Low-frictional-loss thrust conical roller bearing

A tapered roller bearing and tapered roller technology, applied in the field of bearings, can solve problems such as reducing bearing efficiency, friction element wear, reducing bearing life, etc., to improve bearing efficiency and bearing fatigue life, reduce friction, and ensure contact strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

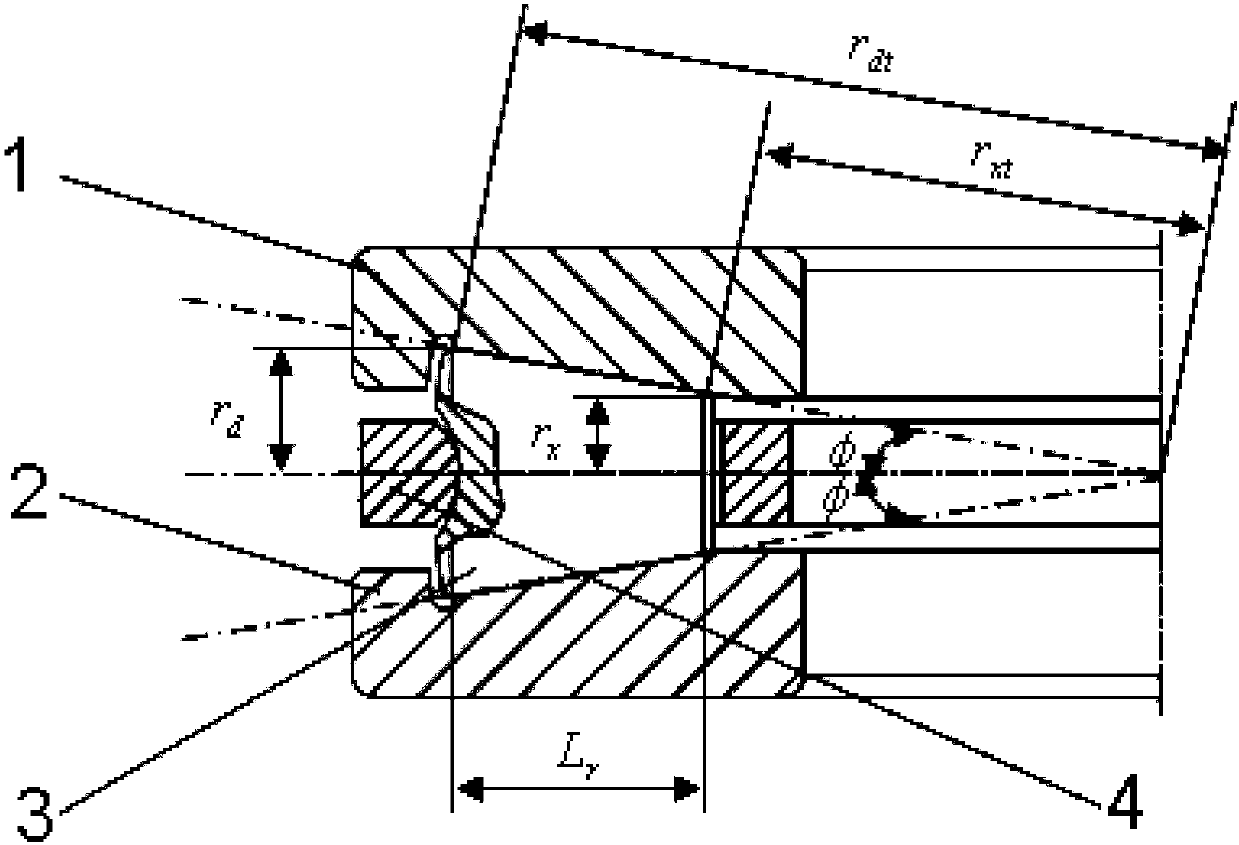

[0069] It is a thrust tapered roller bearing with upper and lower symmetry on the raceway of the upper and lower rings, as shown in the attached figure 1 As shown, the large end face of the tapered roller is a concave axisymmetric surface, and the contact part of the frame pocket of the cage and the large end of the tapered roller is a convex axisymmetric surface. The cage is an integral structure, and the tapered roller The end face of the big end is in contact with the frame pocket of the cage, and there is a gap between the big end of the roller and the rib of the raceway.

Embodiment 2

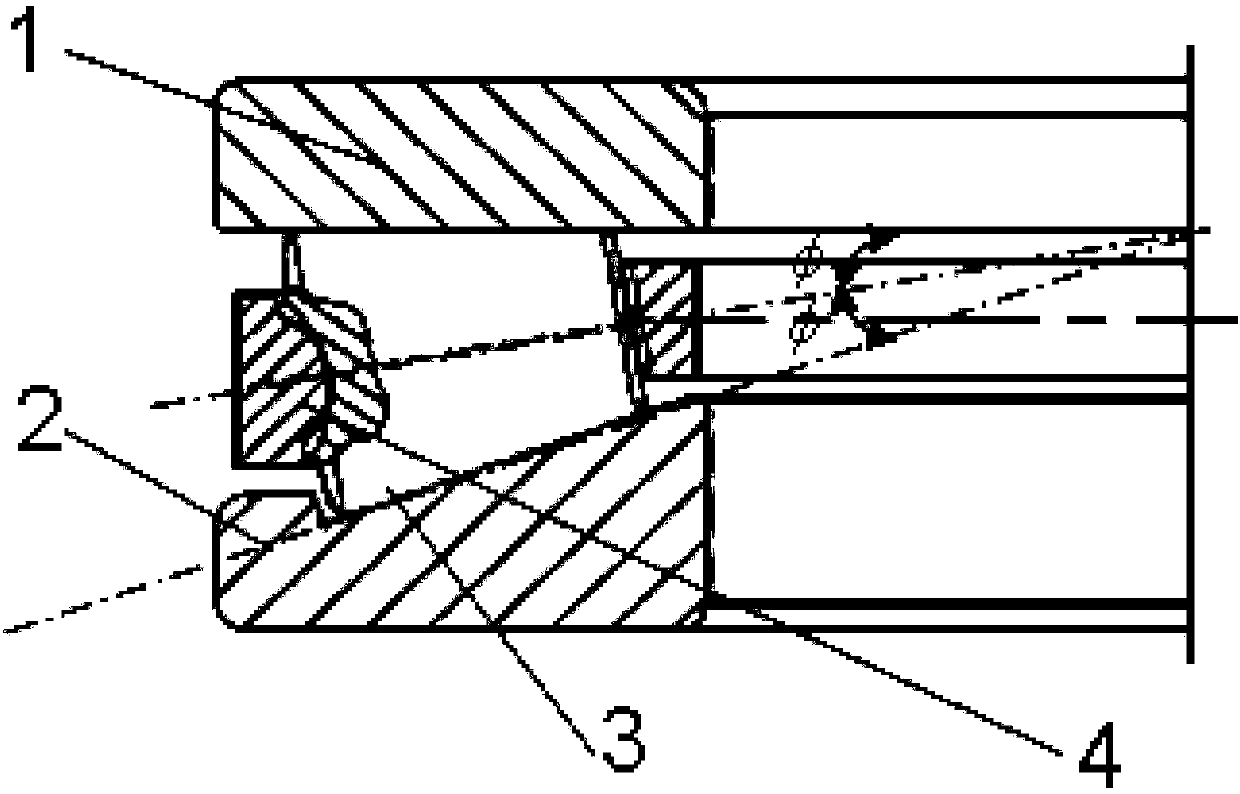

[0071] It is basically the same as Embodiment 1, except that the upper and lower ring raceways of the bearing are asymmetrical up and down, such as figure 2 As shown, the angle between the vertical line between the upper raceway and the bearing axis is 0 degrees, and the angle between the vertical line between the lower raceway and the bearing axis is the roller cone angle. The frame-shaped pockets of the cage are in contact, and there is a gap between the large end of the roller and the raceway rib.

Embodiment 3

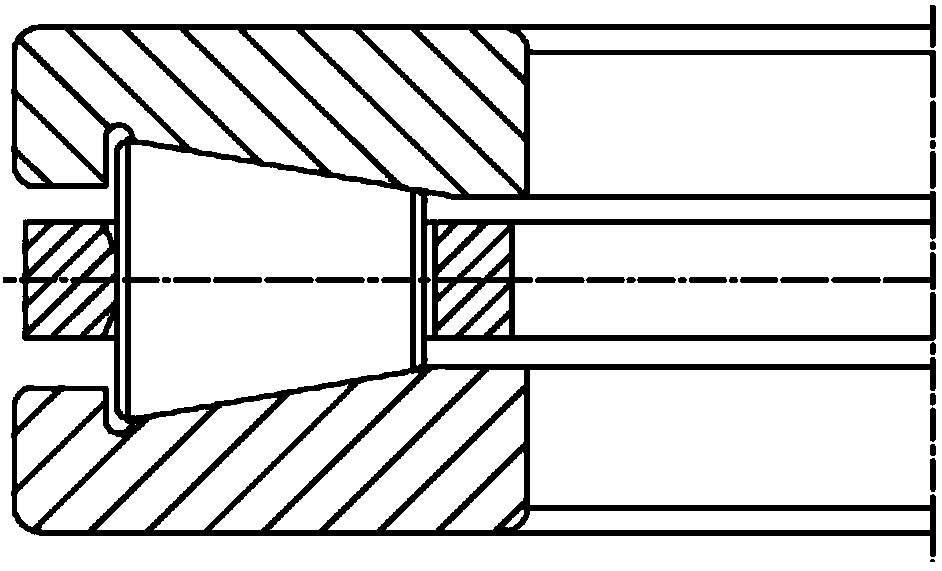

[0073] It is a thrust tapered roller bearing with upper and lower symmetry on the raceway of the upper and lower rings. As shown in Figure 3 (A), the large end face of the tapered roller is a plane perpendicular to the axis of the tapered roller, and the frame-shaped pocket of the cage is aligned with the axis of the tapered roller. The contact part of the large end of the tapered roller is a plane perpendicular to the axis of the tapered roller. The cage is an integral structure. The end face of the large end of the tapered roller contacts the frame-shaped pocket of the cage. gap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com