Gas cutting guiding device

A guiding device and gas cutting technology, applied in auxiliary devices, gas flame welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as increased machine tool maintenance costs, equipment machining accuracy, tool wear, etc., to facilitate large-scale investment Use, improve gas cutting work efficiency, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

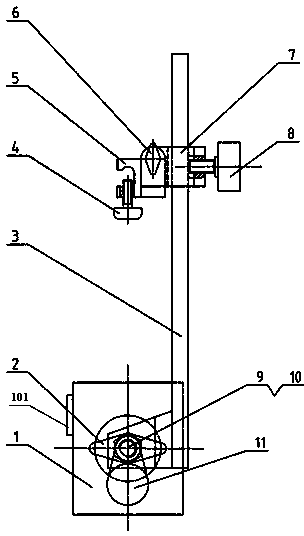

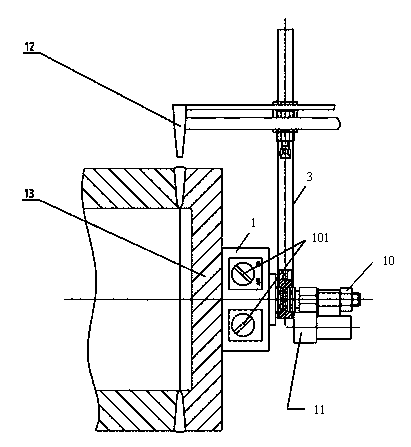

[0023] The following combination Figure 1 ~ Figure 3 , a preferred embodiment of the present invention is described in detail.

[0024] Such as figure 1 Shown is a schematic structural view of the gas cutting guide device in the present invention. The gas cutting guide device includes a clamping and positioning mechanism and a variable speed transmission mechanism 11; the clamping and positioning mechanism includes an end cover connecting guide mechanism and a gas cutting torch installation and positioning mechanism.

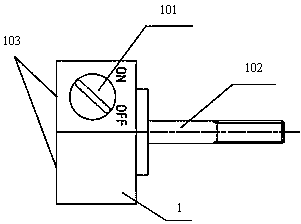

[0025] Wherein, the end cover connection guide mechanism includes a magnetic block 1 and a guide block 3 . Such as figure 2 As shown, the magnetic control switch 101 is installed on the magnetic block 1, the magnetic control switch 101 is turned on, and the magnetic adsorption area 103 of the magnetic block 1 can be controlled to have magnetism, so that the magnetic block 1 can be fixedly installed on the pipe end The end face of the cover 13; when the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com