Method for reducing airfoil differential pressure resistance of fixed-wing aircraft

A pressure differential resistance, aircraft technology, applied in the field of aviation, can solve the problem of inability to eliminate turbulence in the wake area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

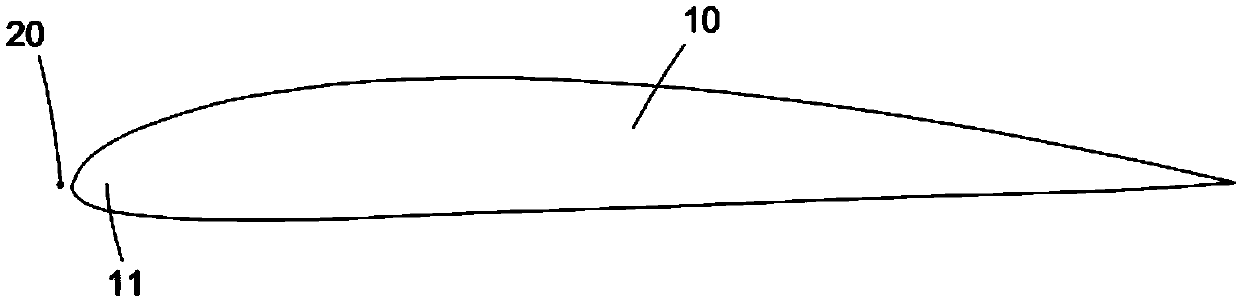

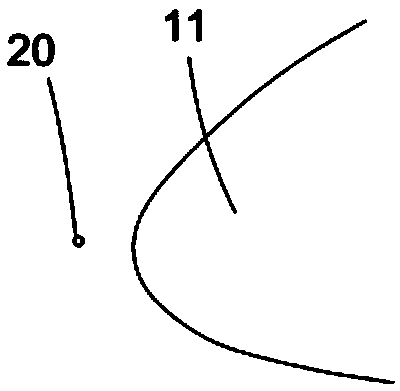

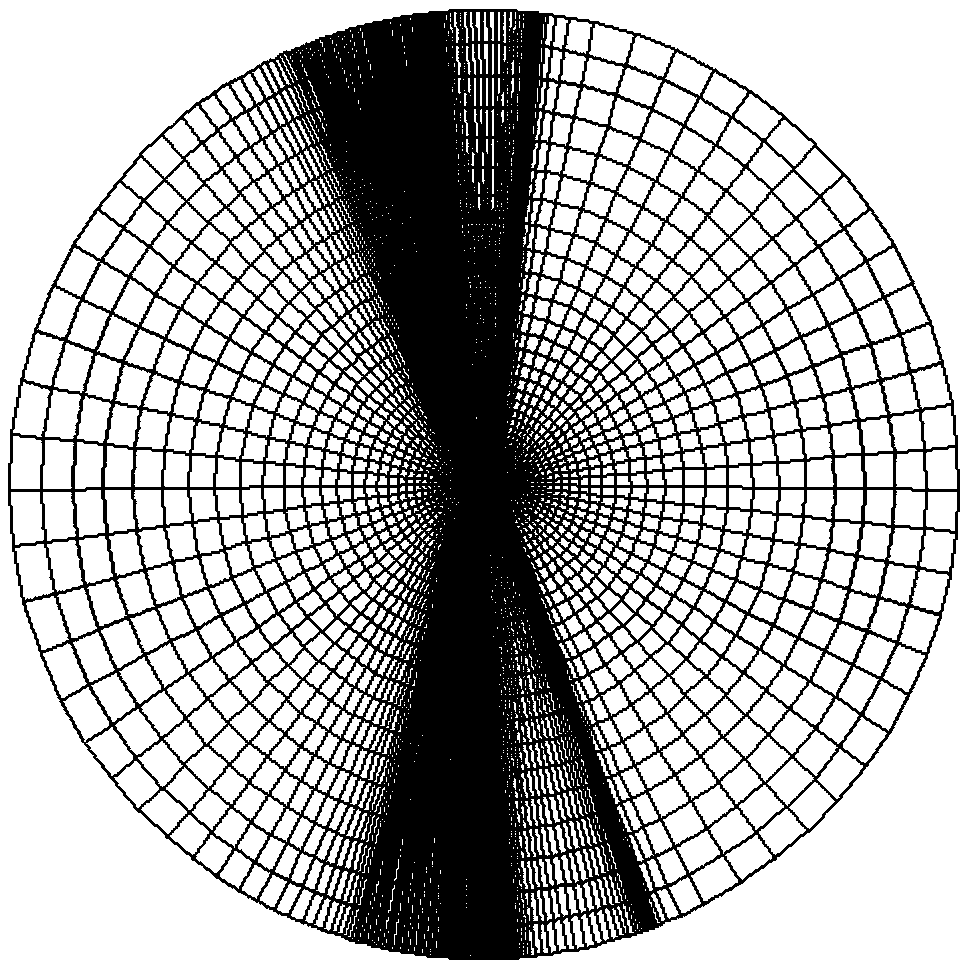

[0023] combine figure 1 , figure 2 , a method for reducing the airfoil pressure resistance of a fixed-wing aircraft: a steel wire 20 is arranged in front of the leading edge 11 of the airfoil.

[0024] The airfoil 10 is a CLARK Y airfoil.

[0025] One end of the steel wire 20 can be fixed on the fuselage of the aircraft, and the other end is fixed on the outer side of the wing. Alternatively, both ends of the steel wire are fixed on the wing, specifically, one end of the steel wire is fixed on the inner side of the wing, and the other end of the steel wire is fixed on the outer side of the wing. The inner end of the wing refers to the end of the wing close to the fuselage, and the outer end of the wing refers to the end of the wing away from the fuselage.

[0026] The diameter of the steel wire 20 depends on the thickness of the airfoil. As a preference, the diameter of the steel wire 20 has a difference of more than 50 times the thickness of the airfoil, that is, the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com