Wet brake convenient to disassemble and assemble

A technology of wet brakes and brake discs, which is applied in the direction of brake types, brake parts, mechanical equipment, etc., can solve the problem of lower work efficiency, cumbersome disassembly and assembly process, and is not suitable for indoor and outdoor dust, sand, iron filings, etc. Wet water ground places and other problems, to achieve the effect of easy disassembly and assembly, and solve the effect of inconvenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

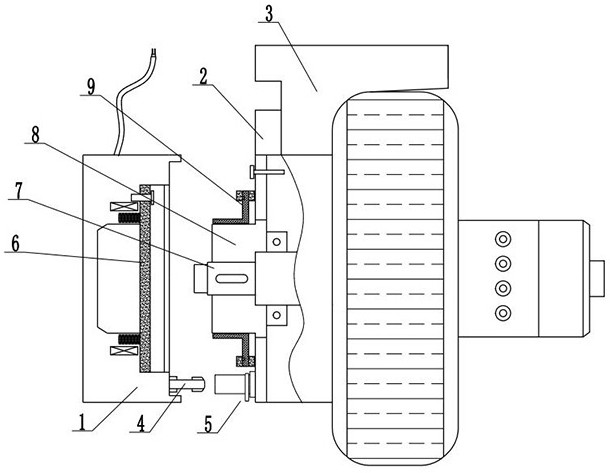

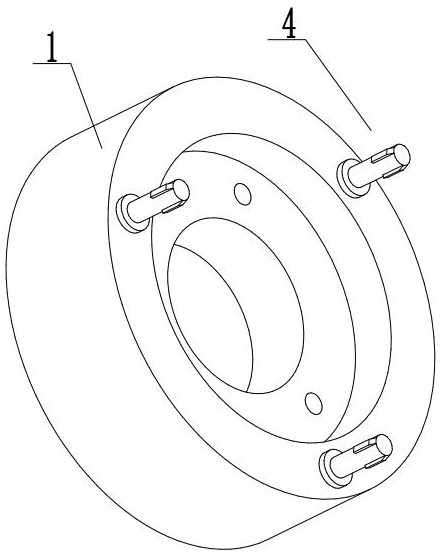

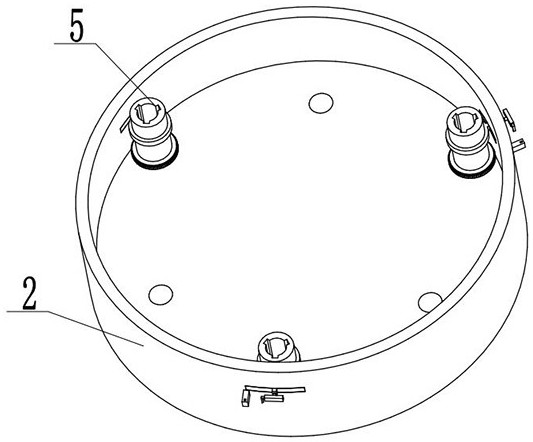

[0015] see Figure 1 to Figure 17 , this embodiment provides a wet brake that is easy to disassemble and assemble, including a main body wire pack 1, an outer brake disc 2, a reduction box 3, an inner brake disc 6, a transmission shaft 7, a transmission gear 8 and a friction plate 9, so The outer brake disc 2 is fixedly connected to the reduction box 3, the inner brake disc 6 is fixedly connected to the main body wire package 1, the transmission gear 8 is connected to the transmission shaft 7 by a key, and the friction plate 9 is movable. It is sleeved on the outside of the transmission gear 8, and also includes:

The plug part 4 on the main body wire package 1 is provided with a straight rod 41, and the surface of the straight rod 41 is connected with a number of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com