Bearing

A bearing, a pair of technology, applied in the direction of bearings, bearing components, roller bearings, etc., can solve the problems of small axial load capacity, limited application occasions, power loss, etc., achieve good axial load capacity, avoid power loss, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

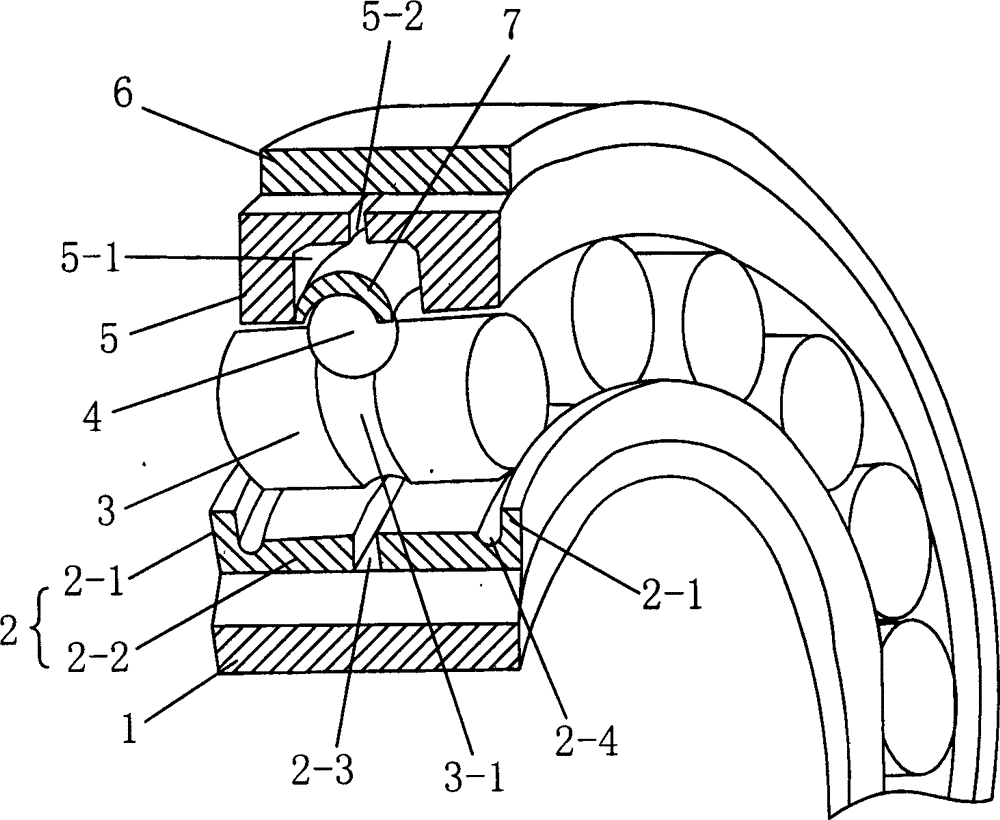

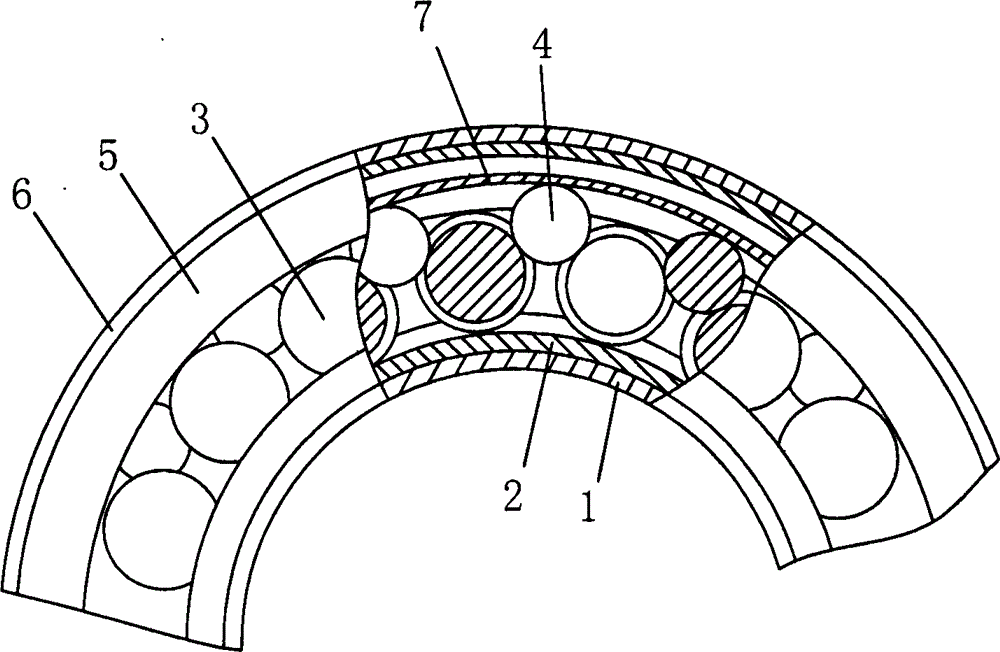

[0026] Example 1: Single row bearing

[0027] See Figure 1-2 , the bearing of this embodiment includes: an inner ring 1, a secondary inner ring 2 tightly fitted on the inner ring 1, rollers 3 distributed on the secondary inner ring 2, and a pair of adjacent rollers 3 arranged between The rollers 4, the annular bridge hoops 7 sleeved on each roller 4, the secondary outer ring 5 tightly sleeved on the bridge hoops 7, and the outer ring 6 tightly sleeved on the secondary outer rings 5; The rollers 3 are axially distributed, and each roller 3 is provided with an annular groove 3-1 with a circular arc-shaped cross section, and the rollers 4 are located between the annular grooves 3-1 of adjacent rollers 3; The inner ring of 7 is provided with an arc-shaped groove suitable for movable cooperation with the roller 4; the auxiliary inner ring 2 includes a pair of axially symmetrical distribution on the outer circumference of the inner ring 1, and the outer side of the auxiliary inner...

Embodiment 2

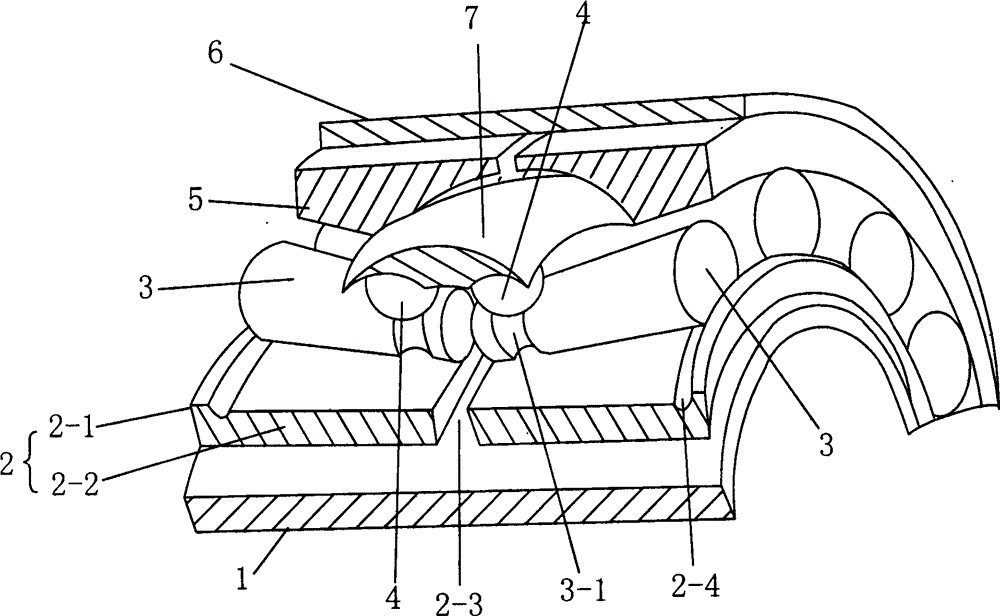

[0033] Example 2: Double column bridge bearing

[0034] On the basis of the above-mentioned embodiment 1, the bearing of this embodiment has the following modifications:

[0035] Such as image 3 , at the same radian position, each of the pair of secondary inner rings 2 is provided with a roller 3, the pair of rollers 3 are axially symmetrically distributed, and the annular groove 3-1 is arranged in the inner ring adjacent to each roller 3 end; the roller 4 is between the annular grooves 3-1 of adjacent rollers 3 distributed on the same circumference; A pair opposite to the annular groove 3-1.

[0036] The roller 3 is in the shape of a truncated cone, and the top end of the roller 3 in the shape of a truncated cone is the inner end; The truncated conical roller is suitable for decomposing the axial force into the radial direction, so it has better axial load capacity, and the roller will not be displaced; More rollers are beneficial to increase the radial load capacity.

...

Embodiment 3

[0042] The assembly method of the bearing described in the above embodiment 1 or 2 includes in sequence:

[0043] The bridge hoop 7 is arranged in the outer ring 6, and then the pair of auxiliary outer rings 5 are symmetrically arranged between the outer ring 6 and the bridge hoop 7;

[0044] The roller 4 and the roller 3 are sequentially arranged on the inner ring of the hoop 7;

[0045]The pair of auxiliary inner rings 2 are arranged symmetrically inside each roller 3;

[0046] The inner ring 1 is tightly fitted on the inner rings of the pair of secondary inner rings 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com