Metallurgical bridge crane

A bridge crane and pin shaft technology, which is applied in the direction of cranes, trolley cranes, load hanging components, etc., can solve problems such as safety accidents, ladle or ladle falling off, beam cracks, etc., to avoid safety accidents and facilitate replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

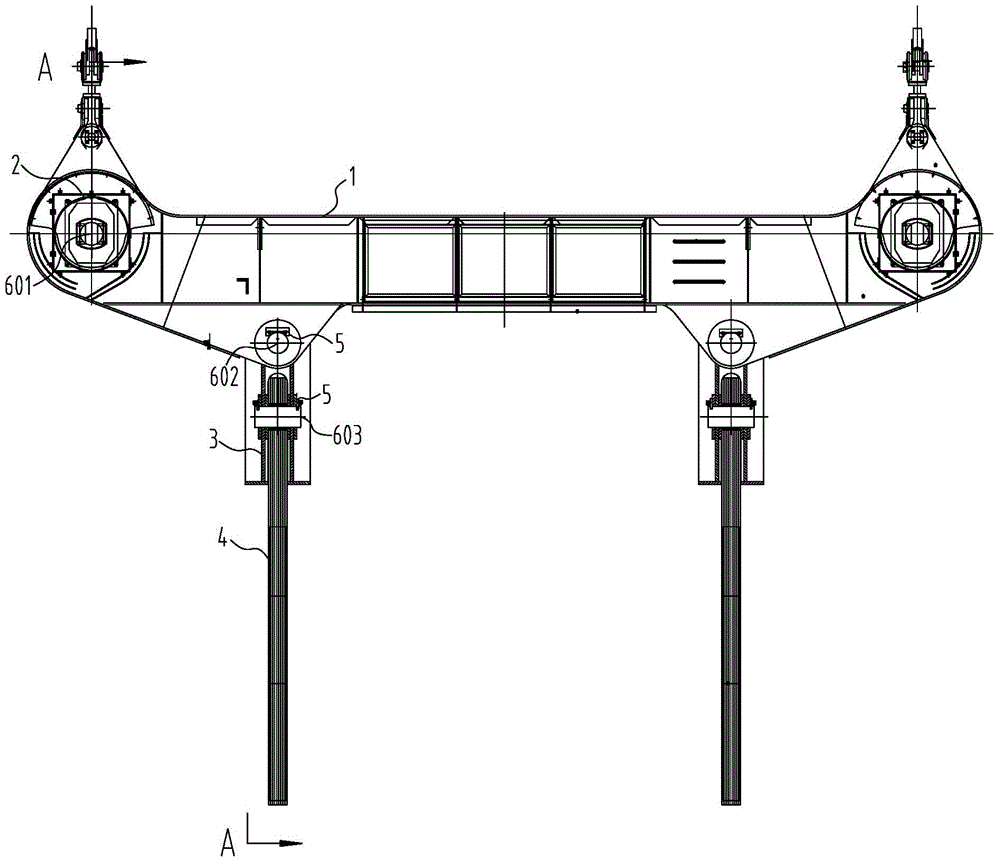

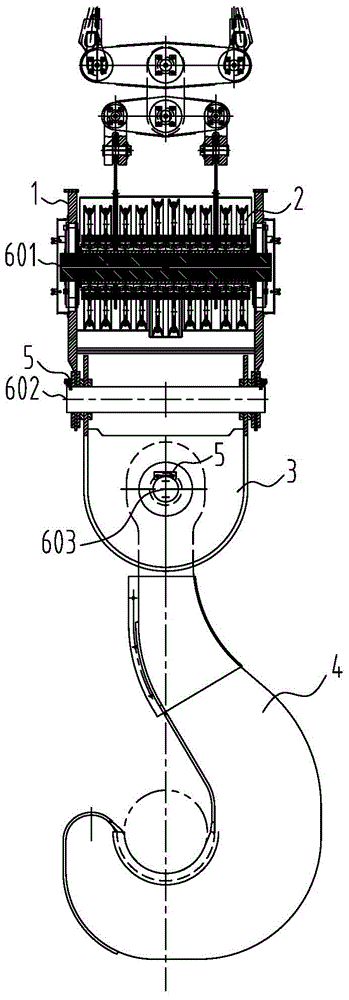

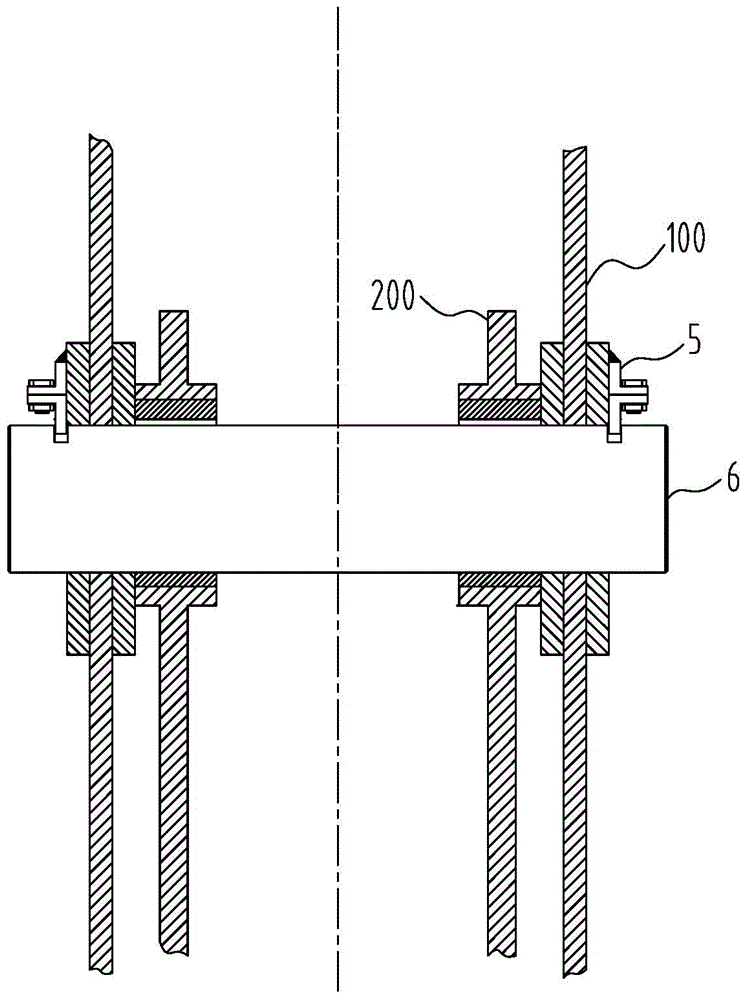

[0034] see Figure 5 ~ Figure 8 , the metallurgical bridge crane of the present invention includes a beam 1, a movable pulley block 2, a suspension fork 3, a suspension hook 4 (a plate hook is shown in the figure) and a plurality of pins 6 for forming hinged joints of two parts, The two parts comprise a first part 100 and a second part 200 located at least partially inside the first part 100 so as to form a hinge with the first part 100 via the pin 6 . Specifically, the two parts include but are not limited to the following situations, the first part 100 is the beam 1, the second part 200 is the moving pulley block 2; the first part 100 is the beam 1, and the second part 200 is the suspension fork 3 ; The first component 100 is the suspension fork 3, and the second component 200 is the suspension hook 4. Of course, this only sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com