Recyclable bearing box

A technology of load-bearing boxes and boxes, applied in the field of packaging, can solve the problems of limited overall structural strength and bearing capacity, damage to metal coils, and shaking of cartons, and achieve the requirements of ensuring suspension stability, improving structural strength, and ensuring accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

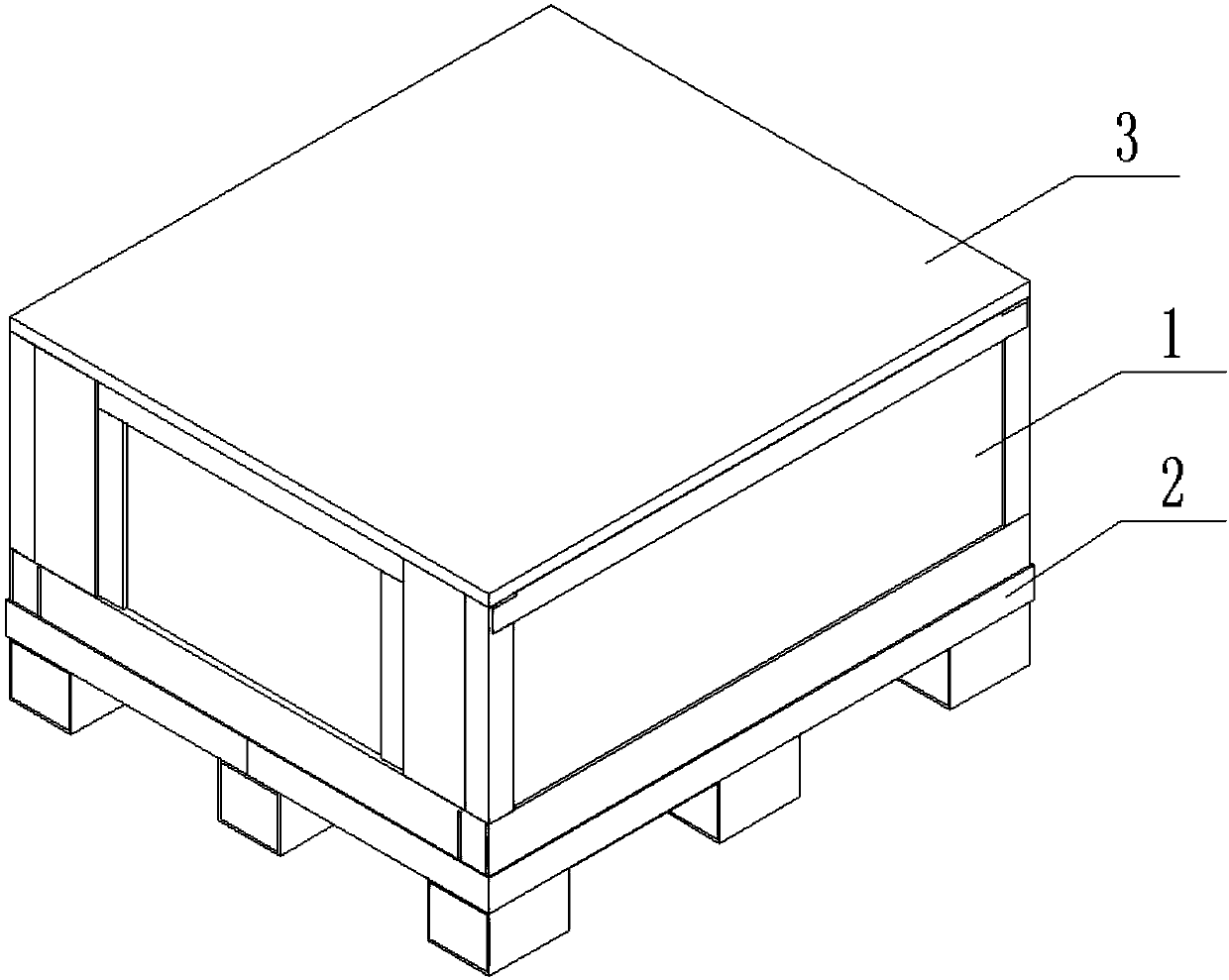

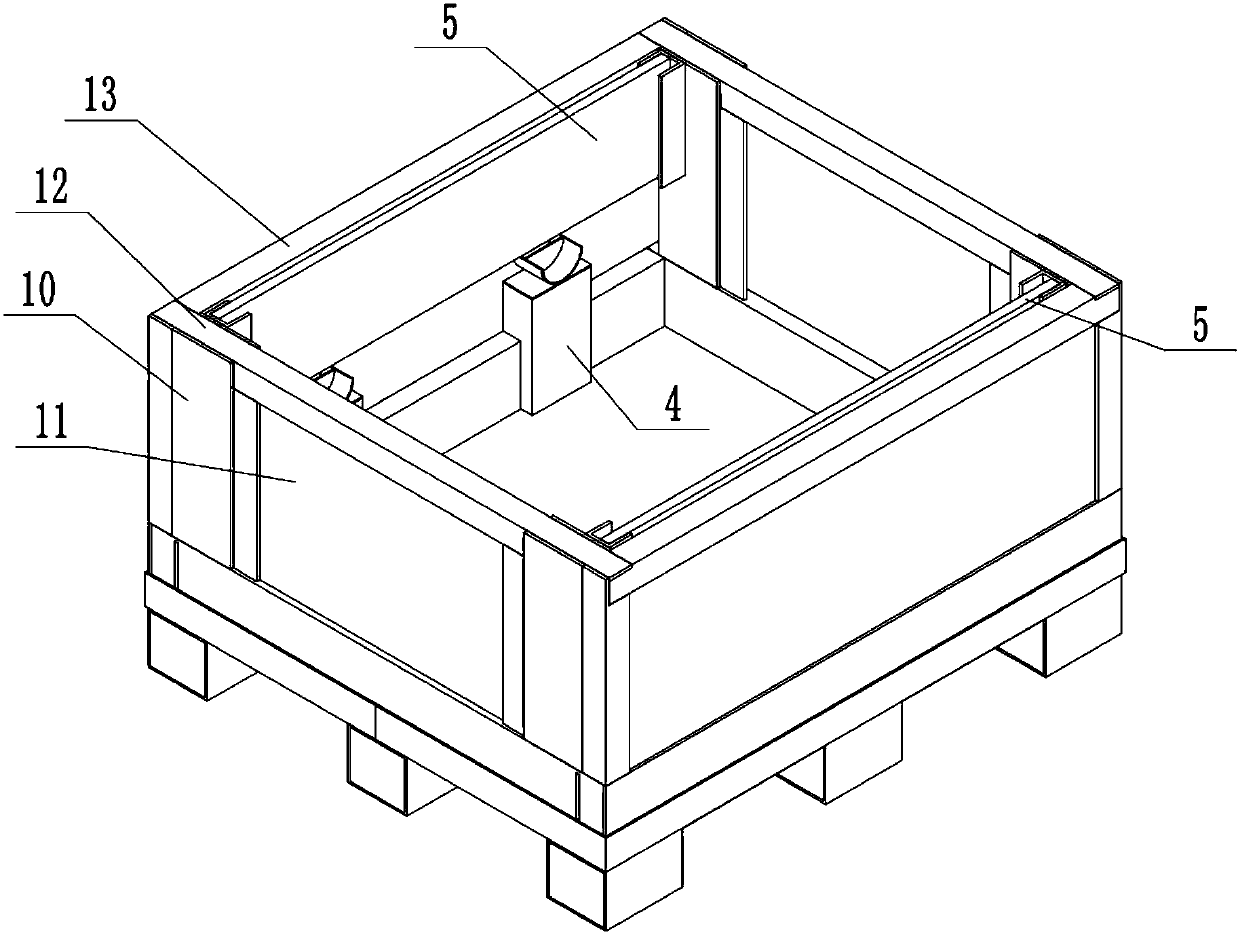

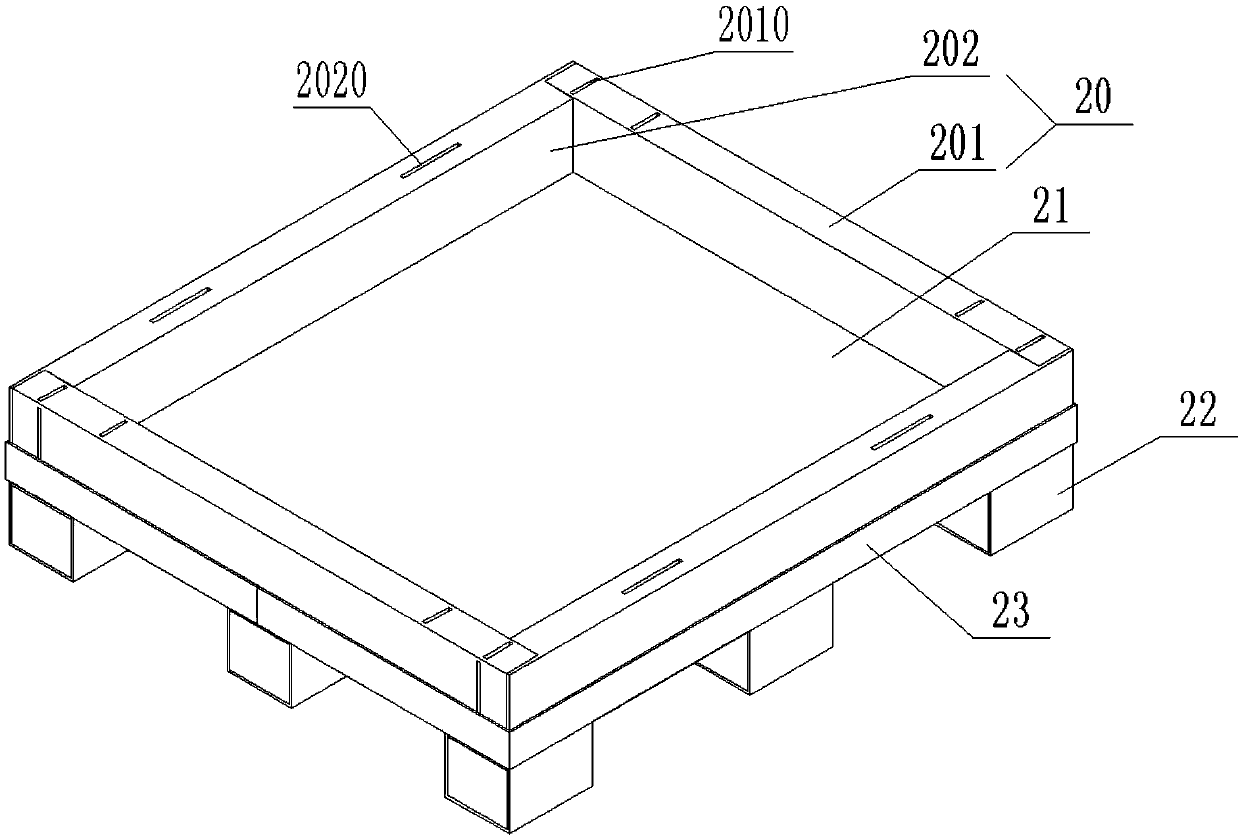

[0067] Such as Figure 1-37 As shown, a recyclable load-bearing box provided by the present invention includes a box body 1, a base 2 arranged below the box body 1, and a cover plate 3 arranged above the box body 1, and the box body 1 is provided with at least one For the bearing seat 4 used to support the mandrel wrapped with the coil, the bearing seat 4 is provided with a limiting part 402 for axially limiting the mandrel; the box 1 is located above the bearing seat 4. It is used for the finale plate 5 for compressing the mandrel.

[0068] The box body 1 includes a plurality of corner posts 10 and a plurality of box side panels 11, the plurality of corner posts 10 and the plurality of box side panels 11 form a ring structure, and the bottom of the corner posts 10 is provided with a The first inserting block 1001 ; the two ends of the finale inserting plate 5 are respectively connected with the two corner posts 10 . In this embodiment, the box body 1 includes four corner co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com