Novel inner release mechanism of vehicle door lock

A technology of automobile door locks and release mechanisms, which is applied in vehicle locks, building locks, locks, etc., can solve the problems of large space occupation, large operating arm, complex structure, etc., and achieve the elimination of relative sliding, simple structure, and small volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

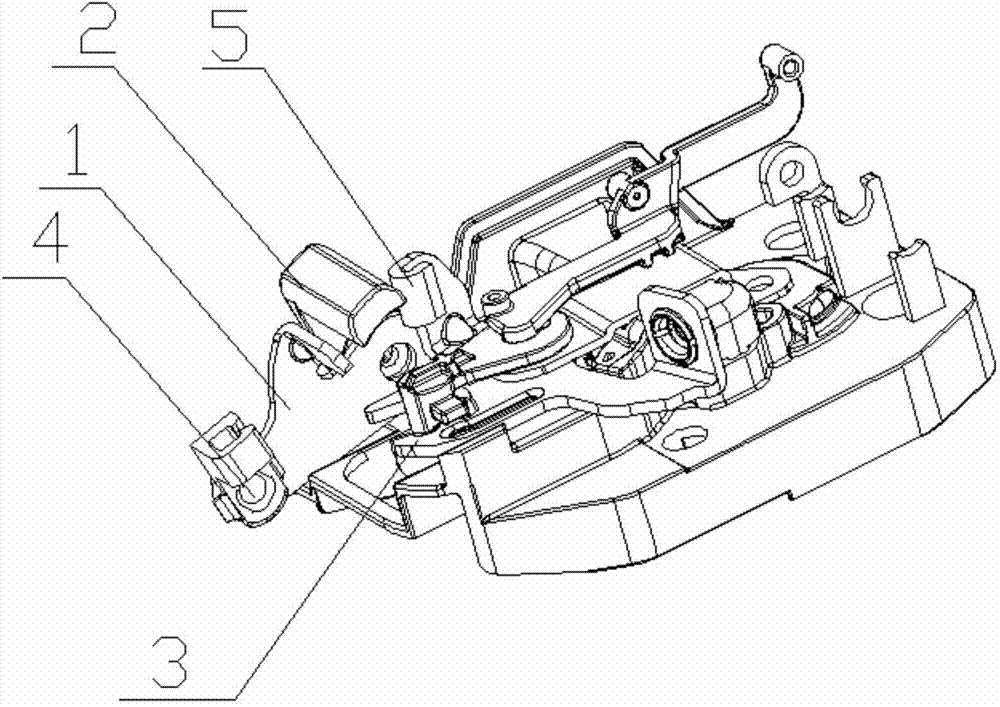

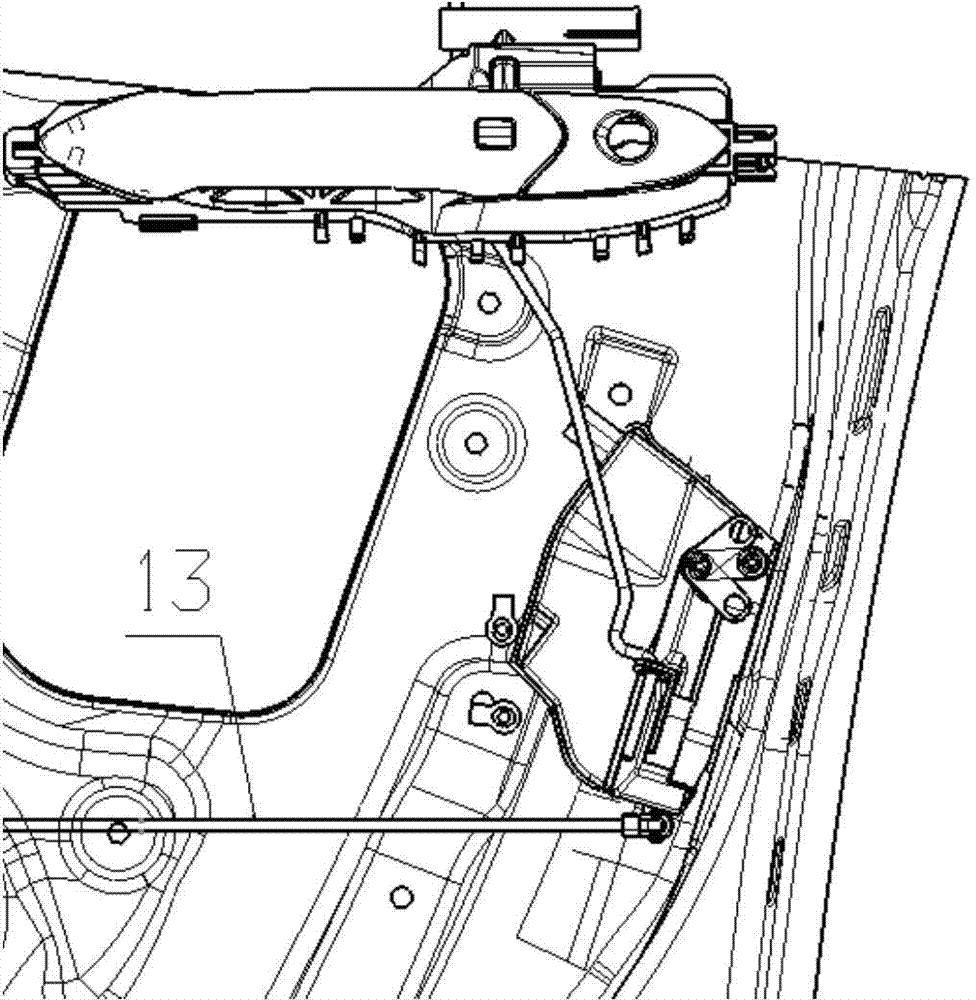

[0011] Embodiment: a new type of release mechanism for automobile door locks, including an internal release arm 1, a child lock connecting rod 2, a release lever 3 and a pawl, and the internal release arm 1 and the child lock connecting rod 2, the release lever 3 and the pawl respectively It can be rotated and positioned on the inner wall of the car door lock. The inner release arm 1 pushes the child lock connecting rod 2 to rotate, the child lock connecting rod 2 pushes the release lever 3 to rotate, and the release lever 3 drives the pawl to rotate. Or the installation part 4 connected by the pull rod 13, the release rod 3 and the pawl rotate around the same axis. When the pull wire or pull rod drives the inner release arm 1 to rotate, the inner release arm 1 drives the child lock connecting rod 2 to rotate, and the child lock connecting rod 2 is pushed and rotated by the inner release arm 1 and then drives the release lever 3 to rotate, and the rotation of the release lever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com