Reinforced prefabricated recycled concrete beam-column joint

A technology of recycled concrete and beam-column joints, which is applied in the direction of architecture and building construction, can solve the problems of increased shear force, increased beam quality, and increased risk factor, so as to facilitate large-scale production and application and meet the needs of the economy. Sexual needs, the effect of avoiding dangerous accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

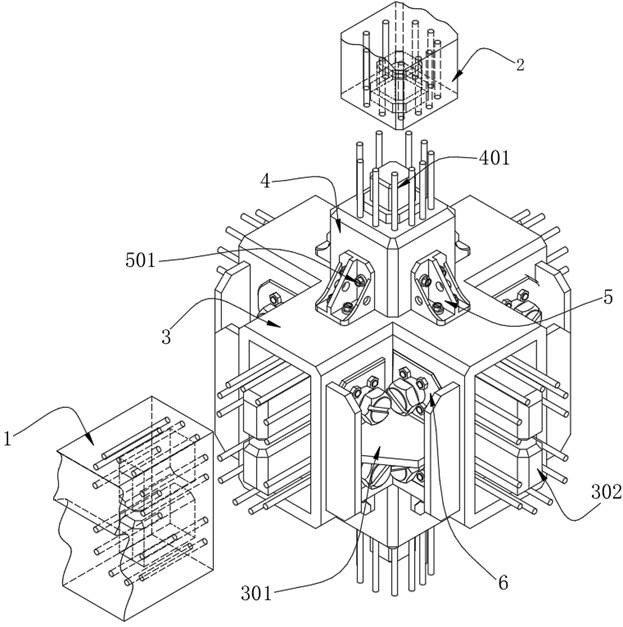

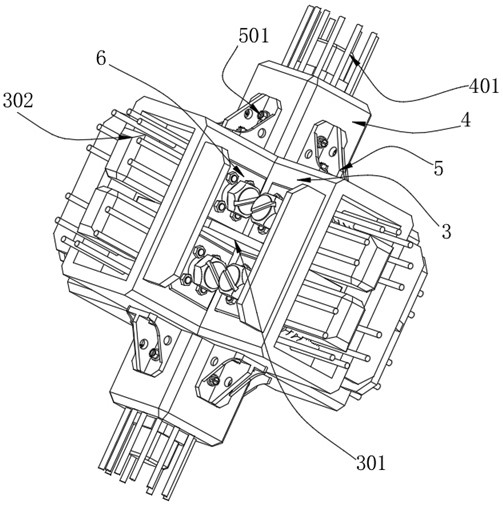

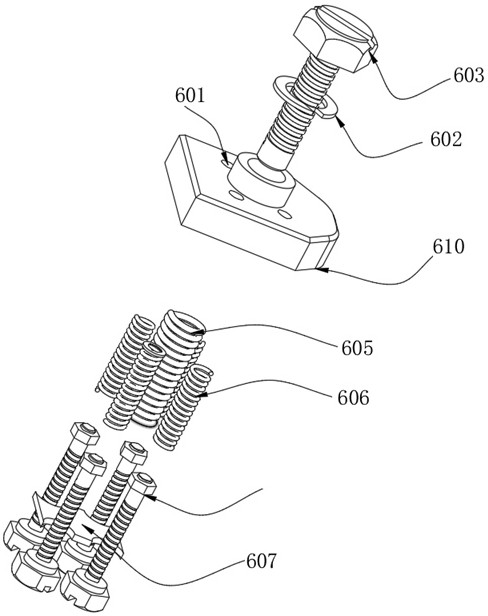

[0022] see Figure 1-5 , the present invention provides a technical solution: a reinforced prefabricated recycled concrete beam-column node, including a main shell 3, the top and bottom of the main shell 3 are welded with two connecting columns 4, and the inner side walls of the connecting columns 4 are integrated A longitudinal beam bar 401 is formed, and the connecting column 4 is plugged with the longitudinal beam 2 through the longitudinal beam bar 401. Four fixing plates 5 are welded on the front surface, the rear surface and the two sides of the connecting column 4, and the inner side of the fixing plate 5 passes through two The first bolt 501 is threadedly connected with the main casing 3, and the front surface, the rear surface and the two sides of the main casing 3 are integrally formed with four beam bars 302, and the outer surface of the beam bars 302 is fixedly connected with sixteen anti-shear fixing Group 6, the beam rod 302 is screwed to the beam 1 through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com