Horizontal type multiple-stage centrifugal pump

A centrifugal pump and horizontal technology, applied in the field of horizontal multi-stage centrifugal pumps, can solve the problems of shortening the service life of the balance disc and the balance ring, wear of the balance disc and the balance ring, affecting the normal operation of the centrifugal pump, etc. The effect of prolonging the service life and working stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

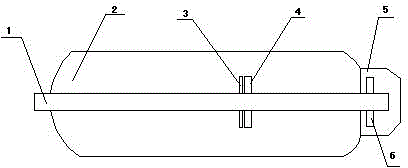

[0008] Horizontal multistage centrifugal pump, the centrifugal pump includes carbon steel shaft 1, cast iron impeller 6, balance plate 4, rolling bearing 5, tension bolt 3 and filler 2, and the two ends of the cast iron impeller 6 are supported on the carbon steel shaft 1, the balance plate 4 is fixedly connected to the carbon steel shaft 1 through the tension bolt 3, the filler 2 is arranged at both ends of the carbon steel shaft 1, and the carbon steel shaft 1 is equipped with a rubber water retaining ring , O-shaped rubber sealing ring, the cast iron impeller 6 is provided with vulnerable parts such as impeller sealing ring and guide vane cover to prevent wear of the middle section and guide vane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com