Patents

Literature

62results about How to "Eliminate relative sliding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

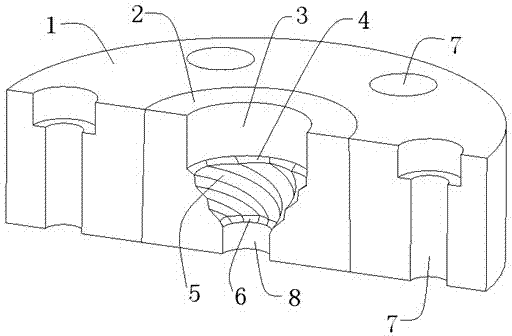

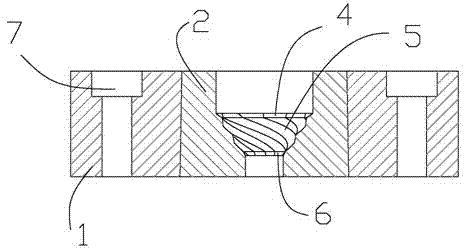

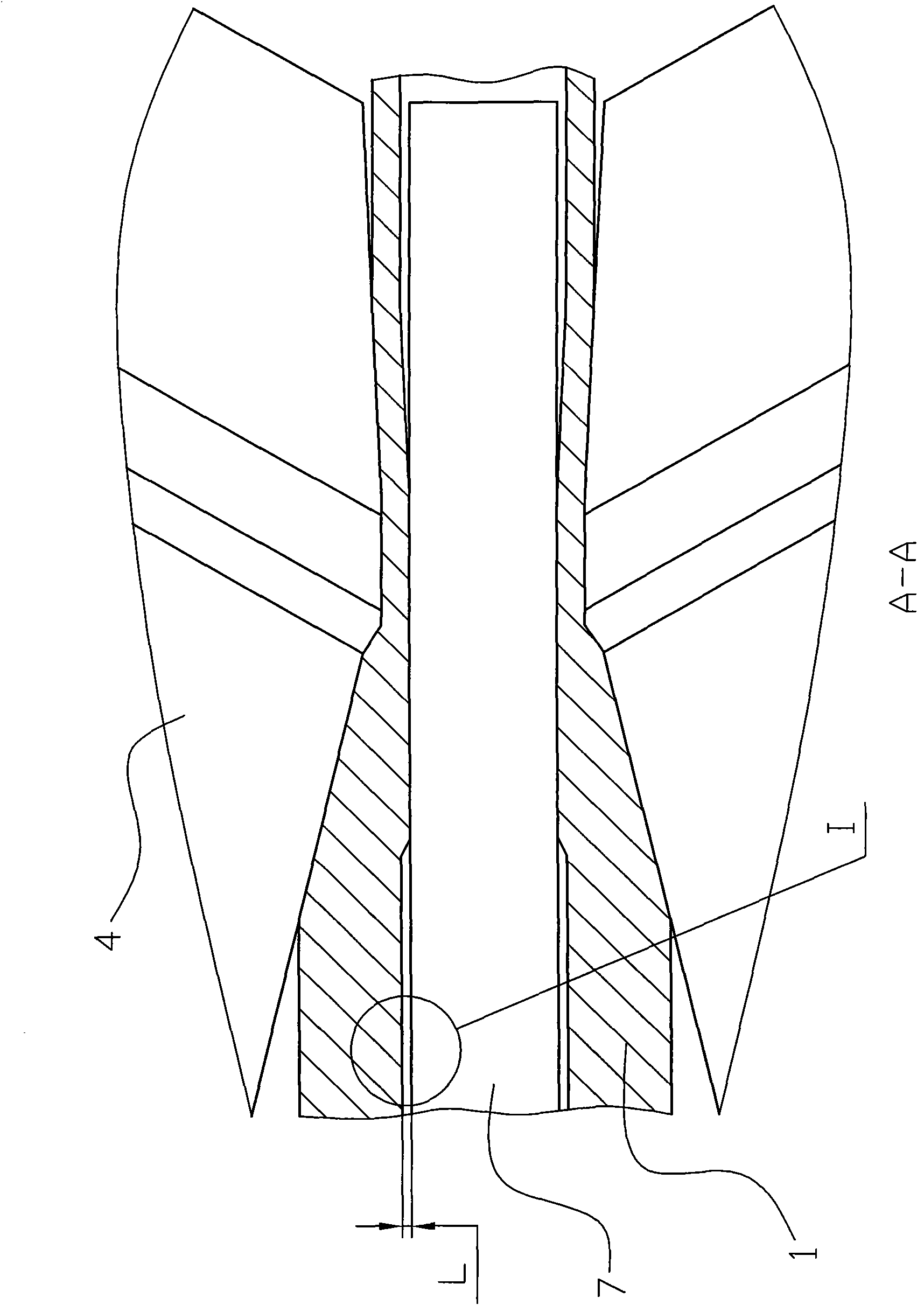

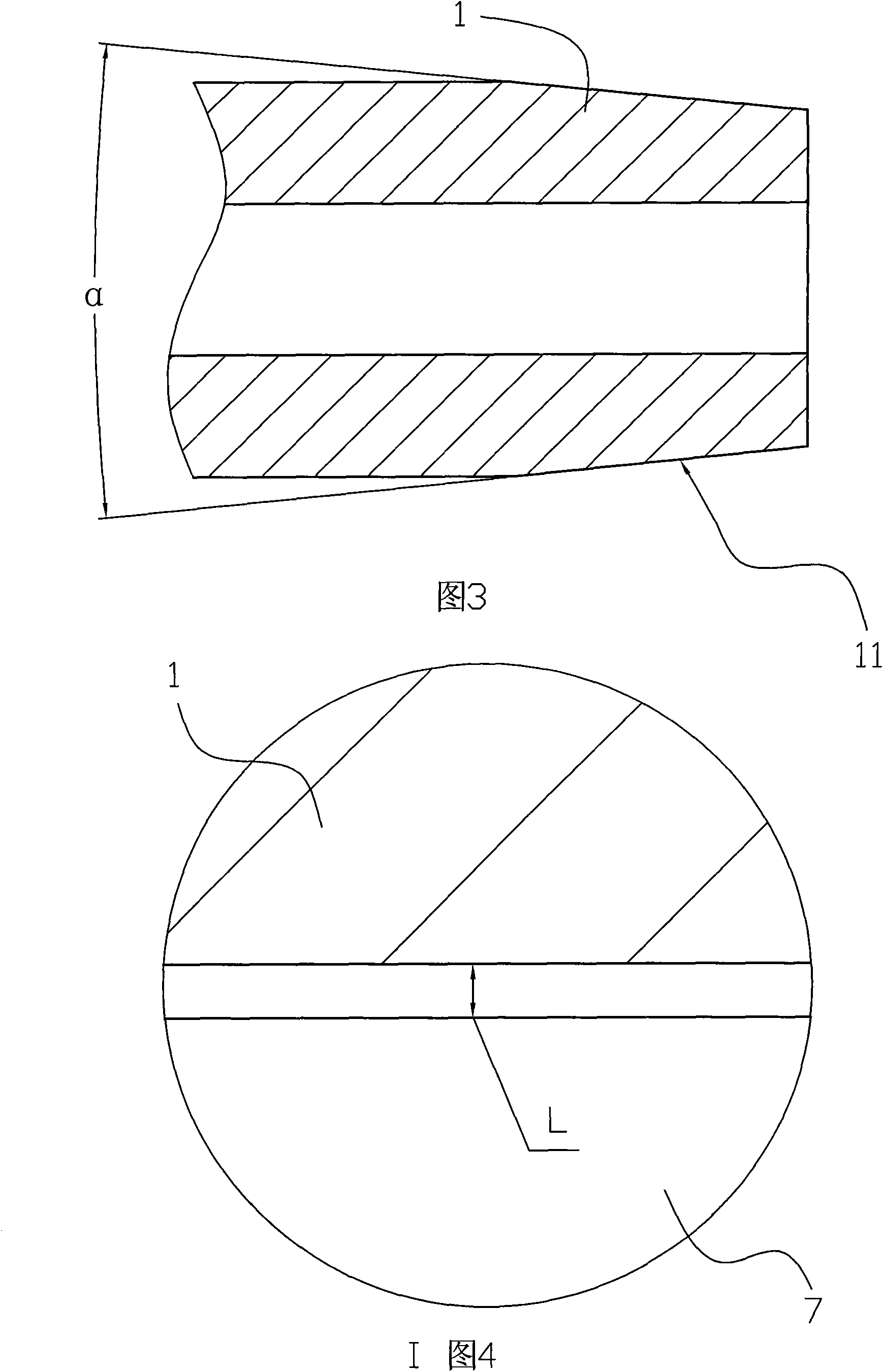

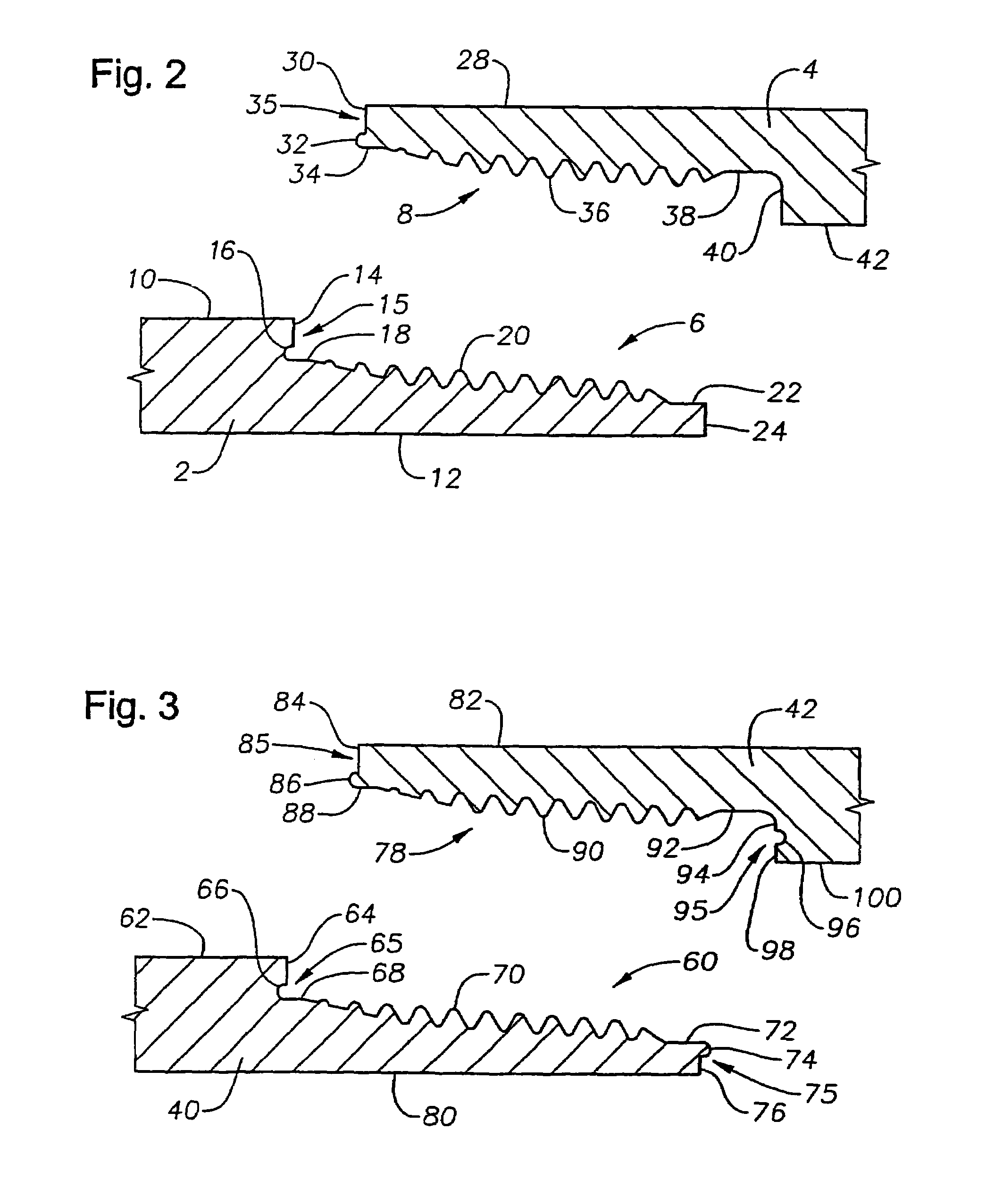

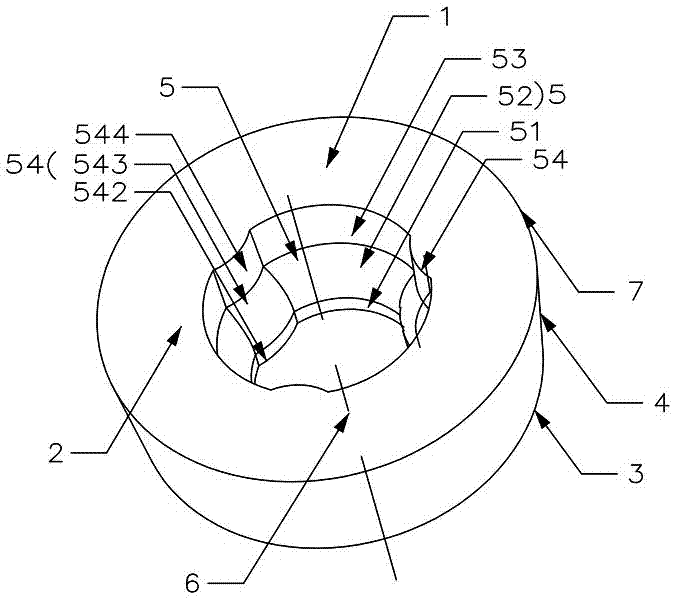

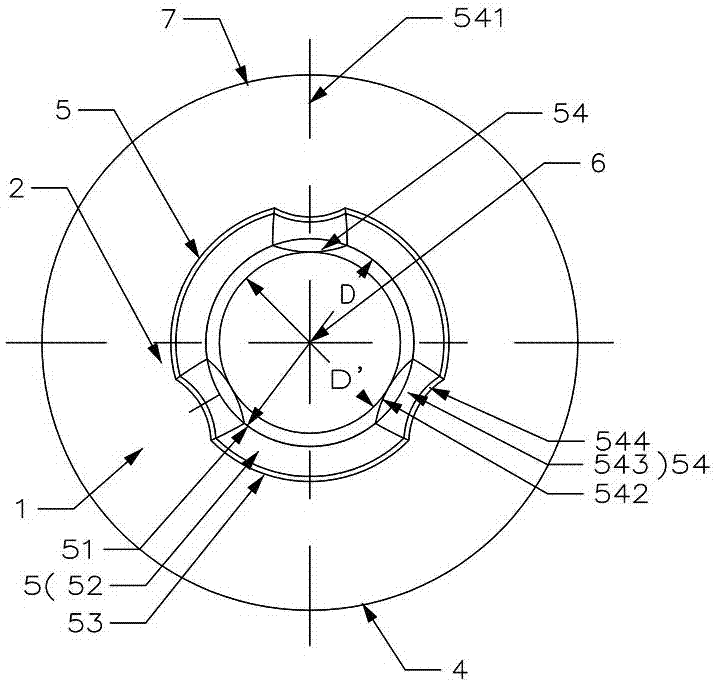

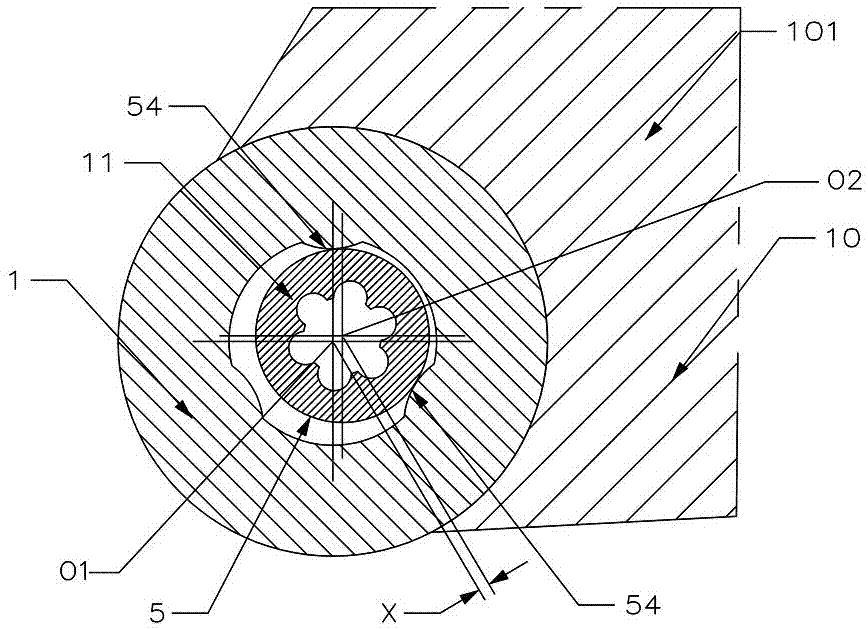

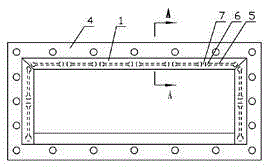

Vortex extrusion type large-plastic deformation device

ActiveCN103785702AIncrease work intensityRealize the twistExtrusion diesExtrusion mandrelsInterference fitExtrusion

The invention discloses a vortex extrusion type large-plastic deformation device which comprises a device main body, wherein the device main body comprises an outer-layer reinforcing ring and an inner-layer concave die in interference fit with the outer-layer reinforcing ring, the inner-layer concave die is provided with a twisting extrusion chamber which is necked from the upper port to the lower port, a twisting extrusion deformation region is formed in the twisting extrusion chamber and comprises a deformation band composed of a plurality of stripe projections or a plurality of stripe grooves, the upper end portions of the stripe projections or the stripe grooves are capable of extending to the upper port of the twisting extrusion chamber, and the lower end portions of the stripe projections or the stripe grooves are capable of extending to the lower port of the twisting extrusion chamber. The vortex extrusion type large-plastic deformation device integrates twisting and extrusion techniques, so that the device is capable of realizing twisting of a material without rotating the die with an extra device and capable of achieving the same effect only through structural design; besides, the device is capable of preventing sliding between the material and the die while twisting; moreover, the device is simple and convenient in design.

Owner:HEFEI UNIV OF TECH

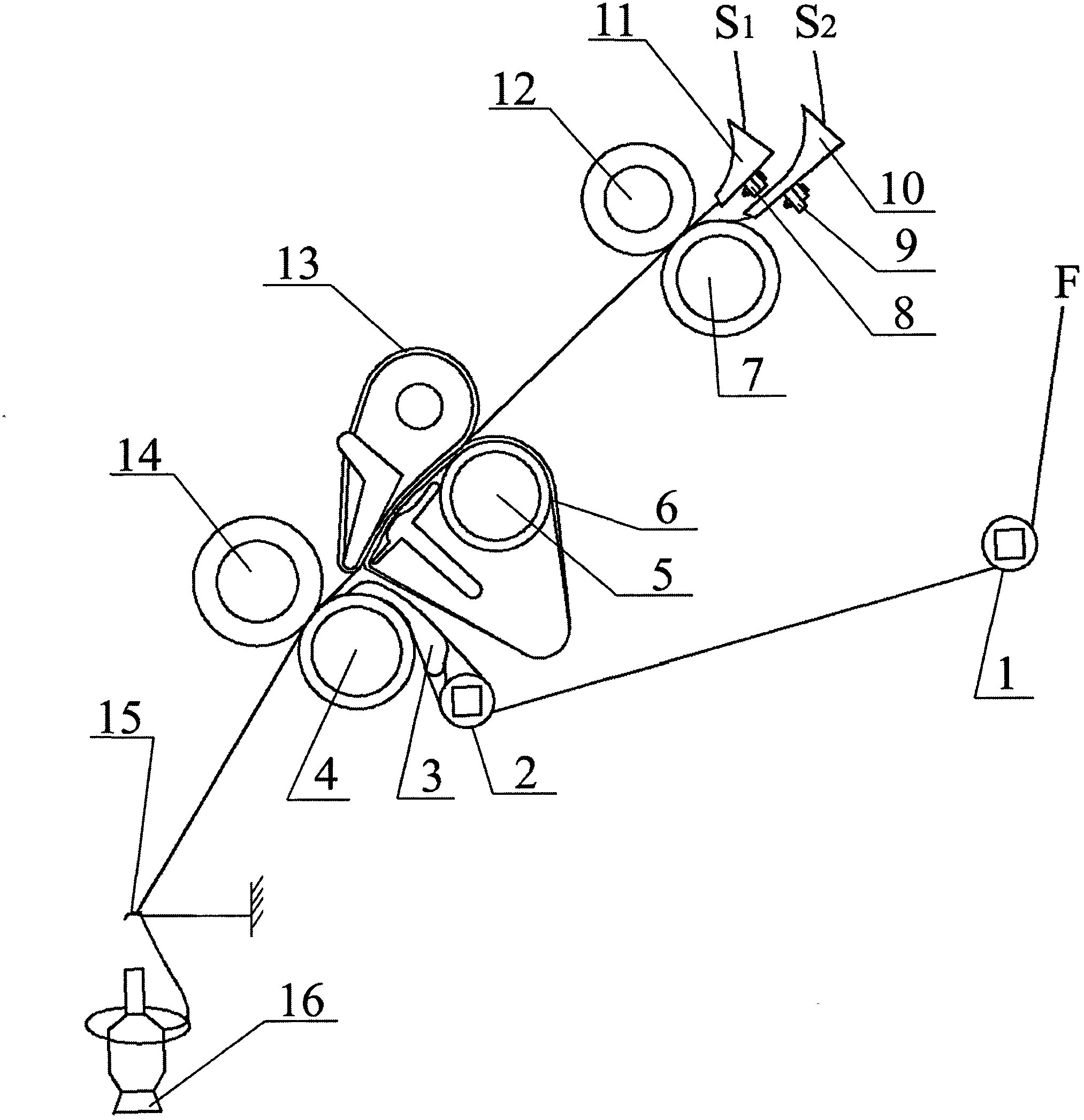

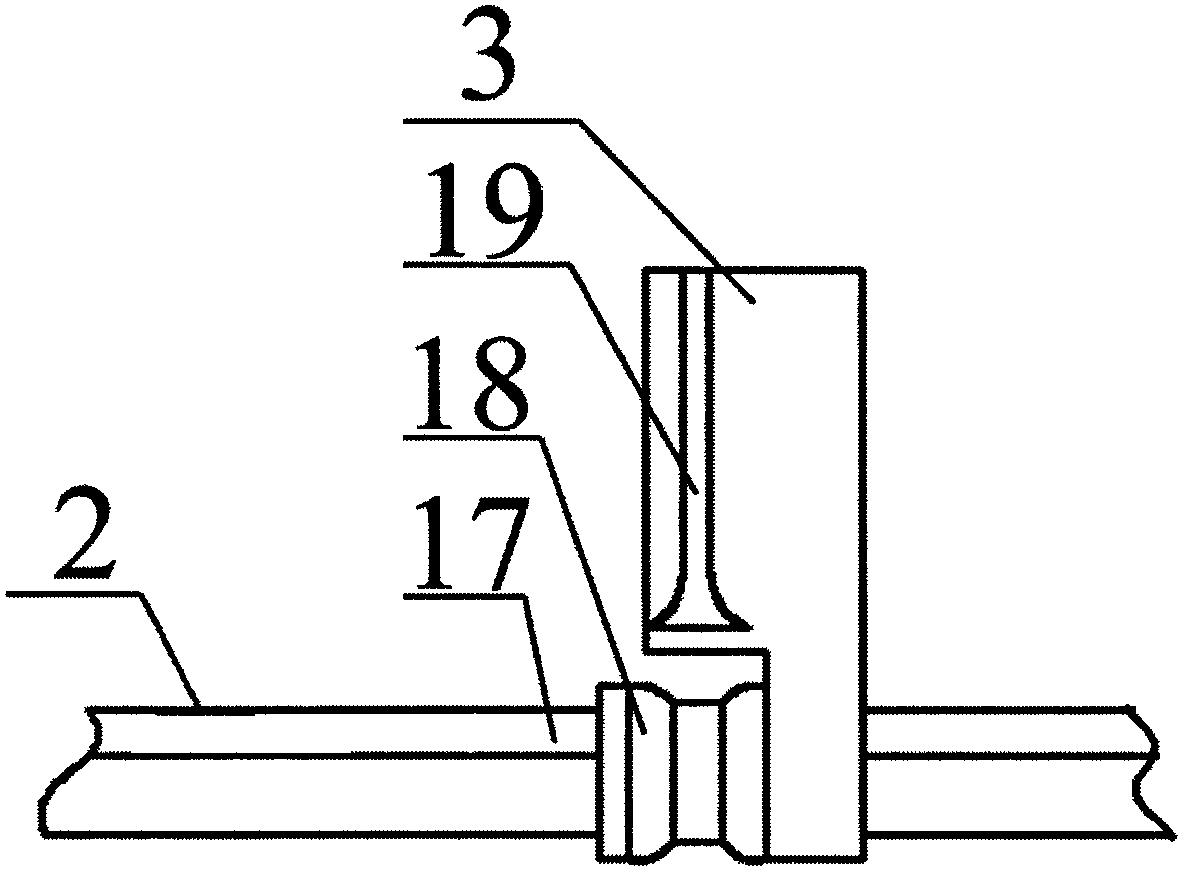

Forced internal and external transfer type composite ring spinning method for filament

InactiveCN102677248AIncrease the degree of mixingIncreased intermixingDrafting machinesYarnYarnTextile processing

The invention relates to a forced internal and external transfer type composite ring spinning method for a filament, which belongs to the technical field of textile processing. The technical scheme disclosed by the invention is that: a first yarn guide trumpet and a second yarn guide trumpet are adopted to do reversed reciprocating motion so as to respectively drive two short fibre rovings to do reversed reciprocating motion on each traction mechanism of a ring spinning frame; a forced yarn guide device feeds the filament into a front jaw in a reciprocating motion form, and is twisted with two short fibres output by a drafting system to form the yarn so as to realize full internal and external transferring of the filament in the finally produced composite yarn; and the filament in the composite yarn body and the fibres are naturally and uniformly mixed and tightly adhered so as to eliminate the relative sliding between the filament and the short fibres in subsequent processing of the yarn. According to the forced internal and external transfer type composite ring spinning method for the filament disclosed by the invention, electric fiber splitting and extra power are not related in actual production, the cost is low, a hidden trouble of igniting of static sparks in production can not be generated, simultaneously the device is simply reformed, and the operation and the use are convenient.

Owner:HUBEI HENGDA TEXTILE CO LTD

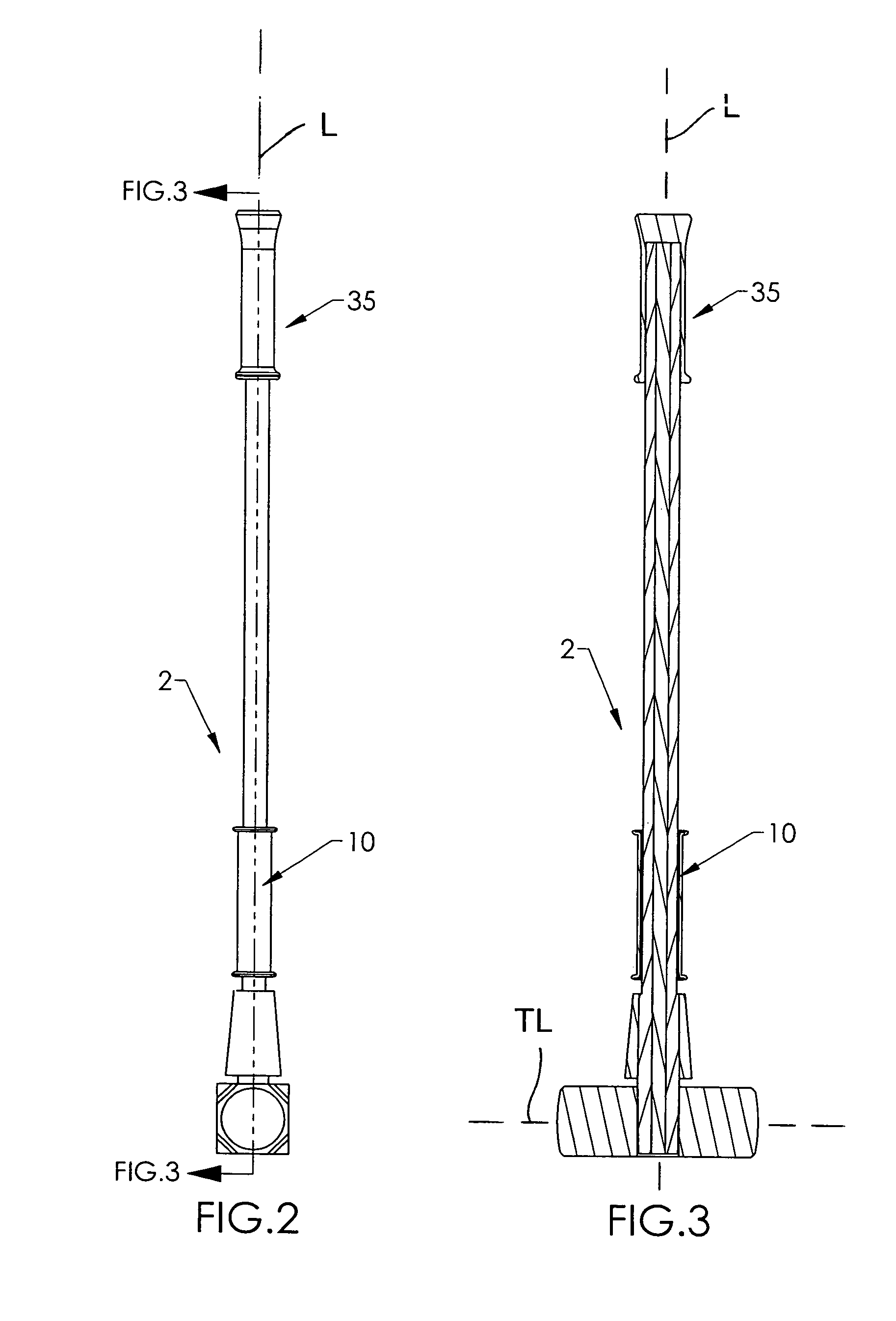

Three-roller planetary rolling method for rolling brass tube

ActiveCN101850364AReduce wall thicknessReduces the possibility of crackingTemperature control deviceMandrelsUltimate tensile strengthMaterials science

The invention discloses a three-roller planetary rolling method for rolling a brass tube. The method is characterized by comprising the following steps of: making the head of a tube blank into a conical surface; selecting a mandril, wherein a unilateral gap L between the mandril and the internal wall of the tube blank is not greater than 2.5mm; before rolling the tube blank by using a three-roller planetary rolling machine, preheating the tube blank to the temperature of between 100 and 500 DEG C first and then feeding the preheated tube blank into the three-roller planetary rolling machine for rolling; spraying emulsified liquid on rollers when rolling, wherein the spraying intensity of the emulsified liquid is of between 0.025 and 0.045MPa; purging by using a purging device arranged at the entrance of the three-roller planetary rolling machine to prevent the emulsified liquid from refluxing so as to prevent the tube blank from contacting the emulsified liquid before entering a rolling region; and processing a tubing rolled out from the exit of the three-roller planetary rolling machine into a finished product by drawing. The method has the advantages that: the brass tube is preheated when rolling, so that the rolling temperature of the brass tube exceeds a medium temperature brittle range of between 400 and 600 DEG C when the brass tube is rolled, namely good quality of a rolled tube body is achieved because of avoiding the medium temperature brittle range.

Owner:NINGBO JINTIAN COPPER TUBE

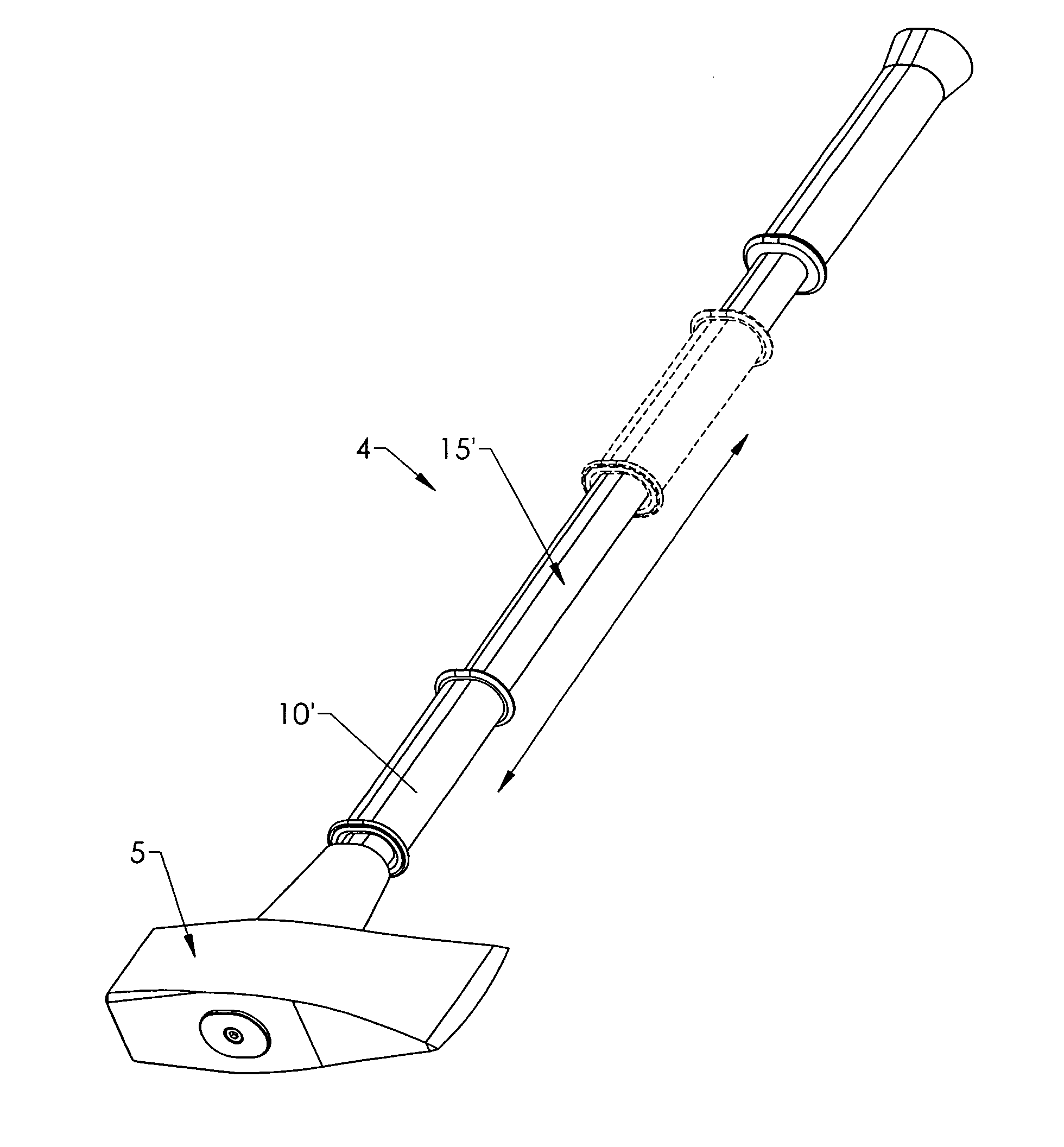

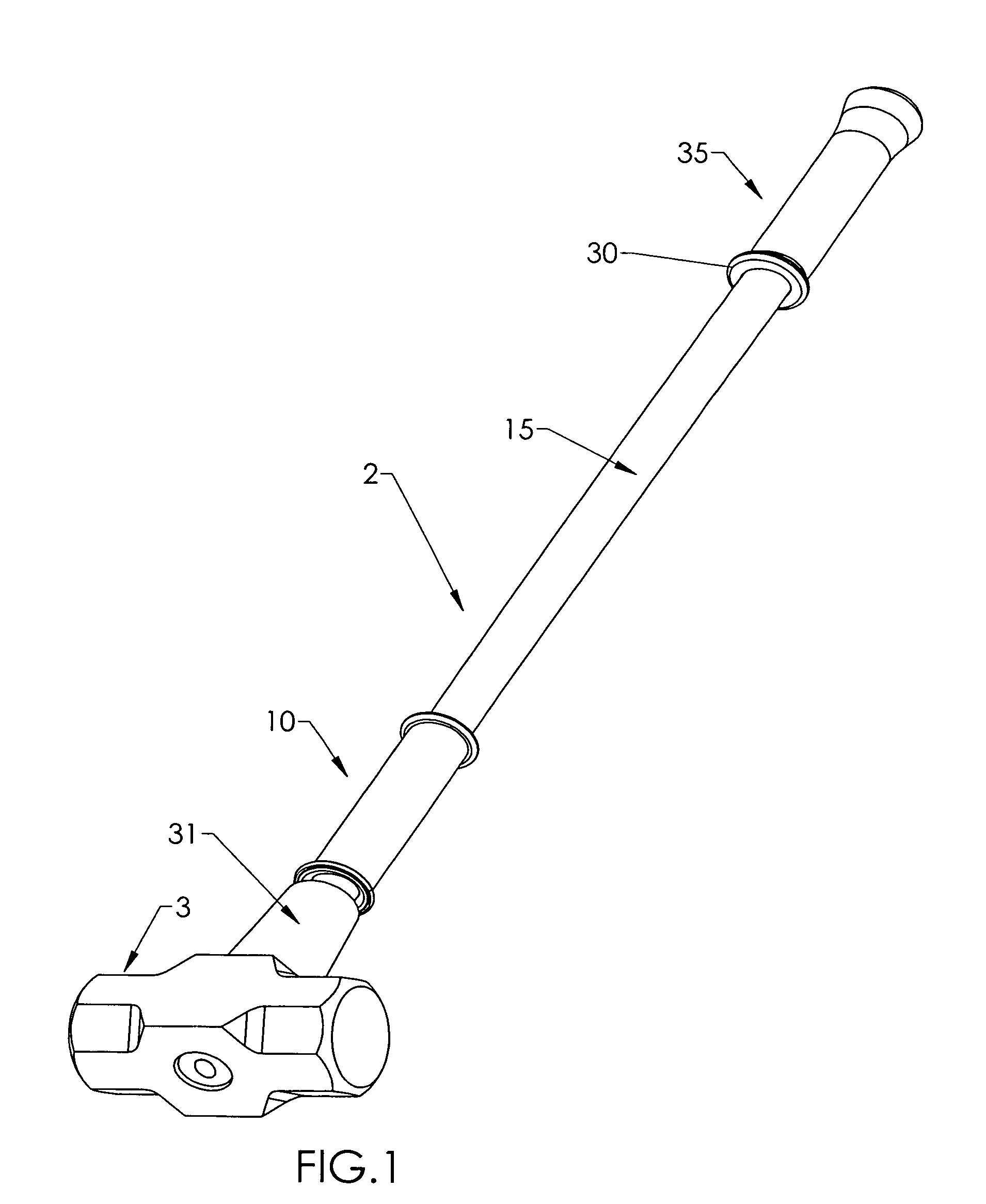

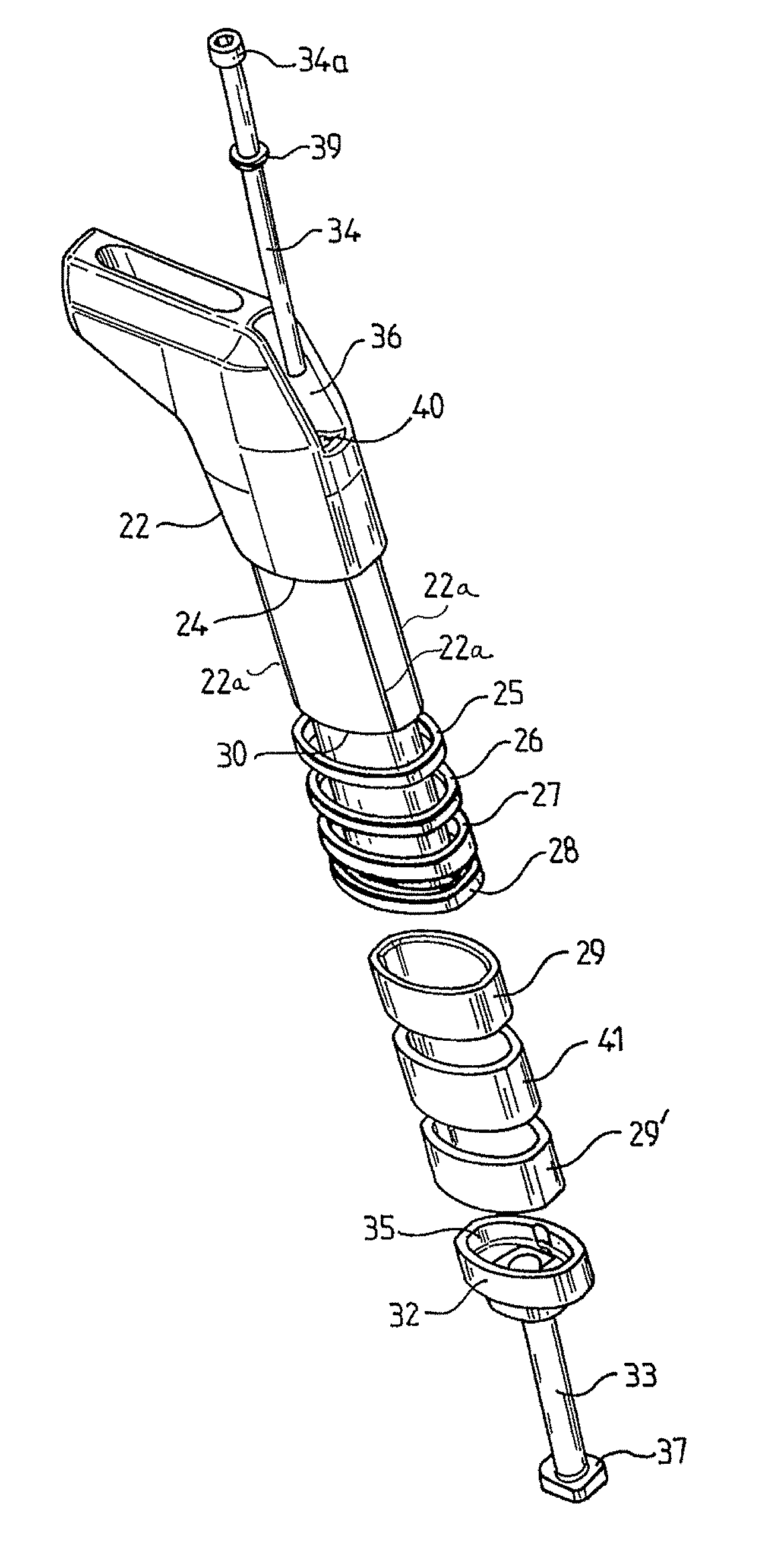

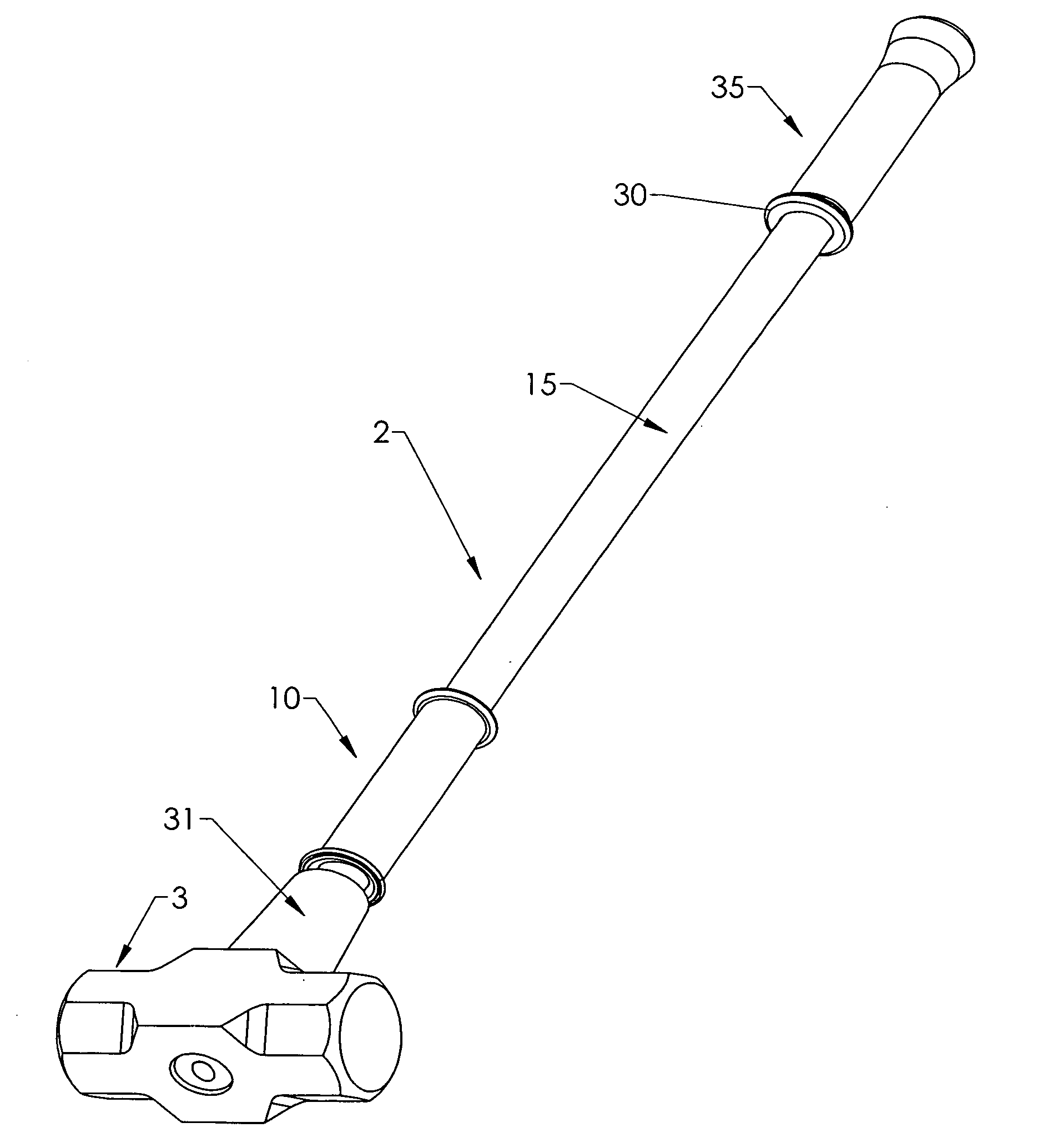

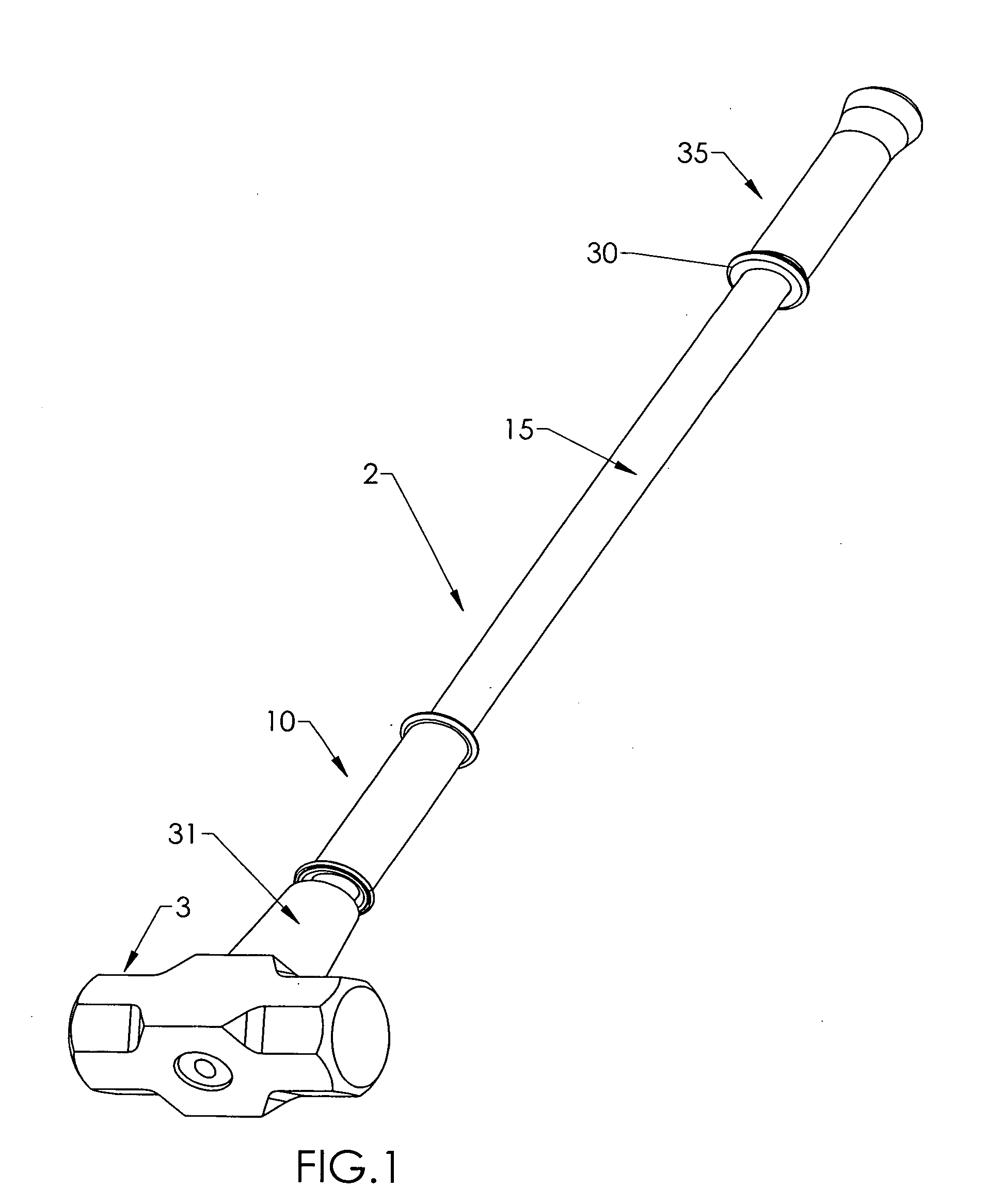

Impact tools with slidable grip

InactiveUS7694392B2Accurate and easy and safe to useFirm and reliable and predictable and smooth-moving grasp-pointTravelling carriersHoldersEngineeringMechanical engineering

Tools and methods of making tools that are swung toward a work-piece are more accurate and / or safer to use because of a moveable grip provided on the tool handle. The tool handle slides through the moveable grip, with minimal or no rotation or shifting relative to the grip. The movable grip eliminates the need for the forward hand of the user to loosen its grip during portions or all of the swing, eliminates the need for the hand itself to slide along the surface of the handle, and, importantly, greatly reduces or eliminates the chance that the tool and the impact head of the tool hand will rotate or shift relative to user's hand(s). The moveable grip and handle are preferably rigid and hard and mated in shape and size so that rotation and shifting is reduced or eliminated. The preferred embodiment includes one or more control members for retaining or latching the moveable grip in one or more desired locations on the handle, so that the moveable grip may be prevented from sliding along the handle until the user desires it to slide.

Owner:TOUCHETTE SHANE M

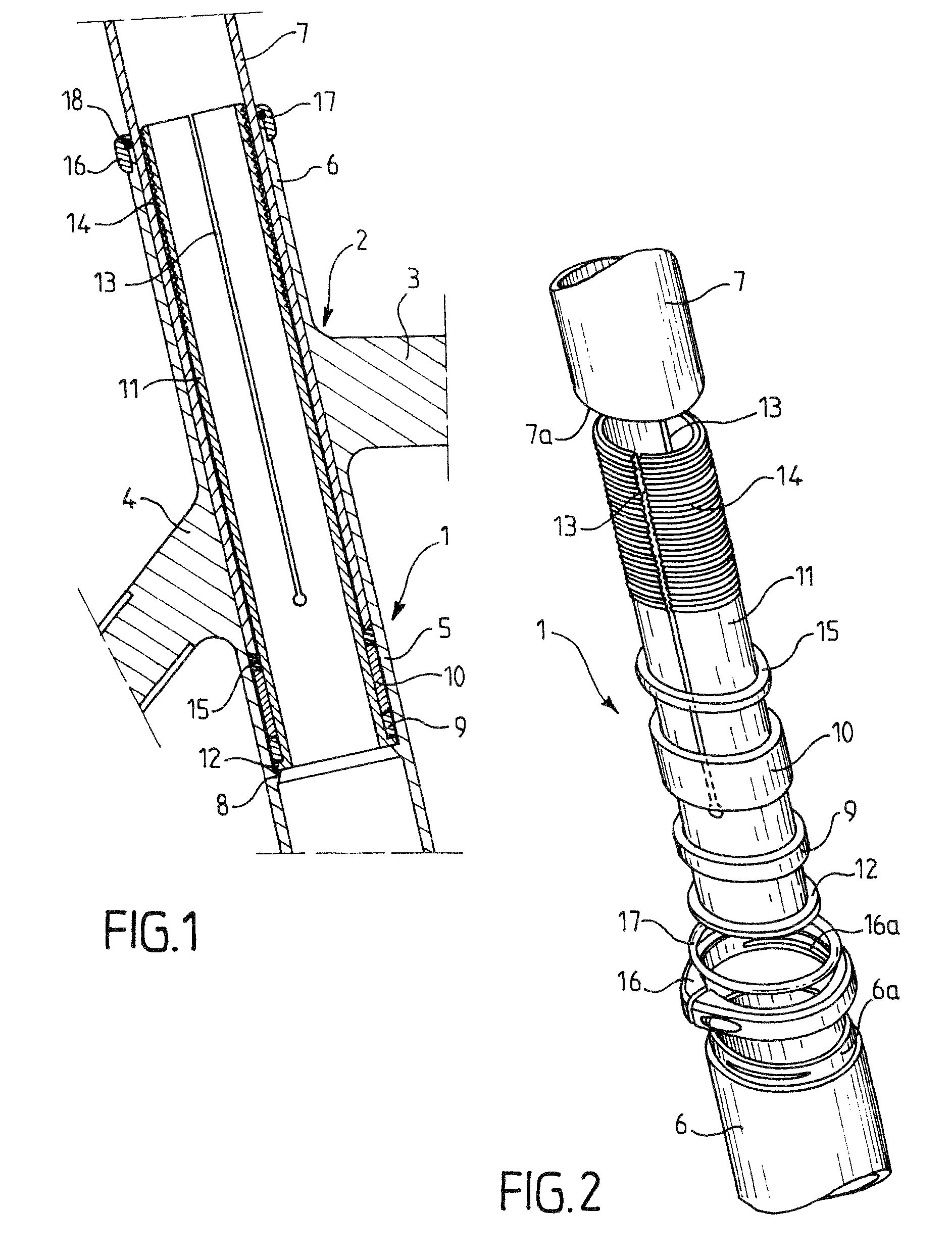

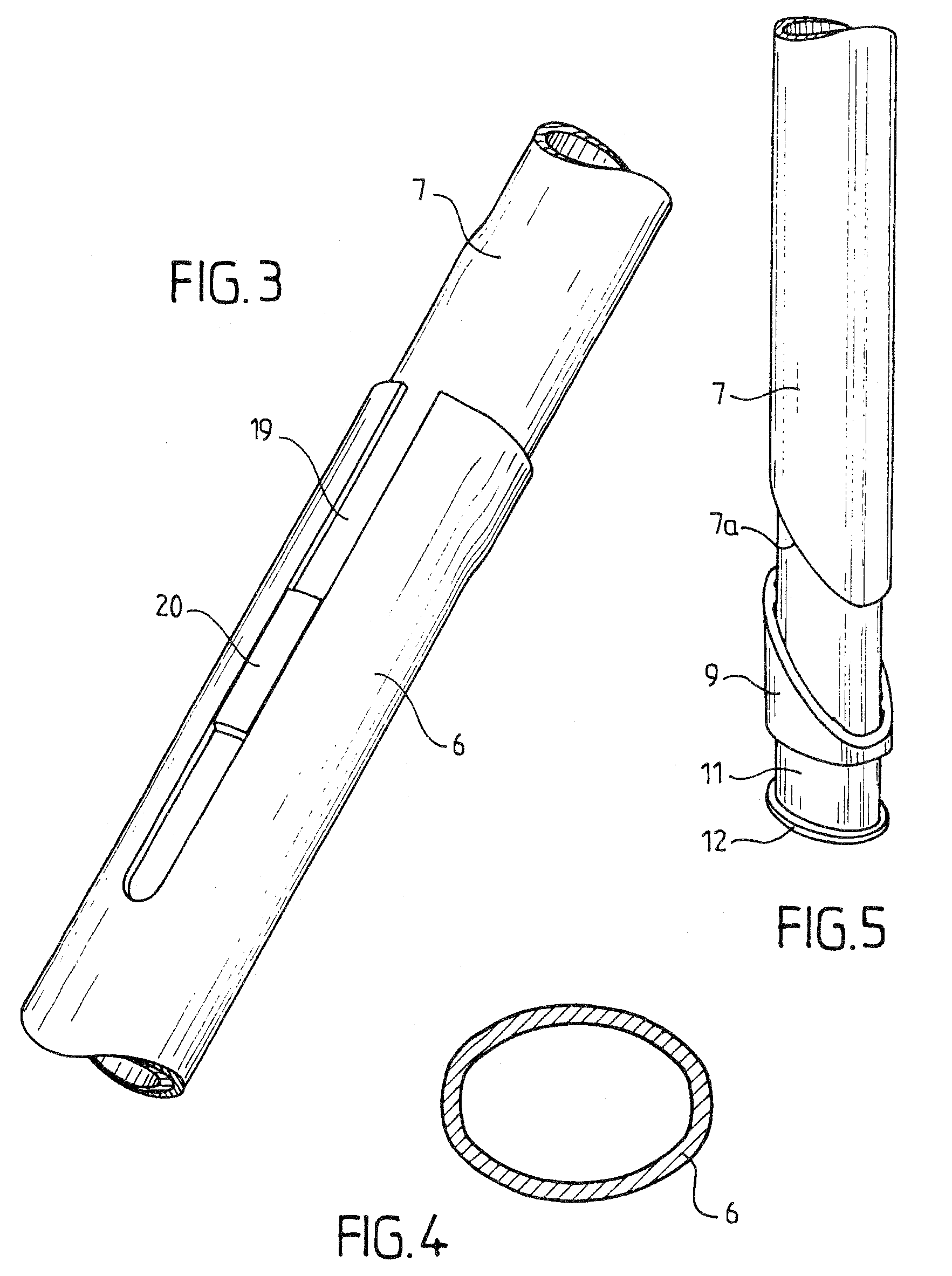

Saddle post supporting device

InactiveUS7712828B2The method is simple and reliableDrawback can be obviatedVehicle seatsCycle saddlesEngineering

The device includes a tubular fitting (6) that is part of a bicycle frame and able to accommodate a saddle post (7), elements (19,20) for locking the saddle post (7) in rotation, and members (8) for holding the saddle post (7) in a longitudinal position that is determined relative to the tubular fitting (6). The holding members comprise a stop surface (7a) that is provided on the saddle post (7) and able to work with a stop (8) that is provided on the fitting (6) so as to delimit the insertion length of the saddle post (7) in the latter. The holding members also include at least one annular crosspiece (9, 10) that can be arranged between the stop surface and the stop so as to allow the adjustment of the insertion length.

Owner:LOOK CYCLE INT

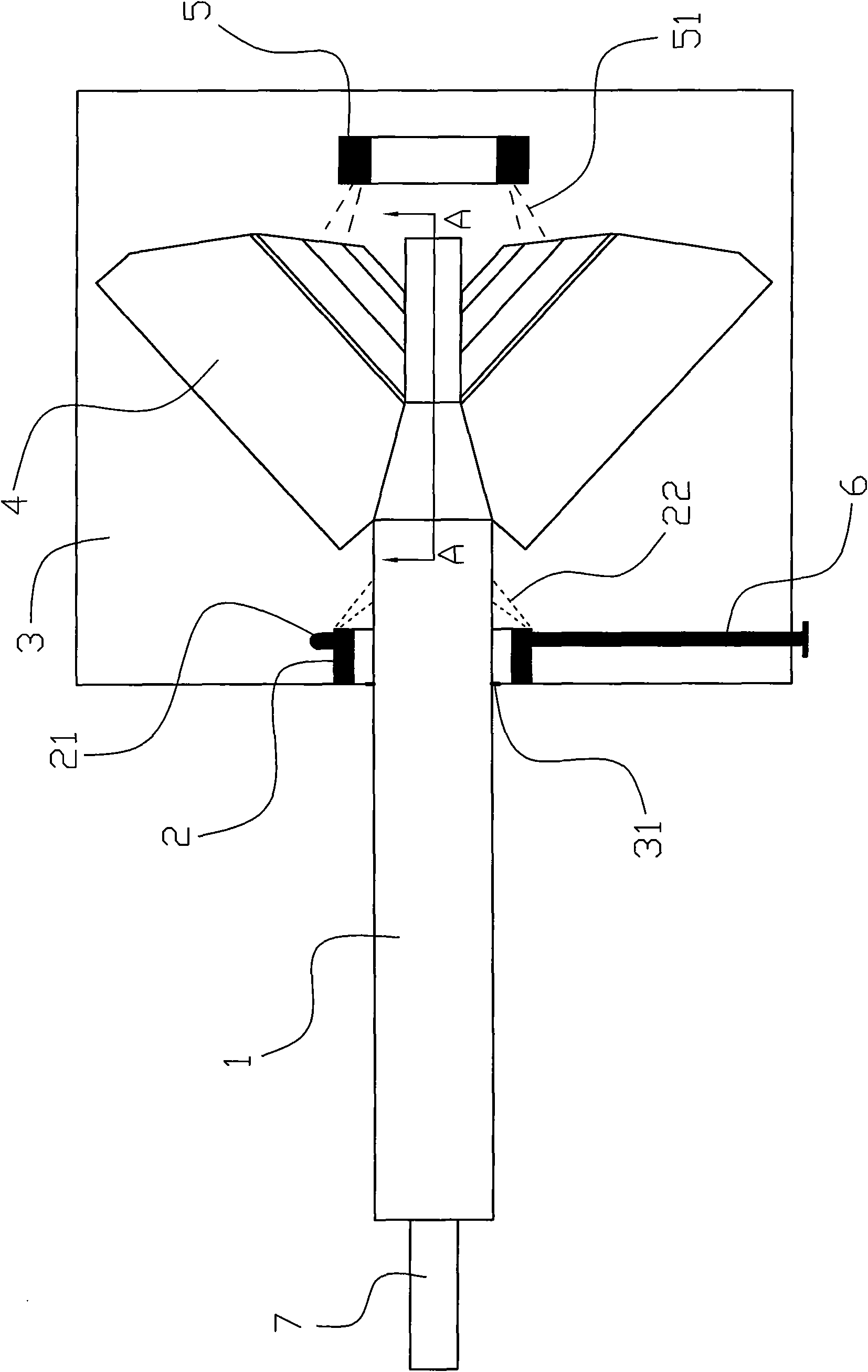

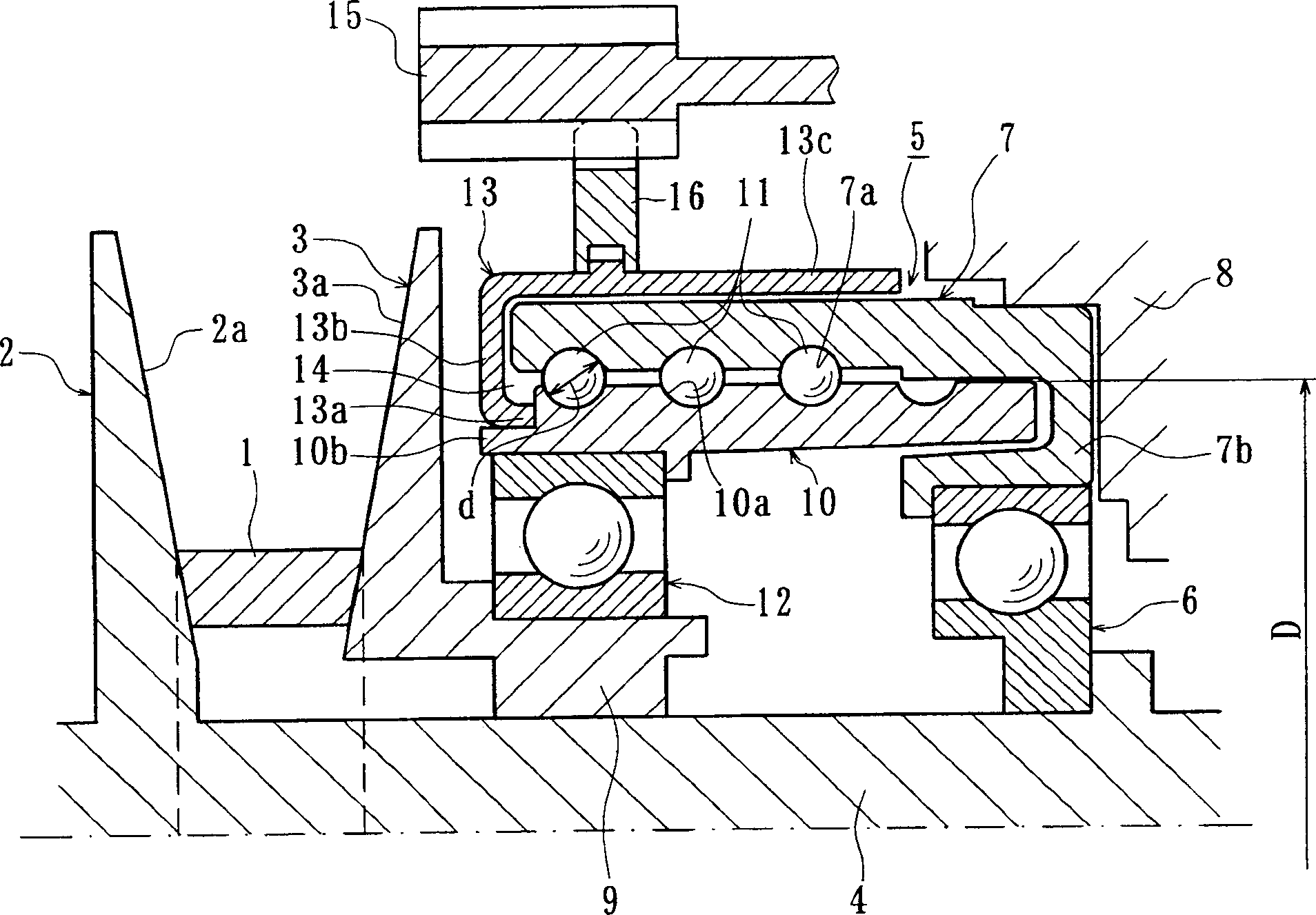

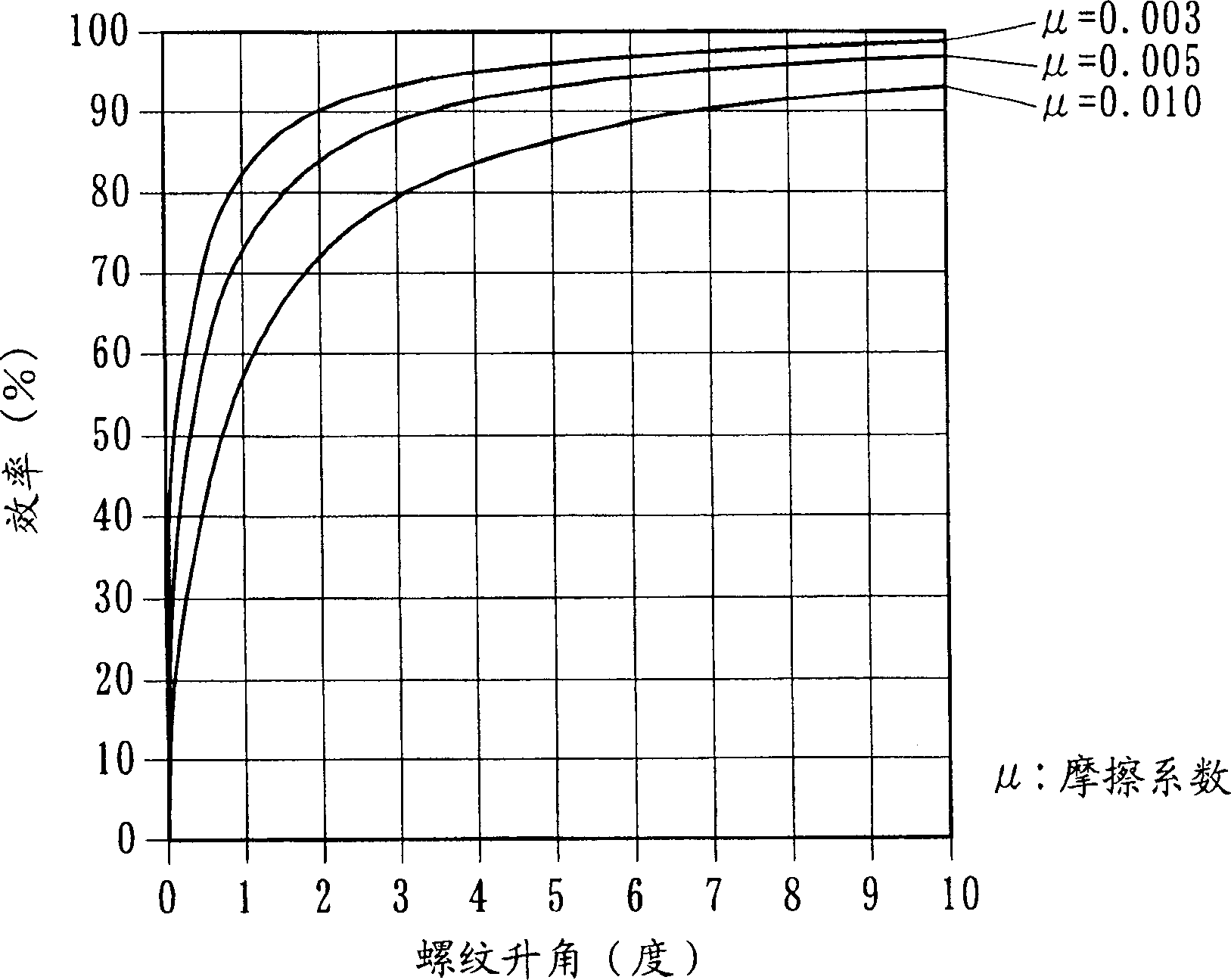

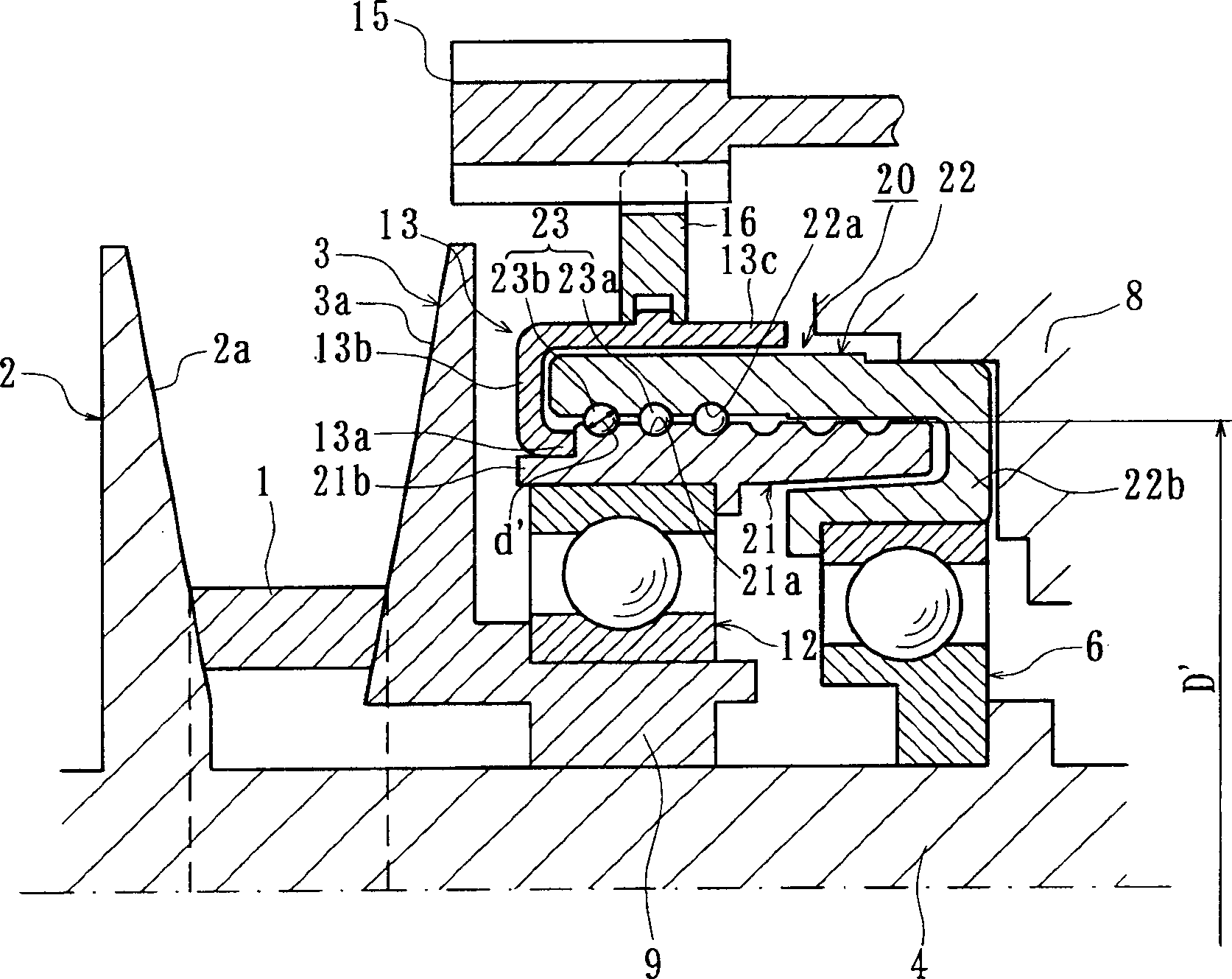

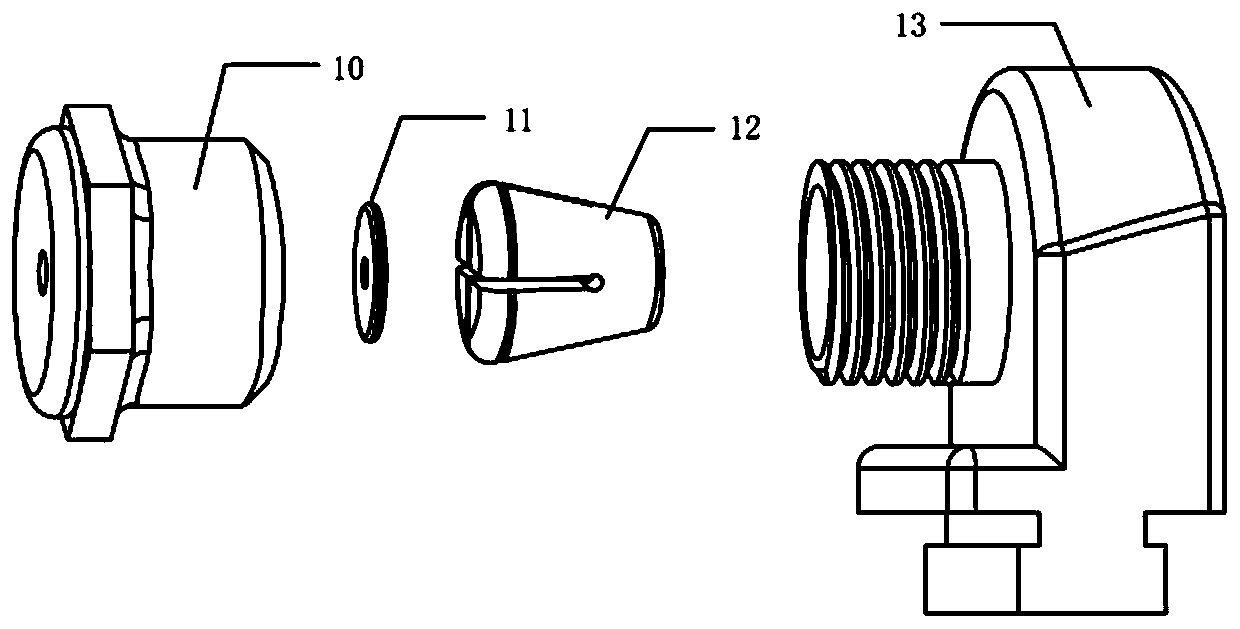

Ball screw and belt stepless variable speed devcie with same

InactiveCN1420293AShorten the overall lengthEliminate relative slidingGearing controlBearing componentsBall screwPulley

There are provided a ball screw enabling the reduction of weight and size of a CVT without reduction of the transmission efficiency as well as a CVT in which the ball screw is incorporated. A CVT of the present invention comprises an axially immovable pulley half 2 and axially movable pulley half 3 both mounted on a rotary shaft 4, and the axially movable pulley half 3 being moved by a ball screw 20 so as to infinitely vary the belt wrapping radius and thus the transmission speed, and is characterized in that a nut 22 forming one part of the ball screw 20 is immovably secured both in axial and rotational directions, a screw shaft 21 forming the other part of the ball screw 20 is movable both in axial and rotational directions and connected to the axially movable pulley half 3, and the axially movable pulley half 3 is axially moved by rotating the screw shaft 21.

Owner:NTN CORP

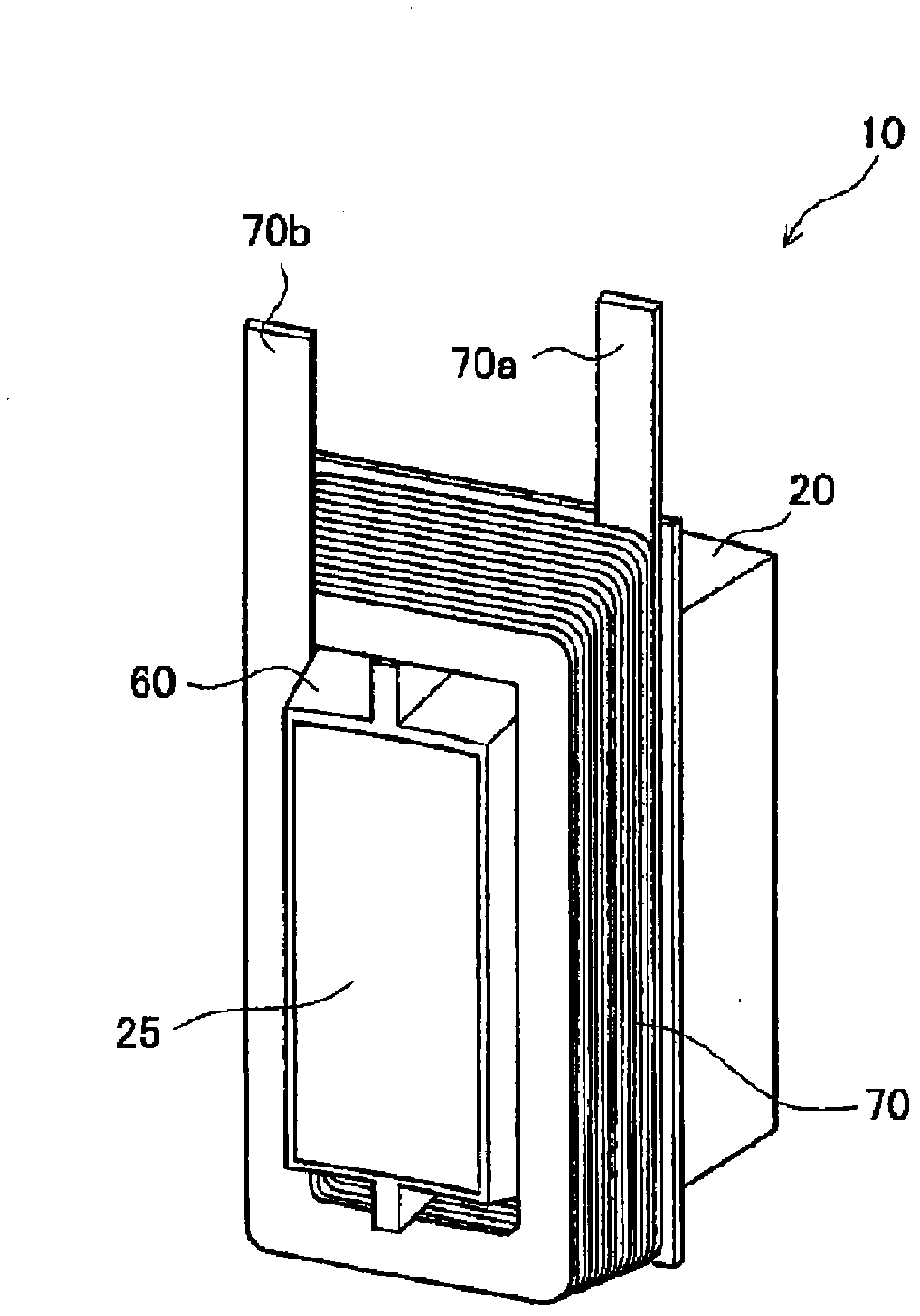

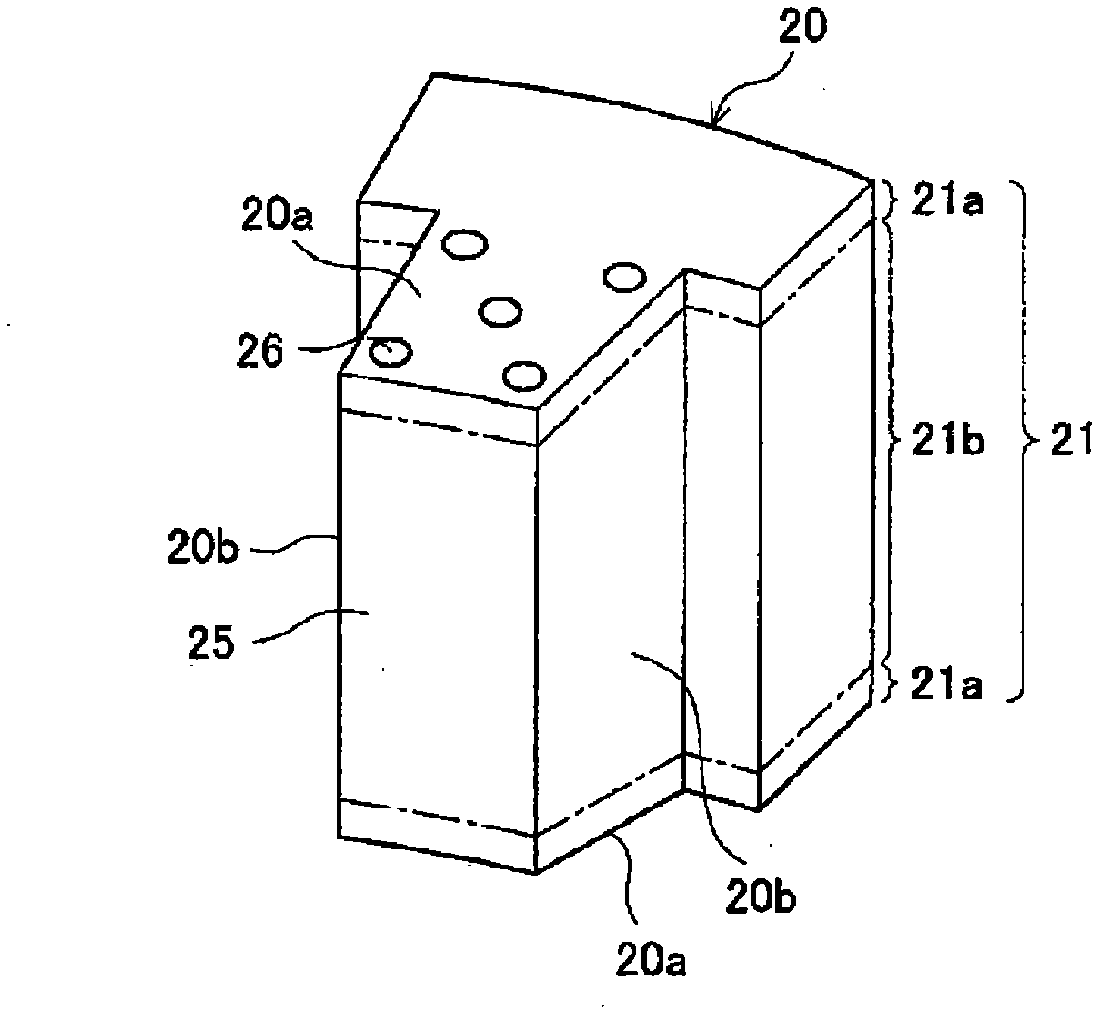

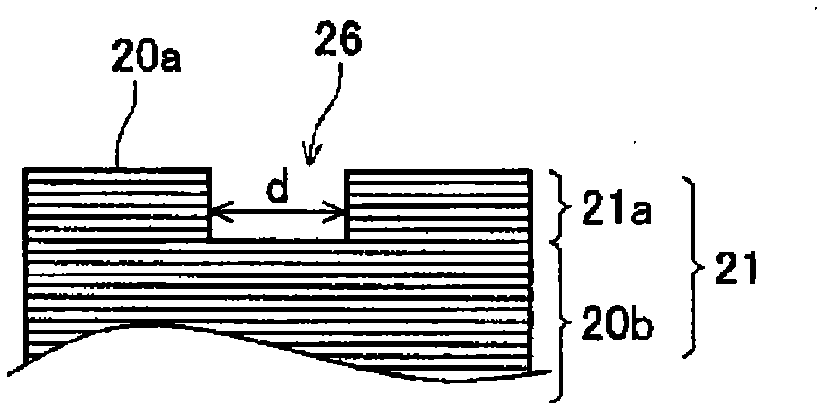

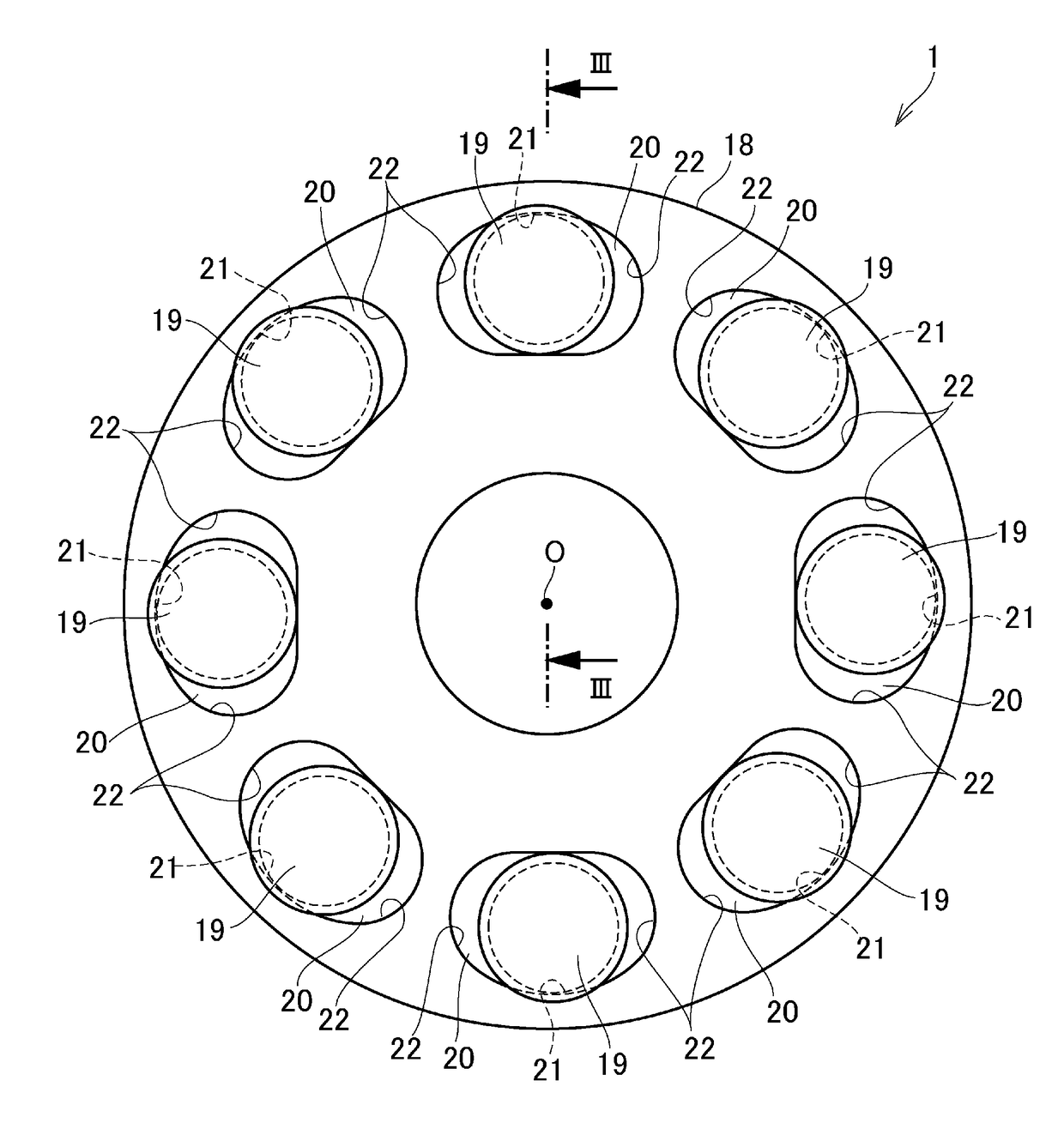

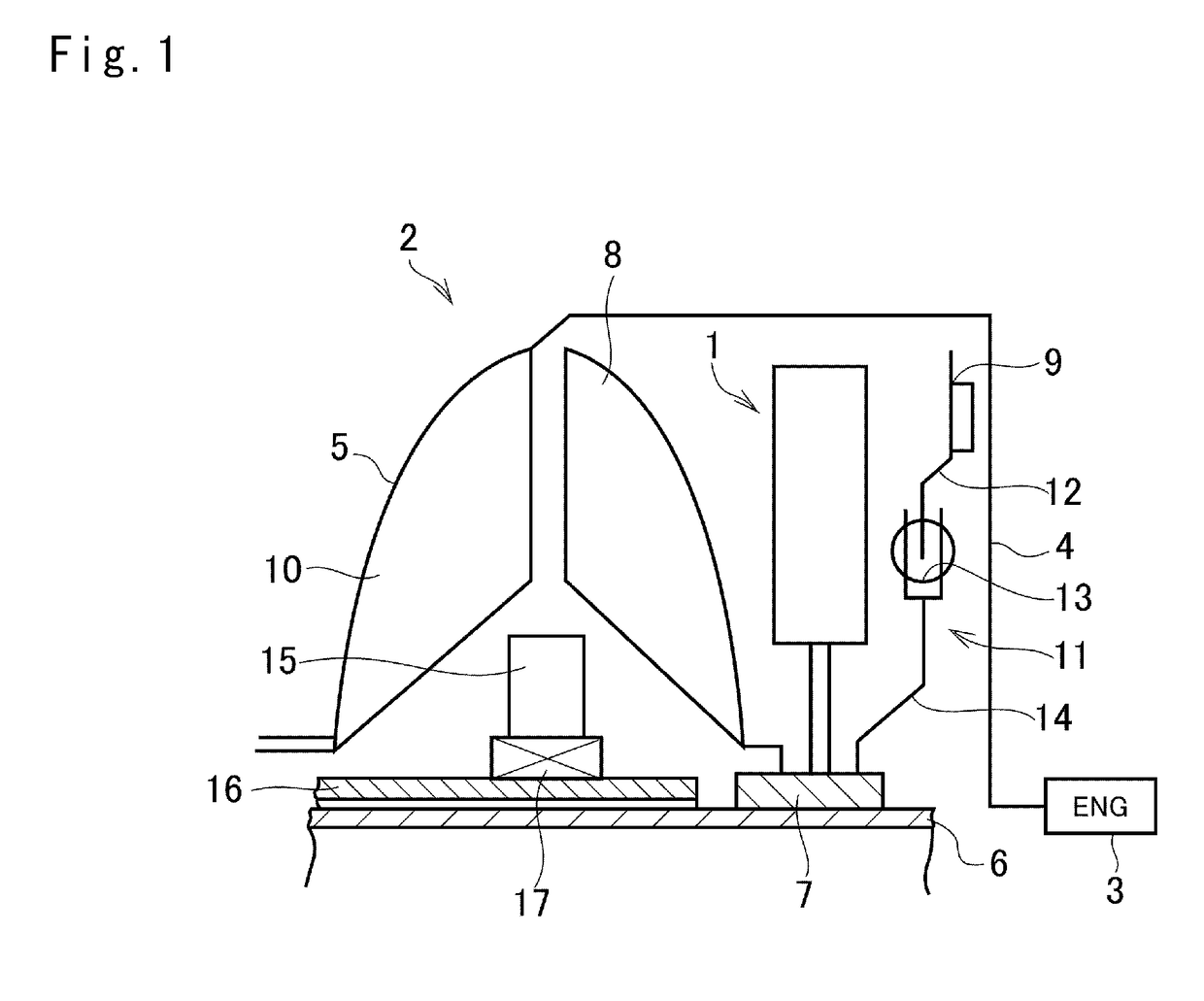

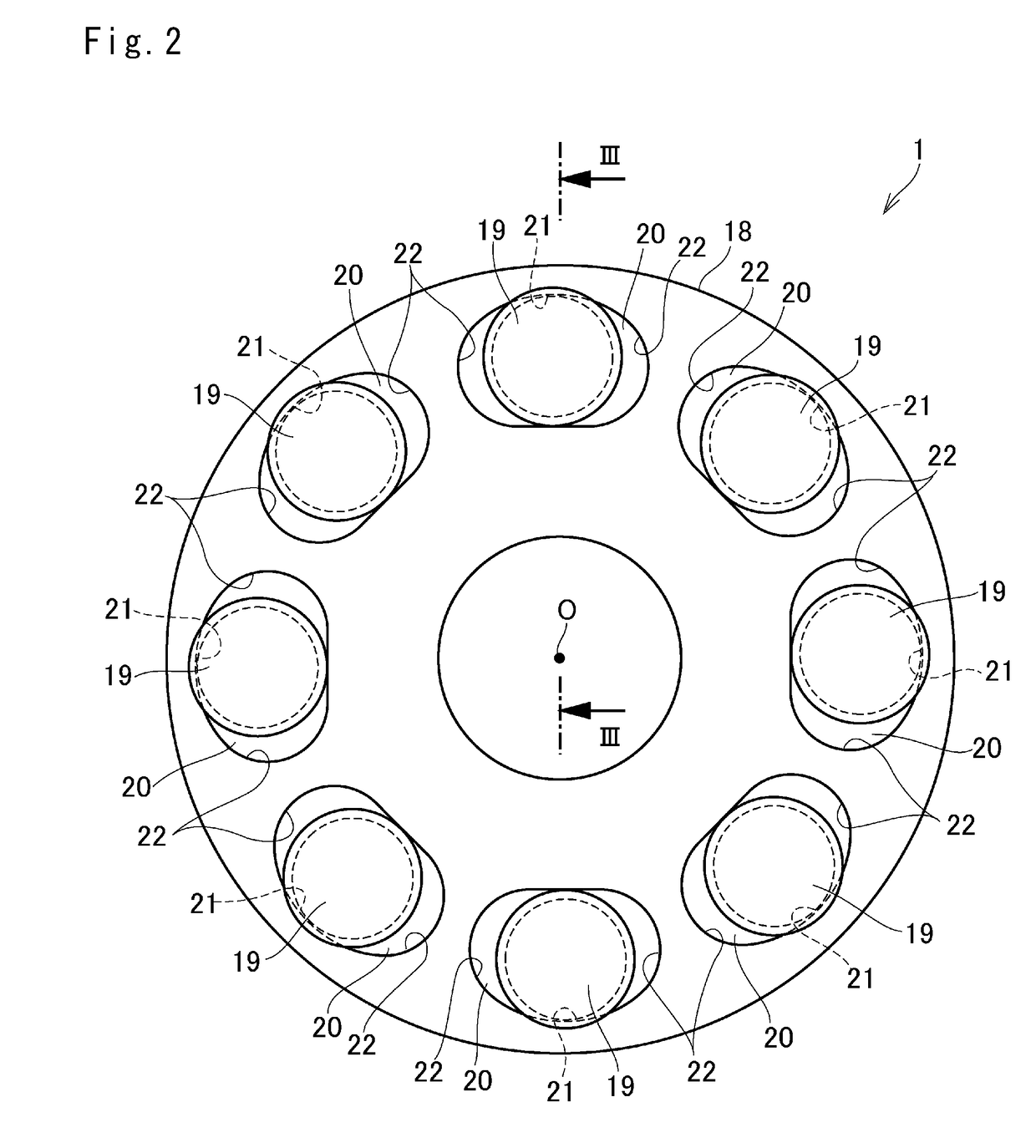

Split stator and manufacturing method therefor

InactiveCN102449879AEliminate relative slidingAvoid deformationWindingsMagnetic circuit stationary partsEngineeringElectrical and Electronics engineering

Disclosed are a split stator and a manufacturing method therefor with which insulation reliability can be improved by preventing the occurrence of deformation or cracking in the insulator by eliminating slippage of the insulator at the coil end face. A slippage preventing mechanism that prevents slippage of the insulator is provided at the coil end face, and using insert molding, the insulator is integrally molded to a split stator core provided with the slippage preventing mechanism.

Owner:TOYOTA JIDOSHA KK

Impact tools with slidable grip

InactiveUS20080168629A1Accurate and easy and safe to useFirm and reliable and predictable and smooth-moving grasp-pointTravelling carriersHoldersEngineeringMechanical engineering

Tools and methods of making tools that are swung toward a work-piece are more accurate and / or safer to use because of a moveable grip provided on the tool handle. The tool handle slides through the moveable grip, with minimal or no rotation or shifting relative to the grip. The movable grip eliminates the need for the forward hand of the user to loosen its grip during portions or all of the swing, eliminates the need for the hand itself to slide along the surface of the handle, and, importantly, greatly reduces or eliminates the chance that the tool and the impact head of the tool hand will rotate or shift relative to user's hand(s). The moveable grip and handle are preferably rigid and hard and mated in shape and size so that rotation and shifting is reduced or eliminated. The preferred embodiment includes one or more control members for retaining or latching the moveable grip in one or more desired locations on the handle, so that the moveable grip may be prevented from sliding along the handle until the user desires it to slide.

Owner:TOUCHETTE SHANE M

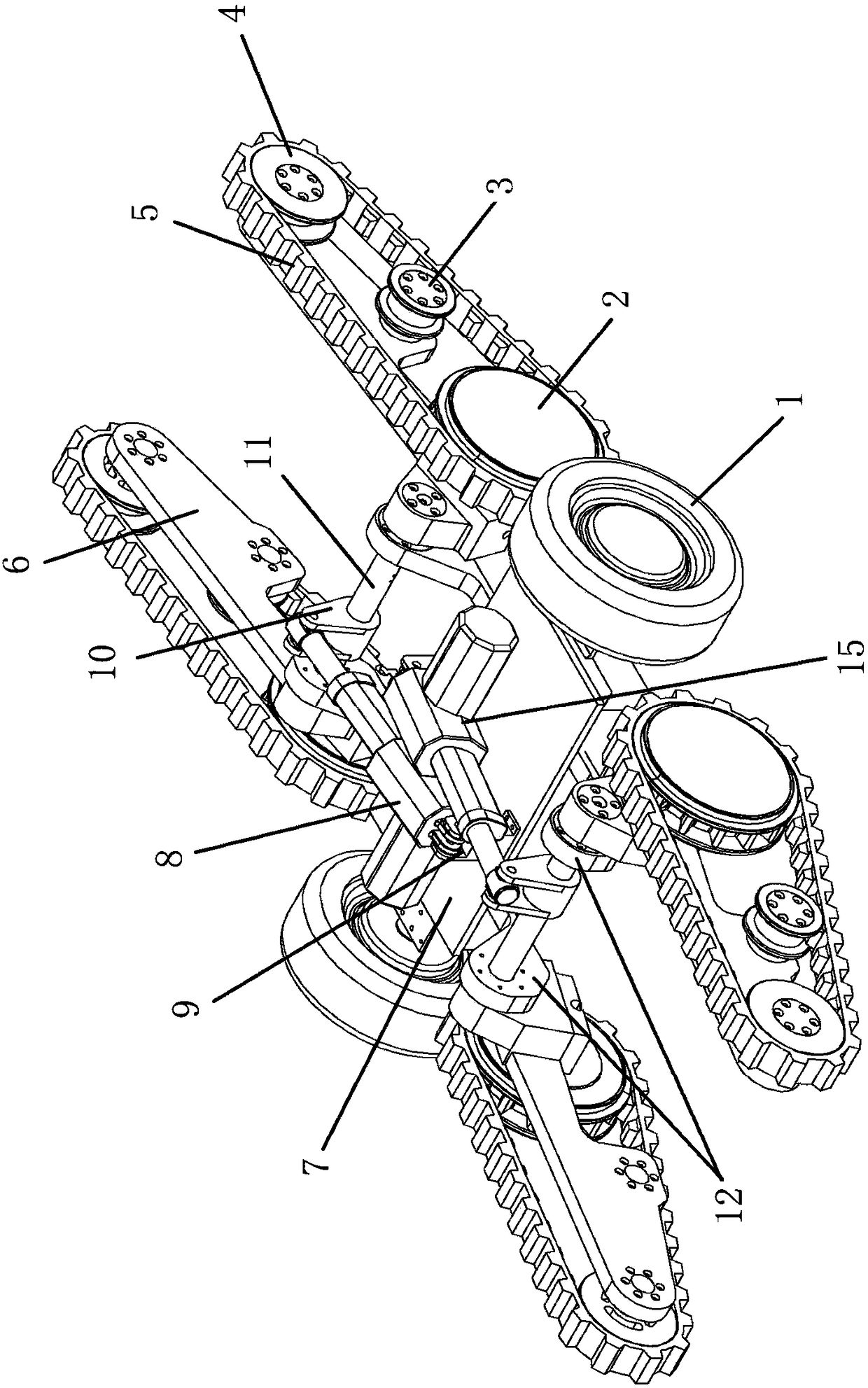

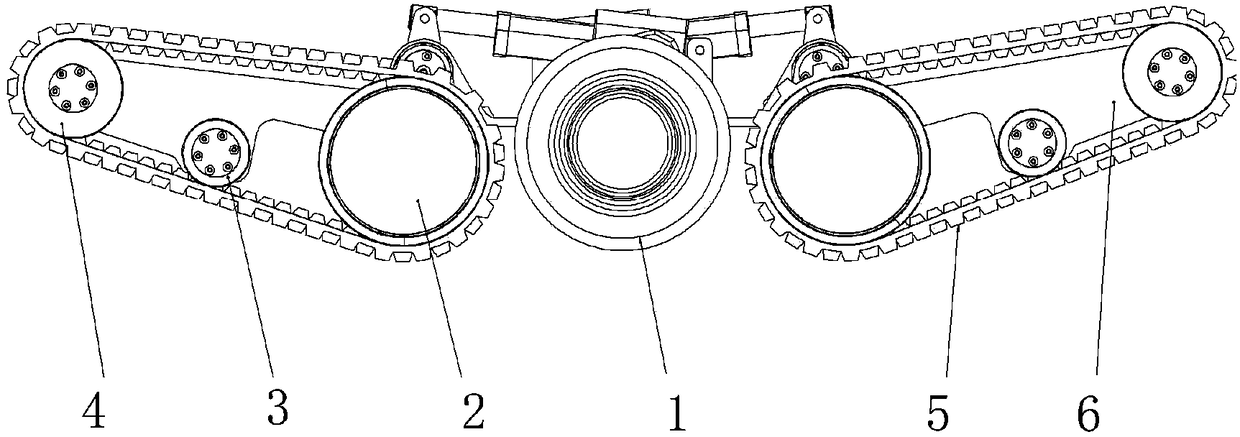

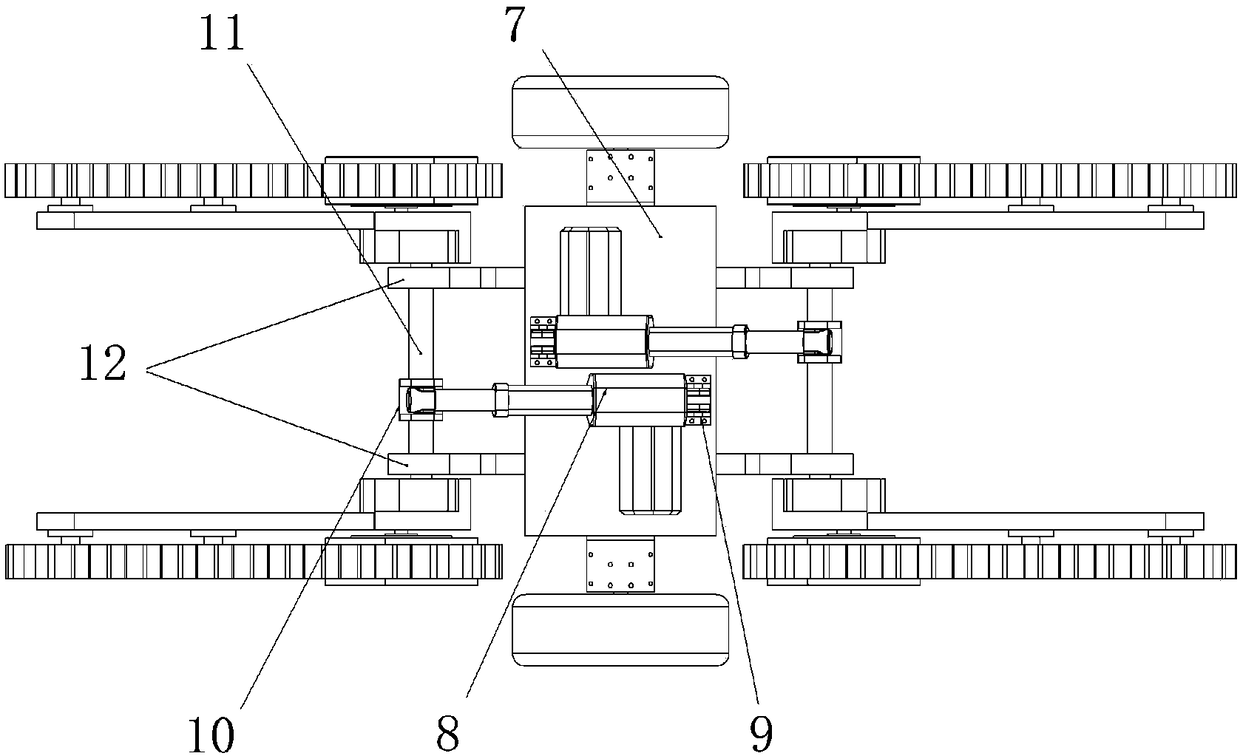

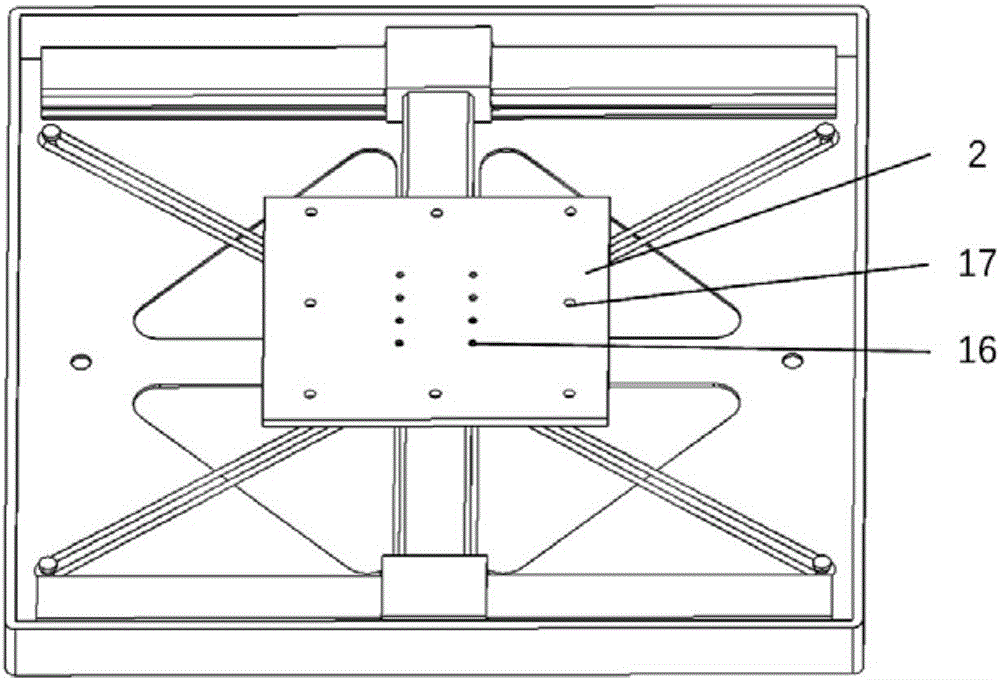

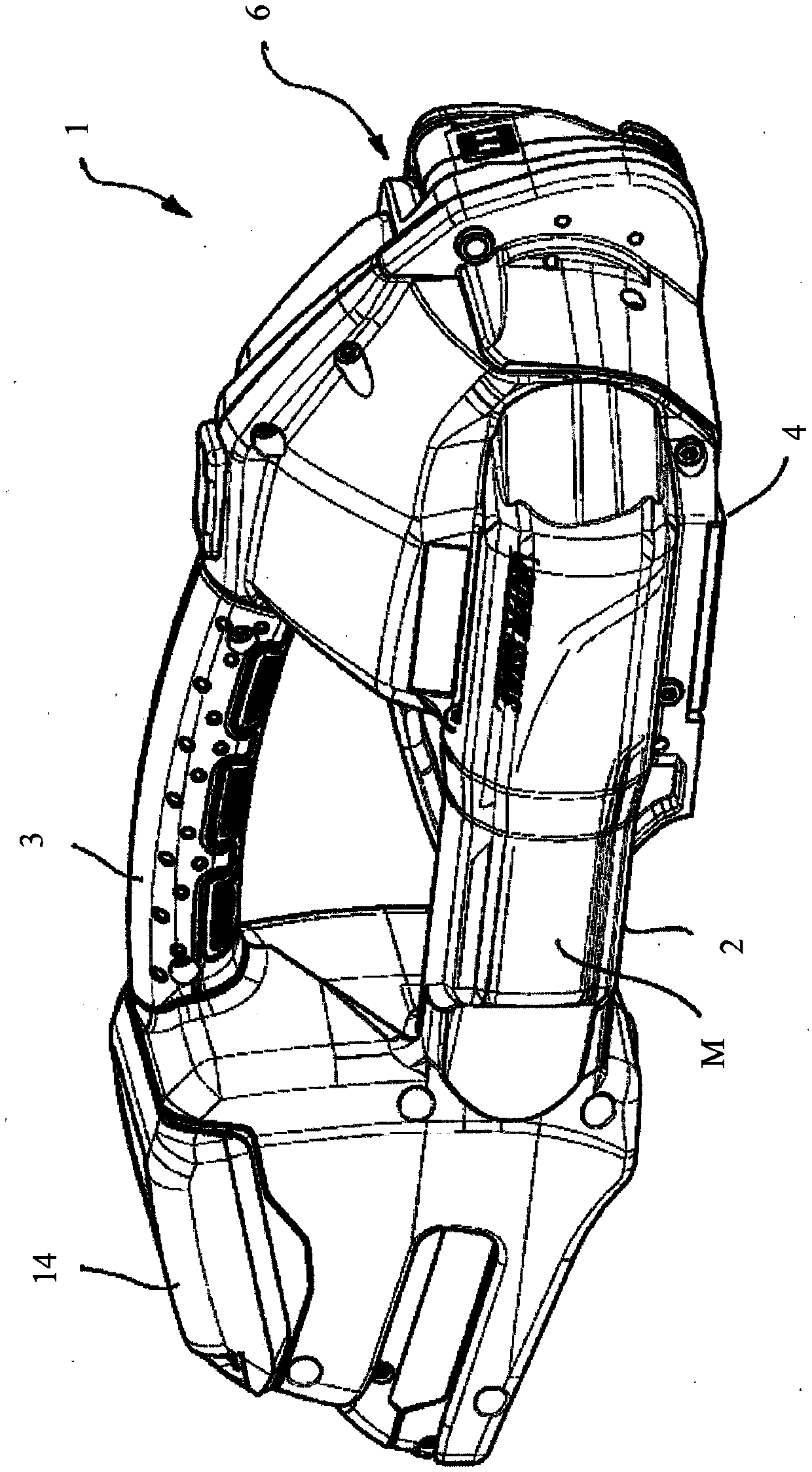

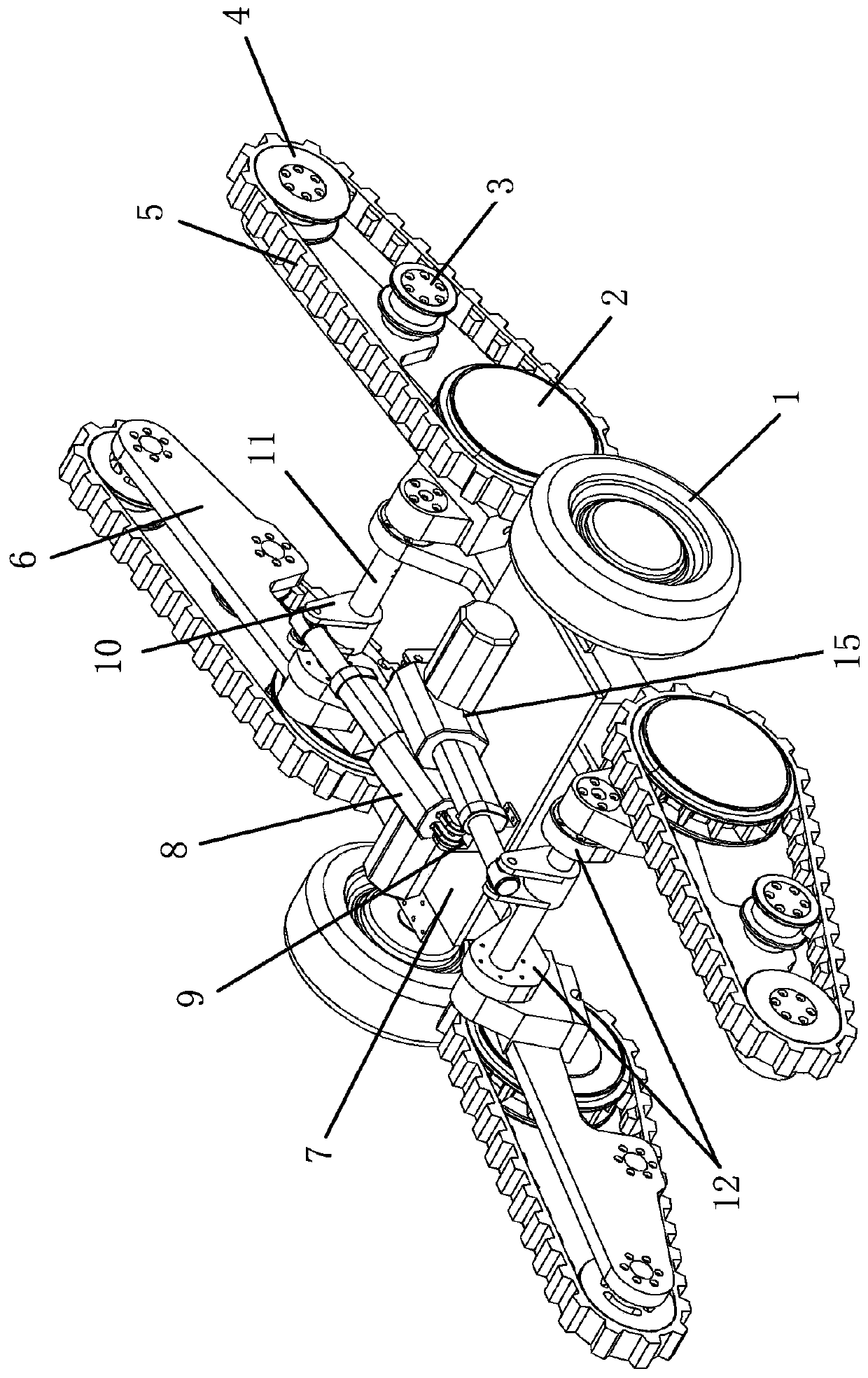

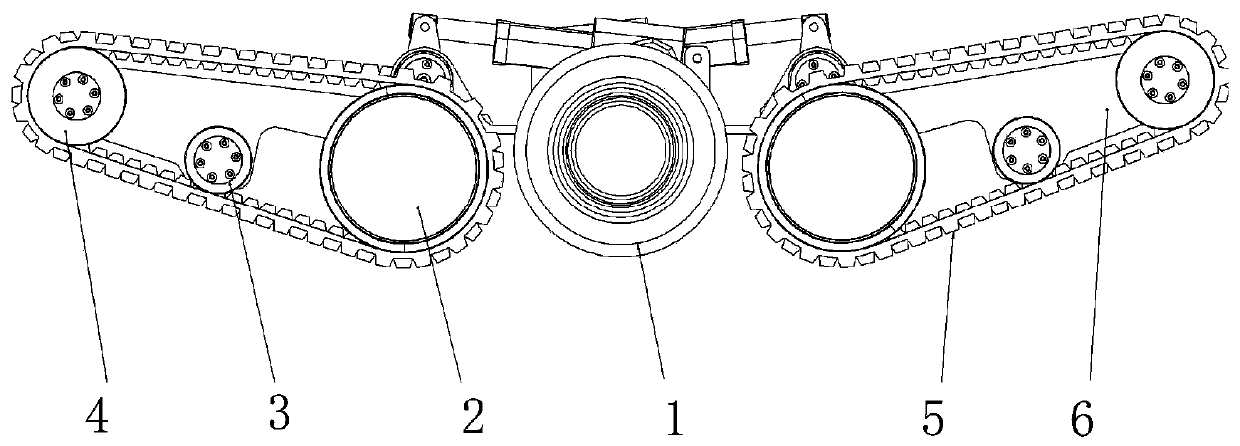

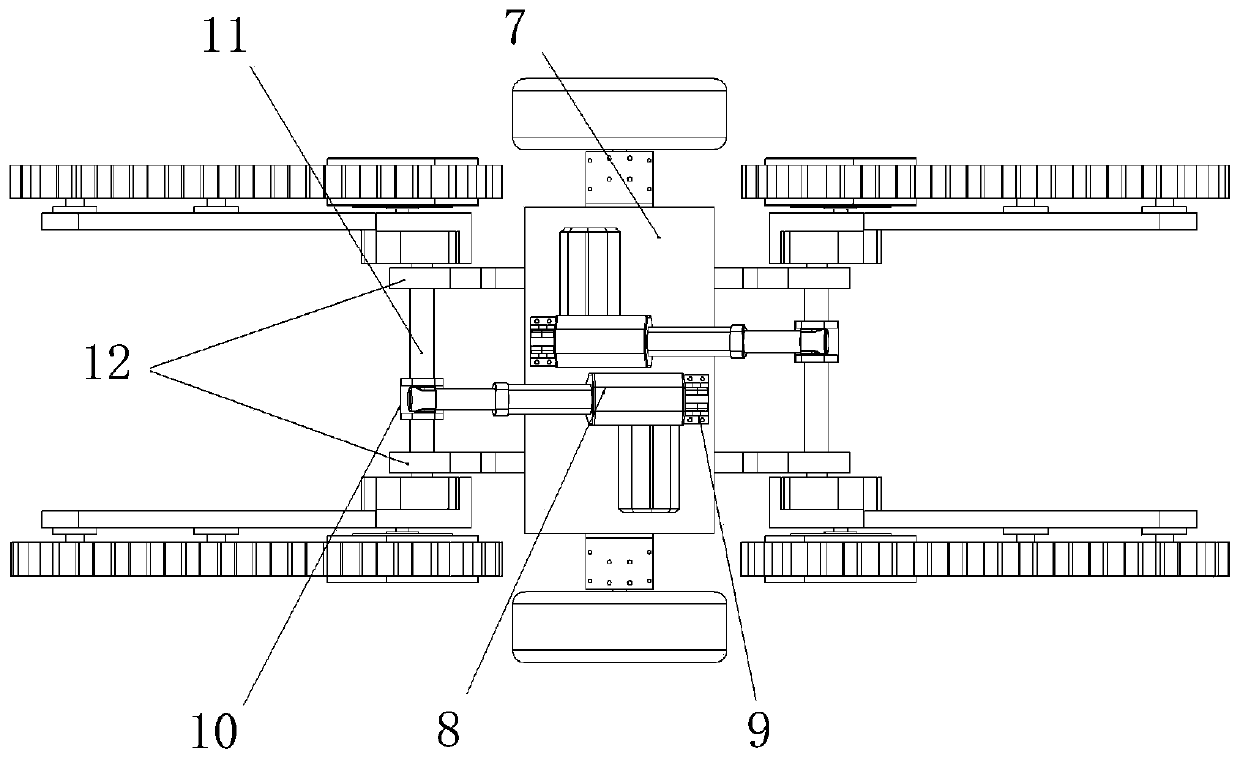

Two-wheel-leg-caterpillar band compound type movement mechanism

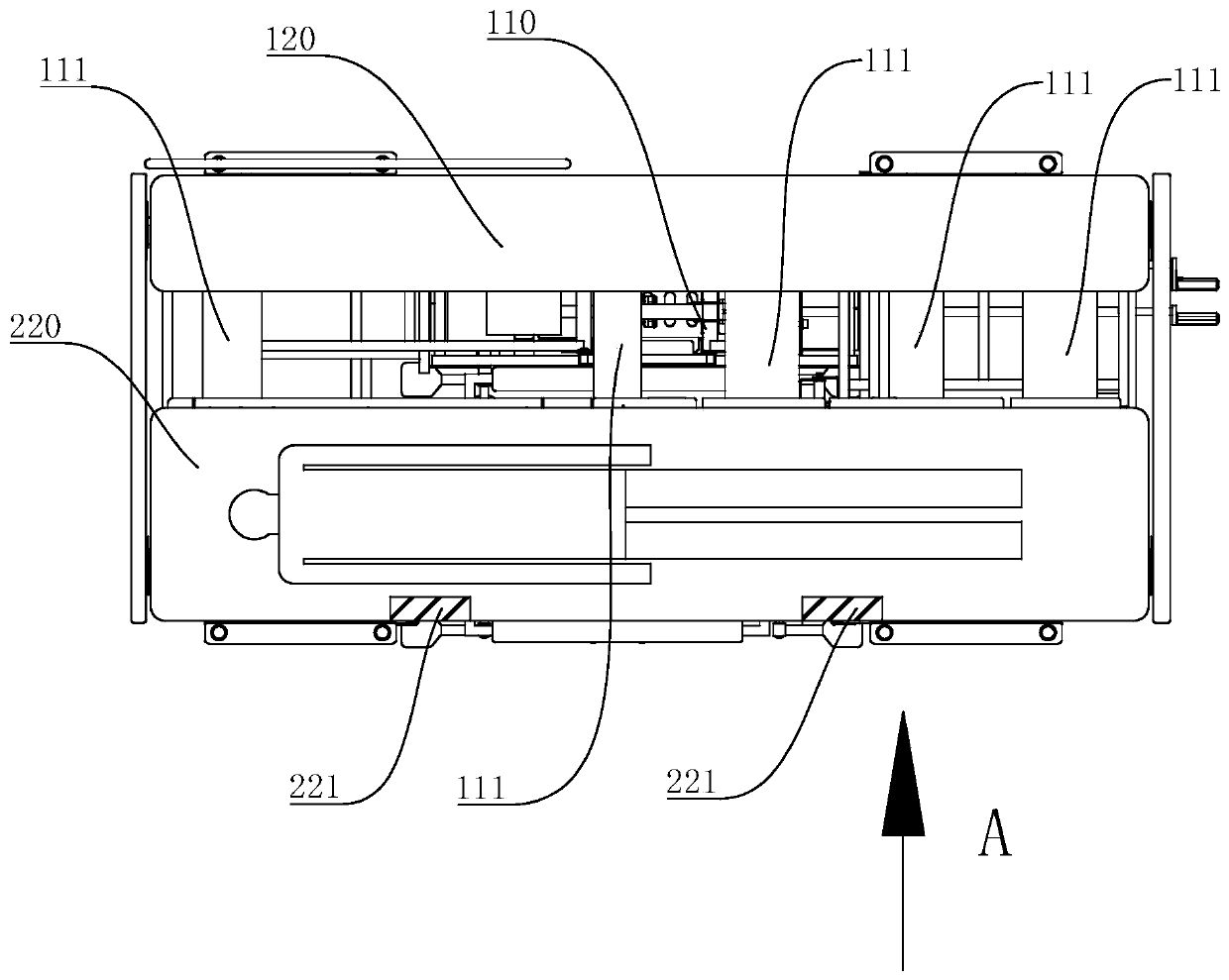

ActiveCN108791548AImprove mobile efficiencyAchieve direct driveEndless track vehiclesTerrainDrive shaft

The invention relates to the technical field of specialized robots, in particular to a two-wheel-leg-caterpillar band compound type movement mechanism. The two-wheel-leg-caterpillar band compound typemovement mechanism comprises a movement seat body, walking wheels, swing leg drive mechanisms and swing leg assemblies. The two walking wheels are installed at the left end and the right end of the movement seat body. Walking wheel drive motors are arranged in the walking wheels. The swing leg assemblies are arranged on the front side and the rear side of the movement seat body. The two swing legdrive mechanisms are arranged on the movement seat body. The swing leg assemblies on the two sides of the movement seat body are driven by the different swing leg drive mechanisms to swing. The swingleg assemblies located on the same side of the movement seat body are connected through a swing leg drive shaft. The swing leg drive shafts are driven by the swing leg drive mechanisms to rotate anddrive the swing leg assemblies to swing. The swing leg assemblies are provided with caterpillar bands. When the walking wheels make contact with the ground to rotate, the caterpillar bands leave the ground, and when the caterpillar bands make contact with the ground to rotate, the walking wheels leave the ground. The problems that an existing robot movement mechanism is poor in maneuvering flexibility, low in movement efficiency and the like on a complex terrain are solved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

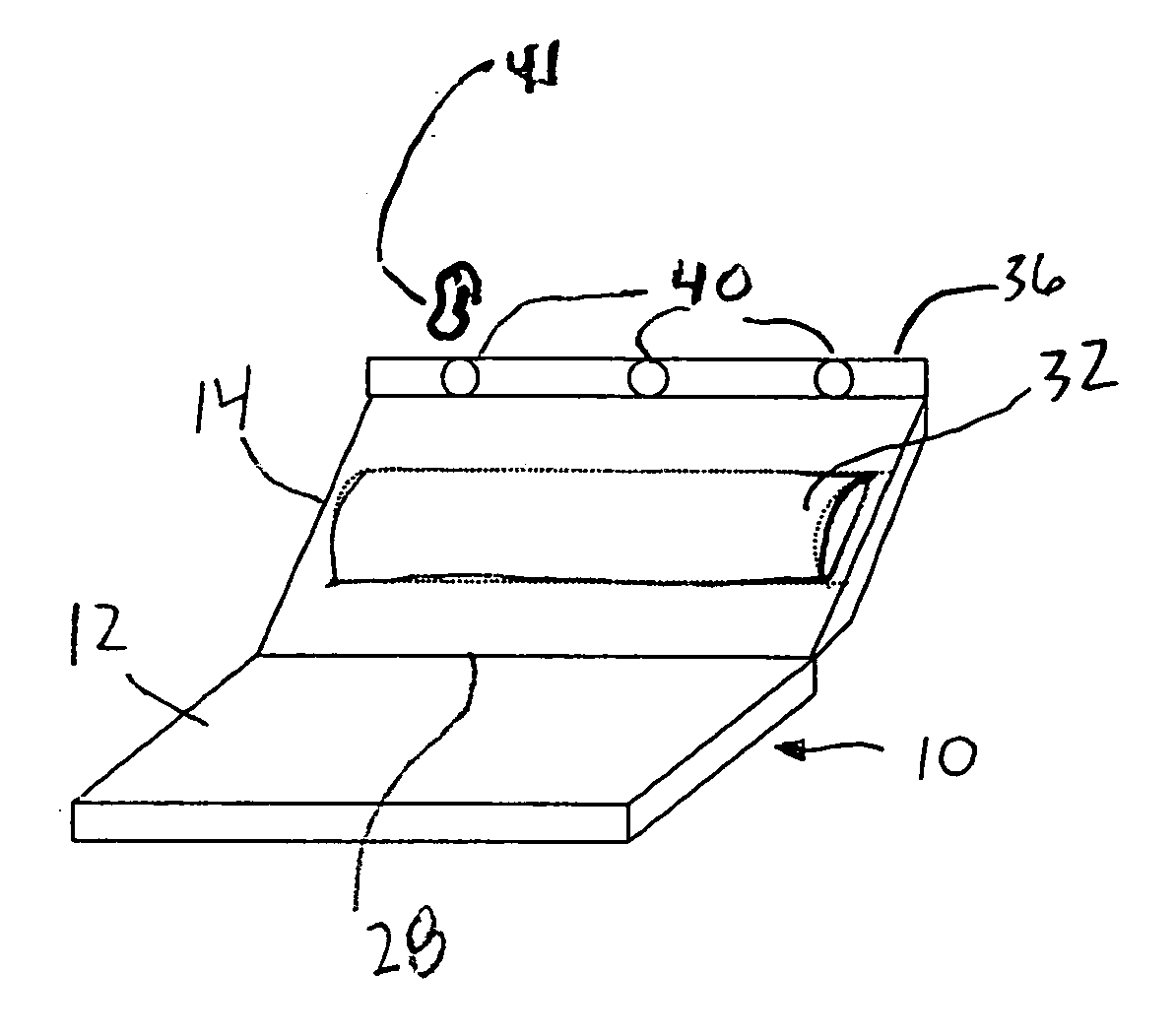

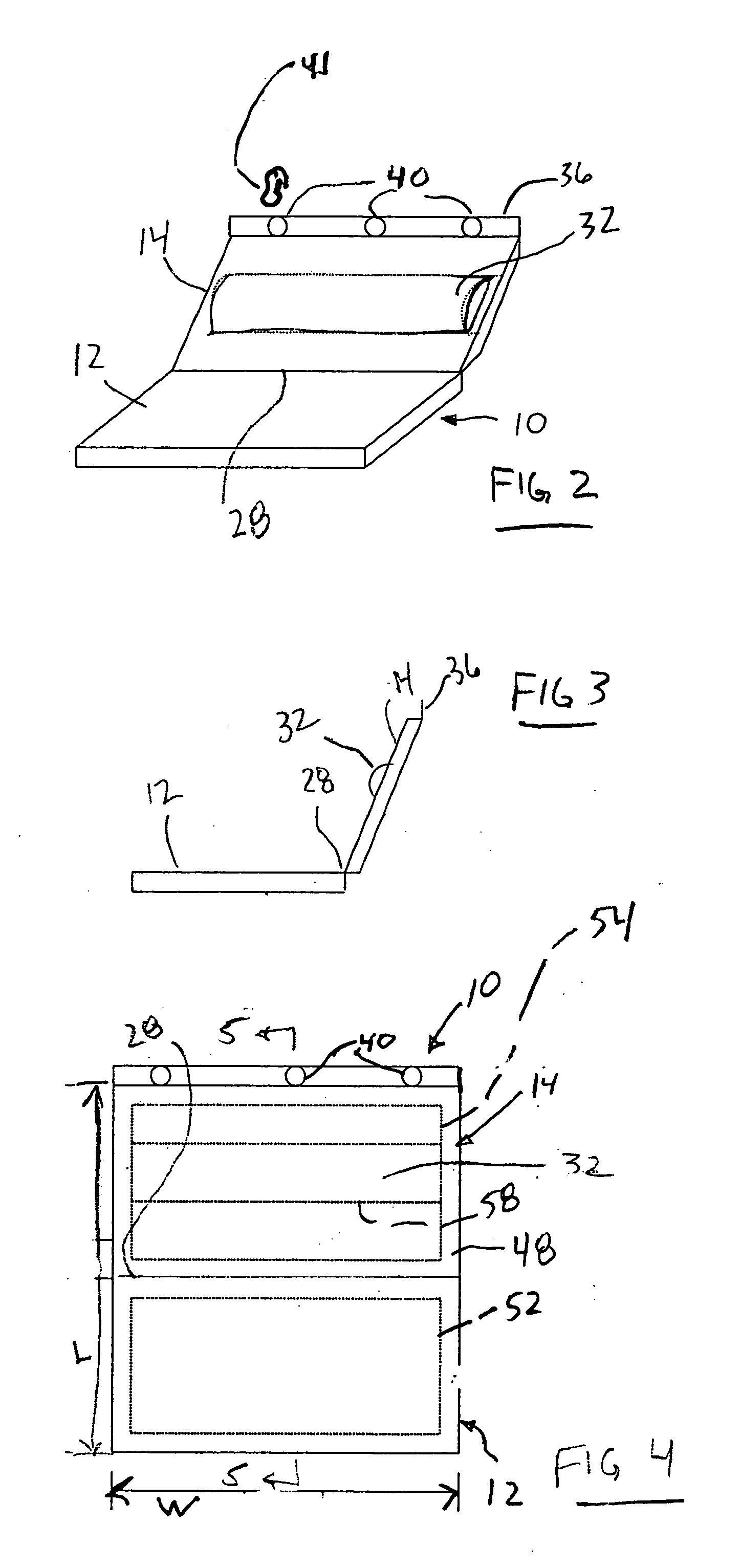

Automobile pad for transporting canines

InactiveUS20070084410A1Eliminate relative slidingReduce shockAnimal housingOther apparatusIn vehicleEngineering

A pad for protecting animals transported in vehicles includes a cushioned base portion arranged to be laid flat onto a support surface of the vehicle such that the first portion has a top surface. The pad can also have a cushioned rear portion arranged to be positioned adjacent to the base portion at an angle to the base portion such that the second portion has a front surface. The top and front surfaces are preferably covered by a vinyl covered fabric composite material. The base and rear portions can be contiguously connected along a fold line.

Owner:HAIN RONALD C

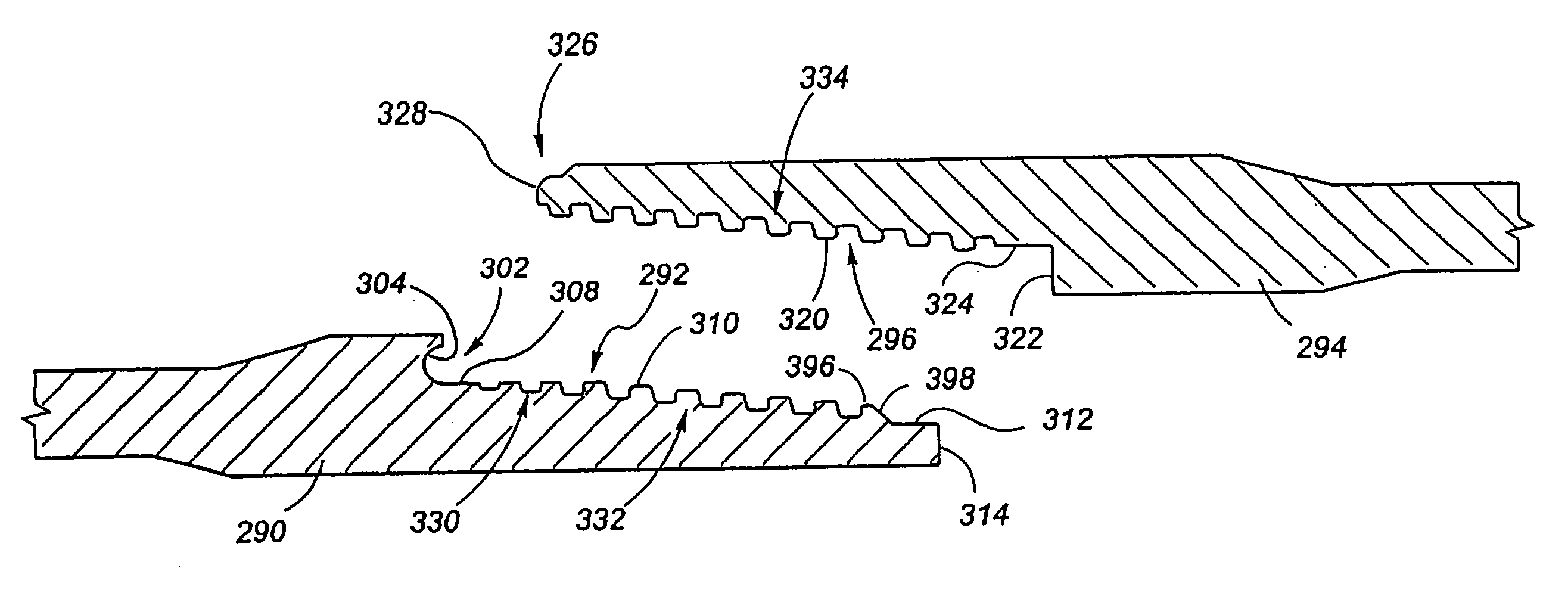

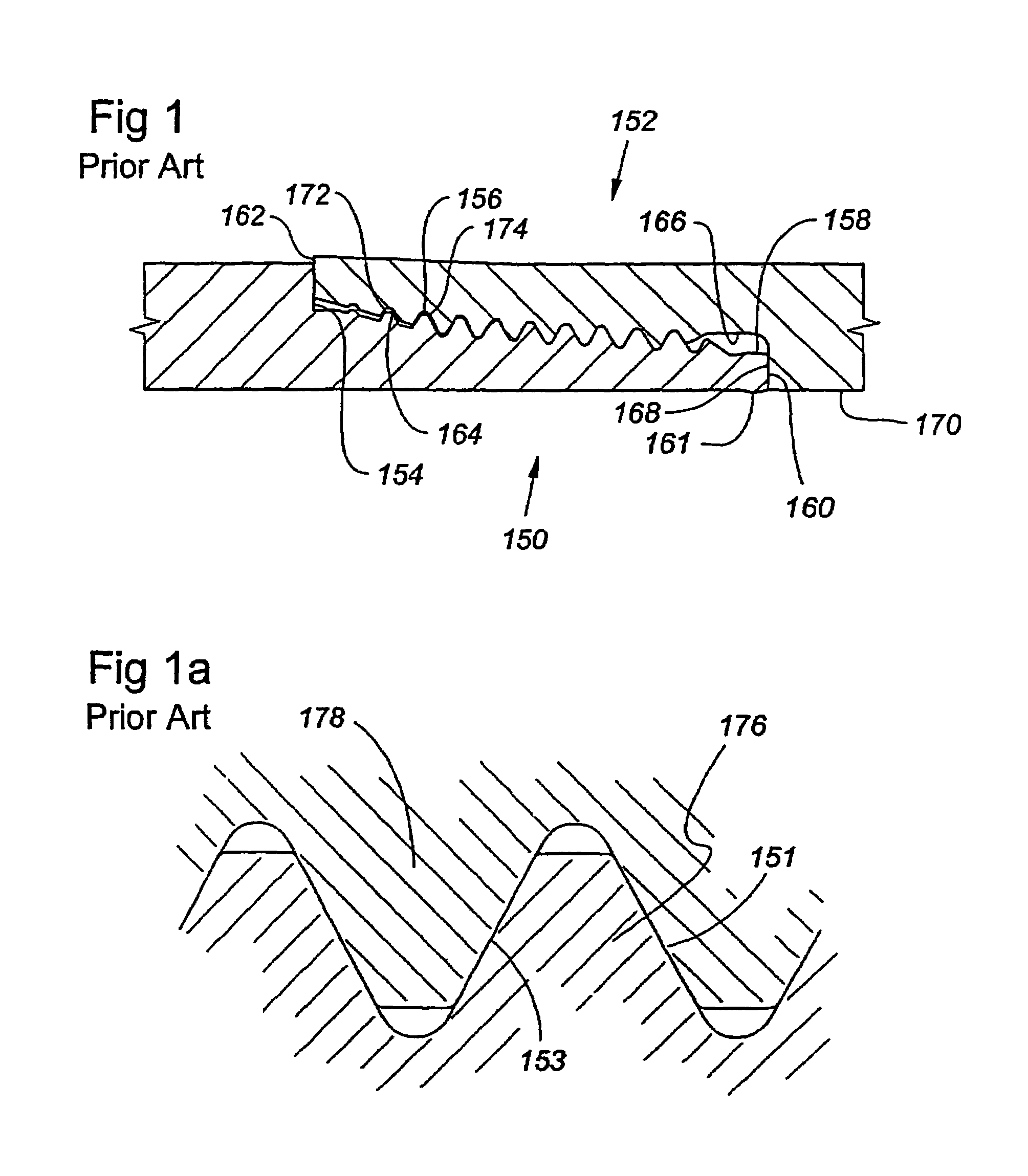

Connection

InactiveUS6990719B2Firmly connectedPrevents rampingDrilling rodsHose connectionsEngineeringScrew thread

A drill string includes a plurality of tubular members each having a connection with a pin connector and a box connector on adjacent tubular members. The pin connector has an external thread with negative load flanks and positive stab flanks, adapted for threadingly engaging an internal thread second threads with negative load flanks and positive stab flanks on the box connector of the adjacent tubular member. The positive stab flanks have corner radiuses and the negative load flanks have radiuses forming a S-shape. The pin connector has an outer groove for receiving a protuberance on the terminal end of the box member forming locking shoulders. The protuberance and groove have contoured surfaces providing large metal-to-metal contact for preventing the contoured surfaces from sliding during over-torquing and cyclic bending of the drill string. The negative load flanks and locking shoulders lock the connection together. The negative load flanks absorbing the tension and the locking shoulders absorbing the compression on the connection.

Owner:HUNTING ENERGY SERVICES LLC

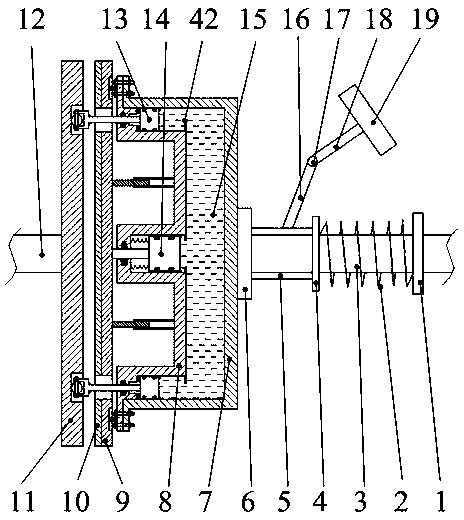

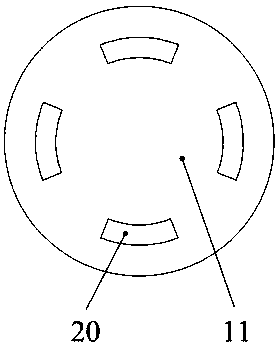

Flexible damping clutch based on hydraulic pressure

ActiveCN107763114APrevent disengagementPressure balanceFriction clutchesVibration absorptionControl theory

The invention provides a flexible damping clutch based on hydraulic pressure. The flexible damping clutch mainly comprises a hydraulic auxiliary device, a flexible pressing device, a guide device, a control device, and driving and driven devices; the flexible pressing device, the guide device and the control device are respectively mounted on the hydraulic auxiliary device; and the driving and driven devices are connected with the hydraulic auxiliary device through the flexible pressing device and the guide device. The flexible damping clutch has the characteristics of rolling flexible joint and hydraulic vibration absorption. The no-vibration automatic clutching of the clutch is realized through the hydraulic auxiliary device; the low-wear flexible joint and the quick separation of the clutch are realized through the flexible pressing device; the no-deviation oriented motion of a pressing disc and a driven disc is realized through the guide device; the free clutching of the clutch isrealized through the control device; and the power transfer is realized through the driving and driven devices.

Owner:UNIV OF JINAN

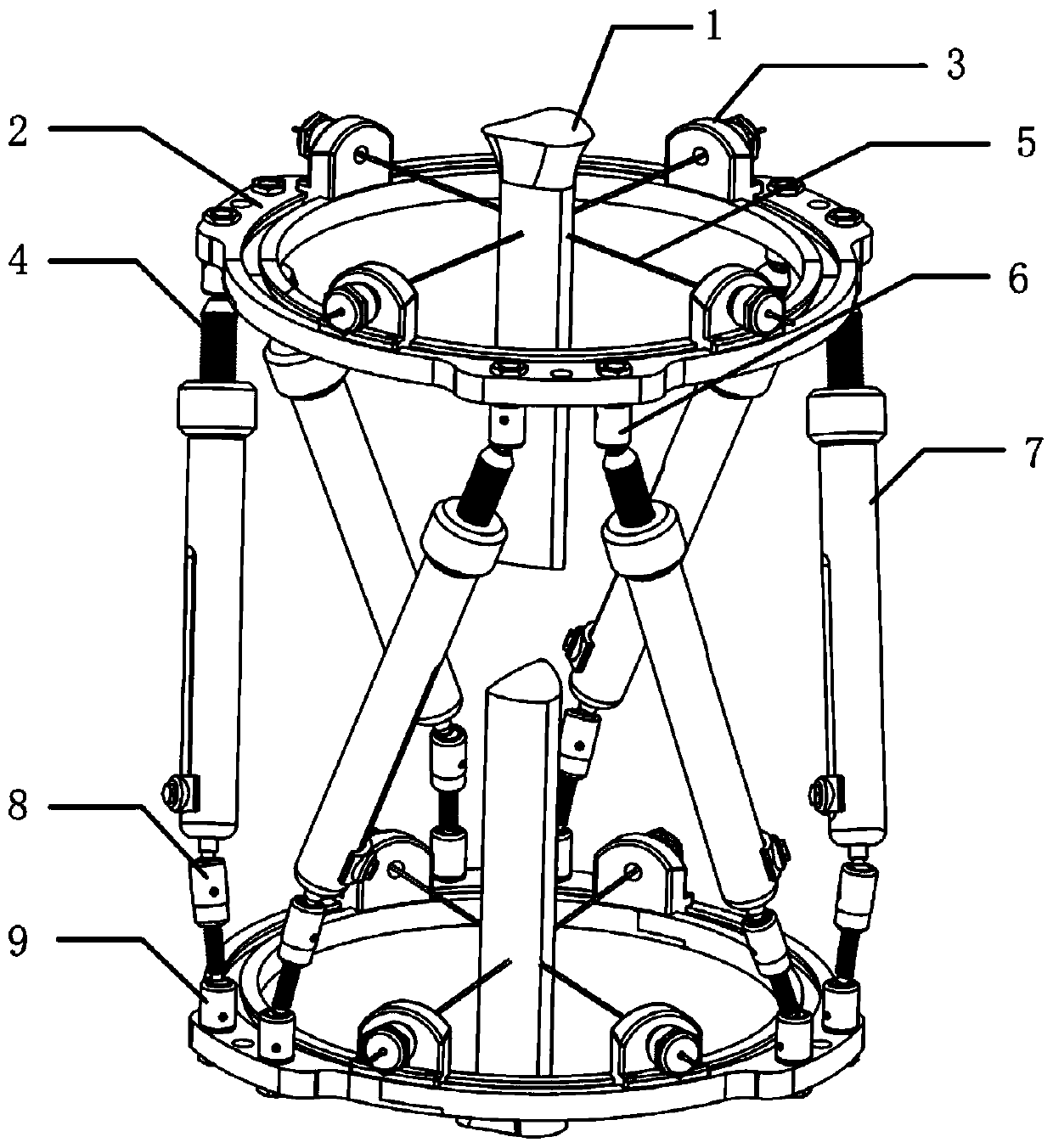

Anti-seizure deformity correction external fixator

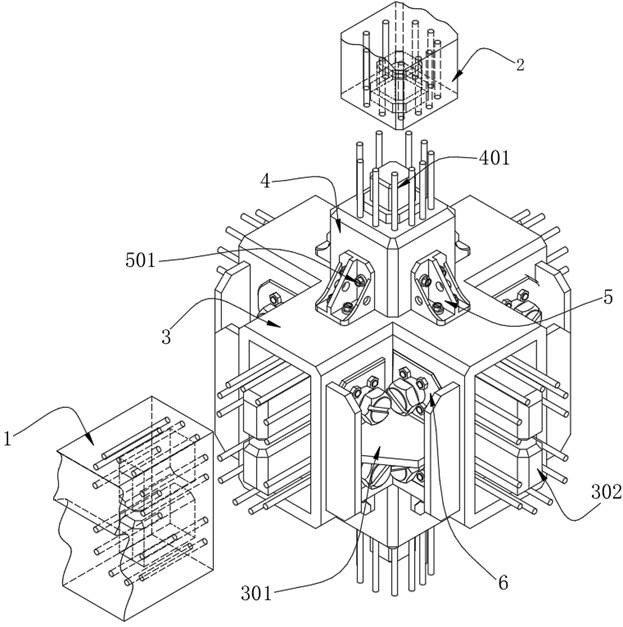

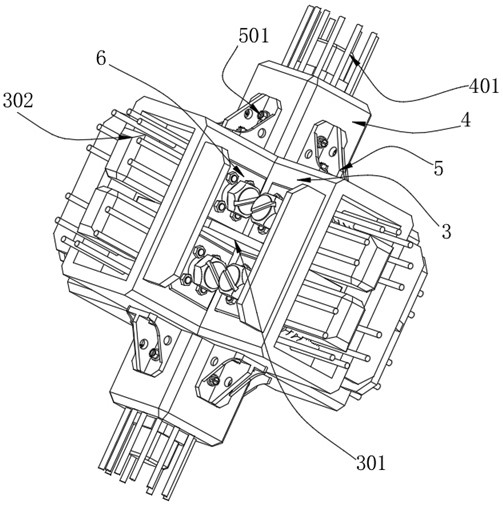

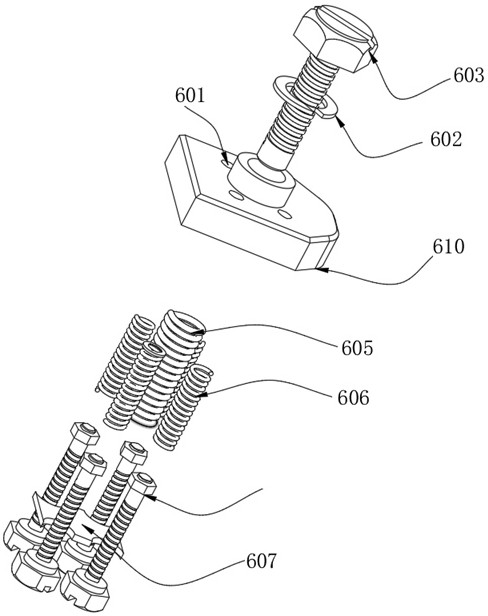

ActiveCN109758218AAchieve correctionAchieve angledExternal osteosynthesisExternal fixatorSelf locking

The invention provides an anti-seizure deformity correction external fixator. The fixator has 6 degrees of freedom and mainly consists of a proximal ring, a distal ring, 6 length adjustable branches,an adjustment knob, a sliding self-locking needle clip, T-ring grooves and a kirschner wire. The deformed bone is fixed on a fixing ring of the fixator by the kirschner wire, the T-ring grooves are formed in the proximal ring and the distal ring, and the self-locking needle clip can slide in the grooves. The posture of a moving platform can be changed by adjusting the length of a branch chain andlocking some moving pairs to achieve correction of three-dimensional deformity such as angle, misalignment, rotation or separation. Three ball joints on each branch chain can achieve separate locking,can effectively solve the problems of interference and seizure during the correction process, and achieve correction of all rotation and displacement deformities. The sliding self-locking needle clipcan effectively prevent complications like needle infection, a frame and a support rod are not required to be changed in the correction process, the fixing is reliable, and the fixator is convenientto use.

Owner:BEIJING UNIV OF TECH

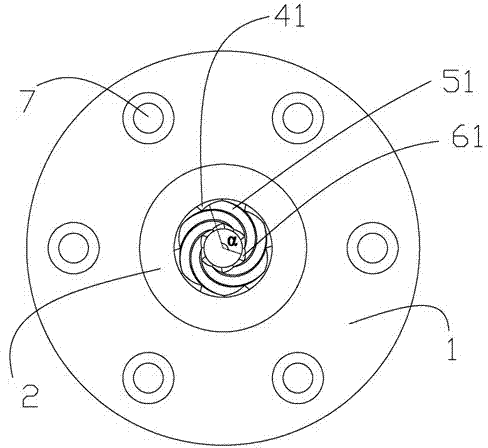

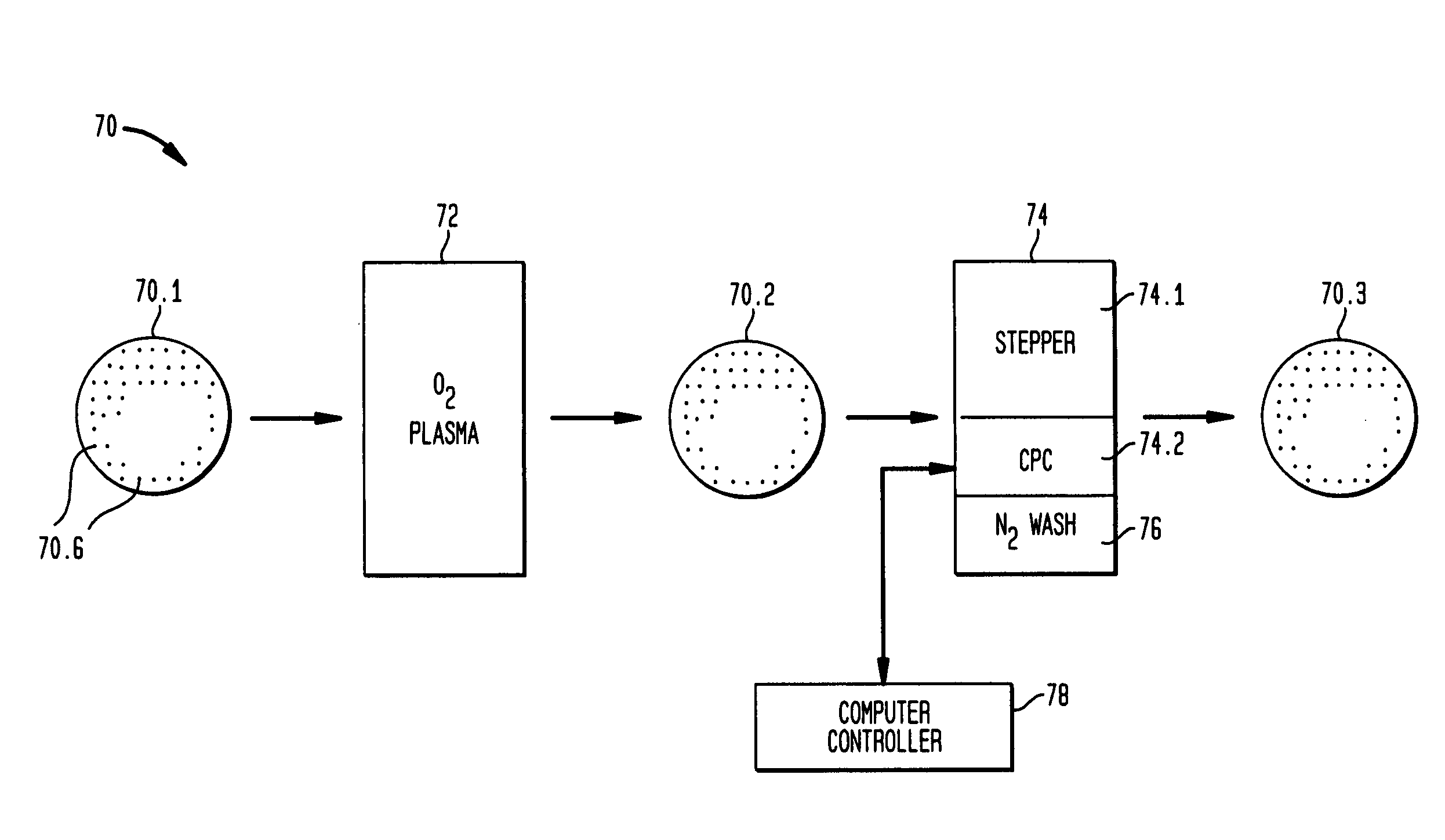

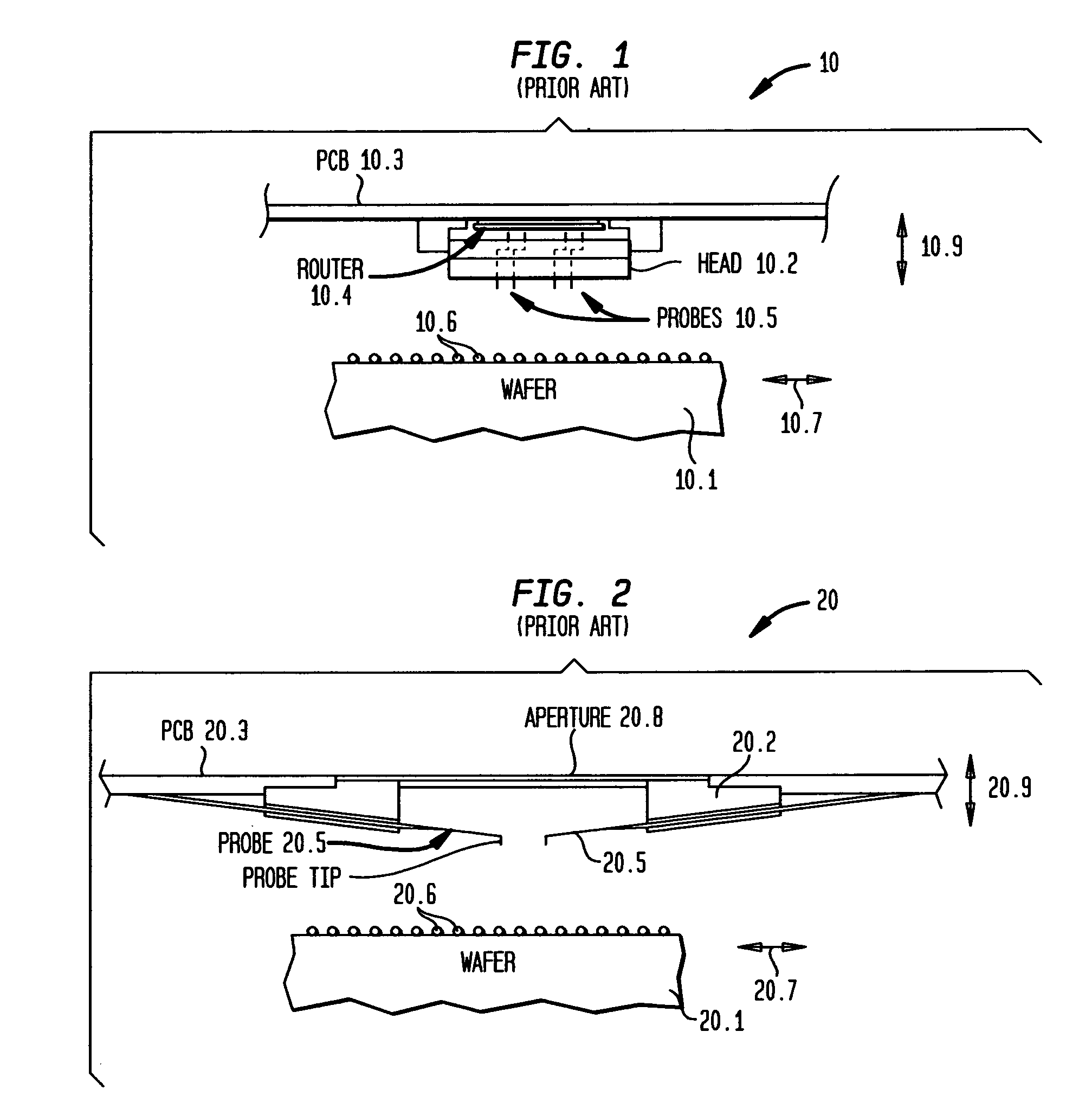

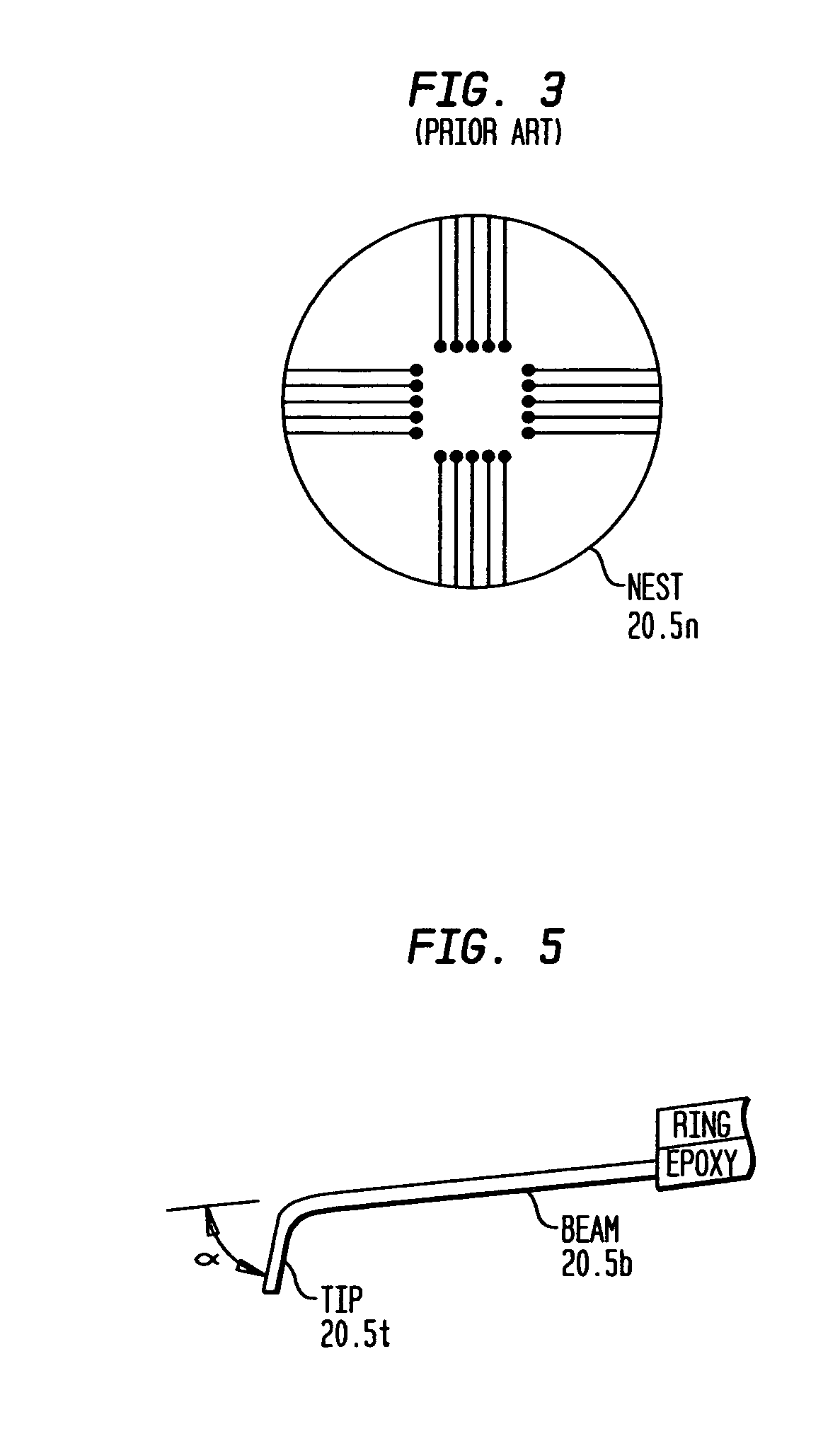

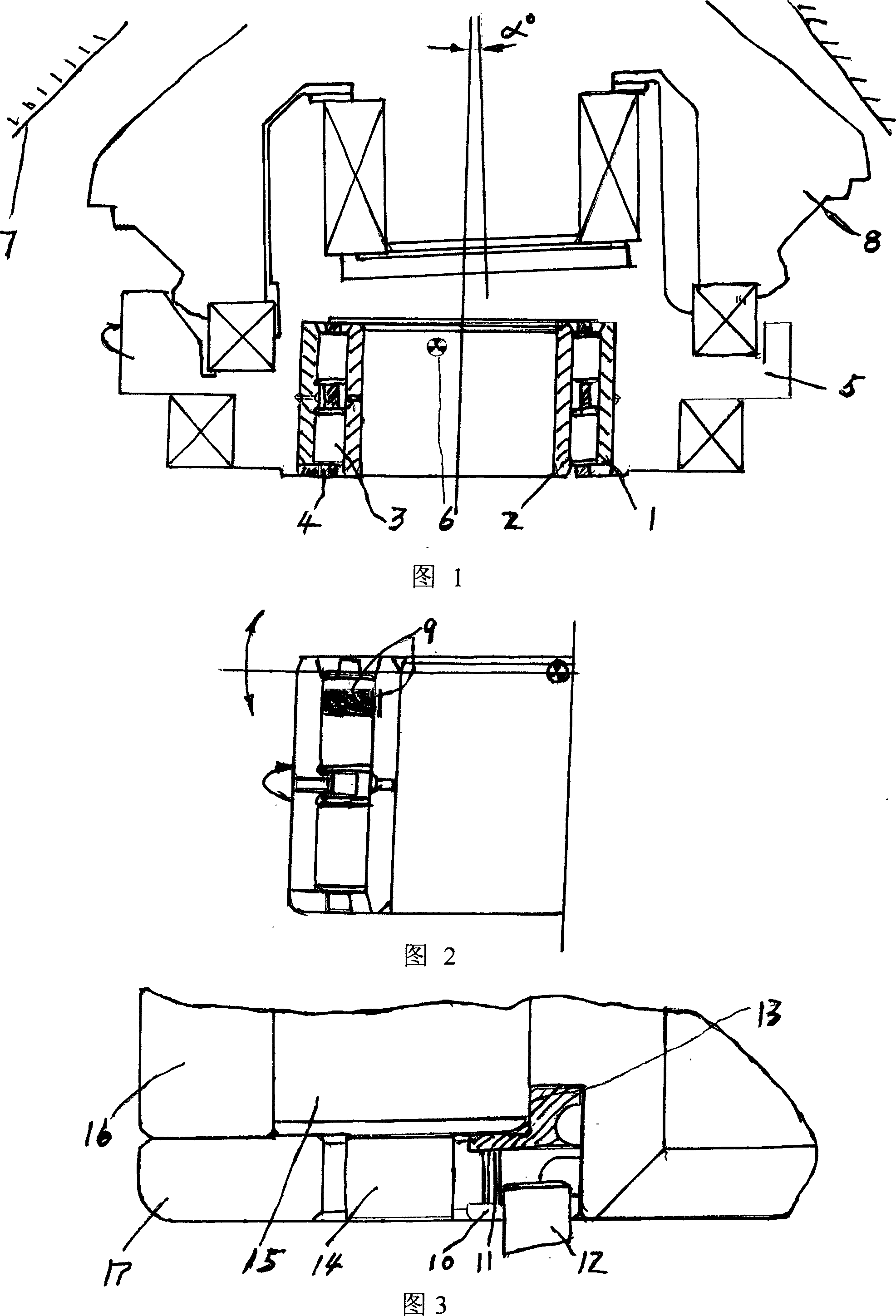

Method of testing electronic wafers having lead-free solder contacts

ActiveUS7005880B1Eliminate relative slidingReduce contact resistanceElectrical measurement instrument detailsIndividual semiconductor device testingElectrical resistance and conductanceElectricity

A cantilever probe method of parametrically testing wafers extends the probe tip cleaning interval, maintains relatively low contact resistance, and reduces contact resistance variability. In one embodiment of our invention, a method of testing electronic circuits formed in a wafer having lead-free terminals, comprises the steps of exposing the terminals to a plasma containing oxygen; providing a test apparatus having cantilevered probes for contacting the terminals; each probe having a cantilevered probe arm and a BeCu probe tip extending from the arm at an acute angle α; the angle α being designed to essentially eliminate sliding movement of the probe tip when in contact with a terminal; and bringing the probe tips into contact with selected ones of the terminals, so as to perform electrical tests on the wafer; and, during the contacting step, exposing the probe tips to a flow of a non-oxidizing gas (e.g, nitrogen, argon). In a preferred embodiment, the terminals are Sn-based solder bumps. In another preferred embodiment the angle α is approximately 87°–90°.

Owner:BELL SEMICON LLC

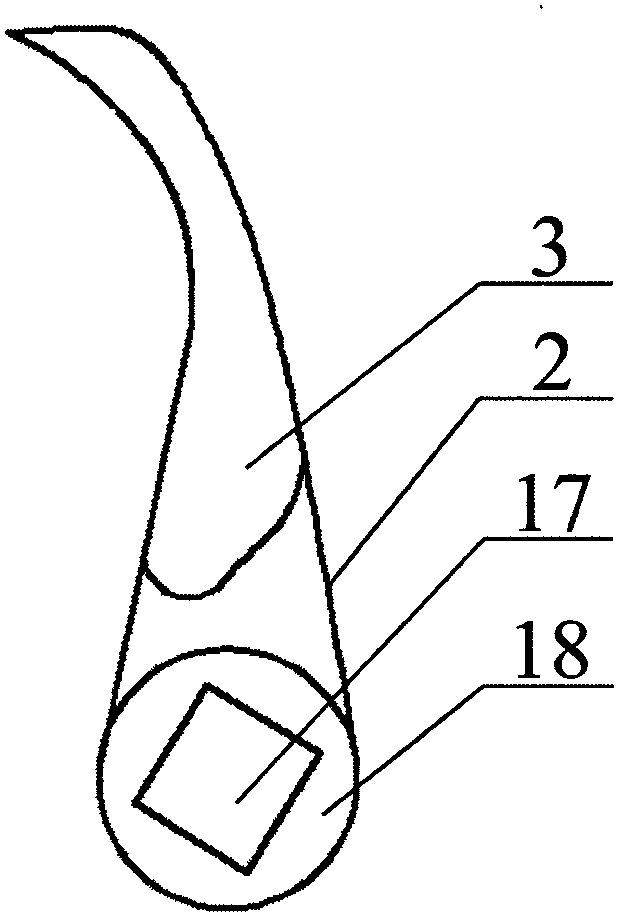

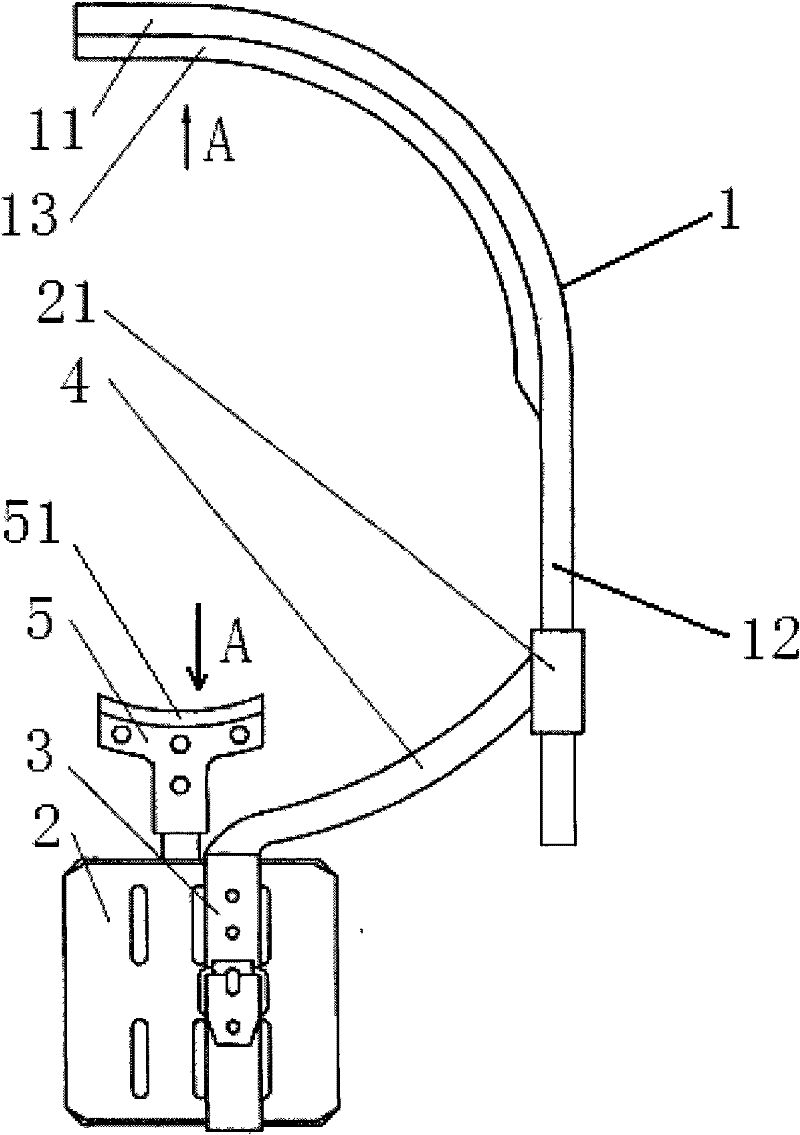

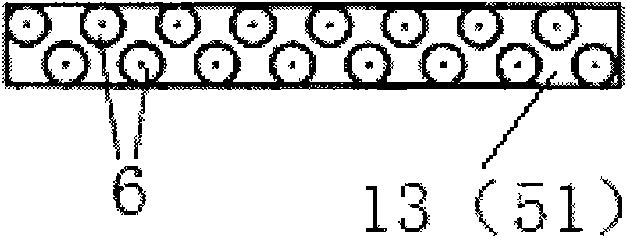

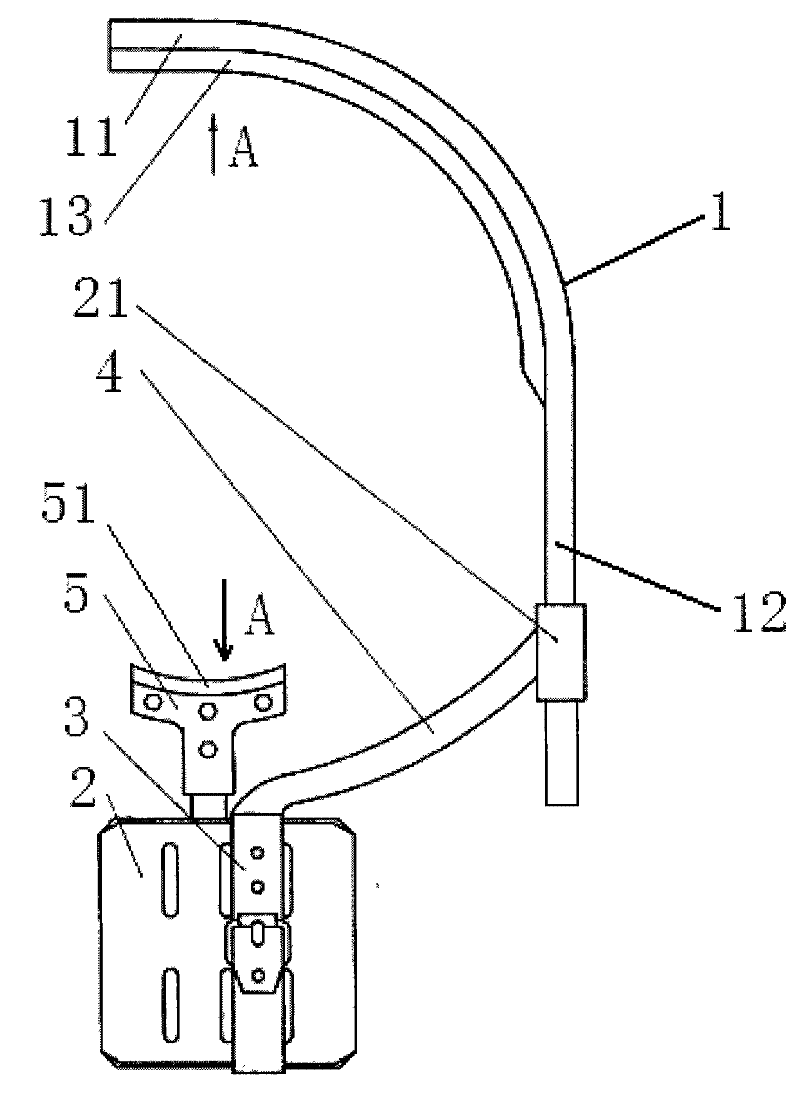

a climbing tool

The invention relates to a climbing tool, which includes a movable hook, a pedal, a connecting rod and a T-shaped claw. The movable hook includes an arc segment and a straight segment integrally formed therewith. The other end of the bottom surface of the pedal is fixedly connected to the sleeve, and the end of the straight section of the movable hook is fixedly connected in the sleeve, and the vertical part of the T-shaped claw is fixedly connected to the pedal. On the bottom surface, an arc-shaped anti-slip block is arranged on the inner surface of the horizontal part, and a rubber pad is arranged on the inner surface of the arc section of the movable hook, and a plurality of steel nails are embedded on the surface of the rubber pad. Even when the invention is used in a humid environment, the concrete pole can be firmly clamped, the relative sliding between the tool and the concrete pole is eliminated, the operator can move up and down freely, the safety factor of the operation is greatly improved, and the preparation time for the operation is reduced .

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Circular blade with accurate positioning structure and cutting tool

ActiveCN107498610AEasy to installImprove clamping rigidityMetal working apparatusTurning toolsEngineeringMechanical engineering

The invention discloses a circular blade with an accurate positioning structure and a cutting tool. The circular blade comprises a blade body, wherein the blade body is composed of an upper surface, a lower surface and a side face which is used for connecting the upper surface with the lower surface; and the blade body is provided with a center hole which penetrates through the upper surface and the lower surface, the blade body is centrosymmetric relative to the central axis of the center hole, the upper surface intersects with the side face to form a cutting edge, the inner surface of the center hole is provided with at least two lug bosses, and the included angle between every two adjacent lug bosses is smaller than 180 degrees. The cutting blade has the advantages that positioning is reliable and stable, multi-ply clamping can be achieved, and the service life is long. The cutting tool is provided with the circular blade, sliding or rotating of the circular blade in the peripheral direction in the using process can be eliminated, the stability of the cutting edge in a cutting region is guaranteed, other cutting processes are prevented from participating in one cutting process, the usable frequency of the circular blade on the cutting tool is effectively stabilized, and then the service life of the cutting tool is prolonged.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

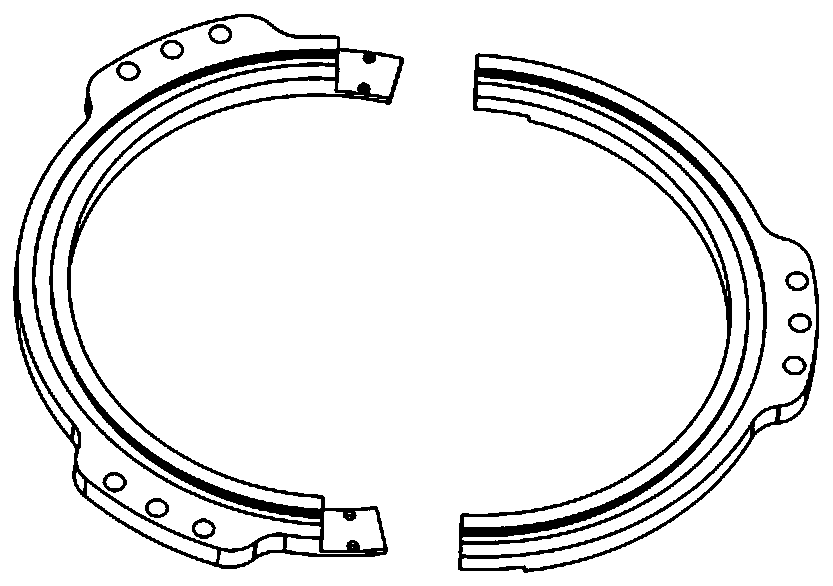

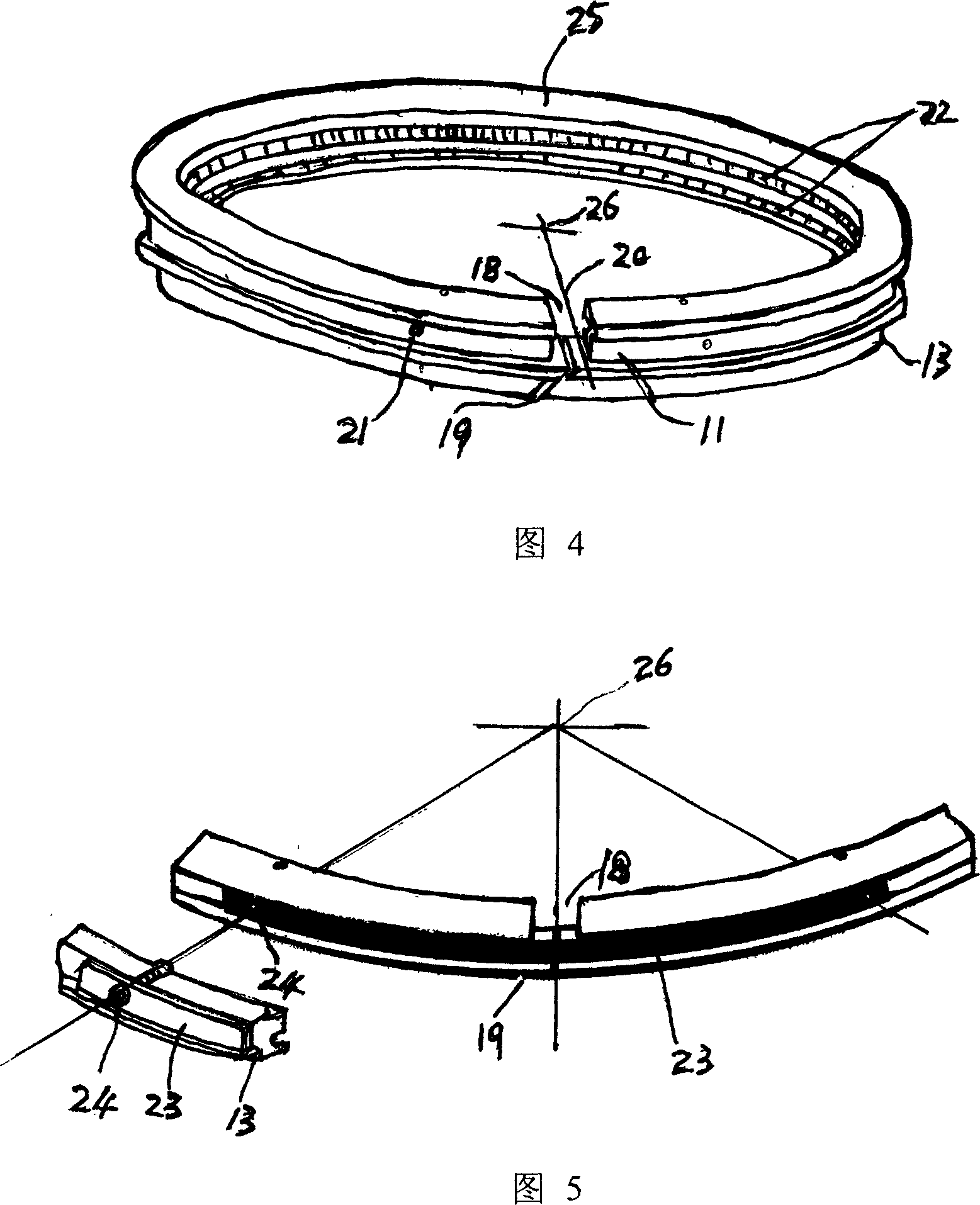

Circlip for cylindrical roller bearing and its production method

InactiveCN101122309AEliminate relative slidingAddress burnsBearing componentsEngineeringSpring steel

A circlip is used in a cylindrical roller bearing. Two ends of the circlip are connected via two spring steel pieces. An opening is arranged on the lower end surface of the connecting end, while an oblique notch connected with the opening is arranged on the upper end surface of the connecting end. An internal ring of the circlip is equipped with two oil-seal grooves, which extend outwards from the left and the right of the opening and become shadow gradually. The external ring of the circlip is equipped with a raceway surface to give load to a roller, and a fixing groove to fix the spring steel pieces. The spring steel pieces are arranged in the fixing groove at an angle of 30 degrees with both sides of the central line of the circlip opening in a perimetric way. As two ends of the opening are fixed with the spring steel pieces due to the size of the opening, the circlip of the invention is provided with the inward elasticity to give load to the roller and press the roller to the raceway in the external ring. When the external ring of the bearing revolves, the roller is forced to rotate. As the circlip cannot rotate with the bearing, the roller will not slide so as to solve the problem of burning of the roller. The invention is simple in the process. The circlip is provided with the good elasticity, the long usable life and the low cost, can greatly promote the working efficiency.

Owner:SHIBIAI SPECIAL BEARING LUOYANG

Torsional vibration damper

ActiveUS20180306271A1Sliding resistanceAvoid contactRotating vibration suppressionYielding couplingEngineeringTorsional vibration

A torsional vibration damper in which vibration damping performance is ensured by preventing a contact between a rolling mass and a rotary member. A rolling mass includes a trunk penetrating through a bore. A first corner formed in an axial end of the trunk is rounded. A rotary member includes a second corner formed in the bore. an axial length of the first corner of the rolling mass is longer than an axial length of the second corner of the rotary member.

Owner:TOYOTA JIDOSHA KK

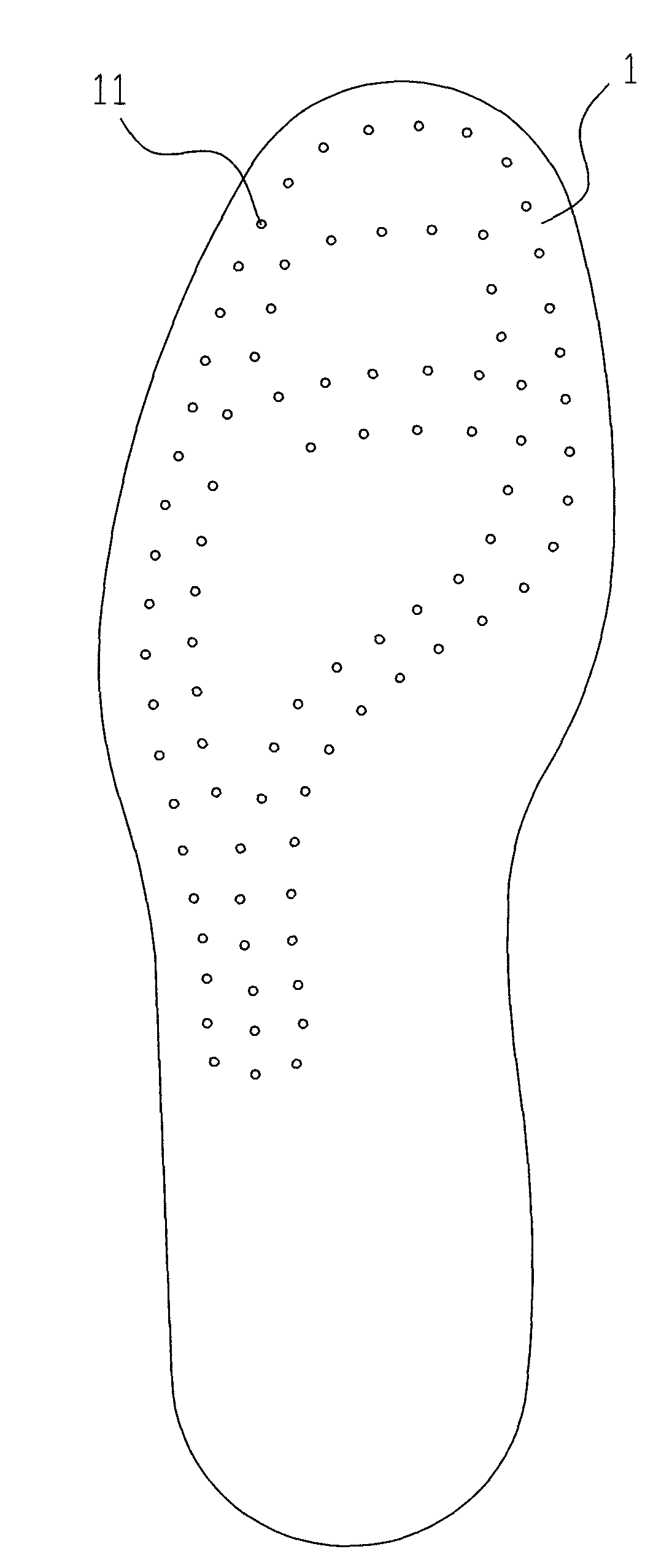

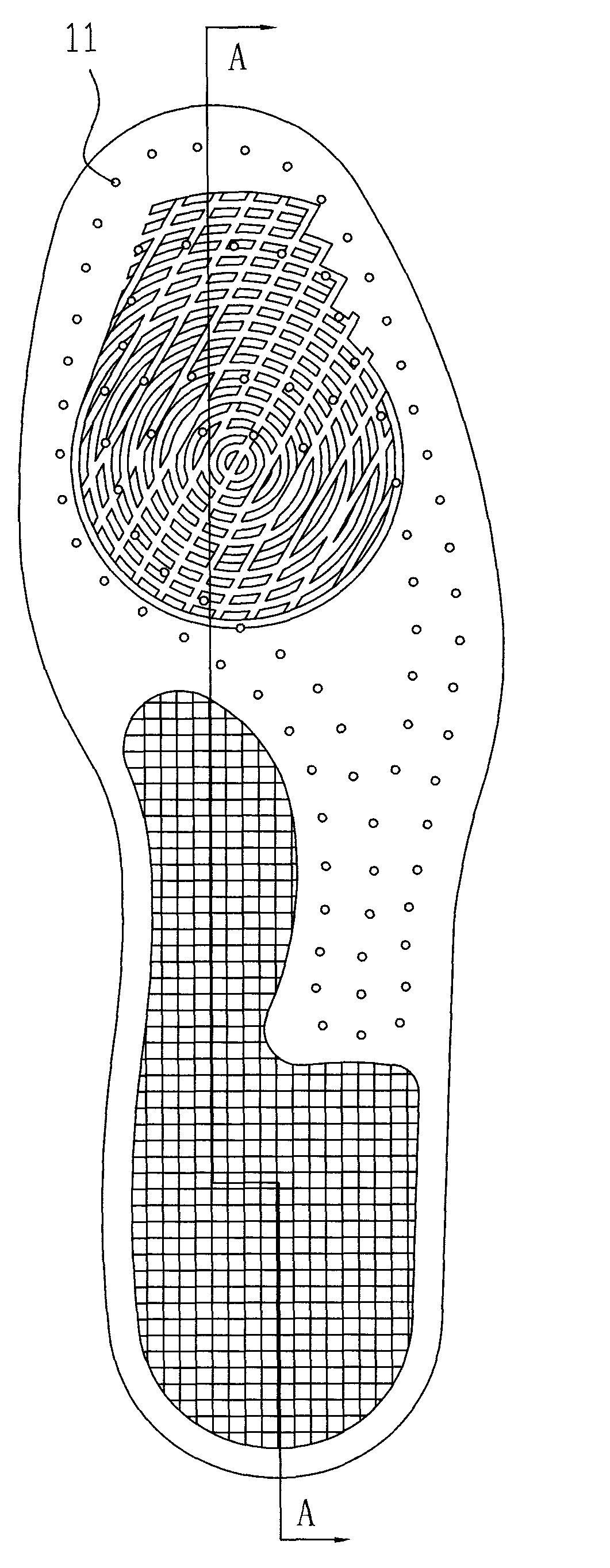

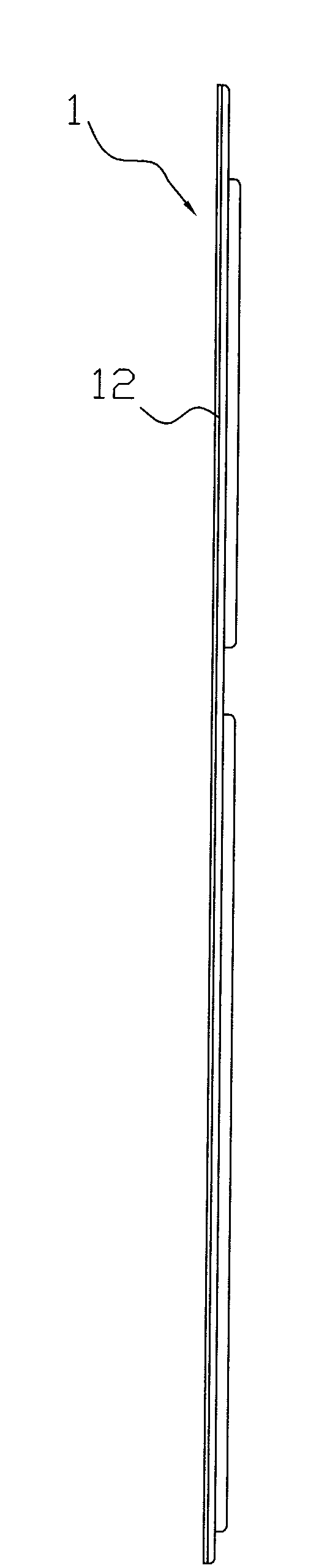

Shoe pad and making method thereof

InactiveCN102704276AEliminates the problem of slippery insolesEliminate relative slidingInsolesFibre treatmentSurface layerEngineering

The invention discloses a shoe pad and a making method of the shoe pad. The shoe pad is characterized in that the shoe pad is composed of an ingredient a and an ingredient b, wherein the mixing ratio of the ingredient a to the ingredient b is 1:3-2:4. The making method of the shoe pad sequentially comprises the following steps of: 1. raw material and additive: selecting shoe pad surface layer cloth as the raw material and preparing the additive capable of being prepared to polyurethane after being mixed; 2. opening a mould, paving the shoe pad surface layer cloth on the inner surface a lower mould body, and closing the mould; 3. mixing the ingredient a with the ingredient b, and injecting the mixed material in the mould through a mould injection opening; and 4. opening the mould, taking out the shoe pad, moving the shoe pad to the lower mould of an edge trimmer, and pressing the upper mould of the edge trimmer downwards to obtain the finished product. The shoe pad disclosed by the invention has the advantages of eliminating the problem that the shoe pad is easy to slide due to the change of sole application point during the walking process of a person.

Owner:宁波市金穗橡塑机电有限公司

Strapping apparatus

ActiveCN109689505ATension effectAvoid sudden changesBinding material applicationBundling machine detailsClassical mechanicsStructural engineering

The invention discloses a strapping apparatus for strapping articles with a strapping band having a tensioning device for imparting a band tension to a loop of the strapping band, the tensioning device including a driveable tensioning element provided for engaging the strapping band to impart a band tension. The strapping apparatus including a connecting device for generating a permanent connection, in particular a welded connection, at two regions, situated one above the other, of the loop of the strapping band. The strapping apparatus is configured to achieve the release of the tensioning element from the strapping band reliably to avoid or reduce adverse characteristics attributed to the release of the tensioning device from the band.

Owner:SIGNODE IND GRP

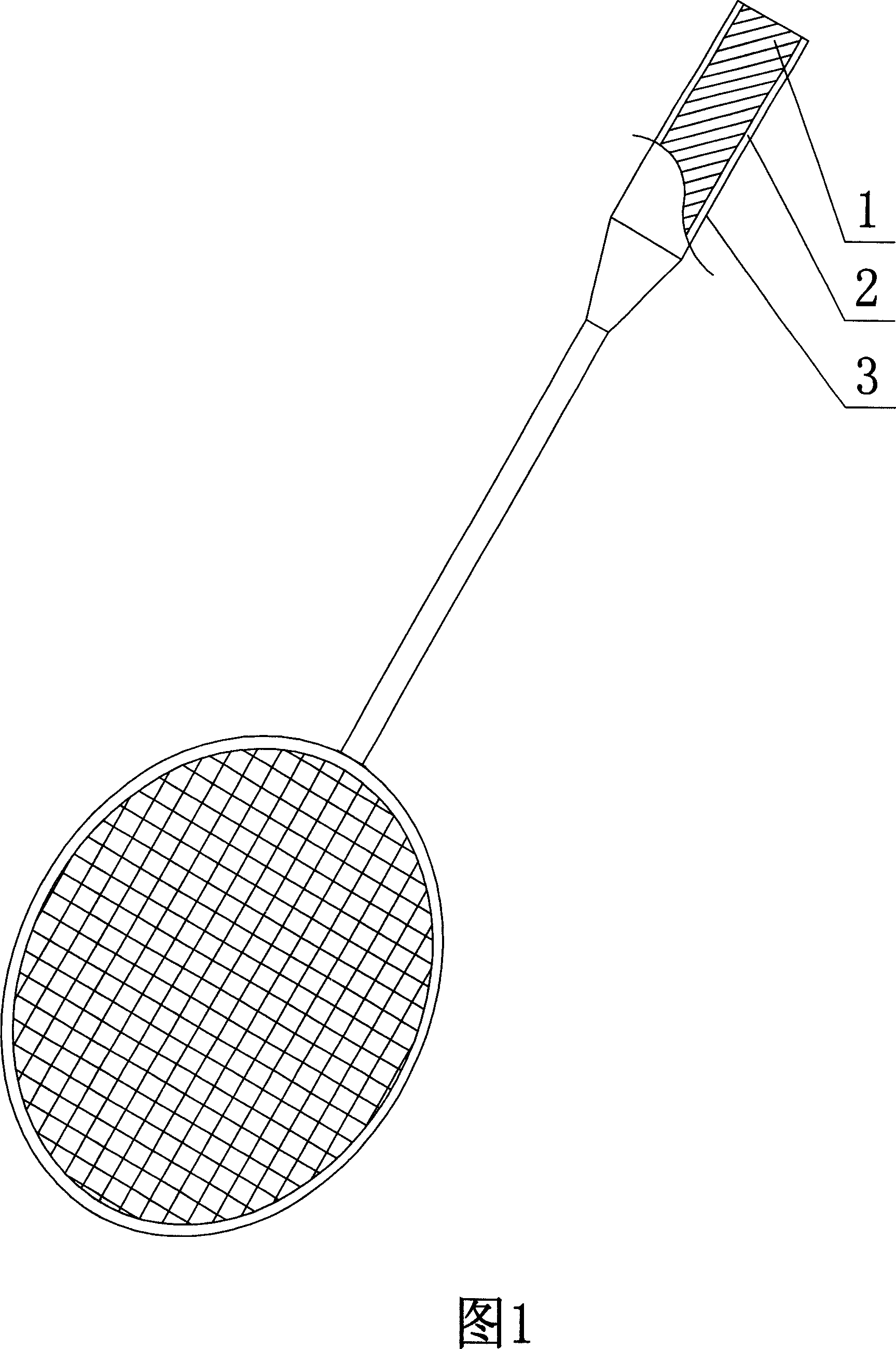

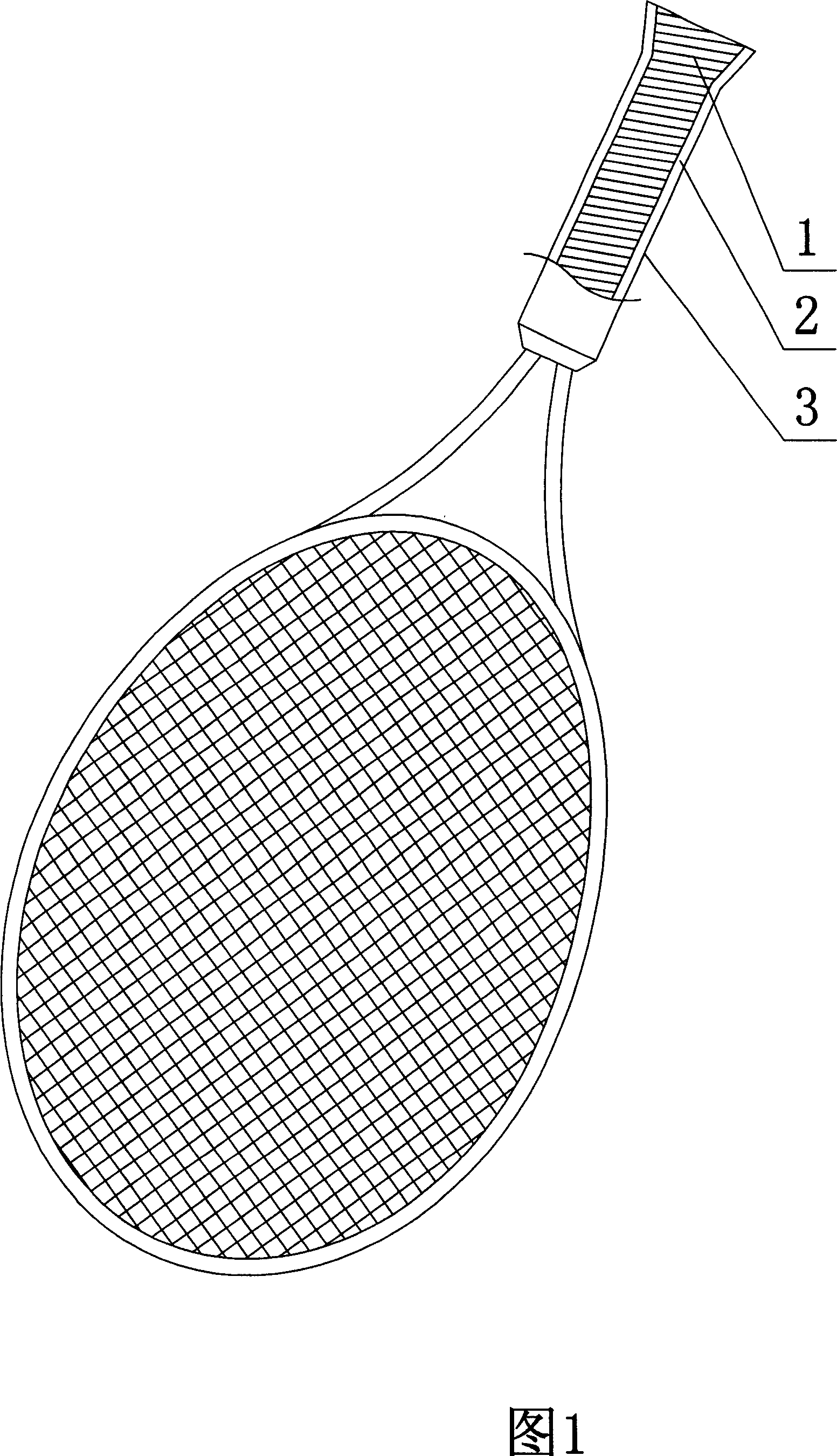

A labor saving battledore

InactiveCN1943828AImprove protectionEliminate relative slidingStringed racketsWater resistantGrip strength

This invention relates to a labor saving battledore by wrapping with water-resistant abrasive paper by glass cement on the handle surface of battledore. It is non-slip, ventilation, more important can reduce the hand grip strength to a large extent, therefore save the athletes' strength, beneficial to their skills, improve their performances.

Owner:SICHUAN UNIV

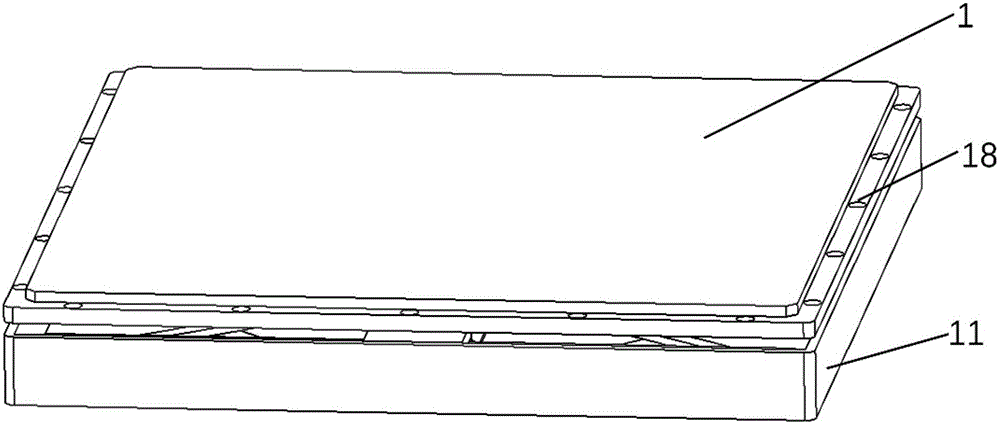

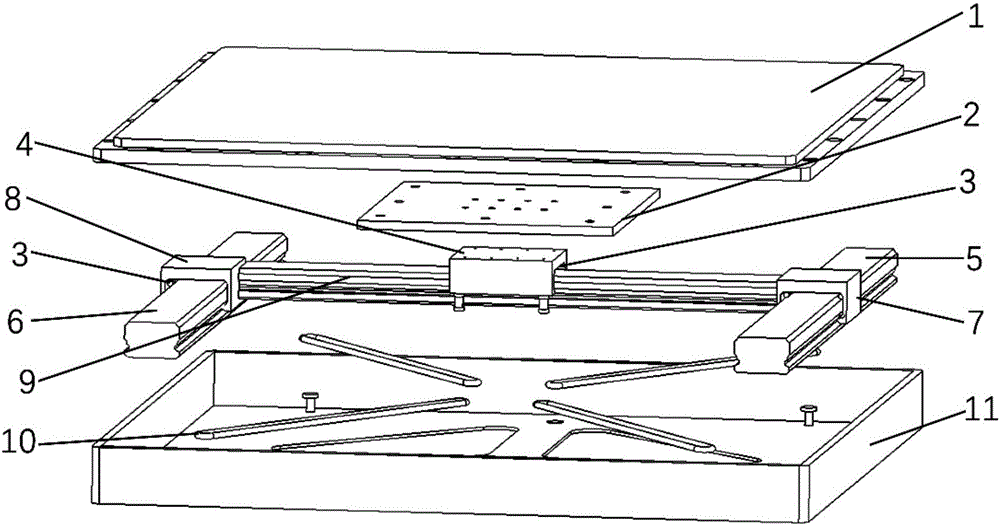

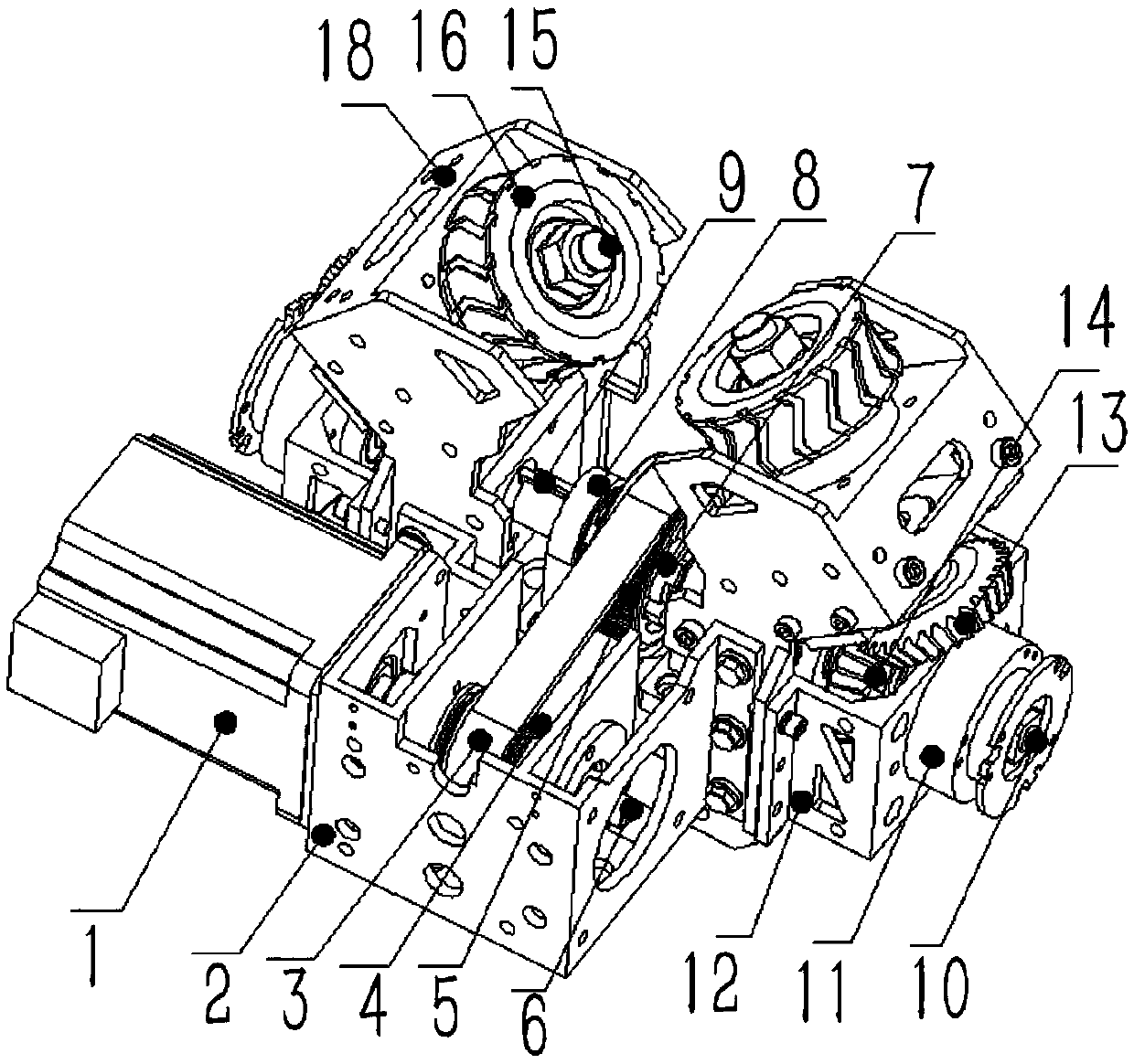

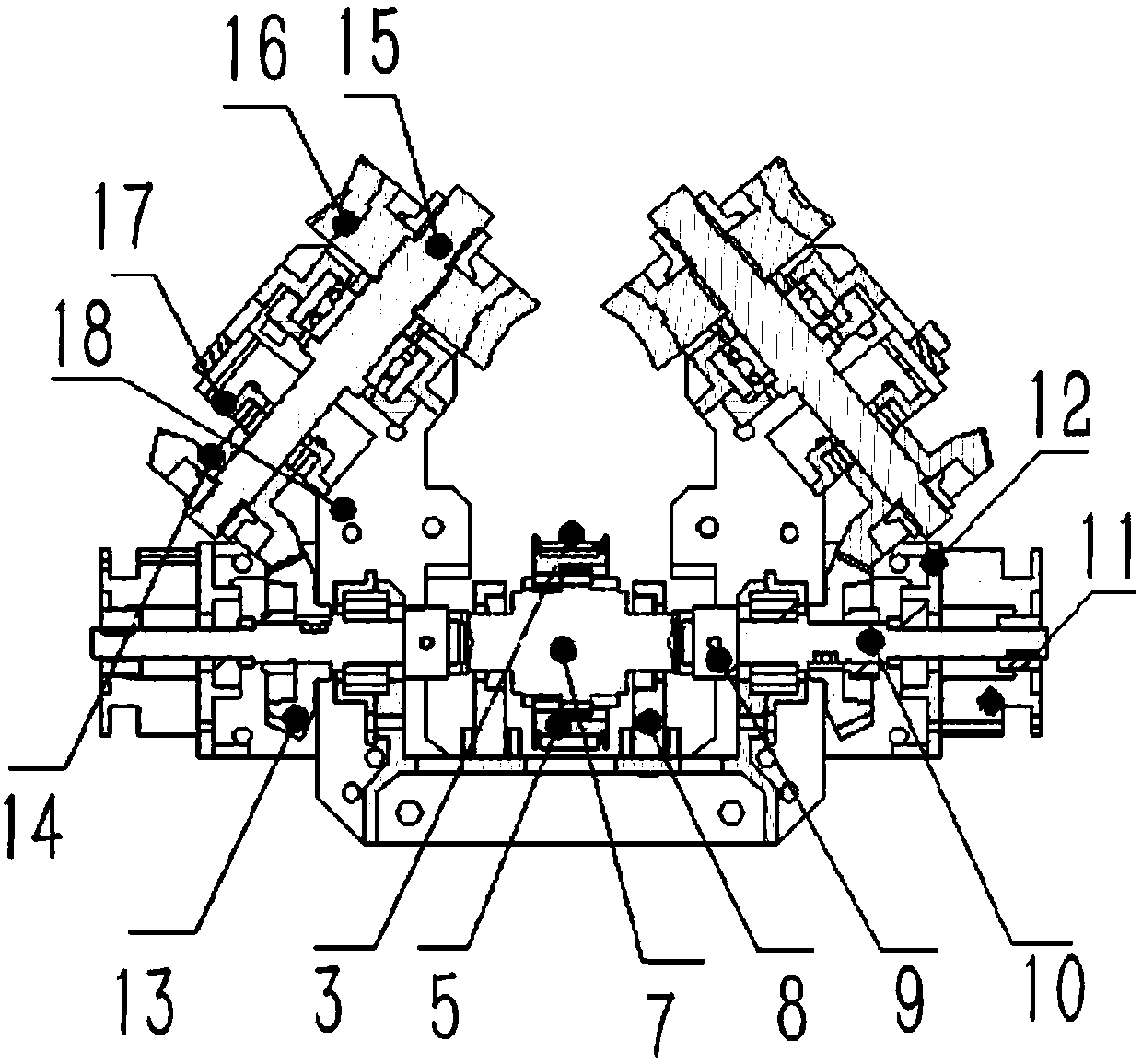

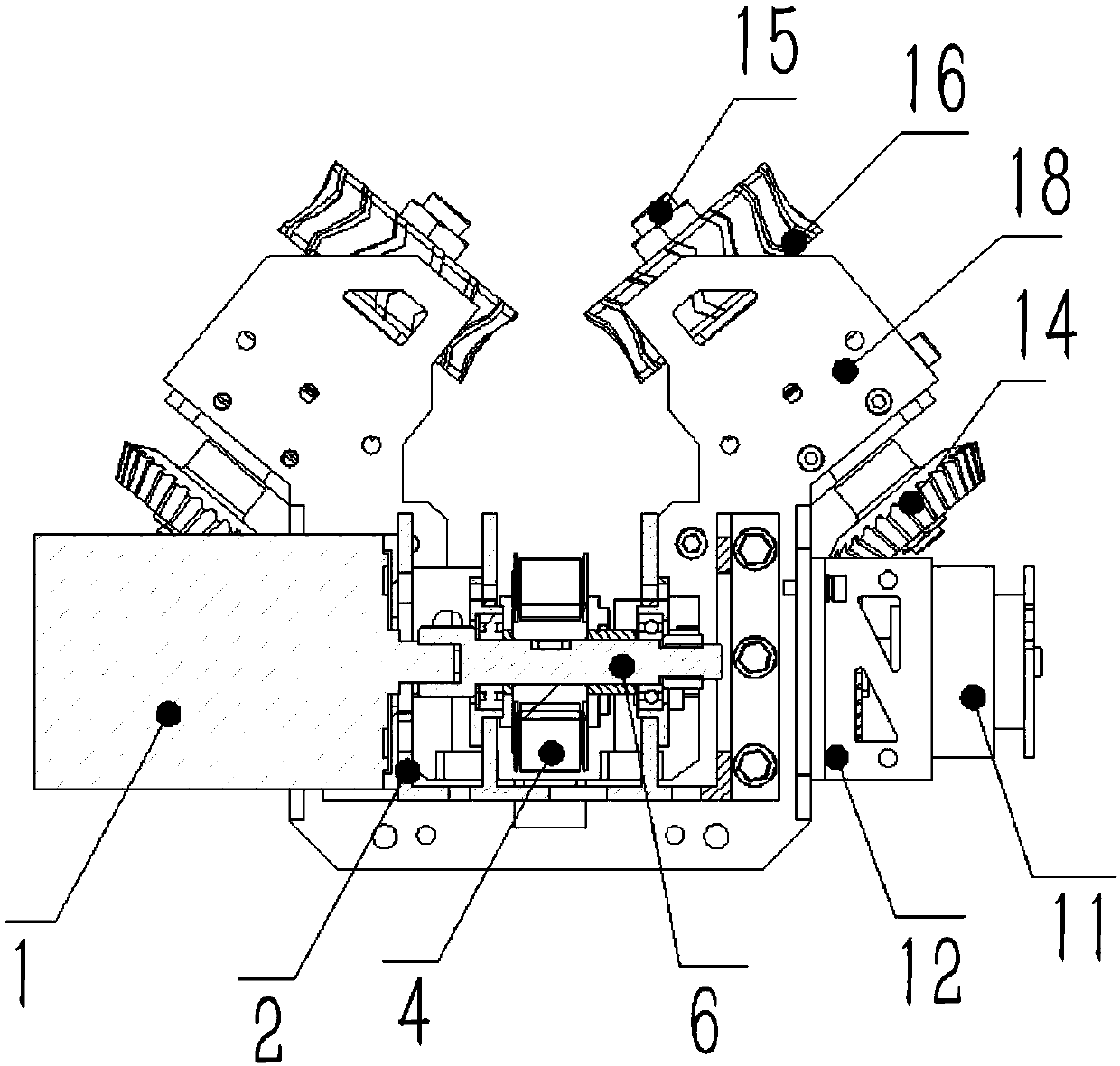

Driving assembly device and round tube track robot

ActiveCN109648537ASmooth motionEliminate relative slidingRail derailment preventionManipulatorDrive wheelEngineering

The invention provides a driving assembly device and a round tube track robot. The driving assembly device comprises a power device used for generating power and transmitting the power to a driving wheel through a first transmission pair and a second transmission pair in sequence, the second transmission pair adopts a bevel gear meshing transmission mode, and finally steady running of the drivingwheel on a round tube track is achieved.

Owner:康威通信技术股份有限公司

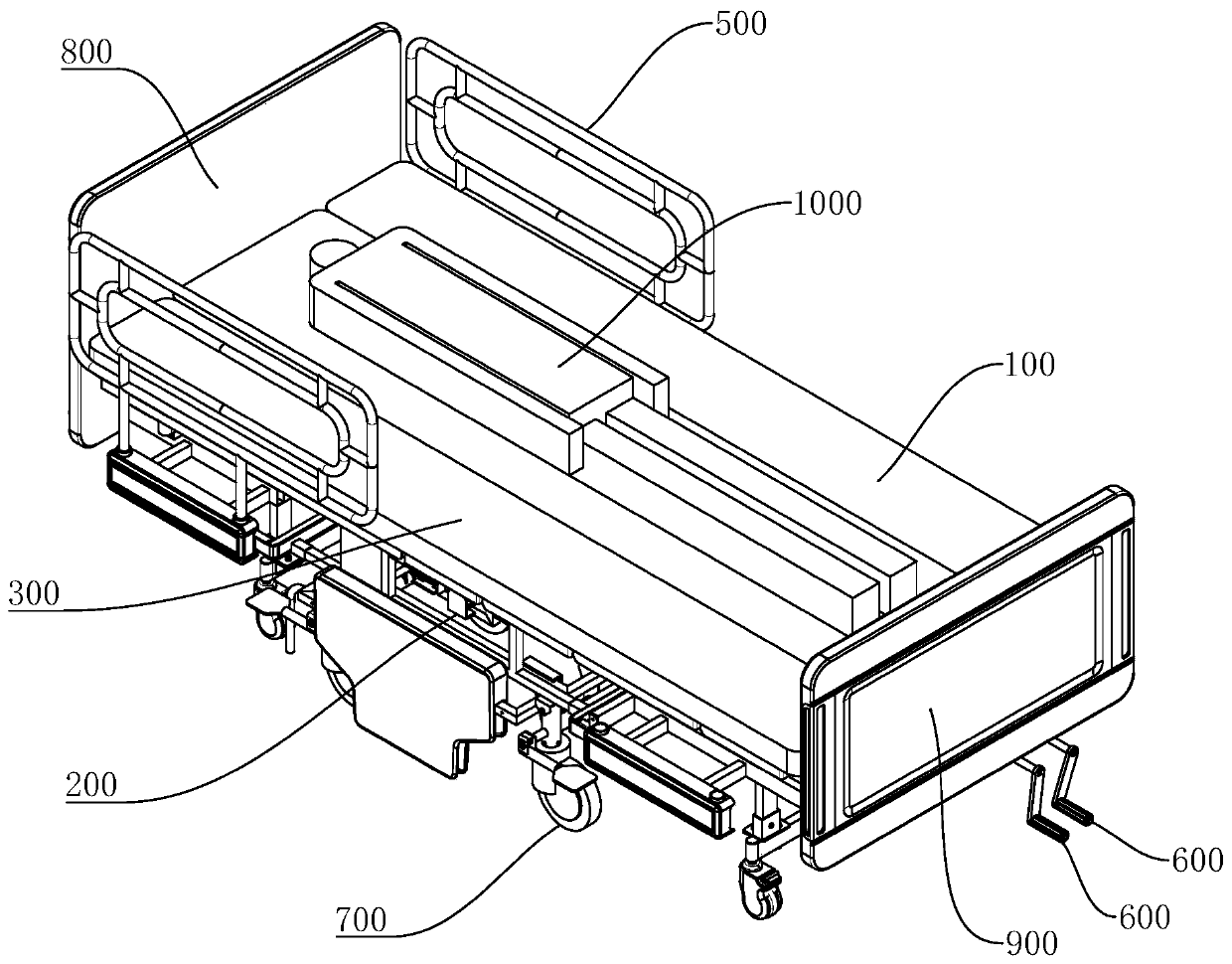

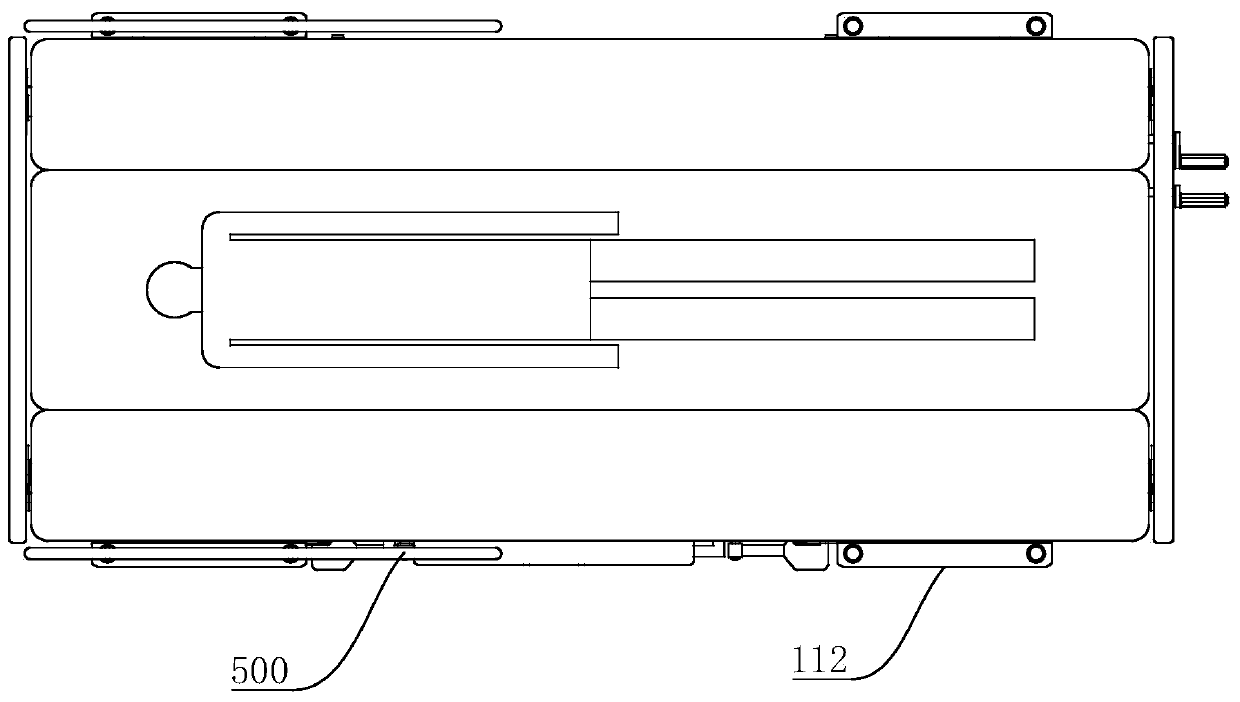

Wheelchair bed

ActiveCN110638592AComfortable Lying ExperienceEasy to operateWheelchairs/patient conveyanceNursing bedsPhysical medicine and rehabilitationWheelchair

The invention provides a wheelchair bed, and relates to the technical field of nursing instruments. The wheelchair bed comprises a bed body, a wheelchair and a movable bed board. The bed body comprises a bed body support and a bed body bed board, the bed body bed board is supported by the bed body support, and wheelchair space for a wheelchair to transversely enter and exit is reserved in the bedbody support. The wheelchair comprises a wheelchair support and a wheelchair bed board, and the wheelchair bed board is connected to the wheelchair support and can transversely move relative to the wheelchair support. The wheelchair bed has a spliced state in which the wheelchair and the bed body are spliced and a split state in which the wheelchair and the bed body are separated. In the spliced state, the movable bed board is detachably installed on the wheelchair support, and the wheelchair bed board is located between the bed body bed board and the movable bed board and spliced onto the bedbody bed board and the movable bed board. The wheelchair is spliced onto the side surface of the bed body, so that the required space is saved. A patient is located in the center of the wheelchair bed, the activity spaces at the two sides are sufficient, and the patient experience is good. Besides, the position of the patient on the wheelchair bed can be changed only by moving the wheelchair bedboard so as to facilitate nursing.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Reinforced prefabricated recycled concrete beam-column joint

ActiveCN112227537ASatisfy the fault tolerance rateEliminate relative slidingBuilding constructionsConcrete beamsArchitectural engineering

The invention discloses a reinforced prefabricated recycled concrete beam-column joint. The reinforced prefabricated recycled concrete beam-column joint comprises a main shell, two connecting columnsare welded to the top end and the bottom end of the main shell, longitudinal beam rods are integrally formed on the inner side walls of the connecting columns, longitudinal beams are inserted into theconnecting columns through the longitudinal beam rods, four fixing plates are welded to the front surfaces, the rear surfaces and the two side faces of the connecting columns, the inner sides of thefixing plates are in threaded connection with the main shell through two first bolts, four cross beam rods are integrally formed on the front surface, the rear surface and the two side faces of the main shell, sixteen anti-shearing fixing sets are fixedly connected to the outer surfaces of the cross beam rods, and the cross beam rods are in threaded connection with cross beams through the anti-shearing fixing set. Through cooperation of a partition plate and the fixing plates on the main shell and the connecting columns, a bolt set is matched with a locking gasket through a series connection steel wire, the relative sliding phenomenon between threads of the bolt set under the action of time is eliminated, and dangerous accidents are avoided.

Owner:江苏晨马建筑科技有限公司

A two-wheel-leg-track compound mobile mechanism

ActiveCN108791548BImprove mobile efficiencyAchieve direct driveEndless track vehiclesTerrainDrive shaft

The invention relates to the technical field of specialized robots, in particular to a two-wheel-leg-caterpillar band compound type movement mechanism. The two-wheel-leg-caterpillar band compound typemovement mechanism comprises a movement seat body, walking wheels, swing leg drive mechanisms and swing leg assemblies. The two walking wheels are installed at the left end and the right end of the movement seat body. Walking wheel drive motors are arranged in the walking wheels. The swing leg assemblies are arranged on the front side and the rear side of the movement seat body. The two swing legdrive mechanisms are arranged on the movement seat body. The swing leg assemblies on the two sides of the movement seat body are driven by the different swing leg drive mechanisms to swing. The swingleg assemblies located on the same side of the movement seat body are connected through a swing leg drive shaft. The swing leg drive shafts are driven by the swing leg drive mechanisms to rotate anddrive the swing leg assemblies to swing. The swing leg assemblies are provided with caterpillar bands. When the walking wheels make contact with the ground to rotate, the caterpillar bands leave the ground, and when the caterpillar bands make contact with the ground to rotate, the walking wheels leave the ground. The problems that an existing robot movement mechanism is poor in maneuvering flexibility, low in movement efficiency and the like on a complex terrain are solved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

A labor saving tennis racket

InactiveCN1943829AImprove protectionEliminate relative slidingStringed racketsEngineeringTennis racket

This invention relates to a labor saving tennis racket by wrapping with water-resistant abrasive paper through glass cement on the handle surface of battledore. It is non-slip, ventilation, more important can reduce the hand grip strength to a large extent, therefore save the athletes' strength, beneficial to their skills, improve their performances.

Owner:SICHUAN UNIV

Antiskid protection pad for double sided adhesive tape

The invention discloses an antiskid protection pad for double sided adhesive tape. The antiskid protection pad comprises a blanket pad and a corner protector. The antiskid protection pad is characterized in that an antiskid protection link plate is composed of a main board, two auxiliary boards and two edge protection boards, the auxiliary boards are hinged to the two sides of the main board through a penetrating rod, and the other sides of the two auxiliary boards are each hinged to one edge protection board through a penetrating rod; the outer side faces of the main board, the auxiliary boards and the edge protection boards are provided with reinforcing ribs, the inner side face making contact with a tire is smooth, the double sided adhesive tape is arranged on the inner side and outer side of one plane of a right angle of the corner protector, the double sided adhesive tape adopts materials conforming to the requirement of environmental protection, the hook face of a nylon hook and loop fastener is arranged on the outer side face of one vertical face of the corner protector, and the loop face of the nylon hook and loop fastener is fixed to the long edge of the back face of the blanket pad to be bonded with the hook face of the nylon hook and loop fastener on the vertical face of the corner protector. The pad is simple in structure, convenient to operate and high in flexibility, abrasion resistance and strength, and the antiskid protection pad eliminates the relative sliding phenomenon.

Owner:陆璐

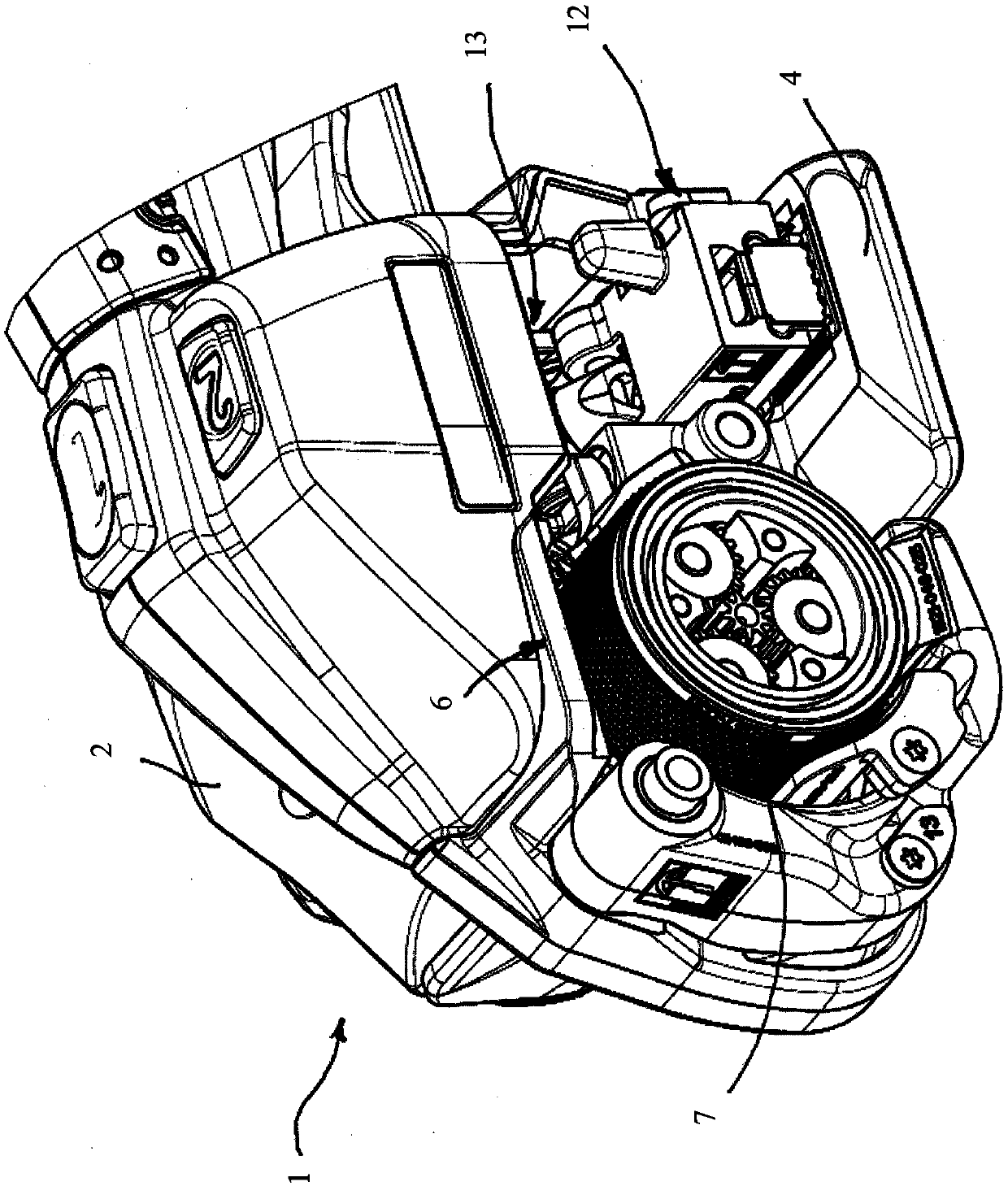

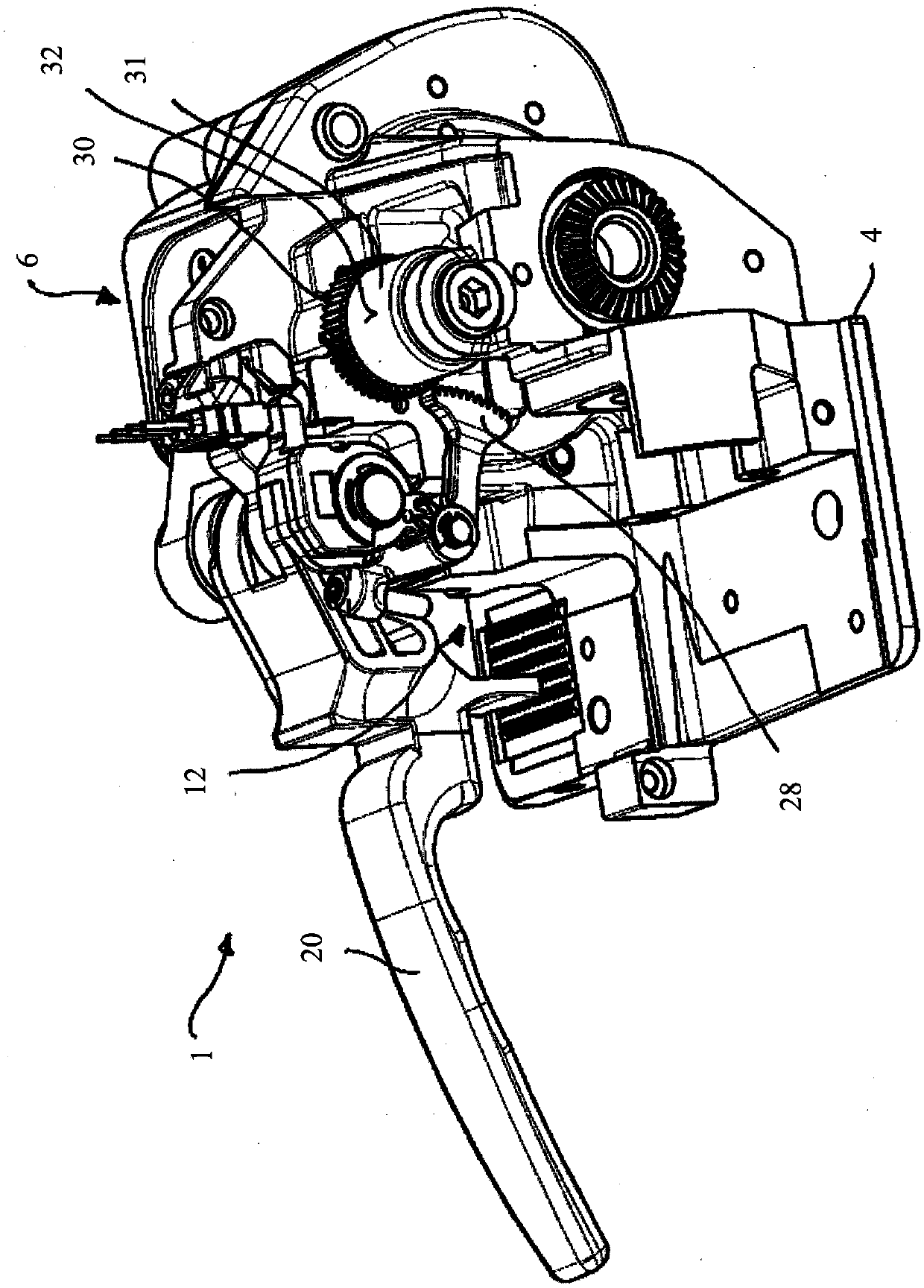

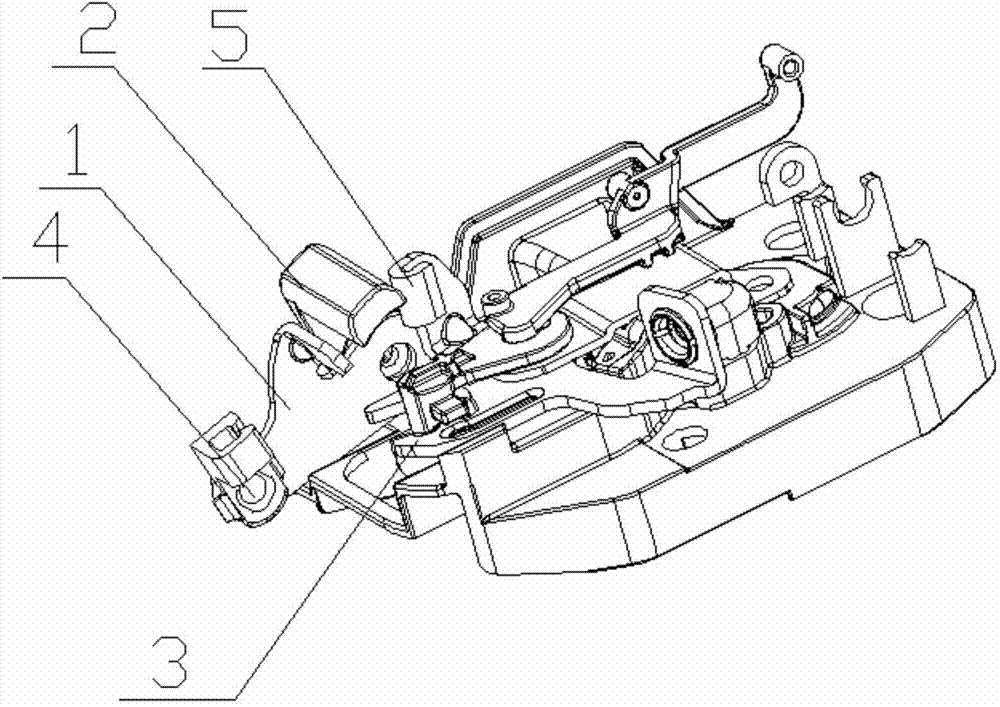

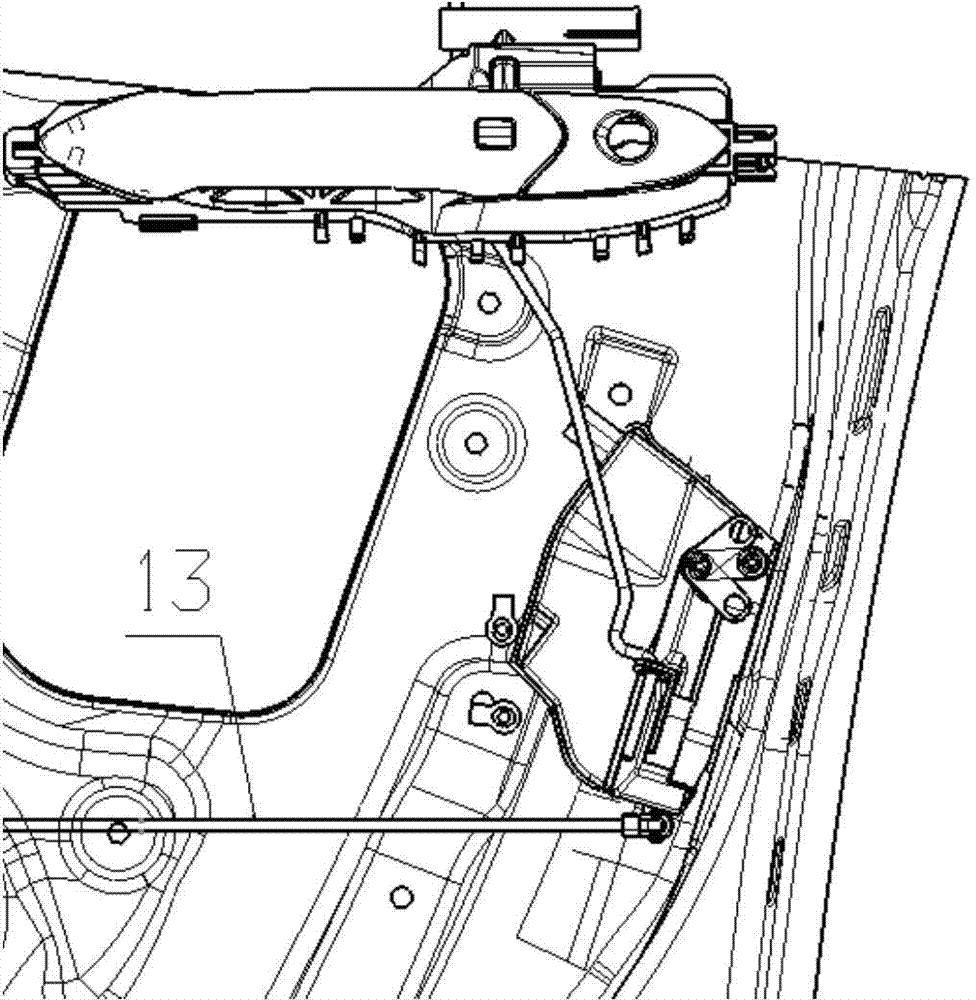

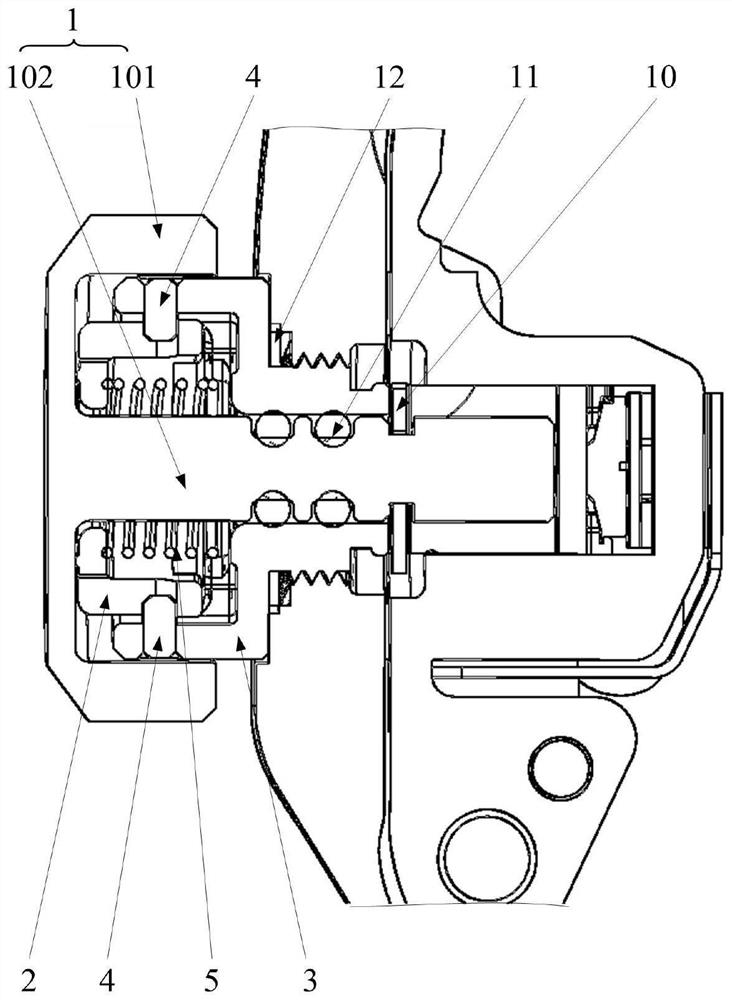

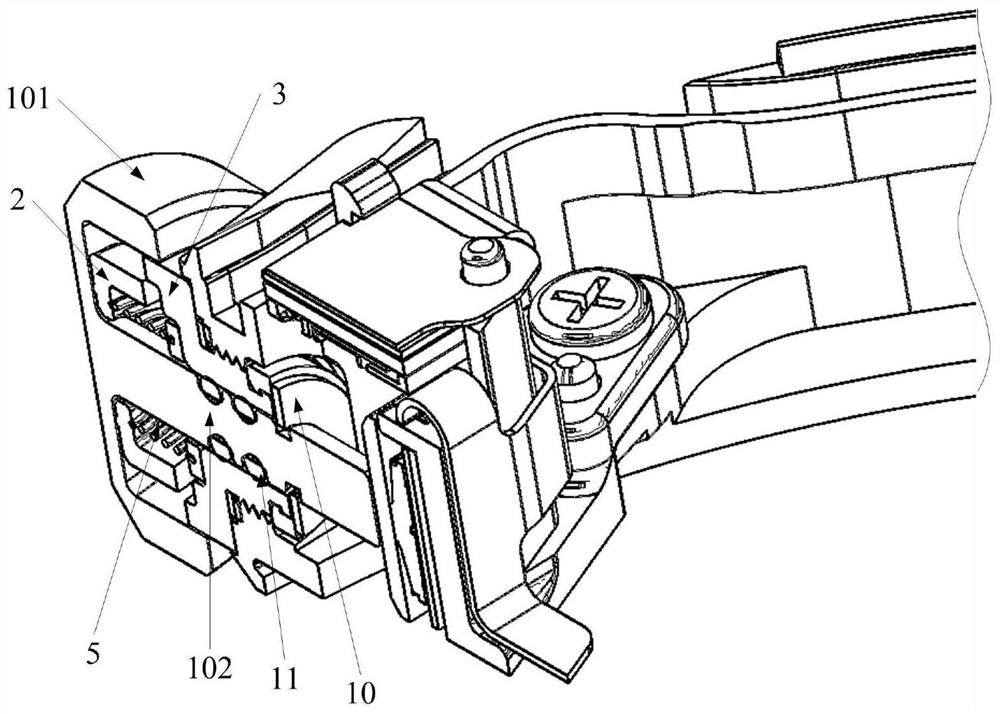

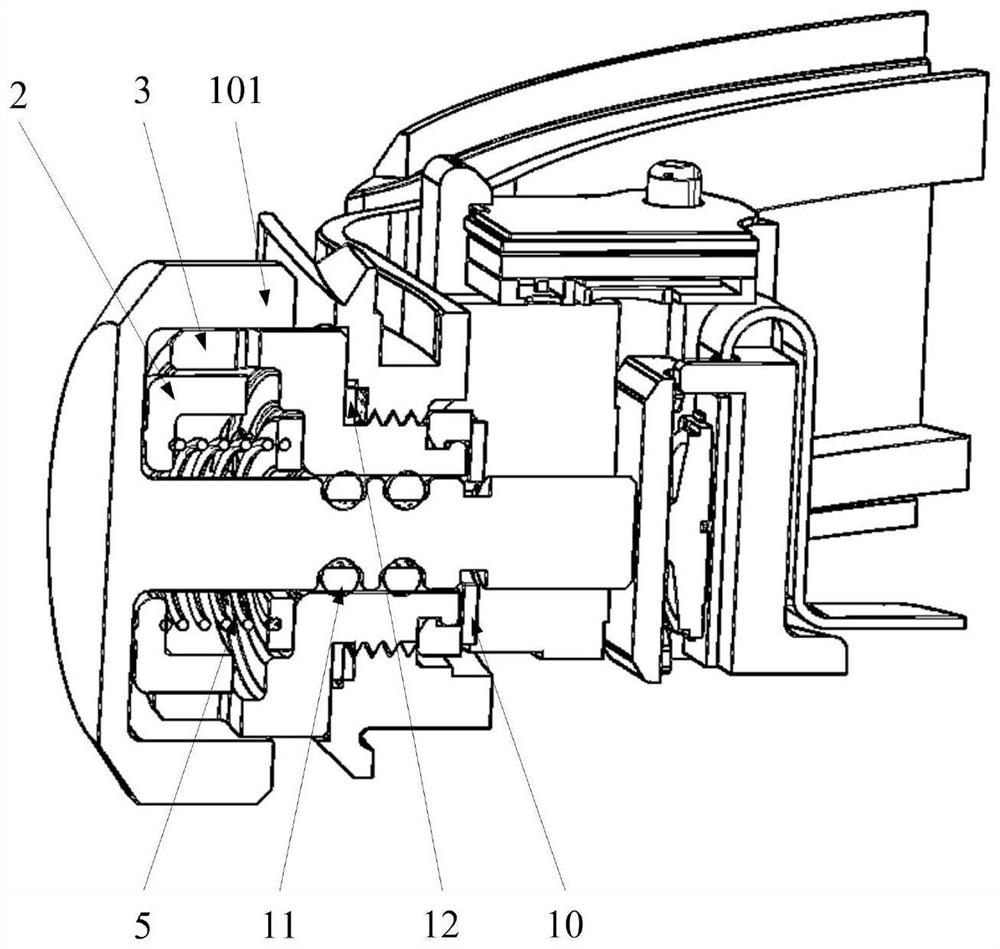

Novel inner release mechanism of vehicle door lock

ActiveCN104712197AEliminate relative slidingReduce sliding friction lossVehicle locksFriction lossEngineering

The invention discloses a novel inner release mechanism of a vehicle door lock. The mechanism comprises an inner release arm, a child lock connecting rod, a release rod and a pawl, wherein the inner release arm and the child lock connecting rod, the release rod and the pawl can be respectively and rotationally positioned on the inner wall of the vehicle door lock; the inner release arm pushes the child lock connecting rod to rotate; the child lock connecting rod pushes the release rod to rotate; the release rod drives the pawl to rotate; the inner release arm is provided with a mounting part connected with a pull wire or a pull rod; and the release rod and the pawl coaxially rotate. The mechanism realizes the driving through coaxially and fixedly connecting the release rod with the pawl; as the inner release arm and the child lock connecting rod are coaxially hinged, various connecting mechanisms are effectively decreased, the relative slip of the release rod and the pawl and the inner release arm and the child lock connecting rod is eliminated, and the slip friction loss is reduced; as the inner release arm is closer to a lock body mounting surface, the inner release structure is integrated in a lock body shell; and the mechanism has the advantages of simple structure, small size, guarantee of water prevention, dustproof performance and convenience for design and manufacturing.

Owner:MAGNA AUTOMOTIVE PARTS (SUZHOU) CO LTD

Rotary key, and wearable equipment with same

ActiveCN112635226AImprove reliabilityEliminate relative slidingElectric switchesKey pressingEngineering

The invention discloses a rotary key. The rotary comprises a bar tube fixedly connected with an equipment shell and a key cap capable of sliding relative to the bar tube, the key cap can rotate relative to the bar tube, the rotary key further comprises a fixed support slidably connected with the bar tube, and the sliding direction of the fixed support relative to the bar tube is consistent with the sliding direction of the key cap relative to the bar tube. The fixed support and the bar tube are kept relatively static in the rotating direction of the key cap, the key cap covers the fixed support, and an elastic piece used for pushing the fixed support and further pushing the key cap to slide and reset is arranged between the fixed support and the bar tube. When the rotary key provided by the invention is applied, the problem of relative sliding of the elastic piece relative to the bar tube and the fixed bracket is fundamentally eliminated. Therefore, even if the key is used for a long time, powder cannot be brought to the end part of the elastic piece due to friction, and the reliability of the rotary key is further improved. The invention further discloses wearable equipment with the rotary key. The wearable equipment also has the technical effects.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com