A hydraulic-based self-correction system for small and medium diameter deep hole machining

A self-correcting, small and medium technology, used in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve problems such as tool instability, insufficient tool rigidity, axis deflection, etc., to ensure processing stability and improve rigidity. , the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

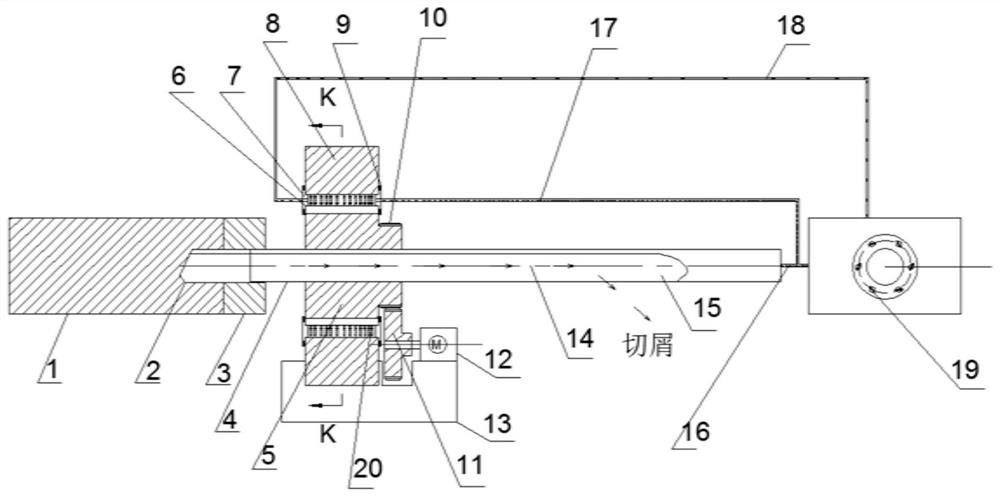

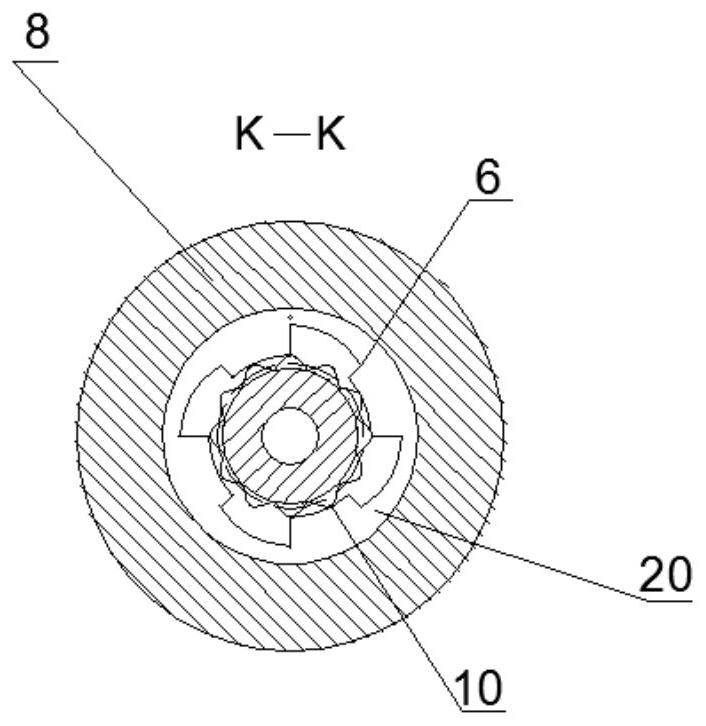

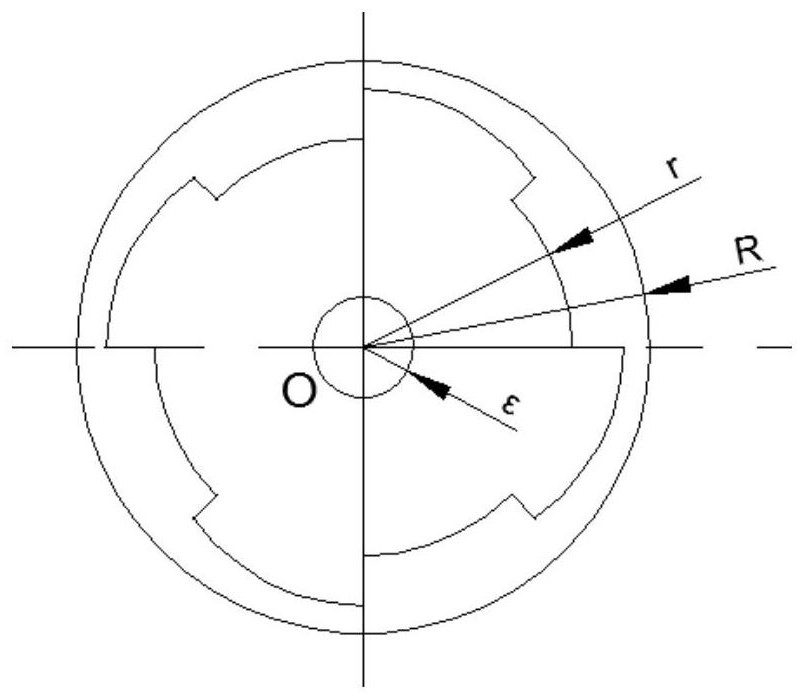

[0046] This deep hole processing deviation correction system is mainly used to improve small and medium diameter deep holes ( The following) axis deflection problem during processing, used in conjunction with carbide gun drills, such as Figure 1-12 As shown, the self-correcting system of the present invention includes parts such as workpieces, cutters, main and auxiliary oil circuits, and correcting bodies.

[0047] The workpiece part includes a workpiece 1 and a drill sleeve 3 .

[0048] The cutter part includes a drill bit 2 and a drill rod 4 on which a V-shaped groove 15 is opened.

[0049] The self-correcting body includes an outer sleeve 8 , an inner sleeve 5 , an elastic plug 7 , a sealing ring 9 , an external motor 12 and a supporting device 13 .

[0050] The main and auxiliary oil passages include an oil feeder 19 , a main oil passage 16 , a debri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com