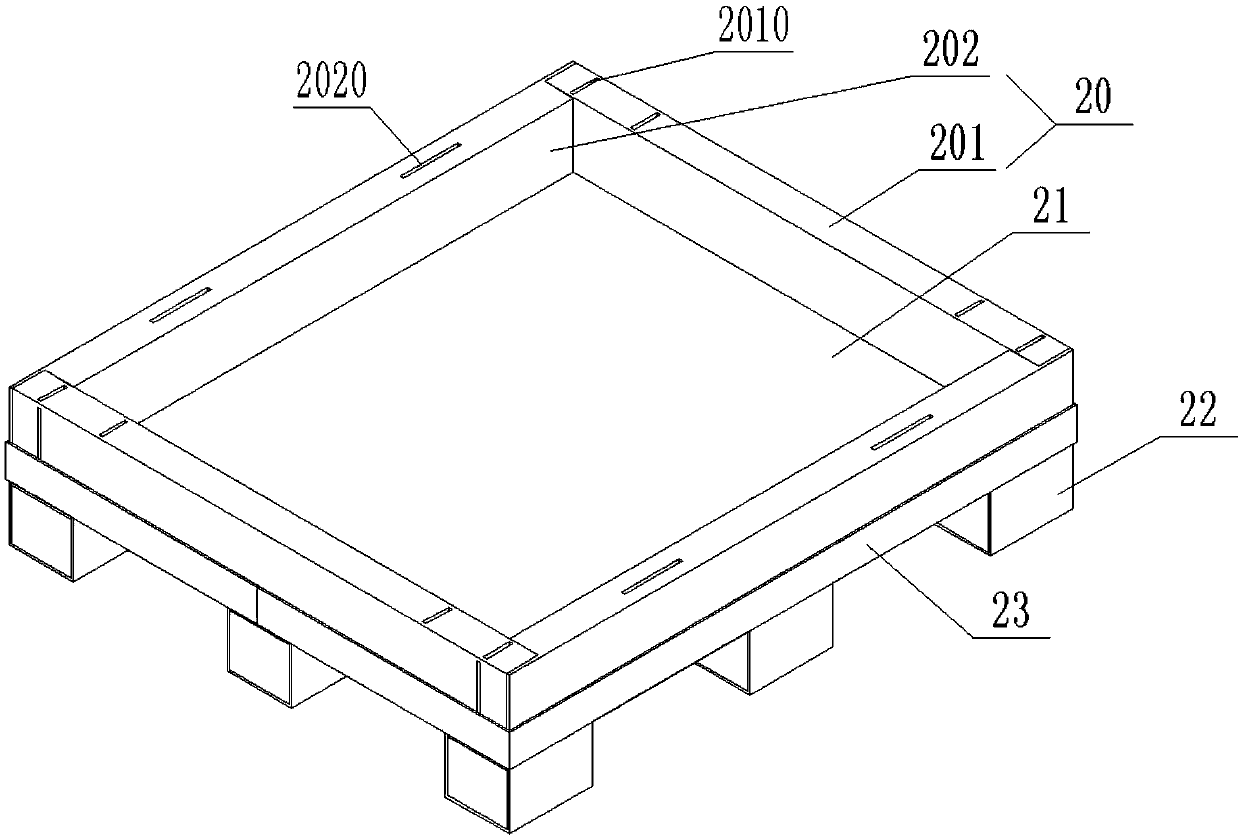

Recyclable bearing box

PendingCN108557218ASuspension stabilityNo wigglePackage recyclingContainer/bottle contructionEngineeringUltimate tensile strength

The invention discloses a recyclable bearing box which comprises a box body, a base and a cover plate, wherein the base is arranged under the box body, the cover plate is arranged above the box body,at least a pair of bearing supports for supporting a mandrel wrapped by a coiled material are arranged in the box body, limiting parts for axially limiting the mandrel are arranged on the bearing supports, and a mandrel pressing plug plate for tightly pressing the mandrel is arranged in the box body above the bearing supports. The recyclable bearing box disclosed by the invention has high structural strength and strong bearing ability and compression resistance and can effectively ensure an accuracy requirement of the metal coiled material; furthermore, the recyclable bearing box is recyclable, so that resources are saved.

Owner:HUNAN HUAWANG TECH

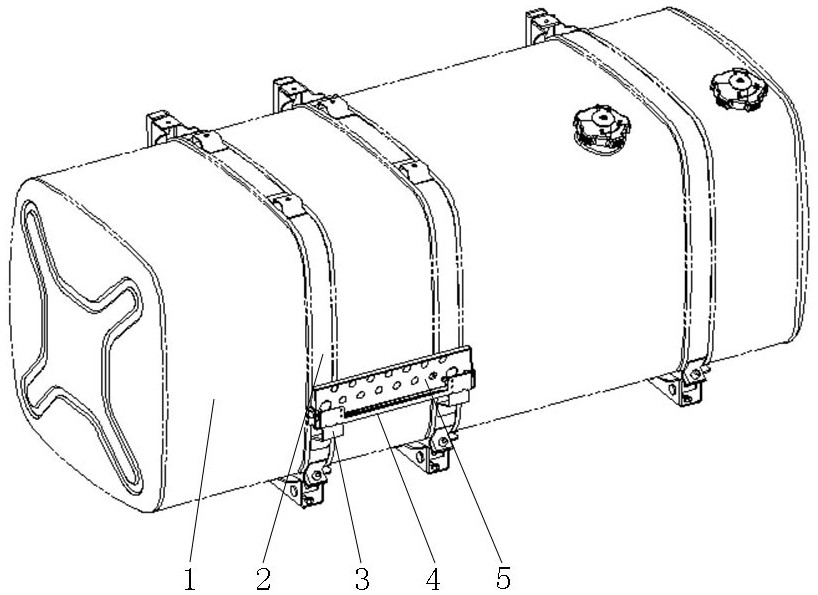

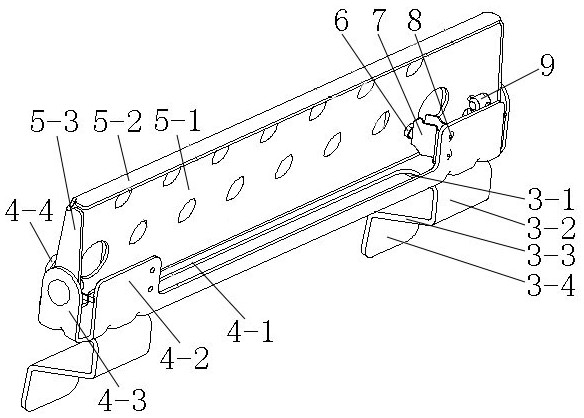

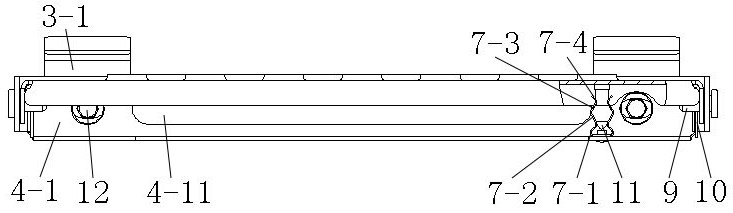

stepping device

ActiveCN110803112BDoes not affect strengthGuaranteed reliabilitySteps arrangementControl engineeringFuel tank

The invention discloses a stepping device for getting on a car, which relates to the technical field of auto parts. It includes a stepping bracket and a stepping plate. The stepping bracket is fixed on the fuel tank band through a mounting bracket. It is hinged with the step bracket, and the range of movement of the inner side of the step plate is within the step bracket; the outside of the step bracket has a support part supporting the step plate; an elastic limit mechanism is arranged between the support part and the step plate, and the elastic limit mechanism includes The limit pin shaft fixed on the inner bottom surface of the step plate and the limit shrapnel assembly installed on the support part, the limit shrapnel assembly has two limit shrapnels that are always clamped to the limit pin shaft, The bit shrapnel is arranged opposite to the length direction of the step plate. The invention solves the problem that the existing stepping device for a large-volume fuel tank vehicle cannot meet the requirements of stepping comfort and safety while ensuring the width of the entire vehicle.

Owner:DONGFENG LIUZHOU MOTOR

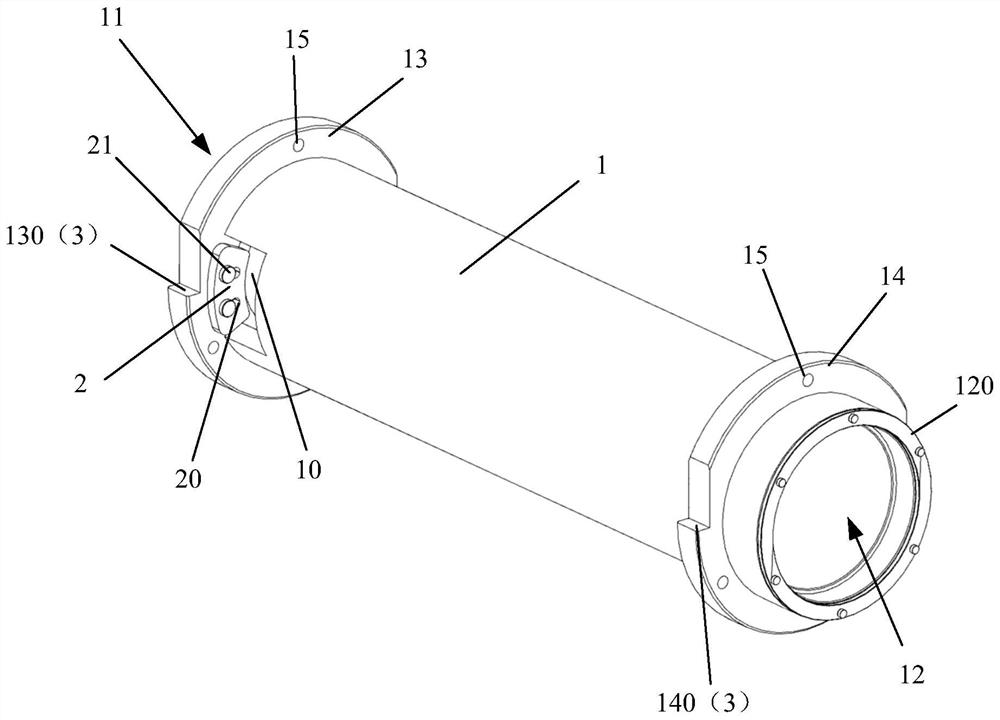

Low-pressure turbine dynamic balance system, dynamic balance tool and dynamic balance method

PendingCN113565588AEliminate the effects ofReduce the impactBlade accessoriesMachines/enginesPhysicsBalancing machine

One purpose of the invention is to provide a low-pressure turbine dynamic balance tool, so that the influence of the balance tool on the dynamic balance of a low-pressure turbine rotor can be reduced while a rotor assembly is supported on a horizontal balancing machine. The other purpose of the invention is to provide a low-pressure turbine dynamic balance system. The invention further aims at providing a low-pressure turbine dynamic balance method. The low-pressure turbine dynamic balance system is adopted for carrying out dynamic balance on the rotor assembly. In order to achieve the purpose, the low-pressure turbine dynamic balance tool comprises an outer barrel, a baffle piece and two installation parts. The outer barrel is provided with a first open end and a second open end, at least one opening is formed in the barrel wall close to the first open end, and the end face of the second open end is provided with a limiting part extending towards the inner side; the baffle piece is arranged at the opening and can move in the radial direction of the outer barrel; and the two installation parts are arranged on the peripheral wall surface of the outer cylinder body corresponding to the positions of the balancing machine bearing bushes.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Thermocouple flexible installing device

ActiveCN102331306BFree from damageLimit axial movementThermometer detailsThermometers using electric/magnetic elementsBiochemical engineeringThermocouple

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Compressors and Air Conditioners

ActiveCN106151042BEliminate periodic noise vibration problemsGuaranteed coaxialityRotary/oscillating piston pump componentsLiquid fuel engine componentsMechanical engineeringCrankshaft

The invention provides a compressor which comprises a motor and a crankshaft. The motor and the crankshaft are arranged in the shell. An axial moving limiting device is arranged at the tail end of the crankshaft and comprises a supporting seat, a bearing and a pressing plate. The supporting seat is inlaid in the shell. The bearing is arranged on the supporting seat. The supporting seat is arranged on the crankshaft in a sleeving manner through the bearing. The pressing plate is fixedly arranged on the supporting seat. The pressing plate is used for limiting the axial movement of the bearing. The invention further relates to an air conditioner. According to the compressor and the air conditioner, the axial moving limiting device is arranged at the tail end of the crankshaft of the compressor, the problem of axial moving of the crankshaft is effectively solved through the bearing and the pressing plate of the axial moving limiting device, the problem of periodical noise vibration of the compressor under some conditions is solved, the axial moving limiting device is simple in structure, convenient to install and high in universality, the problems of radial deflection and eccentricity of the crankshaft are effectively solved, and the coaxility of the whole compressor is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

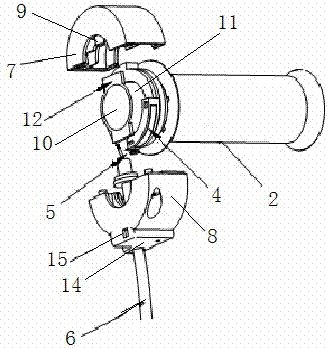

A hybrid electric motorcycle handlebar that is easy to install and use

InactiveCN104401439BDo not change acceleration modeMinor changesCycle control systemsElectric machineryMotor controller

The invention discloses an oil-electric dual-purpose handle for a hybrid motorcycle which is convenient to install and use, comprising an accelerator seat and a turning handle. A cable groove is arranged on the turning handle; A long strip of iron is installed, the acceleration seat covers the cable groove and the iron plate on the turning handle, and a Hall sensor corresponding to the iron plate is installed on the hole wall of the accelerator seat. The Hall sensor is controlled by the signal line and the motor device connection. The acceleration seat is composed of an upper shell and a lower shell that are relatively open, the upper shell or the lower shell is provided with a positioning pin, and the handle tube is provided with a corresponding positioning hole. The handle is improved from the structure of the traditional motorcycle handle, and the modification is small. Whether it is electric or oil-driven, the acceleration is directly realized by turning the handle, and the acceleration mode of the traditional motorcycle driver is not changed at all. The electric structure part and the oil-action structure part of the handle are independent of each other, do not interfere and influence each other, and work reliably.

Owner:力帆科技(集团)股份有限公司

A laser focusing device

ActiveCN112059410BAvoid secondary collisionAvoid damageLaser beam welding apparatusHall elementProtective glasses

The invention discloses a laser focusing device, comprising: a connecting plate, a mounting seat connected to the connecting plate, a lens seat installed in the hollow inner cavity of the connecting plate and the mounting seat and used for fixing a focusing mirror, and mounted inside the mounting seat The adapter sleeve, the protective glass seat placed at the lower end of the adapter sleeve and connected to the adapter sleeve, the gas nozzle connection sleeve connected under the protective glass seat and the gas nozzle connected to the gas nozzle connection sleeve, wherein the adapter sleeve A magnetic part is installed on the upper surface, and a Hall element is installed on the lower surface of the connecting plate opposite to the adapter sleeve. The Hall element is located above the magnetic part and there is a gap between it and the magnetic part. The Hall element is used to sense the magnetic field of the magnetic part. intensity and generate a trigger signal when the distance from the magnet changes. The laser focusing device has an anti-collision function, which can effectively prevent radial and axial collisions from damaging the components of the device.

Owner:XIAN MICROMACH TECH CO LTD

A winch rope arrangement

Owner:WUHAN MARINE MACHINERY PLANT

Horizontal type multiple-stage centrifugal pump

InactiveCN105649995ASimple structureStable jobPump componentsRadial flow pumpsCarbon steelCentrifugal pump

The invention relates to a horizontal type multiple-stage centrifugal pump. The centrifugal pump comprises a carbon-steel shaft, a cast iron impeller, a balance disc, a rolling bearing, a tensioning bolt and fillers. The two ends of the cast iron impeller are supported on the carbon-steel shaft. The balance disc is fixedly connected to the carbon-steel shaft through the tensioning bolt. The fillers are arranged at the two ends of the carbon-steel shaft. A rubber water deflector and an O-shaped rubber sealing ring are installed on the carbon-steel shaft. The cast iron impeller is provided with an impeller sealing ring, guide vane sleeves and other vulnerable parts to prevent abrasion to a middle piece and guide vanes. According to the horizontal type multiple-stage centrifugal pump, the structure is simple, operation is stable, and axial movement of a rotor is limited; the service life is long, the production cost is low, and abrasion to the balance disc and a balance ring is greatly reduced, so that the service life of the balance disc and the service life of the balance ring are prolonged, and the working efficiency of the centrifugal pump is improved.

Owner:李虹

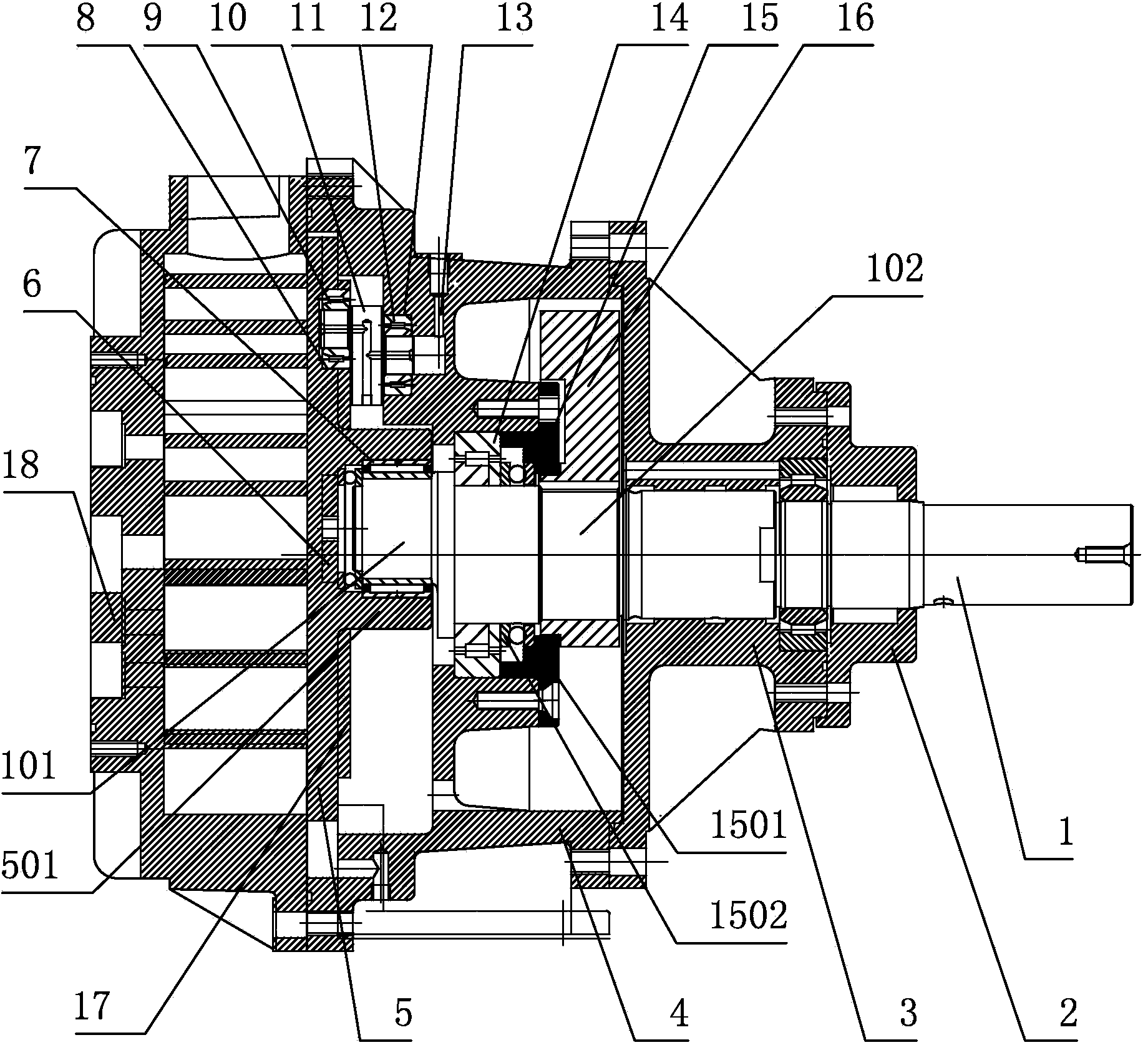

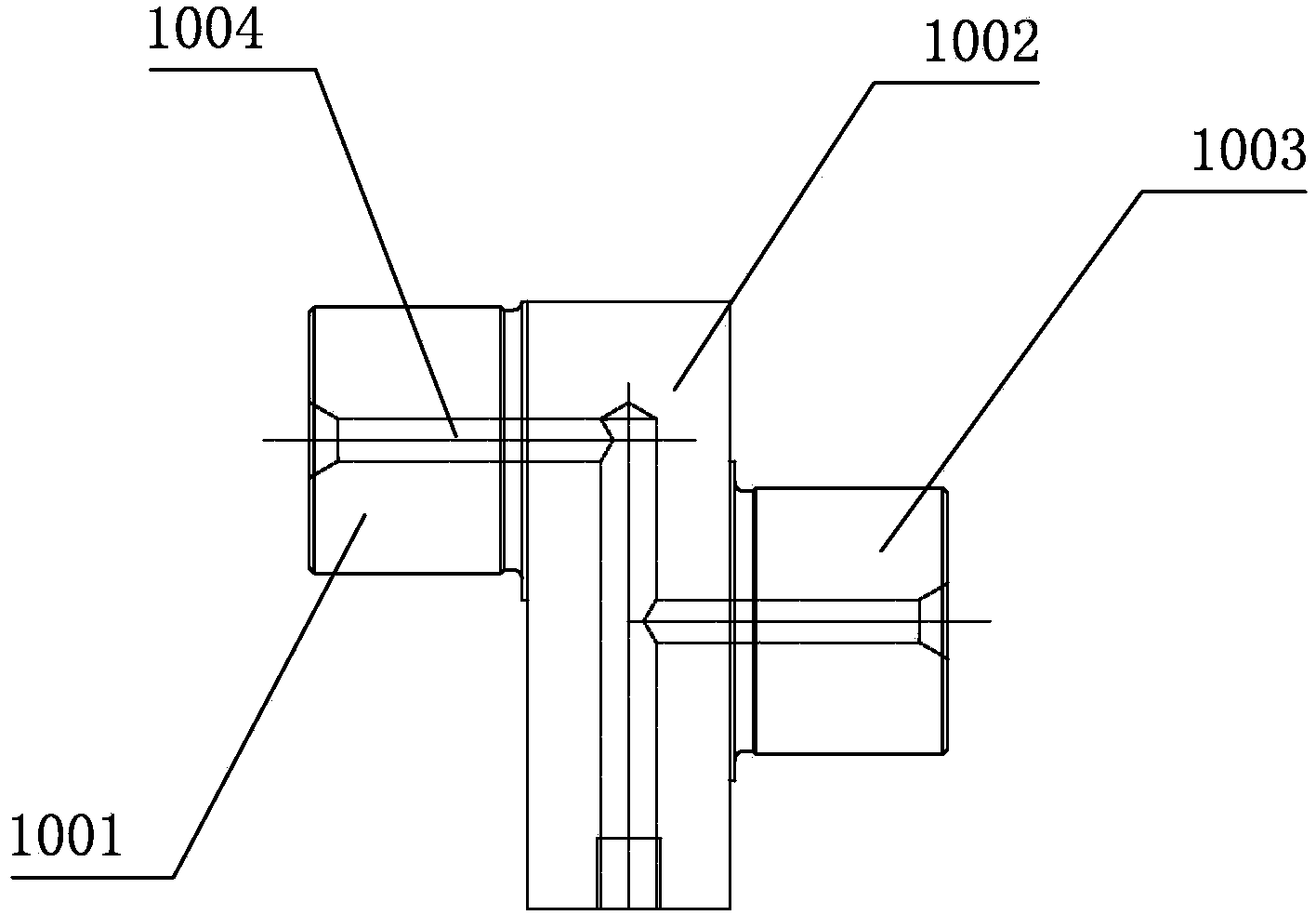

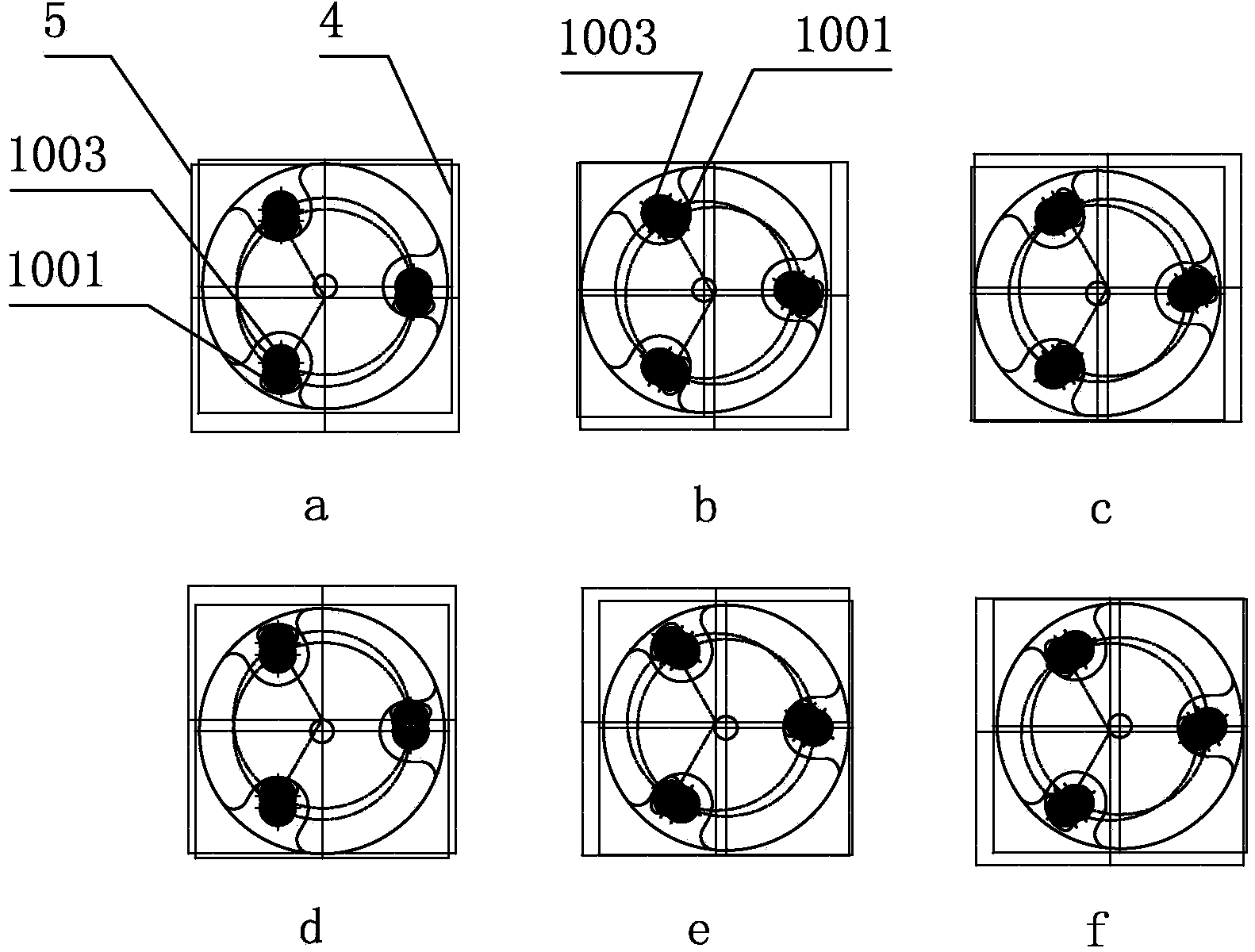

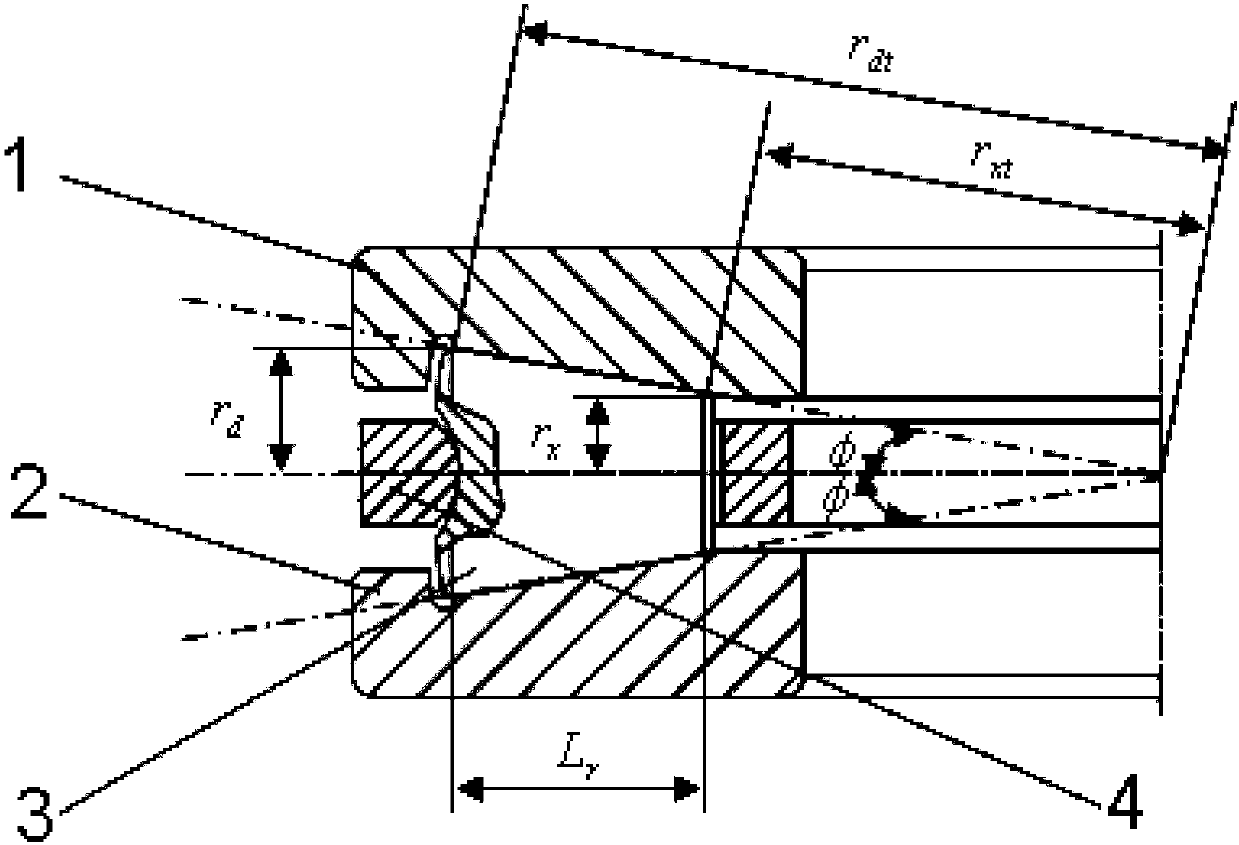

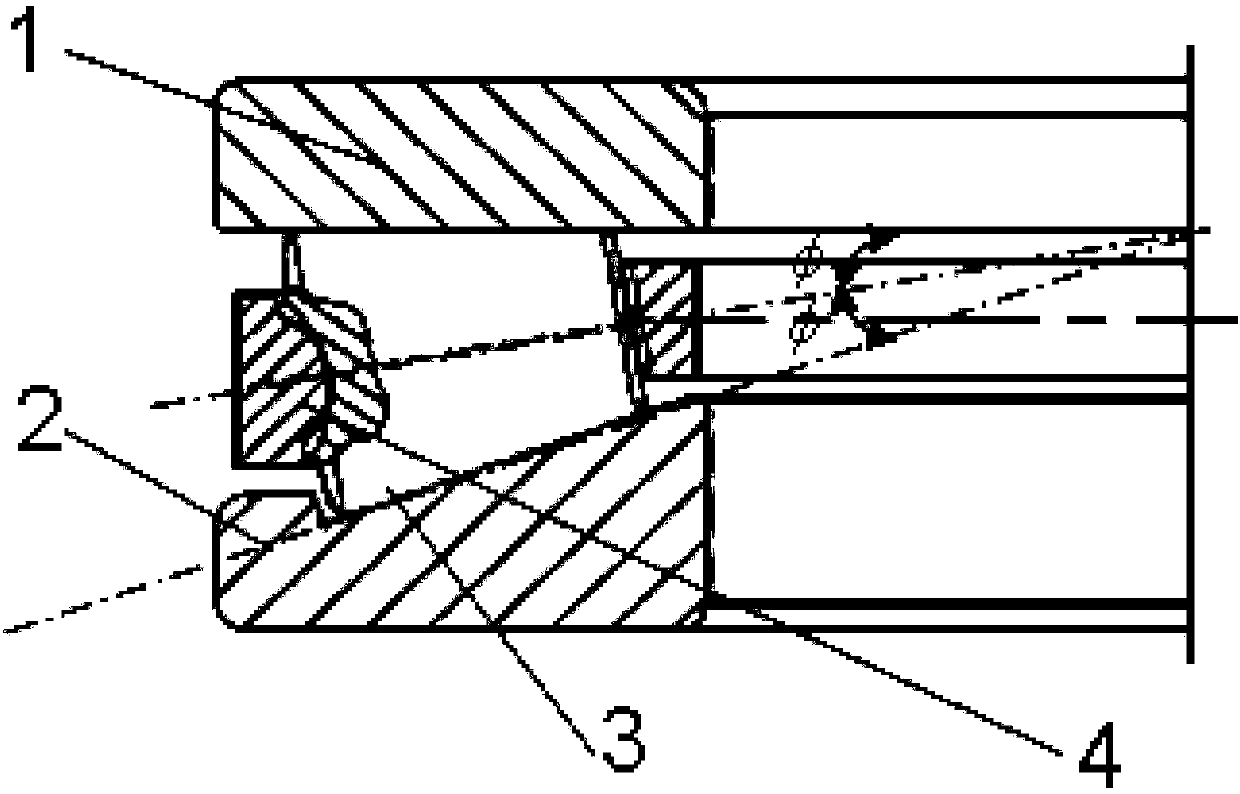

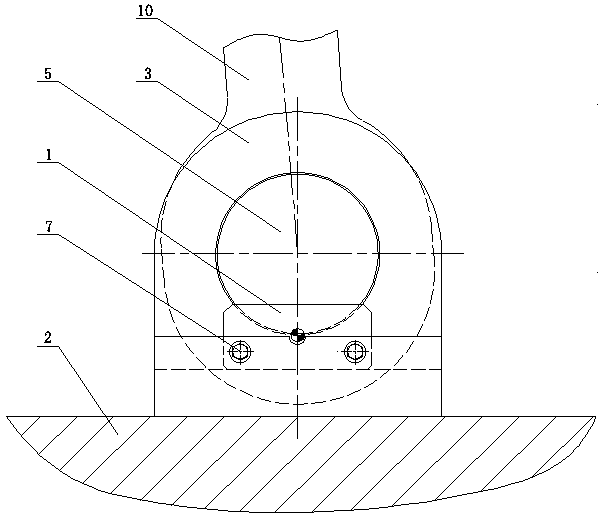

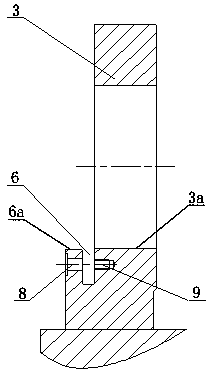

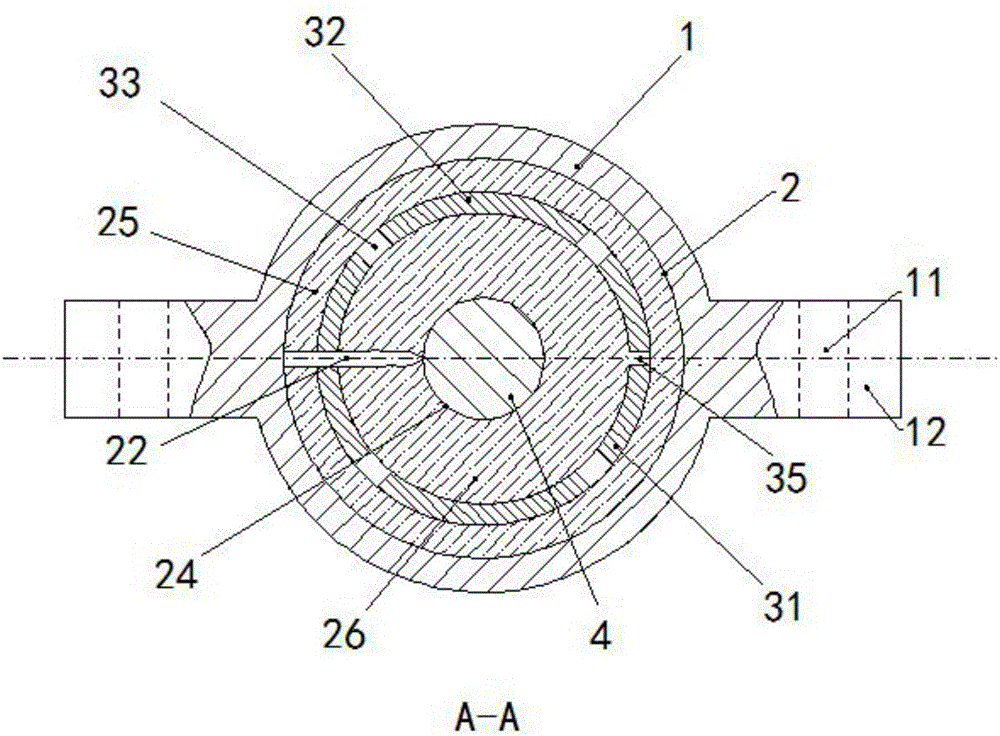

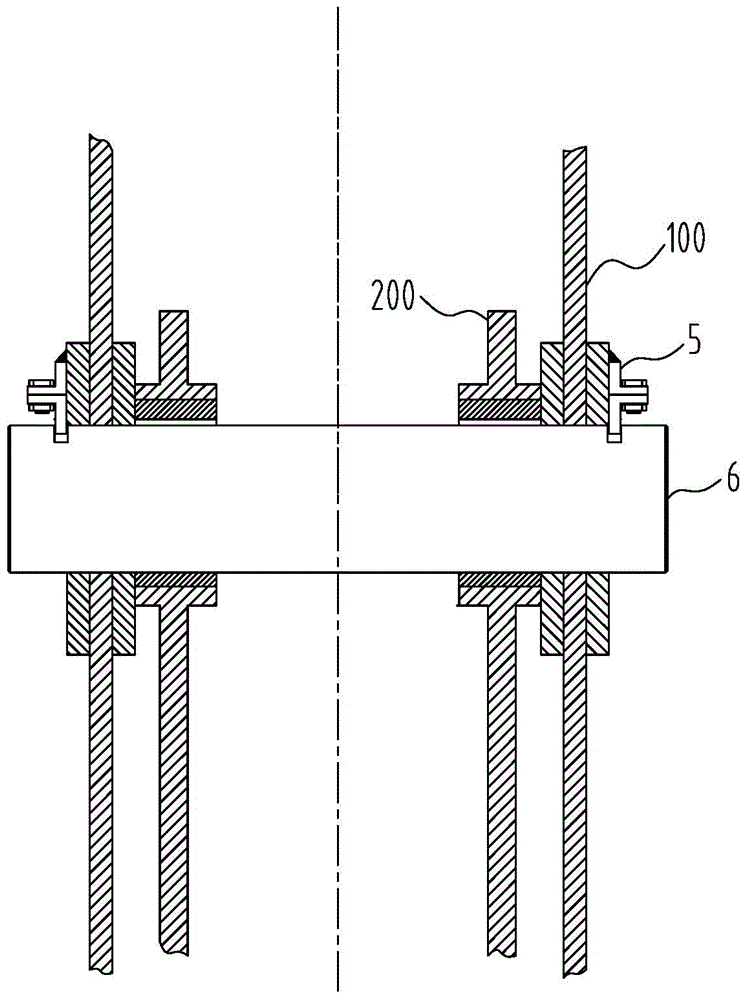

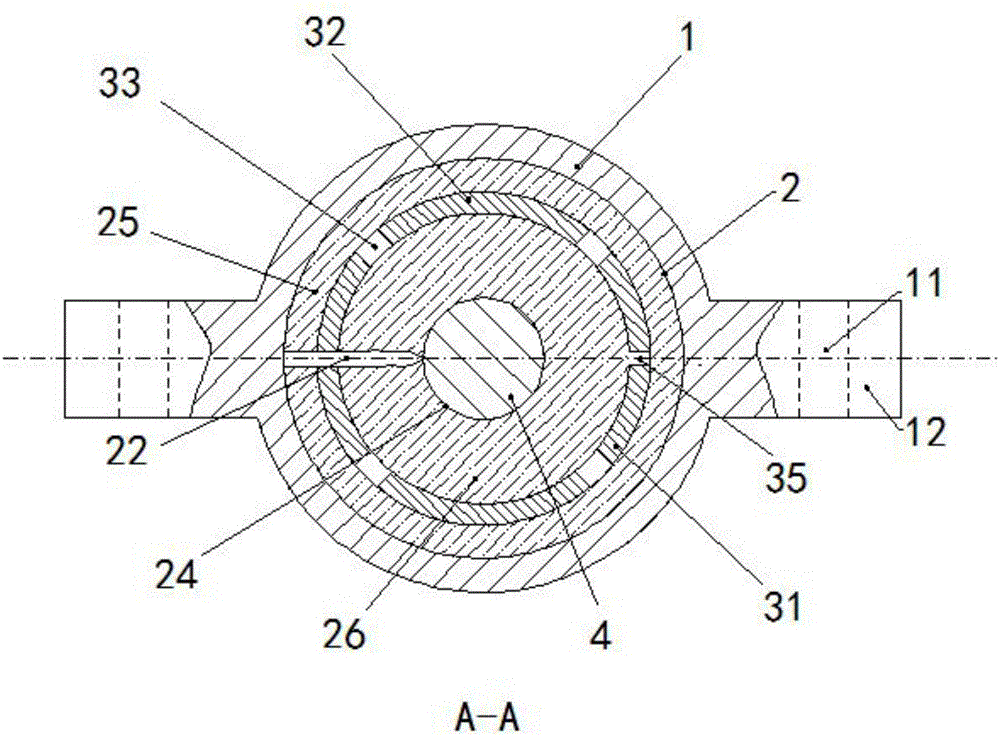

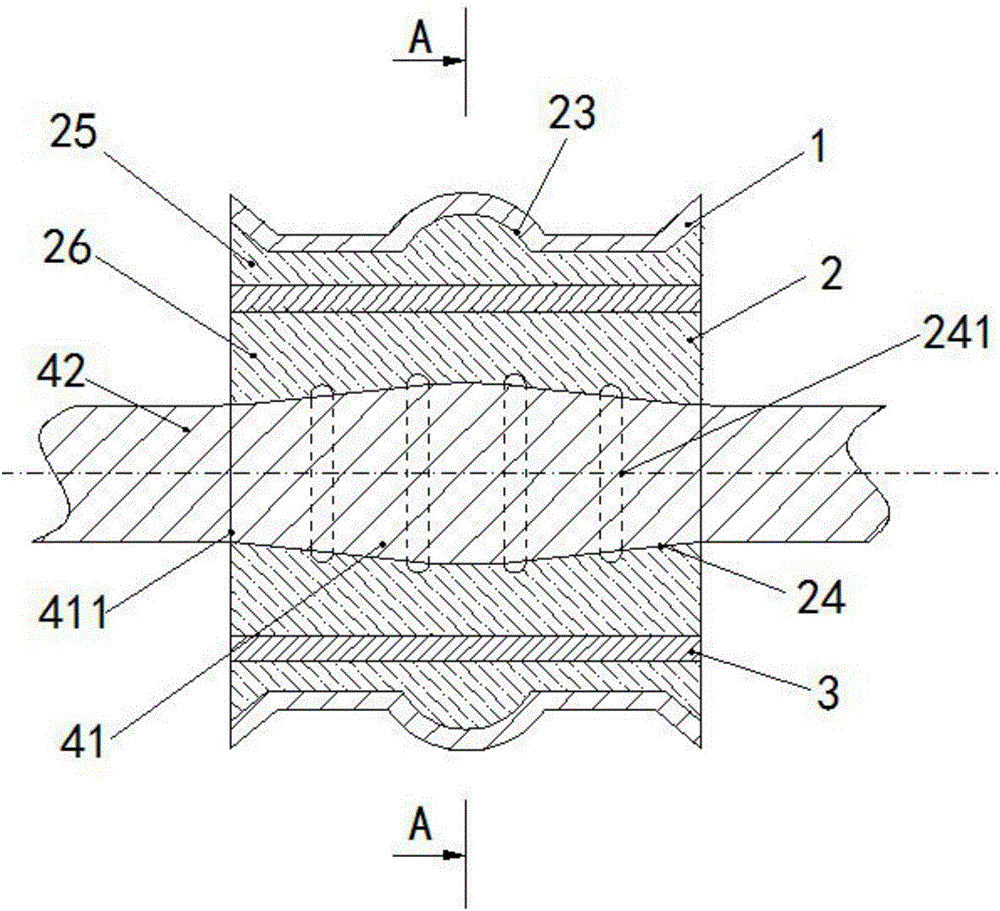

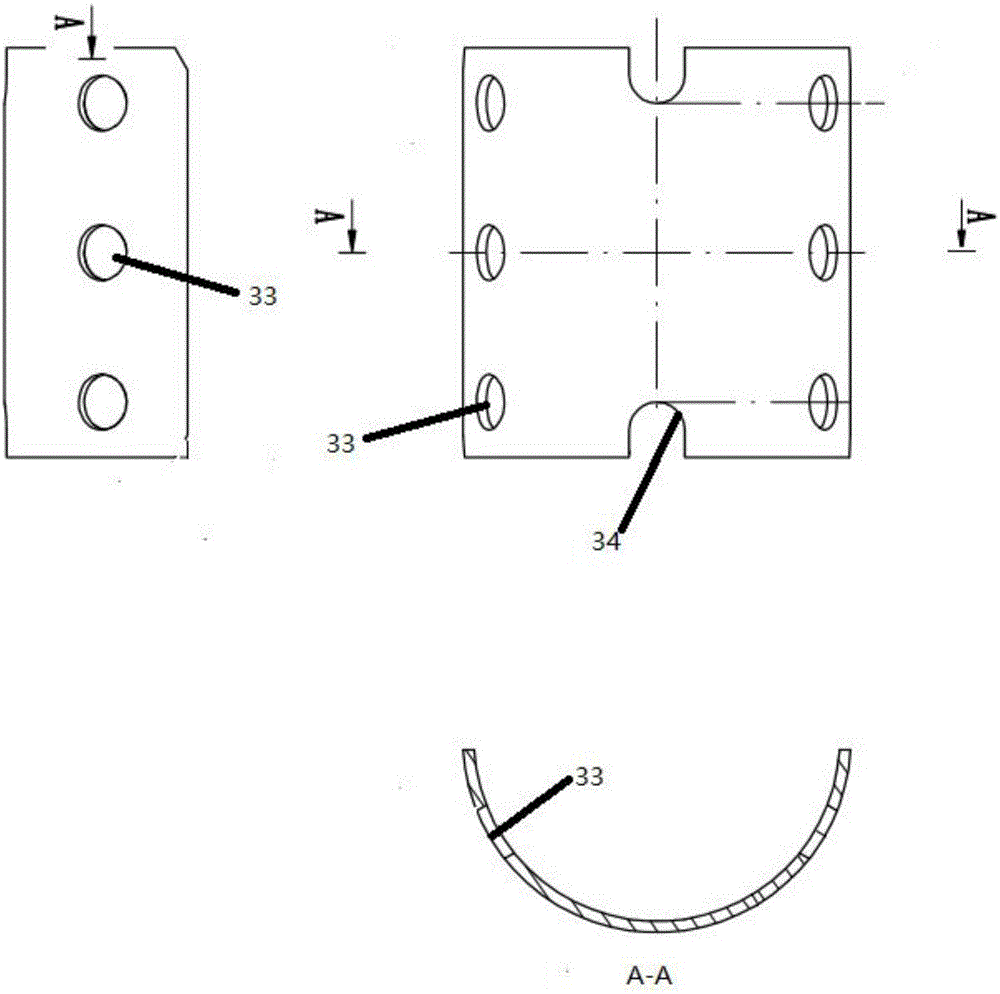

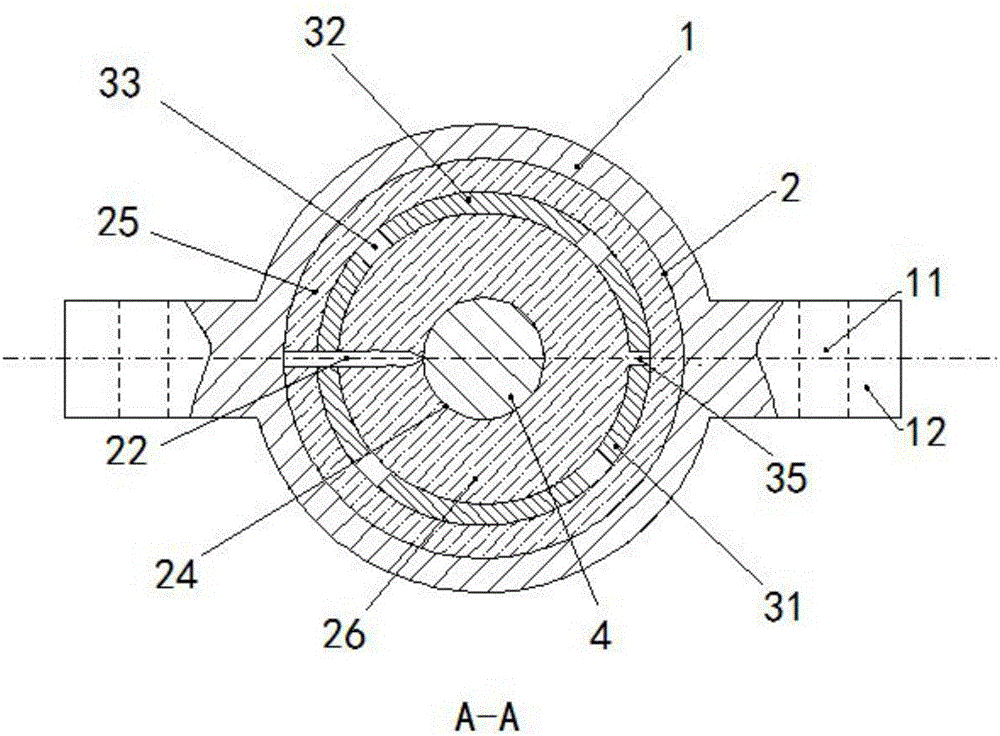

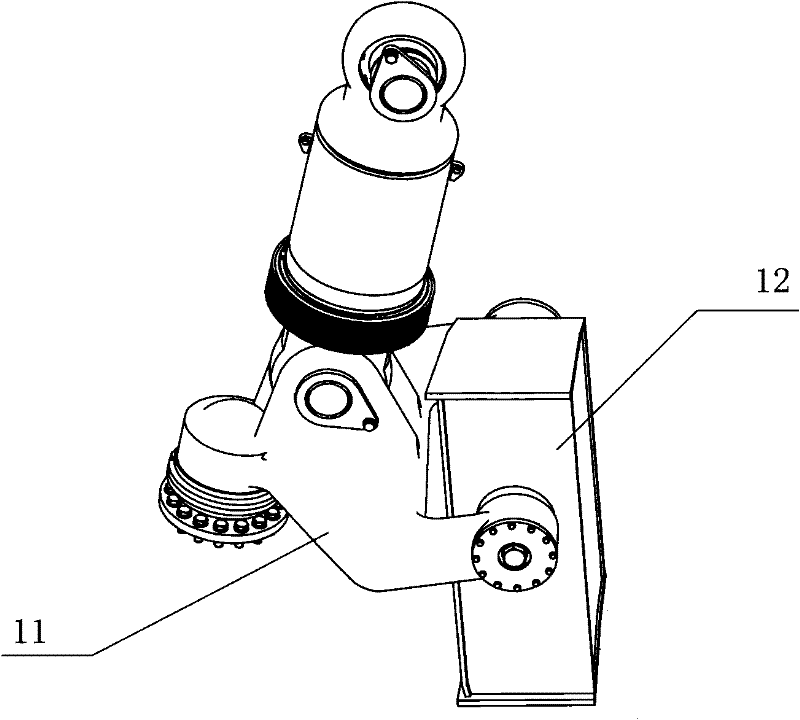

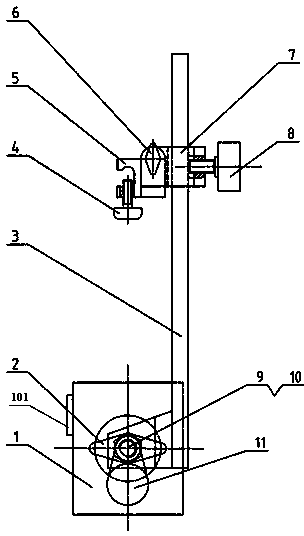

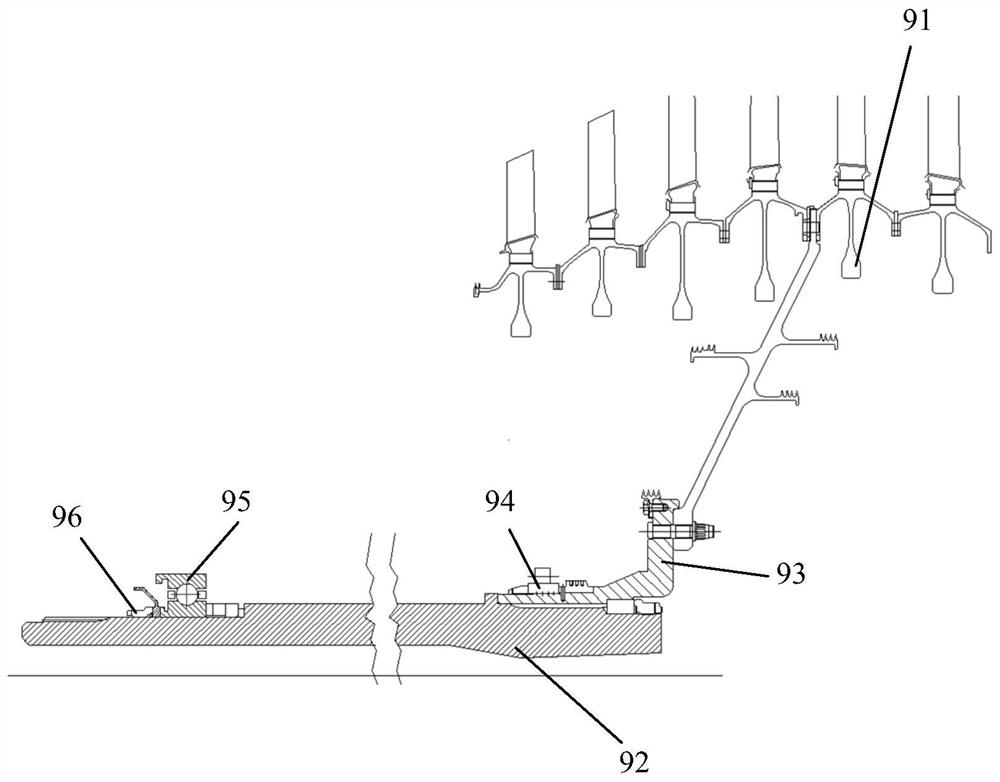

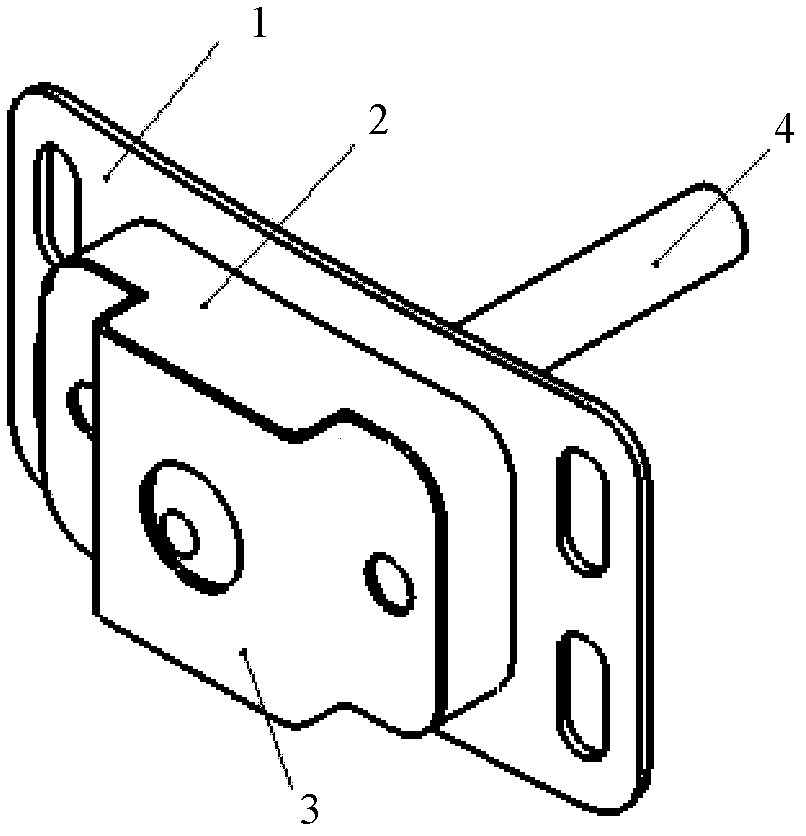

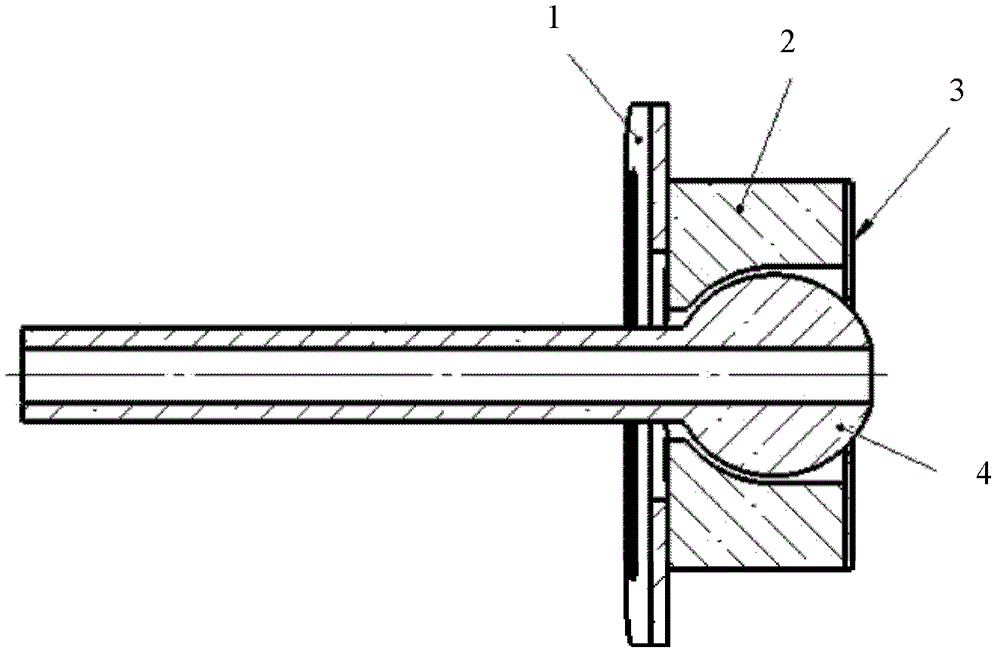

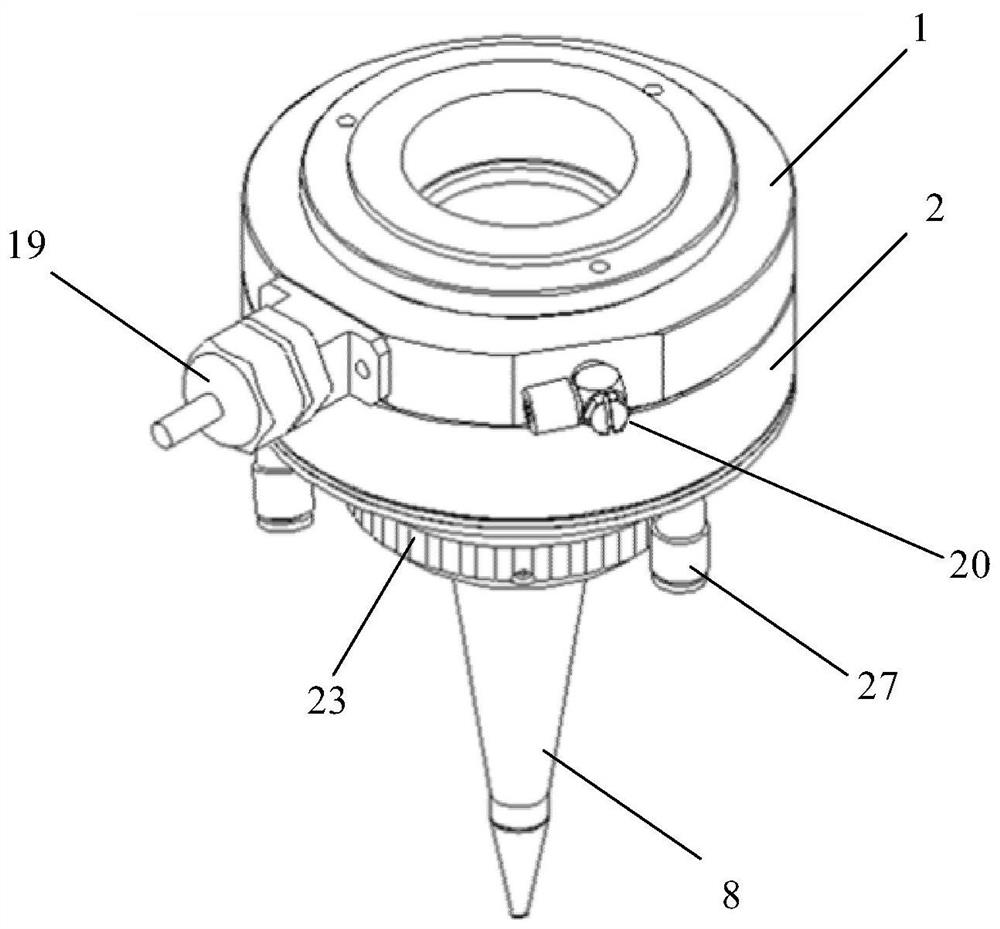

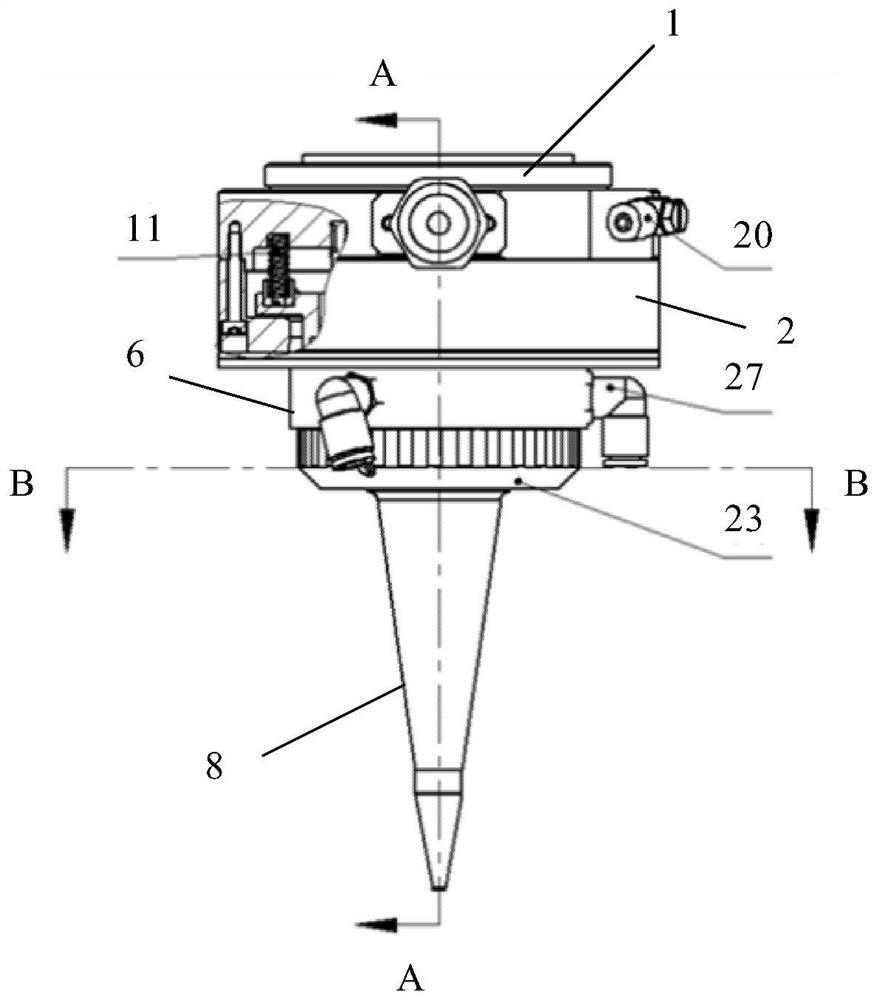

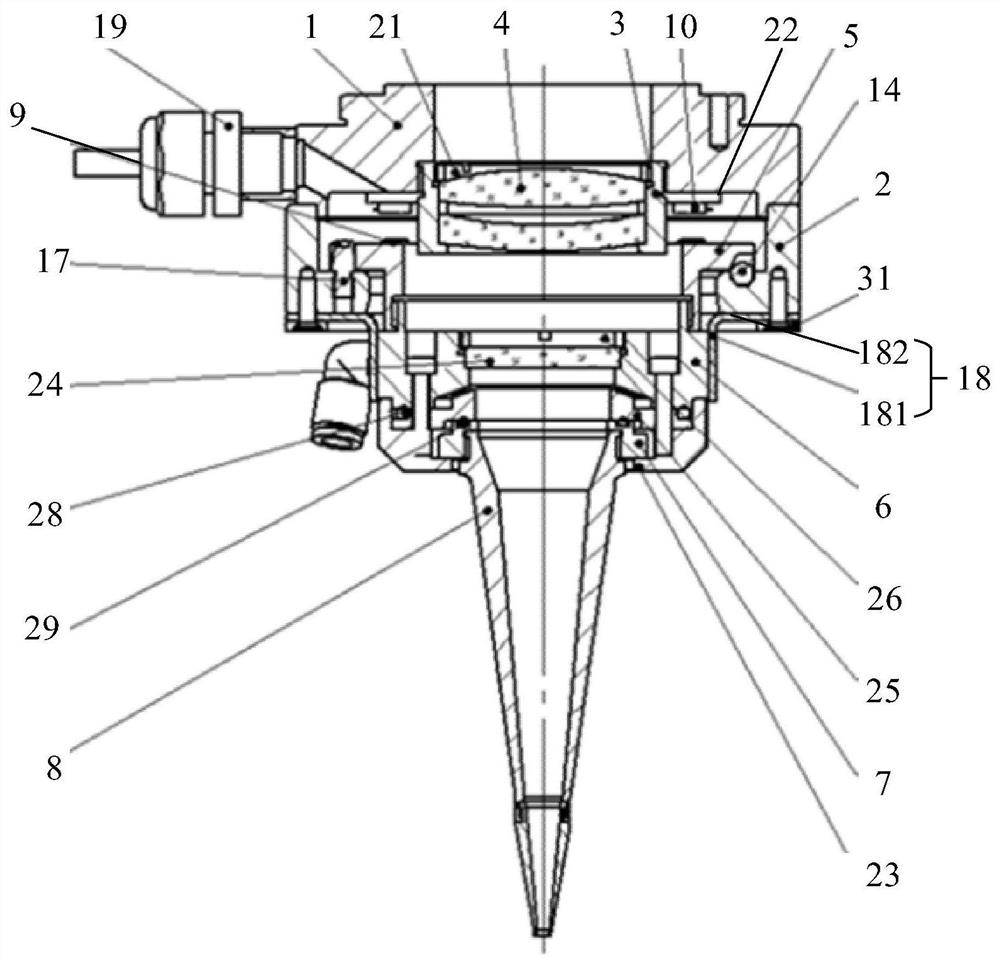

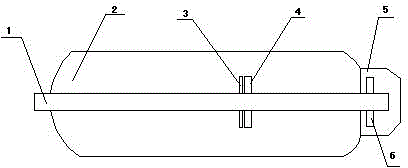

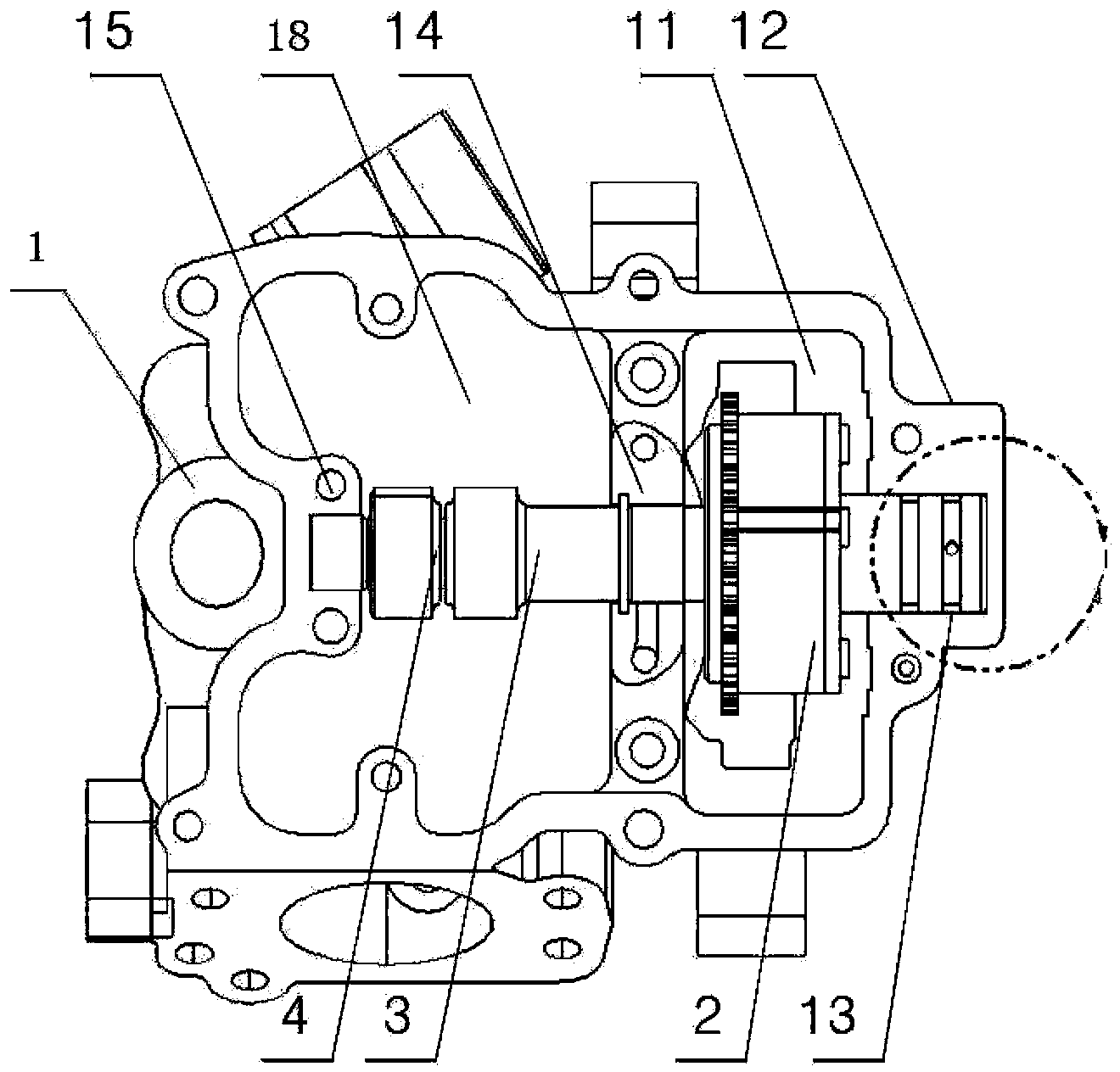

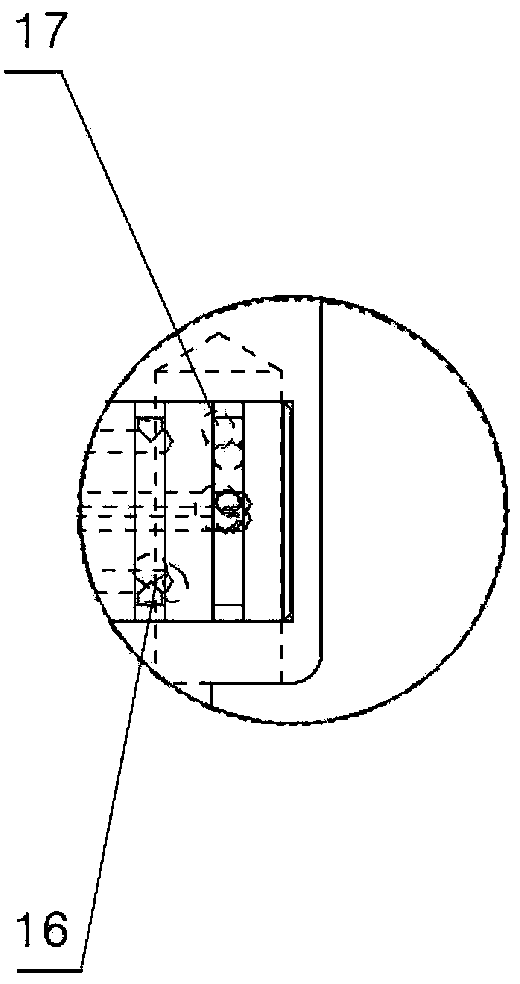

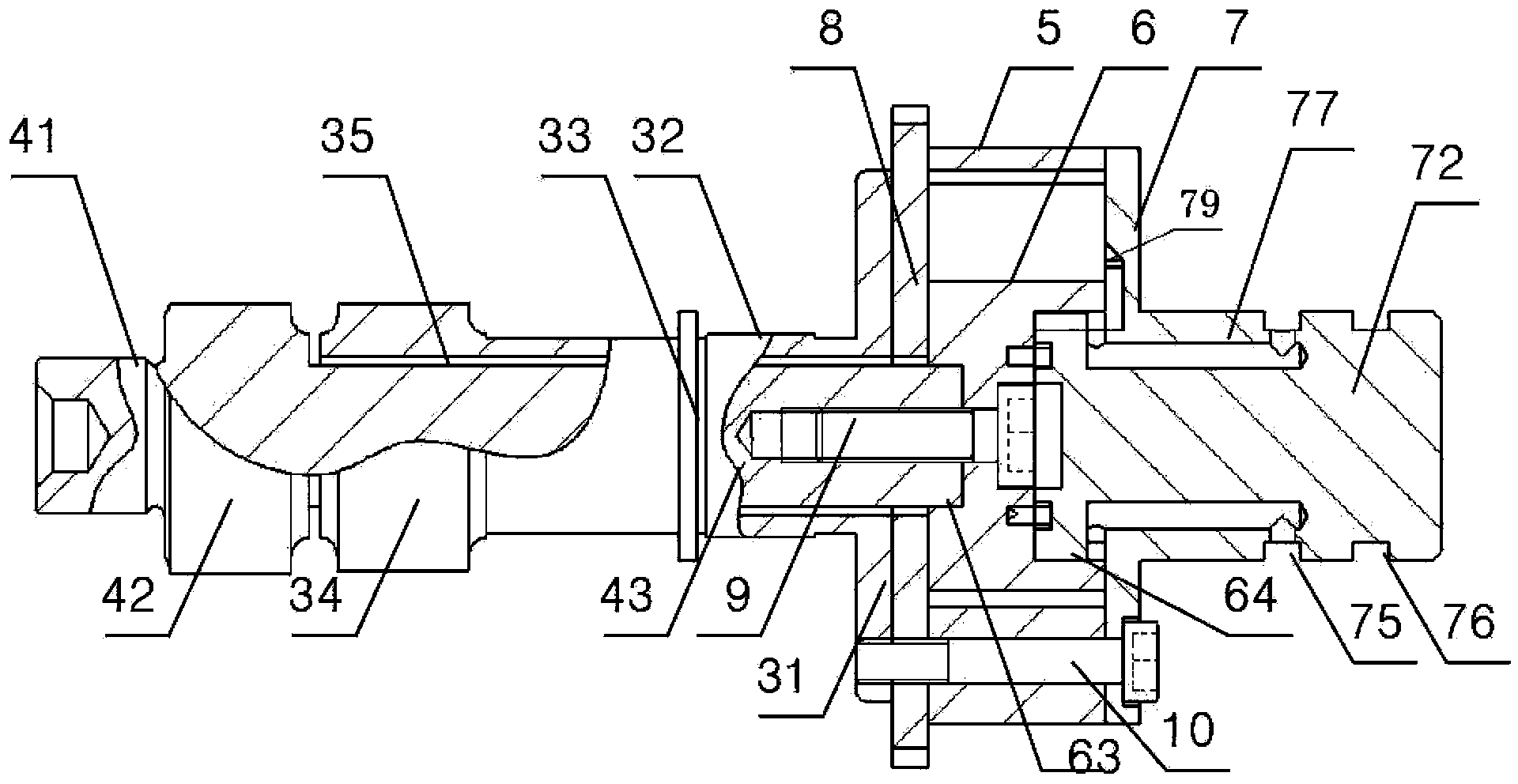

Air inlet phase continuously adjustable device for single-cylinder and single-overhead-camshaft engine

InactiveCN102797529BLimit axial movementSolve layout difficultiesValve arrangementsMachines/enginesSpatial structureEngineering

The invention discloses an air inlet phase continuously adjustable device for a single-cylinder and single-overhead-camshaft engine. The air inlet phase continuously adjustable device comprises a cylinder cover (1), a phase adjuster assembly (2), an air exhaust camshaft (3) and an air inlet camshaft (4), wherein the right side of a chain wheel chamber (11) is provided with a camshaft support boss (12); the phase adjuster assembly (2) is arranged in the chain wheel chamber (11), and is supported through a first bearing seat (13); the air exhaust camshaft (3) and the air inlet camshaft (4) can rotate relatively; and the camshaft support boss (12) is provided with a first oil supply hole (16) and a second oil supply hole (17). The phase adjuster assembly is arranged in the space of the chain wheel chamber of the cylinder cover, so that the limit of the spatial structure of the cylinder cover when the phase adjuster assembly is arranged between air inlet and exhaust cams is avoided, and the arrangement of a vane type continuously variable air distribution mechanism can be realized under the condition of slightly changing the engine cylinder cover.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com