A winch rope arrangement

A technology of rope arranging devices and winches, which is applied in hoisting devices and clockwork mechanisms, etc., can solve the problems of short service life of ropes and narrow application range of rope arranging devices, so as to improve service life, increase application range, and move flexibly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

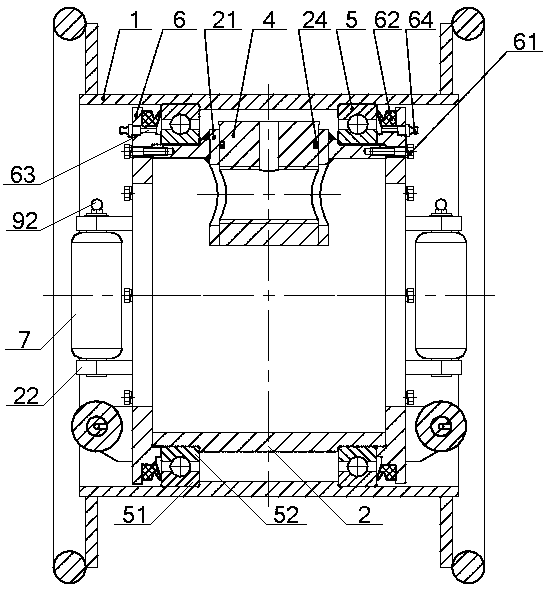

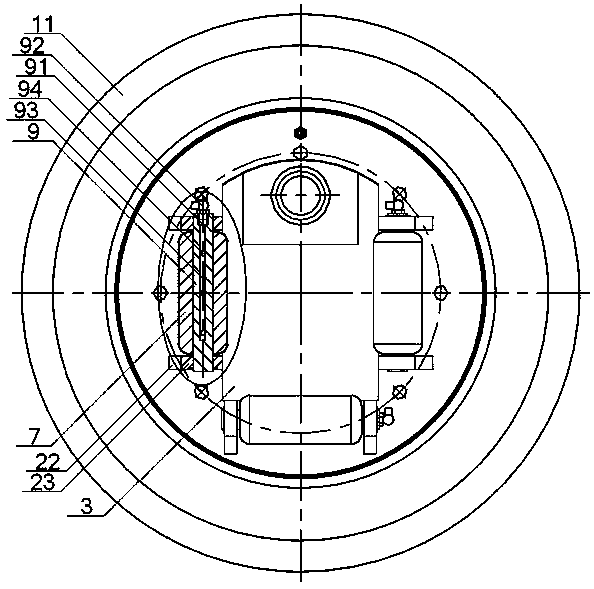

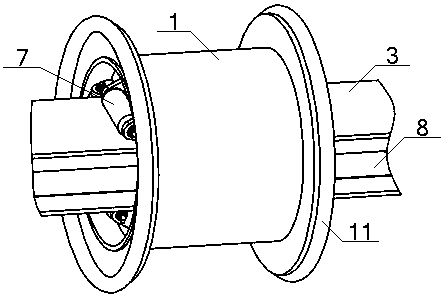

[0043] see Figure 1 to Figure 3 , a winch rope-removing device, comprising a rope-removing device cylinder 1 and a rope-removing device seat 2, the rope-removing device seat 2 is a cylindrical tubular structure, and the interior of the rope-removing device seat 2 runs through a slide along its axis direction. Rail 3, installation sleeve 21 is arranged on the outer peripheral surface of the rope row device seat 2, and the screw nut 4 is arranged in the installation sleeve 21, and the outer peripheral surface of the rope row device seat 2 is set on the rope row device cylinder 1 through the bearing 5 On the inner circumferential surface of the rope guide seat 2, both ends of the rope guide seat 2 are provided with a rope guide end cover 6, and the two ends of the rope guide seat 2 are provided with three rollers 7, and the three rollers 7 are connected to the slide rail 3 respectively. The three end surfaces of the sliding rail 3 are in contact with each other, and the other en...

Embodiment 2

[0045] Basic content is the same as embodiment 1, the difference is:

[0046] see Figure 1 to Figure 3 , the roller 7 is a cylindrical structure, the roller 7 is set on the roller shaft 9, and the roller 7 and the roller shaft 9 are in clearance fit, and the two ends of the roller shaft 9 are respectively installed on the two ear plates 22 on the rope row seat 2 Above, a retaining ring 23 is provided between the end of the roller shaft 9 and the ear plate 22; the end of the roller shaft 9 is provided with a No. 1 oil injection hole 91, and a No. 1 oil nozzle 92 is installed in the No. 1 oil injection hole 91. The roller The shaft 9 is provided with an oil groove 93 communicating with the No. 1 oil hole 91 along its axial direction, and the outer circumferential surface of the roller shaft 9 is provided with an oil hole 94 communicating with the oil groove 93; the manufacturing materials of the roller 7 and the roller shaft 9 All are stainless steel.

Embodiment 3

[0048] Basic content is the same as embodiment 1, the difference is:

[0049] see figure 1 , the number of the bearings 5 is two, and the two bearings 5 are symmetrically arranged at both ends of the rope rower seat 2; the inner peripheral surface of the rope rower cylinder 1 is provided with a No. Cooperate with the outer ring 51 of the bearing 5, the outer peripheral surface of the said rope row device seat 2 is provided with a No. 6 to block the bearing 5; the end cover 6 of the rope arrangement is fixedly installed on the seat 2 of the rope arrangement through bolts 61 and spring washers, the end cover 6 of the rope arrangement blocks the inner ring 52 of the bearing 5, and the end cover 6 of the rope arrangement A V-shaped ring 62 is installed, and the lip of the V-shaped ring 62 is in contact with the outer ring 51 of the bearing 5; the end cover 6 of the rope arranger is provided with a second oil injection hole 63, and two oil injection holes 63 are installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com