Three-roller planetary rolling method for rolling brass tube

A technology of brass tube and planetary rolling mill, which is applied in the direction of rolling, metal rolling, metal rolling, etc., to achieve the effects of temperature uniformity, ensuring continuity, and reducing the possibility of tube blank cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

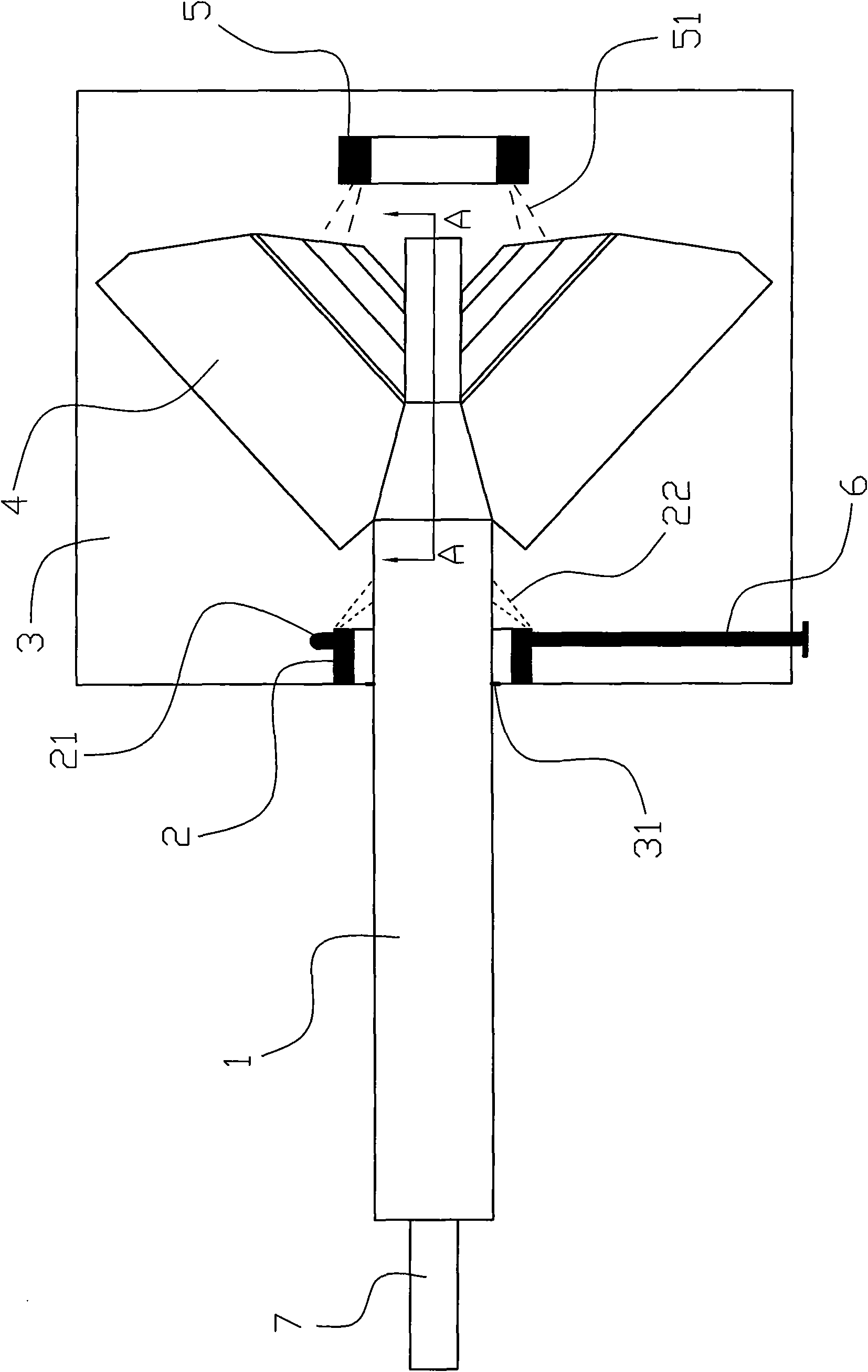

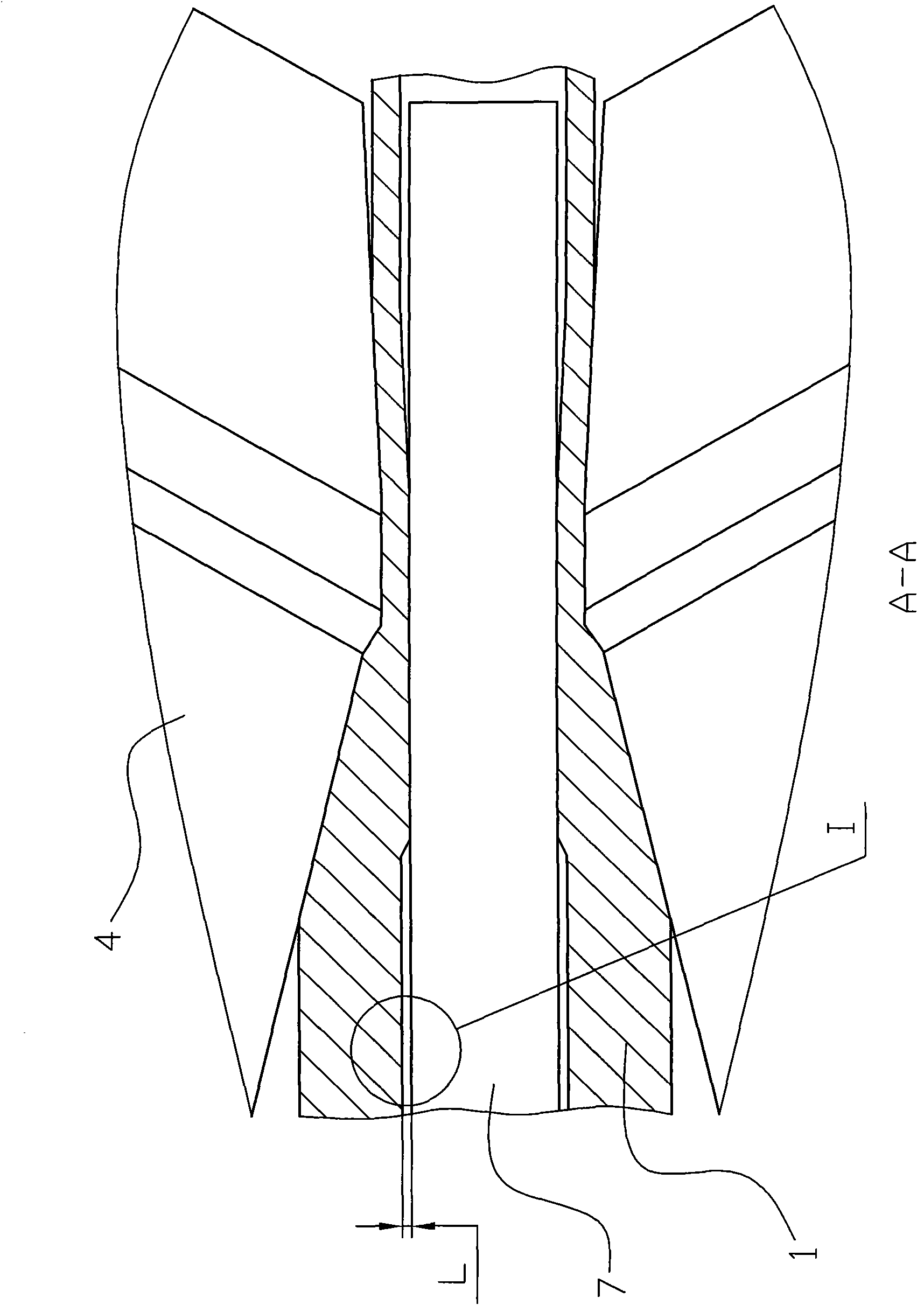

[0021] like Figure 1 to Figure 4 As shown, this embodiment is a three-roll planetary rolling process for rolling brass tubes, which includes the following steps:

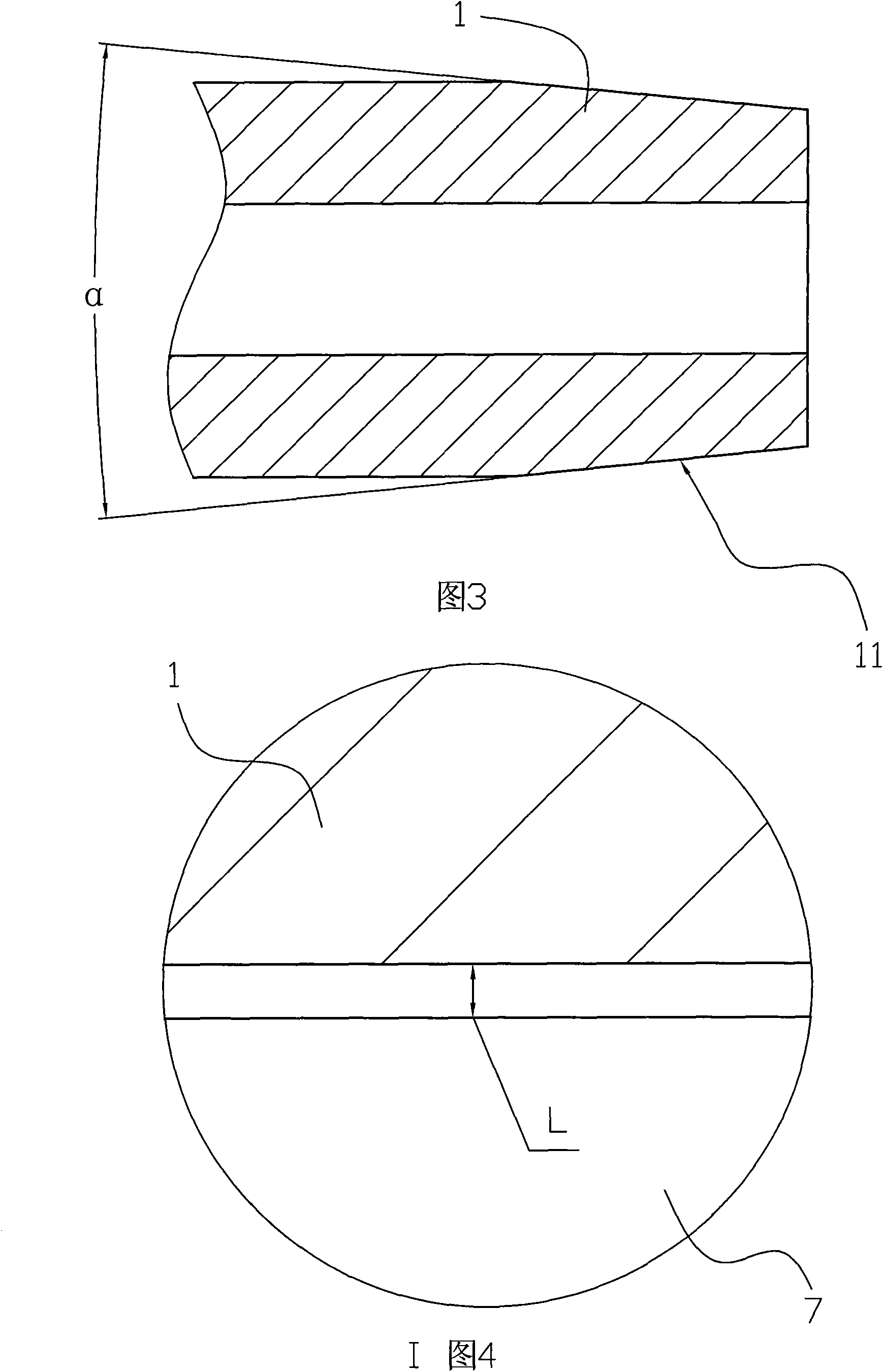

[0022] a. The head of the tube blank 1 is made into a conical surface 11; the conical angle a of the conical surface 11 is selected to be 8-16 degrees, preferably 12 degrees in this embodiment.

[0023] b. Select the mandrel 7, and the unilateral gap L between the mandrel 7 and the inner wall of the tube blank 1 is not greater than 2.5 mm.

[0024] c. Preheat the tube blank 1 to 100-500 degrees before rolling the tube blank 1 in the three-roll planetary rolling mill. The method for preheating the tube blank 1 can be selected as follows: the first way is to use an external heating device to directly heat; the second way is to place a section of copper tube blank at the front end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com