An electronic expansion valve

An electronic expansion valve and valve seat technology, applied in the field of expansion valves, can solve the problems affecting the use effect of the electronic expansion valve, high assembly precision requirements, difficult valve needle processing, etc., to improve work stability, high valve needle strength, The effect of low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

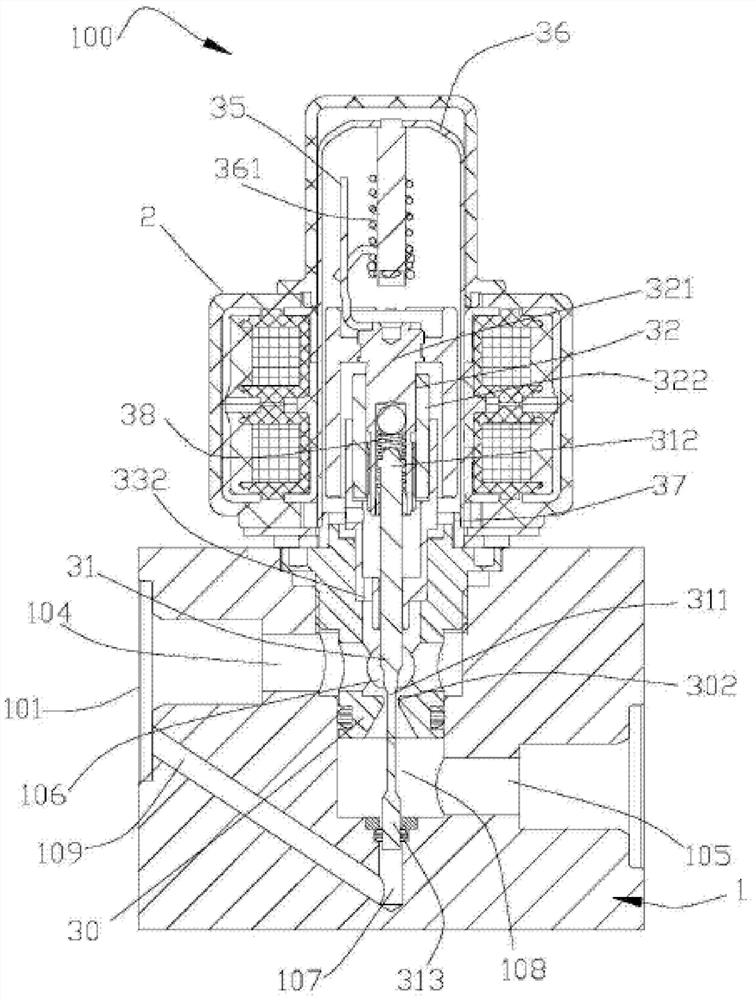

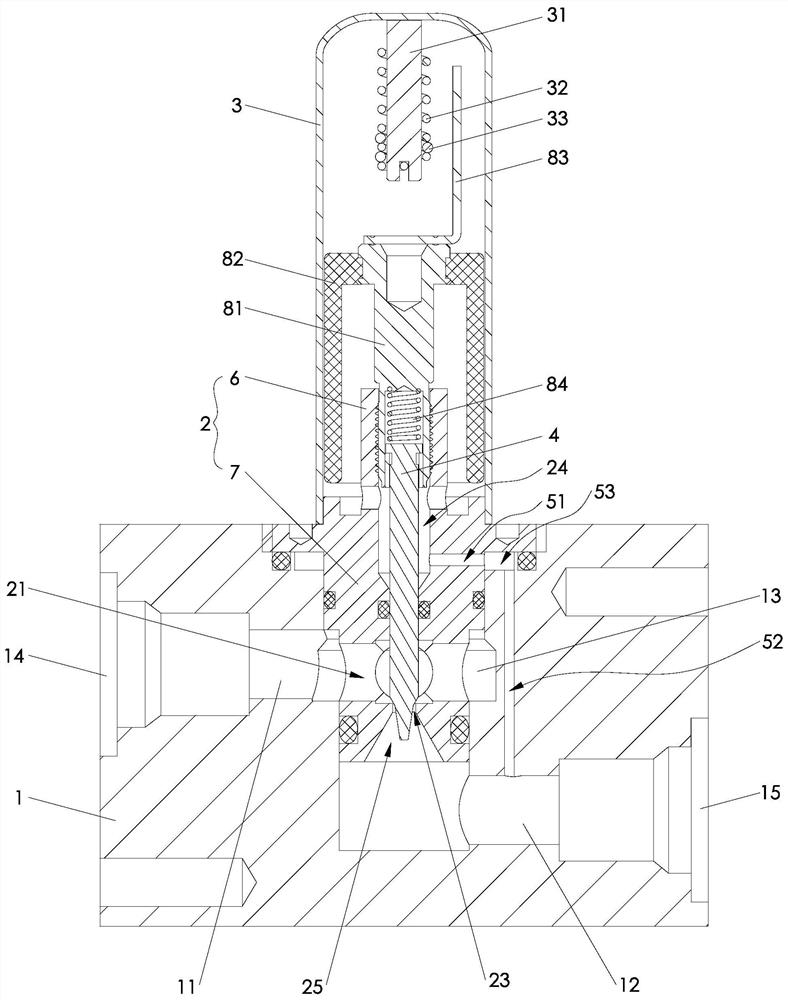

[0035] Such as figure 2 As shown, the electronic expansion valve provided by Embodiment 1 of the present invention includes a valve body 1 , a valve seat 2 and a sleeve 3 , the valve seat is fixed on the valve body, and the sleeve is fixedly sleeved on the valve seat.

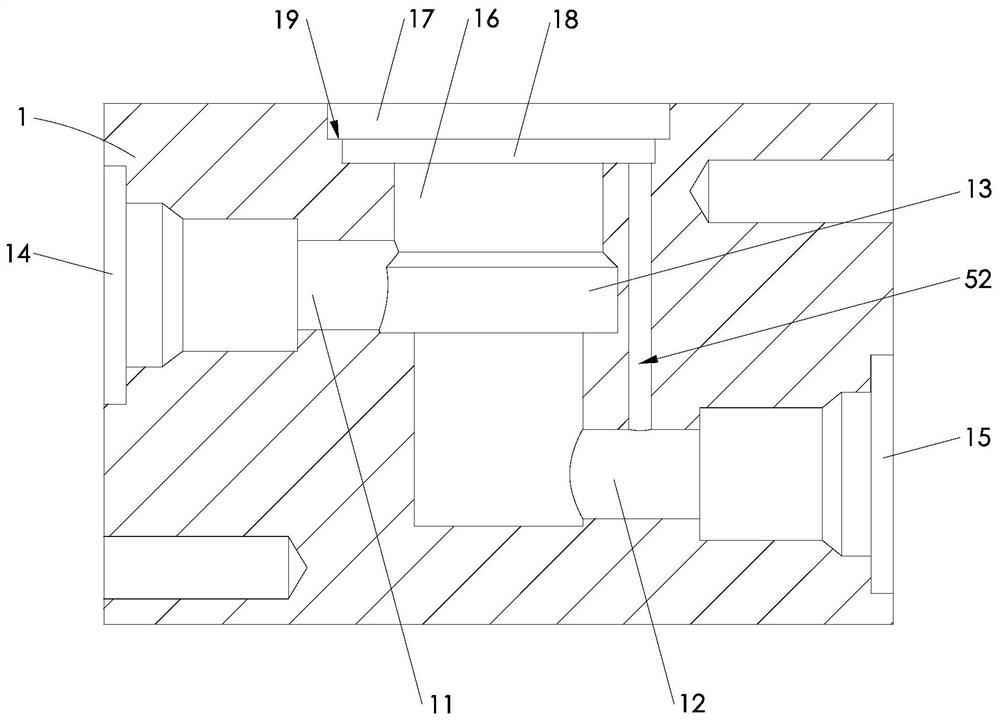

[0036] Such as image 3 As shown, the valve body 1 is provided with a first passage 11, a second passage 12 and an intermediate passage 13 between the first and second passages, and one side of the valve body is provided with a first port 14 communicating with the first passage 11 , The other side is provided with a second port 15 communicating with the second channel 12 . The top of the middle channel 13 is provided with a mounting hole 16 for the valve seat 1 to be loaded into. The top of the mounting hole is provided with a counterbore 17 coincident with the axis of the mounting hole. The aperture of the counterbore is larger than the aperture of the mounting hole.

[0037] Such as Figure 4 As shown, th...

Embodiment 2

[0052] Such as Figure 5 As shown, the difference between the second embodiment and the first embodiment above is that the valve seat 2 includes a nut seat 9 and a valve port seat 7 fixed together after separate molding, and the nut seat 9 is provided with a nut 6 and a fixing part 26 , the connecting portion 27 and the upper balance hole 51 are all located on the nut seat 9, and the valve port 23 is located on the valve port seat 7.

[0053] When the valve seat adopts a split structure, each part has a simple structure and is easy to process, and each part can be assembled with different materials after processing, which is conducive to reducing material costs while meeting the use requirements.

Embodiment 3

[0055] Such as Image 6 As shown, the difference between the third embodiment and the first embodiment above is that the valve seat 2 includes a nut 6 and a valve port seat 7 fixed together after separate molding, the valve port 23, the upper balance hole 51, the fixing part 26 and the The connecting parts 27 are all arranged on the valve seat 7 . The top of the valve seat 7 is provided with a fixing hole matching the bottom of the nut 6, and the nut is fixed on the valve seat by means of welding or interference fit.

[0056] When the valve seat adopts a split structure, each part has a simple structure and is easy to process, and each part can be assembled with different materials after processing, which is conducive to reducing material costs while meeting the use requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com