Vacuum scroll compressor

A vacuum compressor and scroll technology, applied in the field of scroll vacuum compressors, can solve problems such as increased damage to components, increased friction, and high noise, and achieve the effects of improving special industries, small oil injection, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

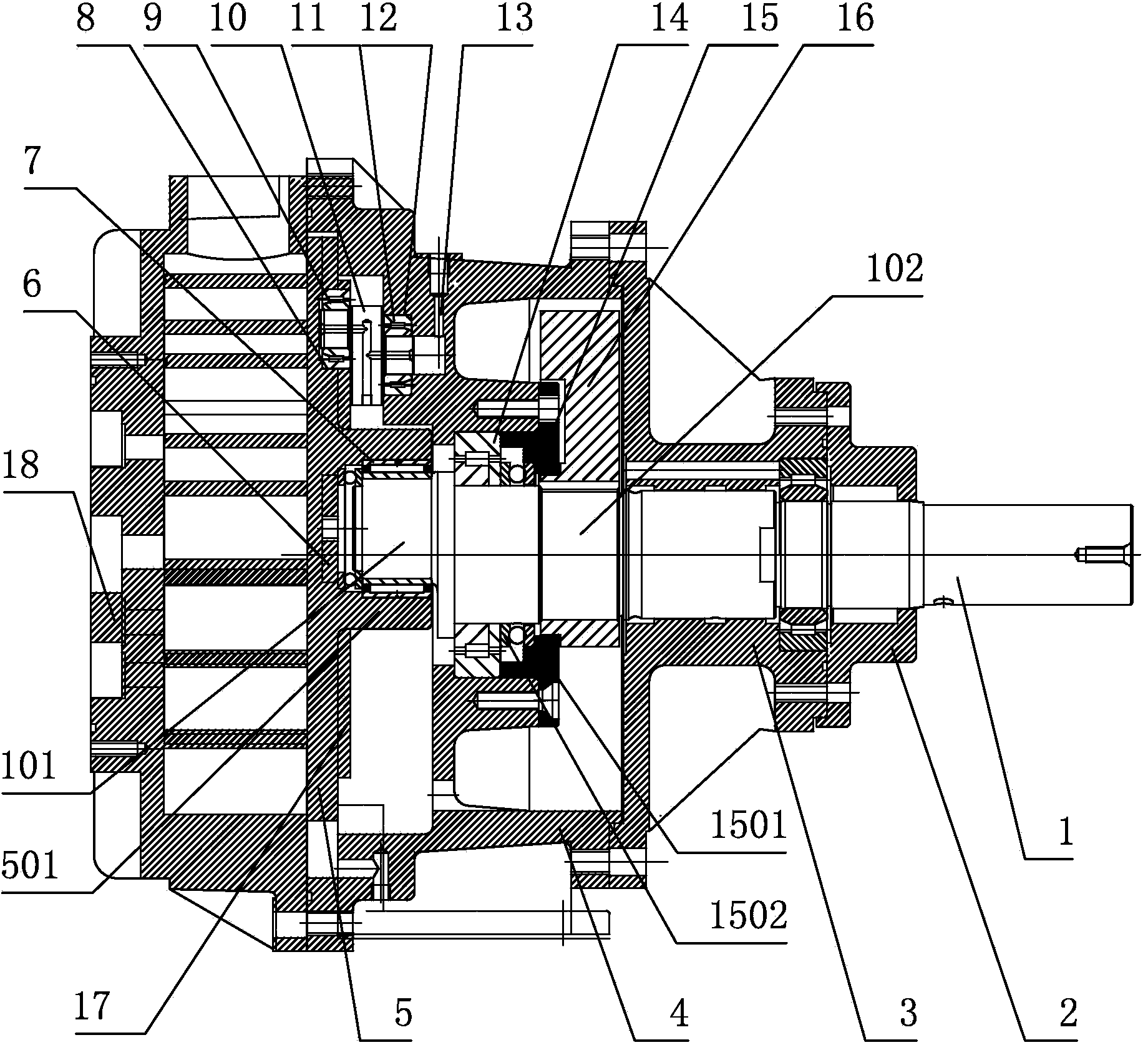

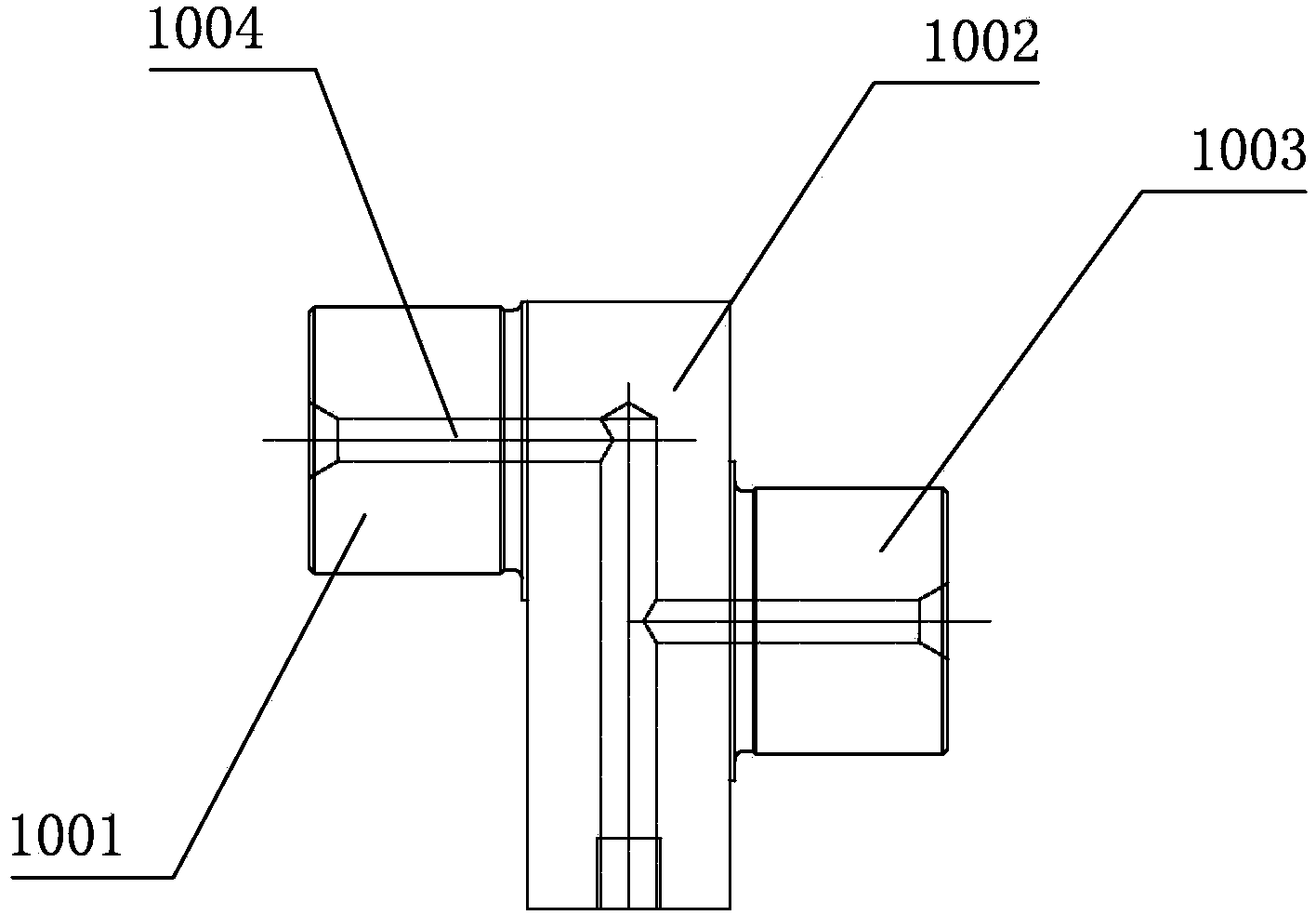

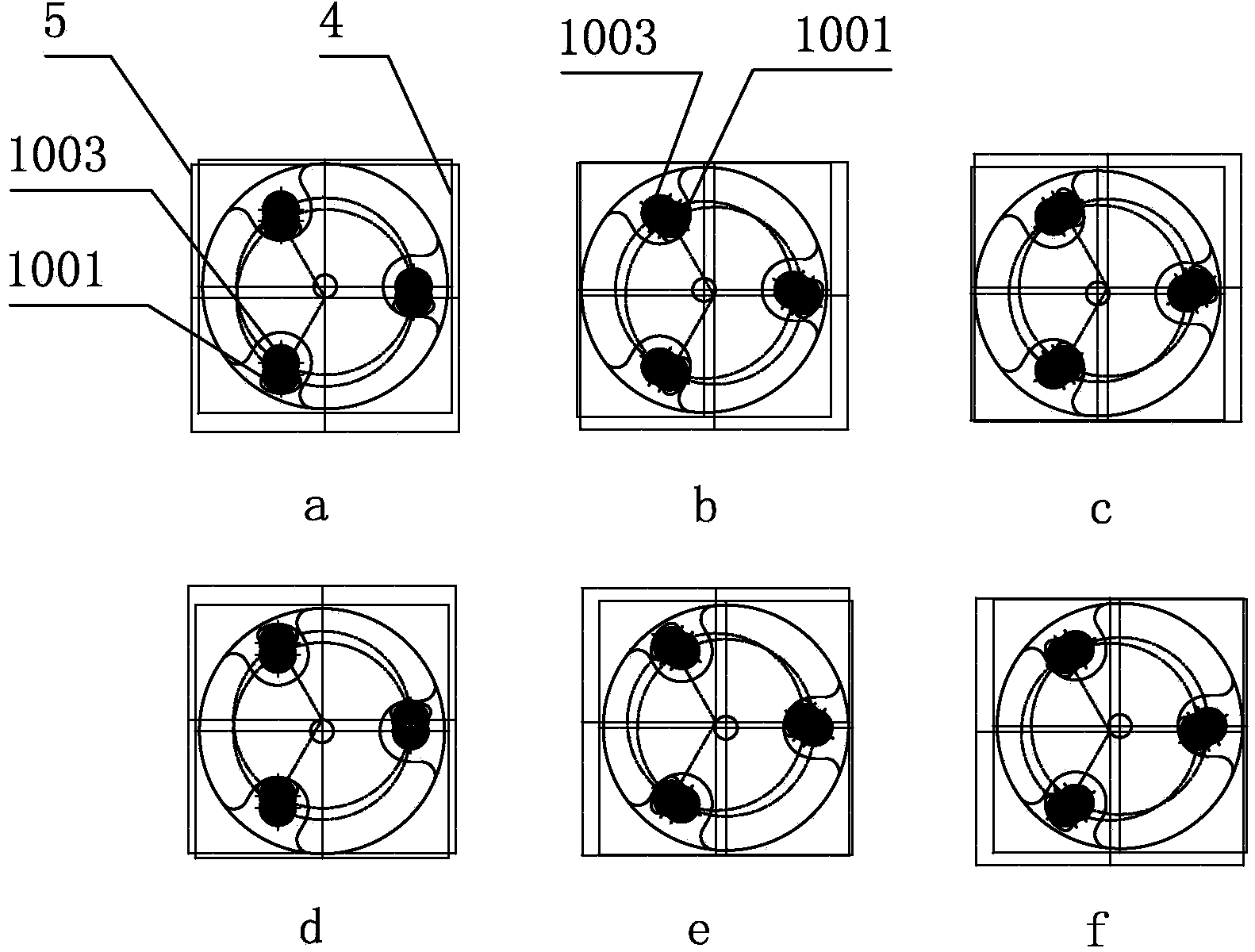

[0027] Such as figure 1 As shown, the scroll vacuum compressor includes a fixed scroll 18, a movable scroll 5 and a crankshaft 1 passing through the base 4, and the fixed scroll 18 and the movable scroll 5 cooperate with each other to form a working chamber. The crankshaft 1 includes a crankshaft front section 101 and a crankshaft rear section 102. The crankshaft front section 101 and the crankshaft rear section 102 are connected by crankshafts. The crankshaft front section 101 has a preset crankshaft eccentricity relative to the crankshaft rear section 102. The movable scroll 5 is installed on the crankshaft 1 At the front end, the movable scroll 5 is connected to the base 4 through the eccentric shaft 10, and the eccentricity of the eccentric shaft section connected to the movable scroll 5 relative to the eccentric shaft section connected to the base 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com