Round tube segmenting machine

A segmented machine and round tube technology, applied in metal processing and other directions, can solve the problems of difficult positioning, axial and radial movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

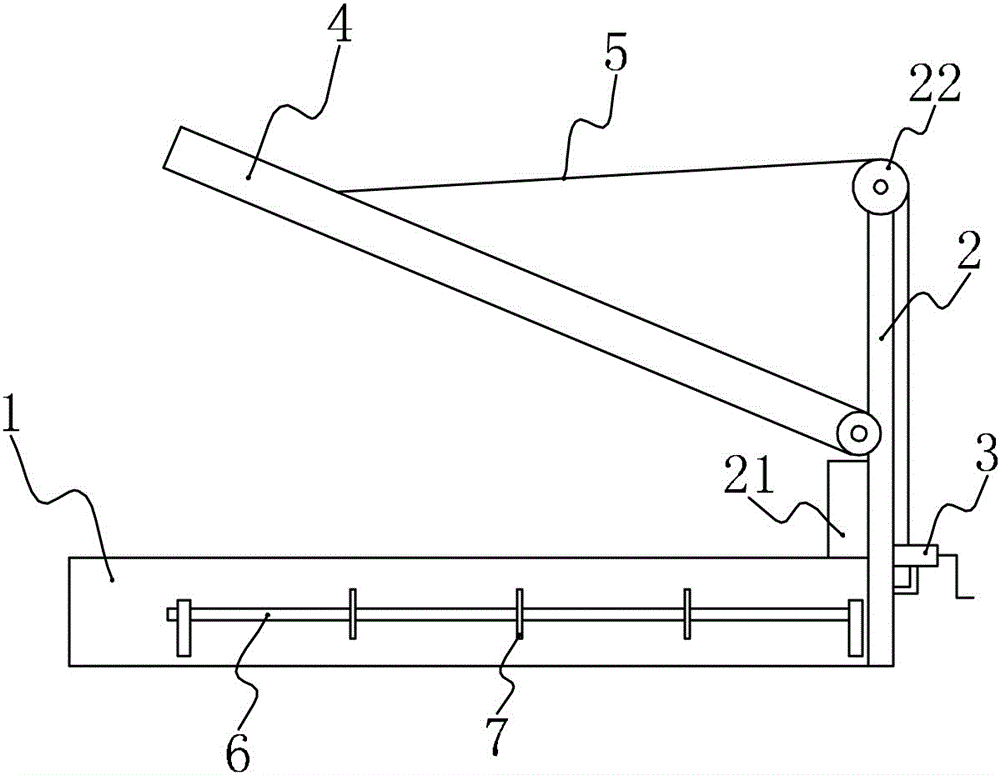

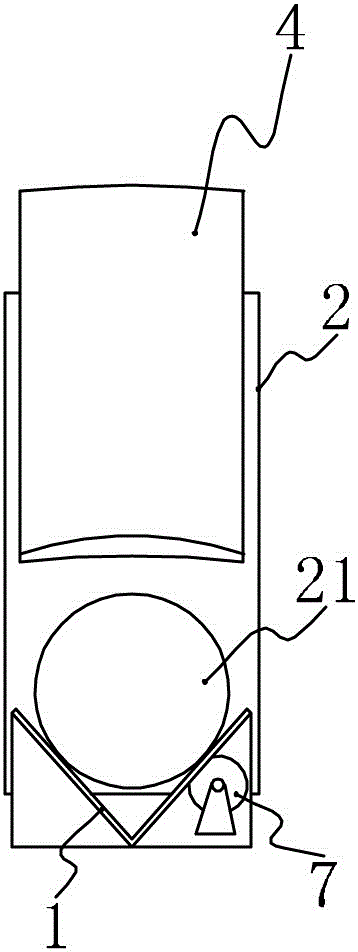

[0013] Such as figure 1 and figure 2 As shown, the round pipe segmenting machine of the present invention includes a fixed base, and the base is provided with a round pipe fixing device and a breaking device. The round pipe fixing device includes a V-shaped limiting groove 1 arranged axially along the round pipe, and the included angle of the limiting groove 1 is 90°. The inner end surface of the limiting groove 1 is provided with a convex line that limits the axial sliding of the circular tube. This setting can better play the role of axial limit through the cooperation of the convex strip and the corrugation on the round tube. The right end of the limit groove 1 is provided with a vertical support plate 2, a circular limit boss 21 is provided on the side of the support plate 2 opposite to the limit groove 1, and a hinge wheel is arranged on the other surface of the support plate 2. 3. A pressure plate 4 is hinged on the support plate 2 above the limiting boss 21, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com