Patents

Literature

41results about How to "Address burns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

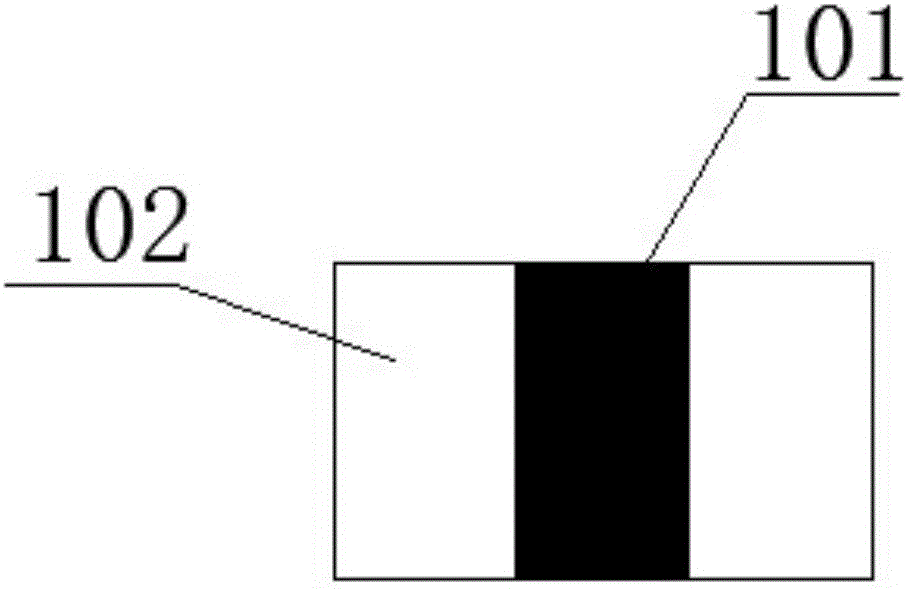

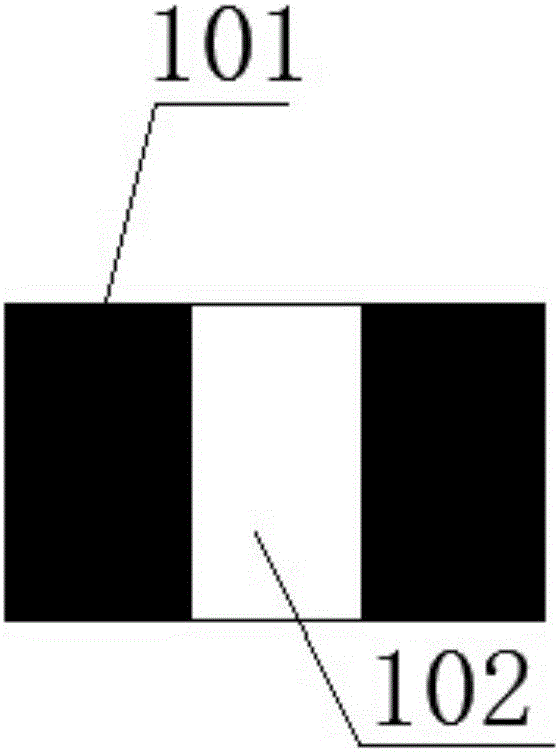

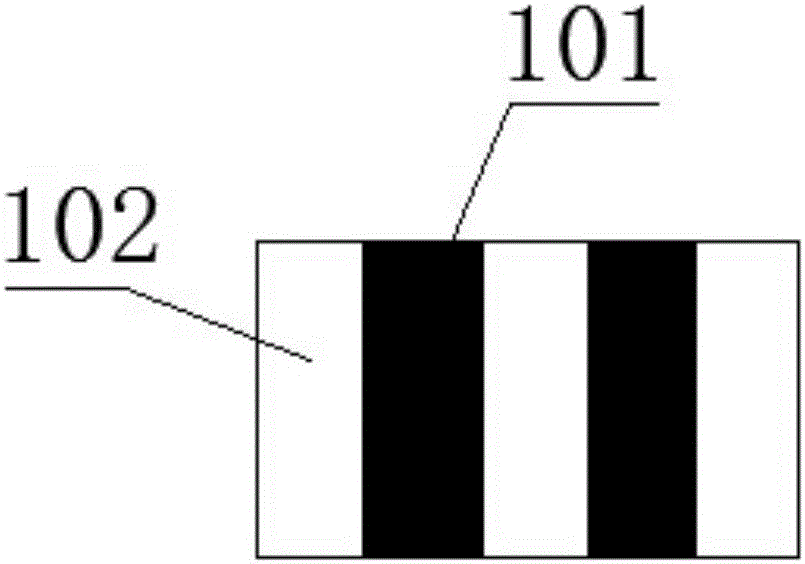

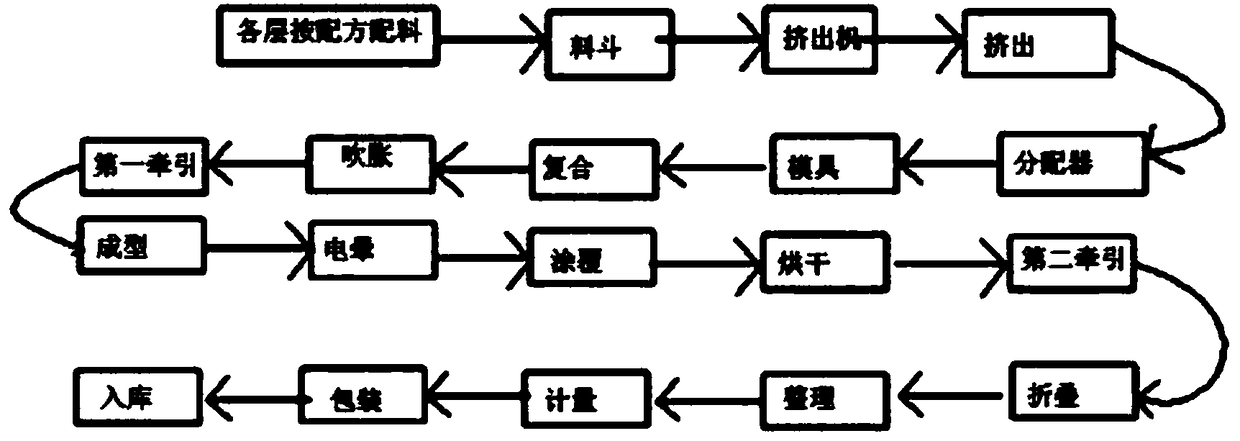

Bicolor agricultural soil covering film and preparation method thereof

The invention discloses a bicolor agricultural soil covering film and a preparation method thereof and relates to the field of an agricultural soil covering film, comprising at least one black mulch film and at least one white mulch film, the white mulch film is effective in increasing surface temperature so as to partially remove weeds, in case of a single-color mulch film, a color combination is changed by changes in an extrusion passage in a nose so that a color combination mode is changed, and existing single-color mulch film is finally imparted two colors and is suitable for various applications, and the film has temperature rising, humidity holding and good weeding effect, is very applicable to agriculture, and is simple to prepare, low in cost and higher in economic benefit.

Owner:康胜金

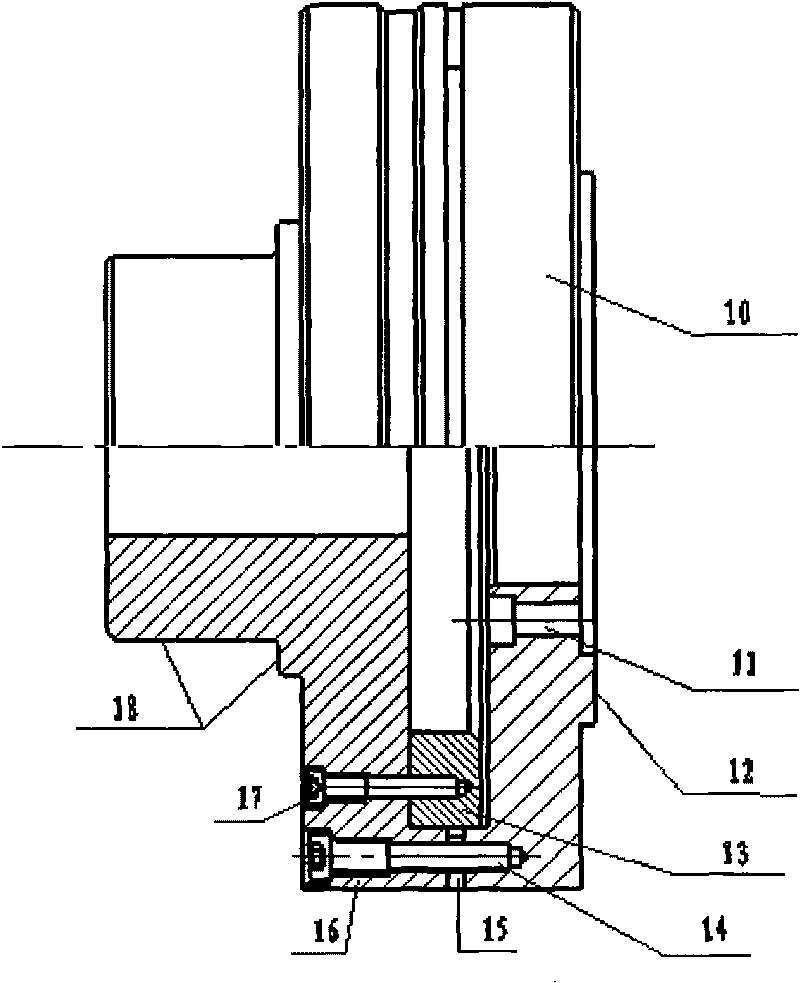

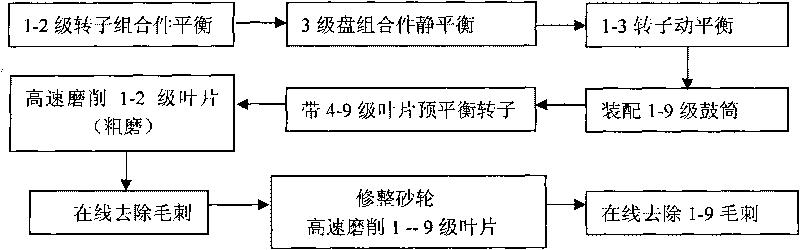

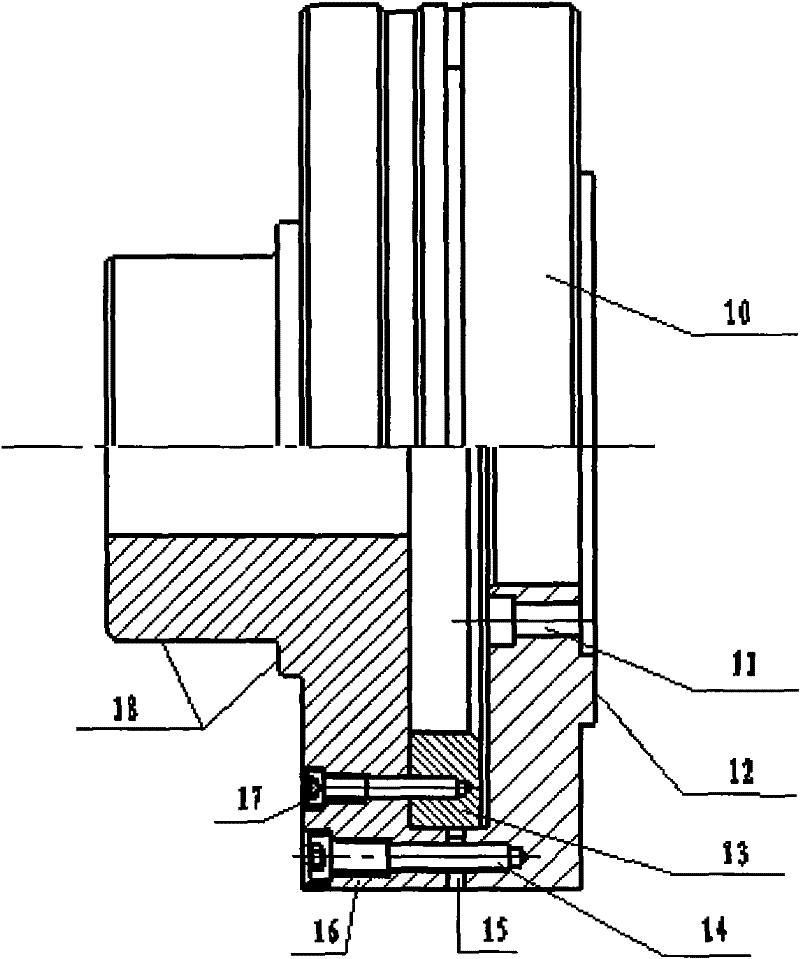

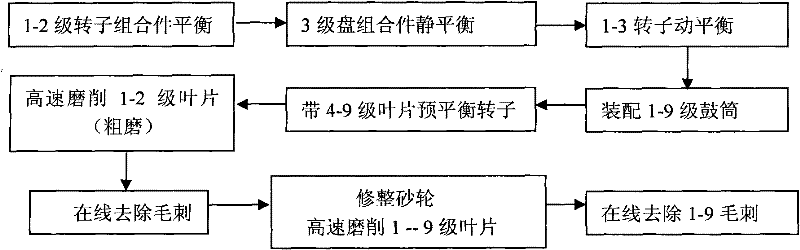

Composite processing method for grinding vane apex of rotor vane of aeroengine at high speed

ActiveCN101722459AGuaranteed GrindingMeet the design requirementsGrinding machinesAviationEngineering

The invention relates to a composite processing method for grinding the vane apex of a rotor vane of an aeroengine at a high speed, which comprises the following steps of: firstly, balancing a rotor in advance, controlling unbalance quantity which is permitted to be used for balancing the rotor in advance to be within 254g.mm, then installing the rotor on a fixture, enabling the rotor to be in a stretching state and grinding at a high speed. In the grinding process, the rotational speed of a processing part is 1600-2000r / min, the linear speed of a grinding wheel is 33-36m / s, the rotational speed of a scrubbing brush is 1500-1900r / min, and the control temperature during grinding is 20+ / -5 DEG C.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

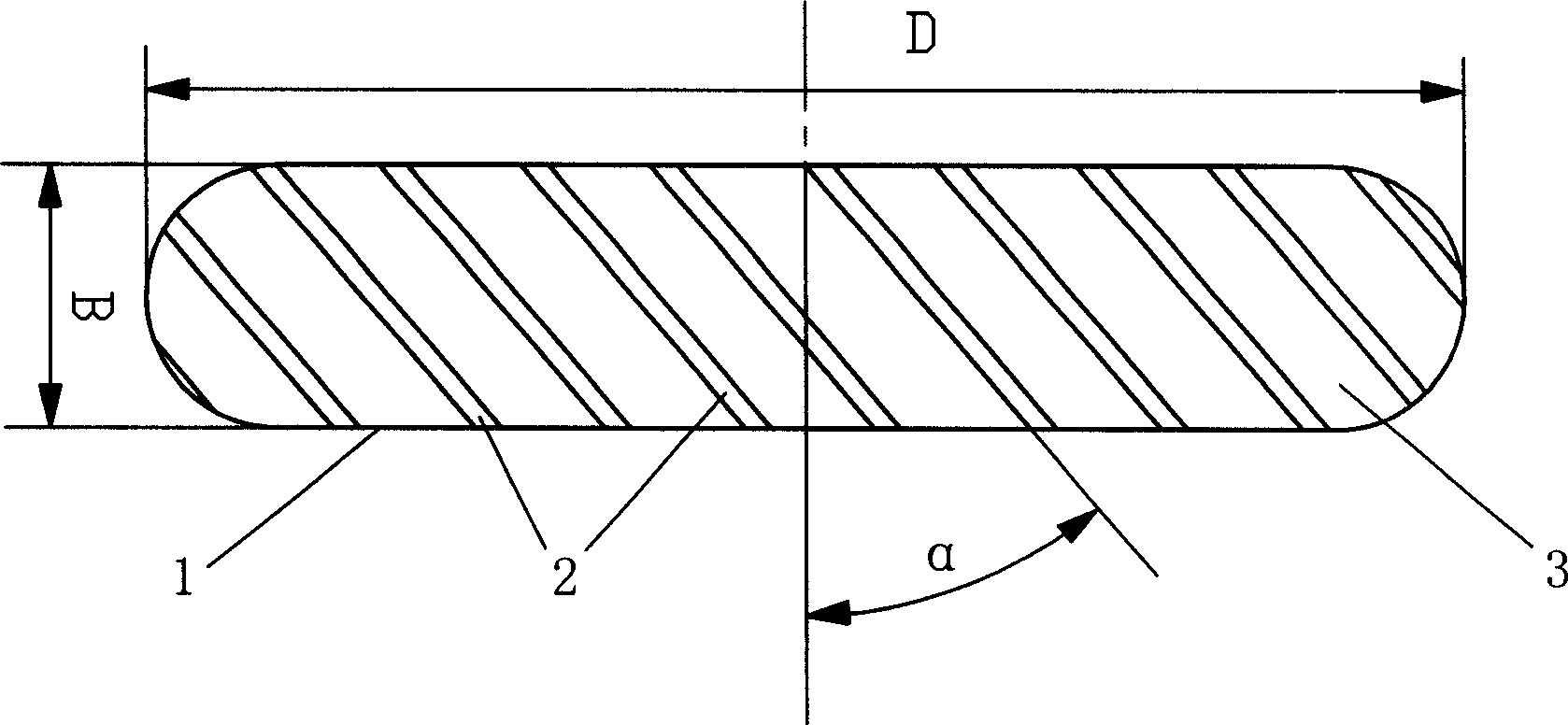

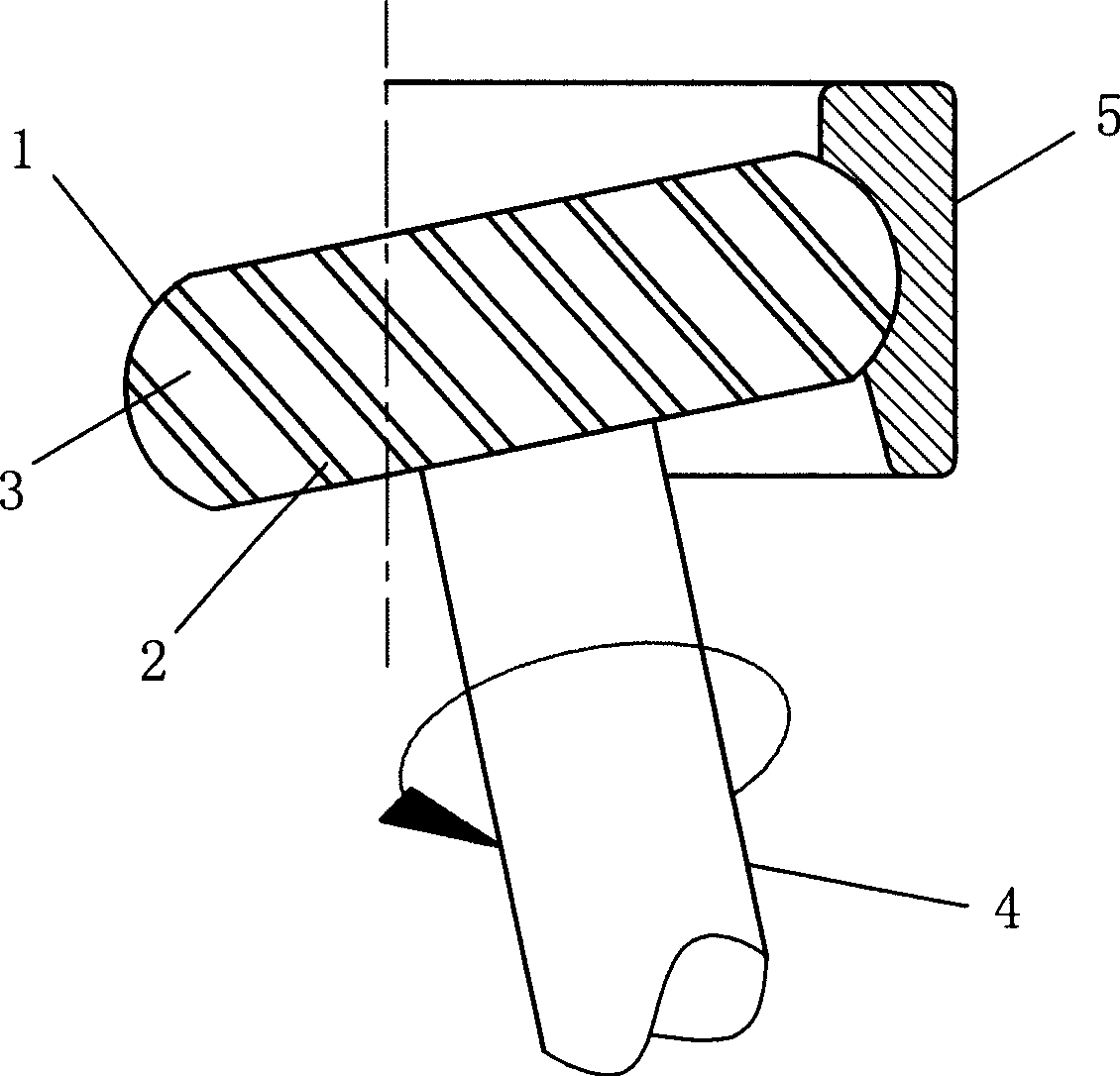

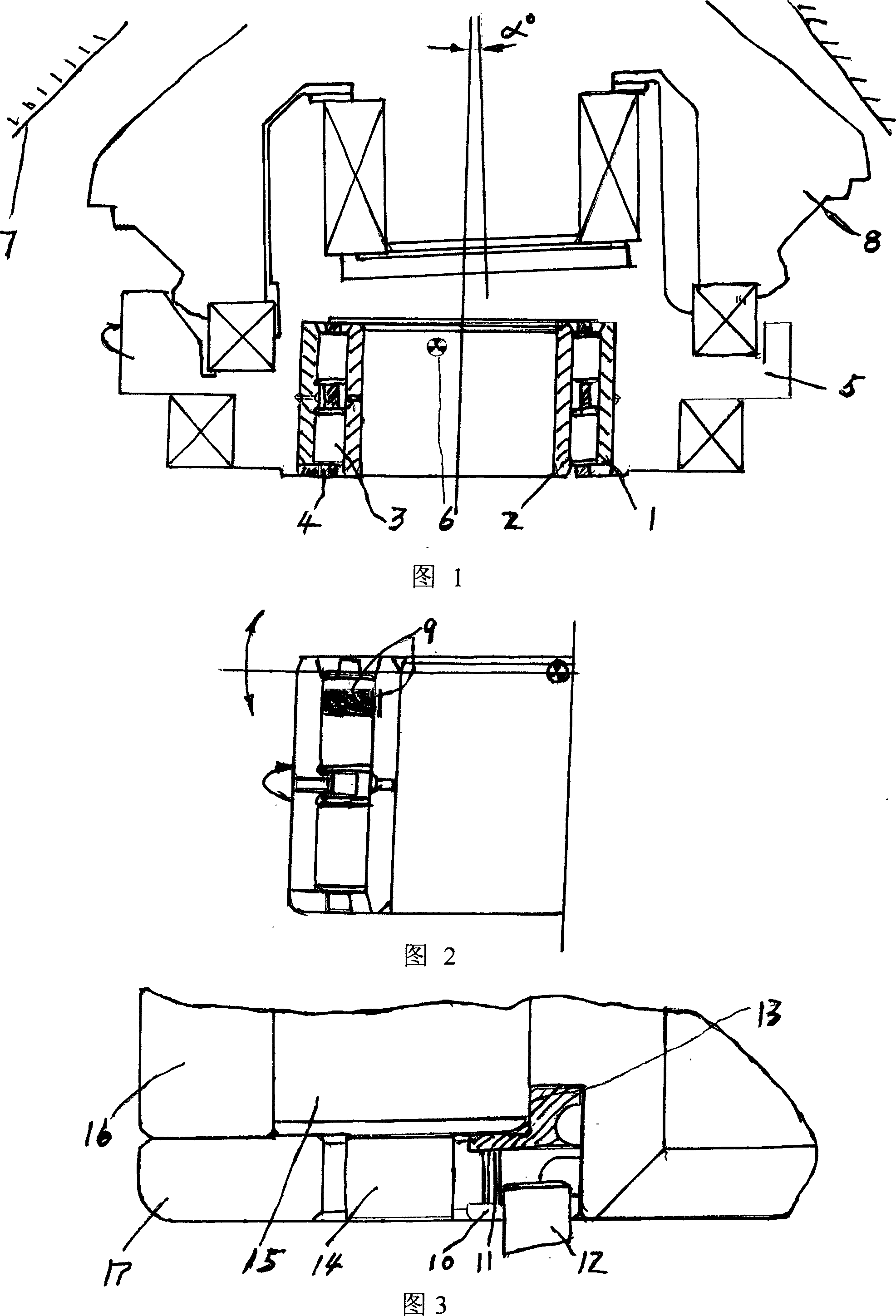

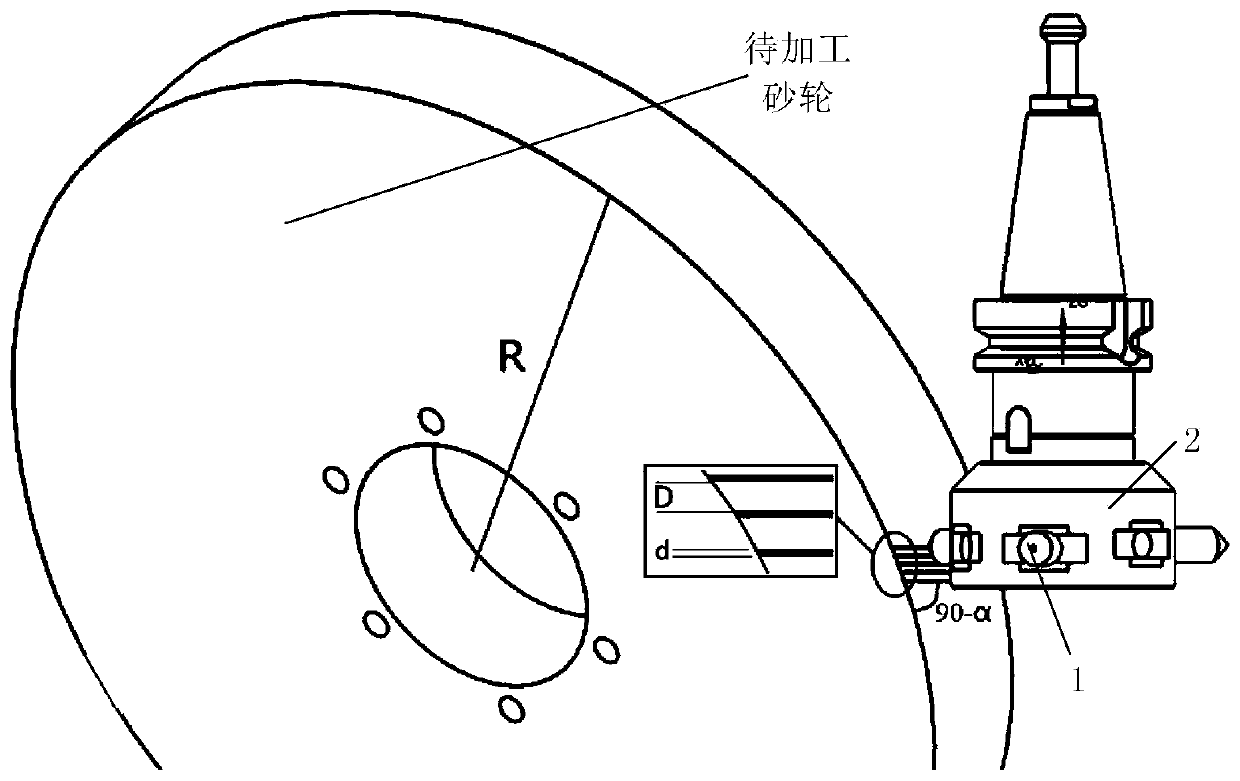

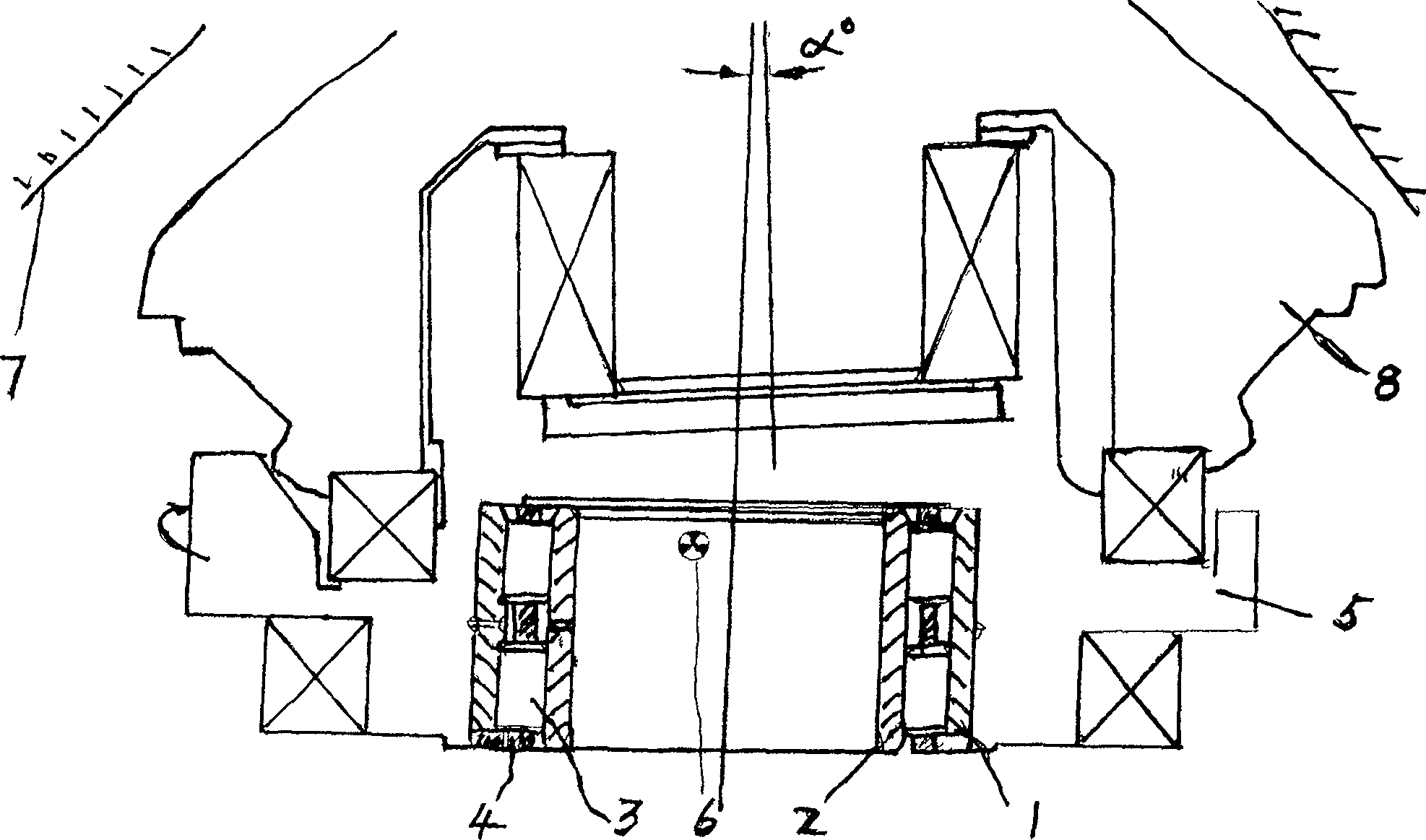

Grinding wheel for grinding large contact surface

InactiveCN101386155AReduced grinding lengthAddress burnsBonded abrasive wheelsEngineeringGrinding wheel

The invention discloses a grinding wheel which has large contact surface and can be used for grinding, comprising a grinding wheel body and is characterized in that the outer circumference of the grinding wheel is evenly provided with a set of slots used for removing chips and dissipating heat. As the slots are arranged on a grinding surface of the grinding wheel, the grinding lengths of the grinding wheel and workpieces are simultaneously shortened, and cooling fluid flows into grinding area through the slots to cool and lubricate the grinding surface, thus solving the problem that the grinding surface is burnt, increasing the quality of the grinding surface without the reduction of grinding efficiency. The parts along the axial direction of adjacent slots are overlapped, thus the length where the grinding wheel is contacted with workpieces is even and stable grinding can be ensured. The included angel alpha formed by grinding wheel axis lines is 45-55 degrees. The relationship between include angle alpha of grinding wheel diameter D, width B, the slots and the axis lines and the number of the slots N can be described as N=(arc sin(B* tg alpha / D)).

Owner:ZHEJIANG DBD BEARING

Traditional Chinese medicament liquid for treating burnt and scald through both topical application and oral administration and preparation method thereof

InactiveCN102125596ADoes not cause burning painEasy to breatheDermatological disorderPlant ingredientsInjury mouthBurning Pain

The invention relates to traditional Chinese medicament liquid for treating burnt and scald through both topical application and oral administration and a preparation method thereof. The traditional Chinese medicament liquid is prepared from living sponge gourd juice, Japanese honeysuckle and Chinese lobelia. Topical application of the liquid does not induce burning pain of wound, allows spreading, spraying, smearing and coating, has the effects of clearing away heat, relieving pain, eliminating inflammation and promoting tissue regeneration, and has the characteristics of quick healing, no scar left, and the like. Oral administration of the liquid has the effects of clearing away heat, eliminating inflammation and moistening throat; and for burnt of upper respiratory tract and scald of oral cavity and throat, the liquid is directly applied at the burnt or scald part through drinking or buccal application. The traditional Chinese medicament liquid provided by the invention has particularly distinct effect through the treatment combining external application and oral administration.

Owner:游从鑫 +2

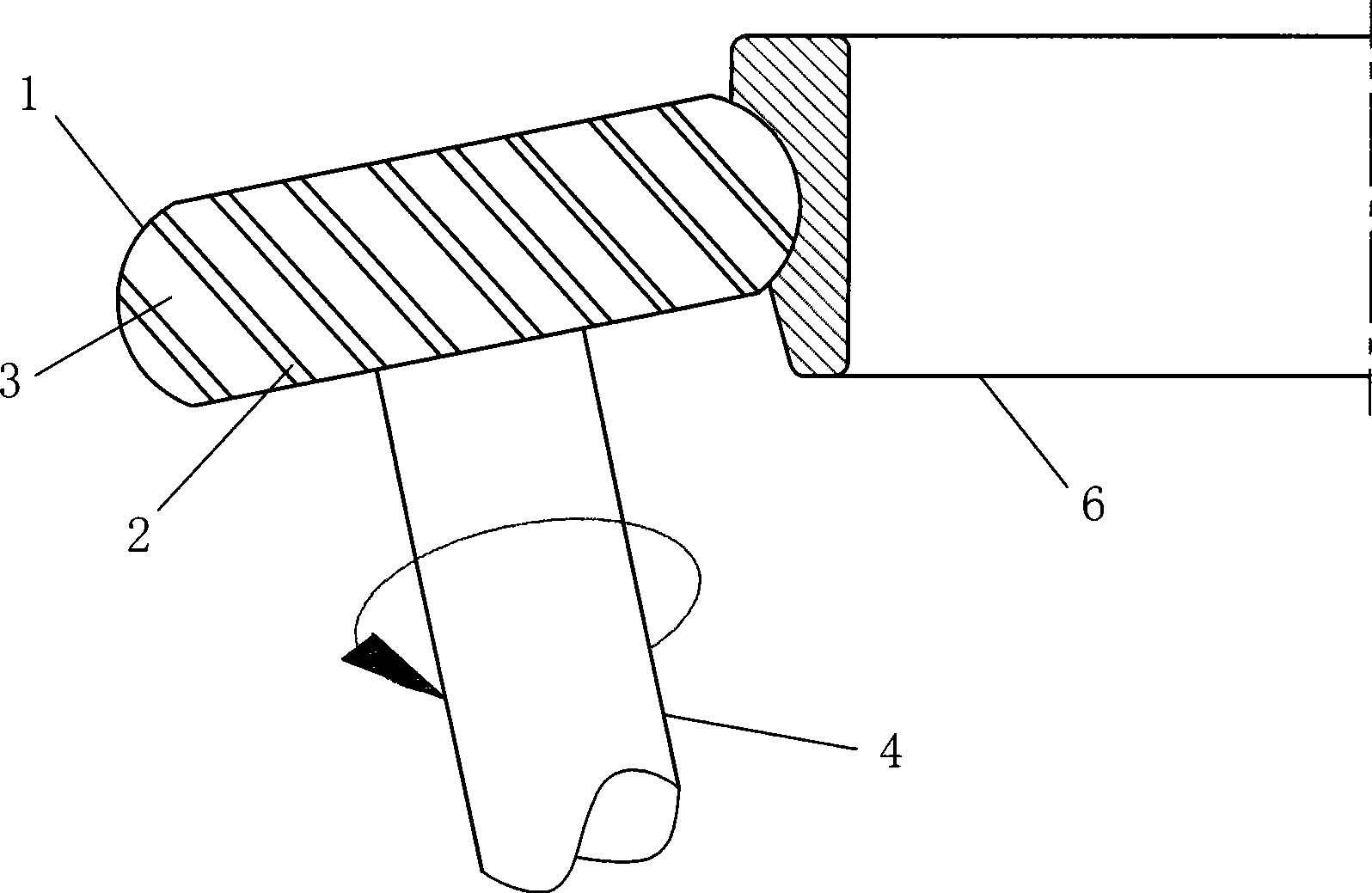

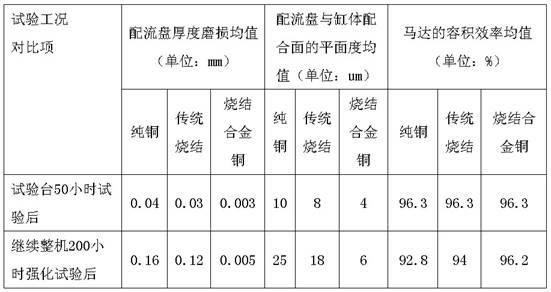

High-strength high-wear-resistance valve plate and preparation method thereof

ActiveCN102251144AHigh strengthImprove wear resistanceSoil-shifting machines/dredgersUltimate tensile strengthWear resistance

The invention provides a high-strength high-wear-resistance valve plate and a preparation method thereof. The high-strength high-wear-resistance valve plate comprises an iron base plate, and is characterized in that a copper plating layer and a copper alloy sintered layer are sequentially formed on the iron base plate; and the copper alloy sintered layer is prepared from 0.125-0.145% of Zn, 13-15% of Pb, 5-7% of Sn, 0.4-0.6% of Fe, 0.25-0.28% of Si, 0.07-0.1% of Se, 0.007-0.009% of P, 0.0035-0.0038% of Ag, 0.004-0.006% of Cr, 0.05-0.07% of S, 0.1-0.2% of As, 0.03-0.04% of B and the like. The invention has high strength and wear resistance.

Owner:龙工(上海)精工液压有限公司 +1

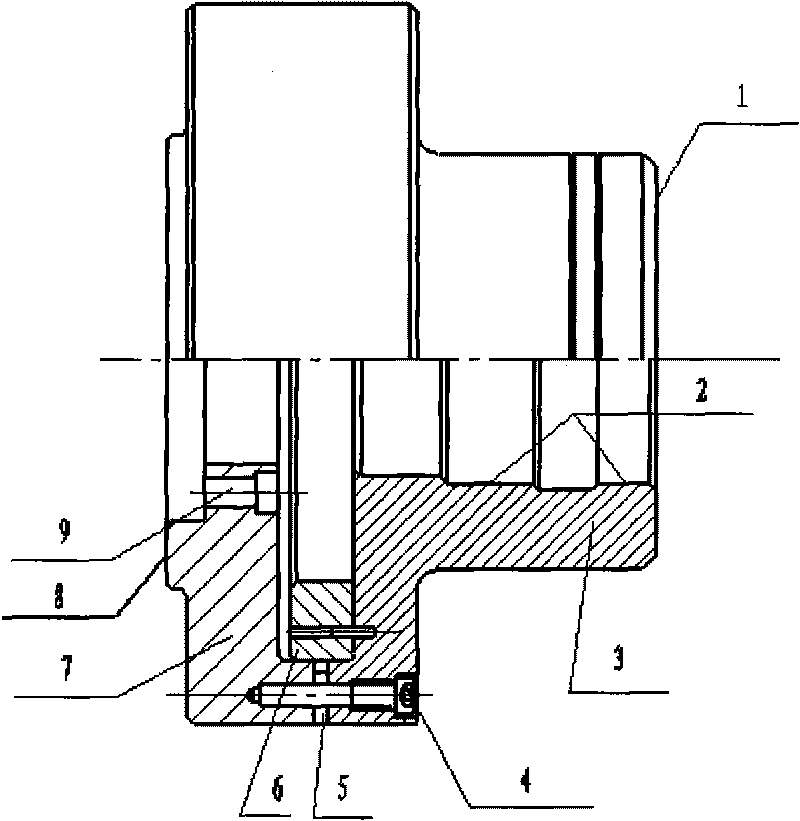

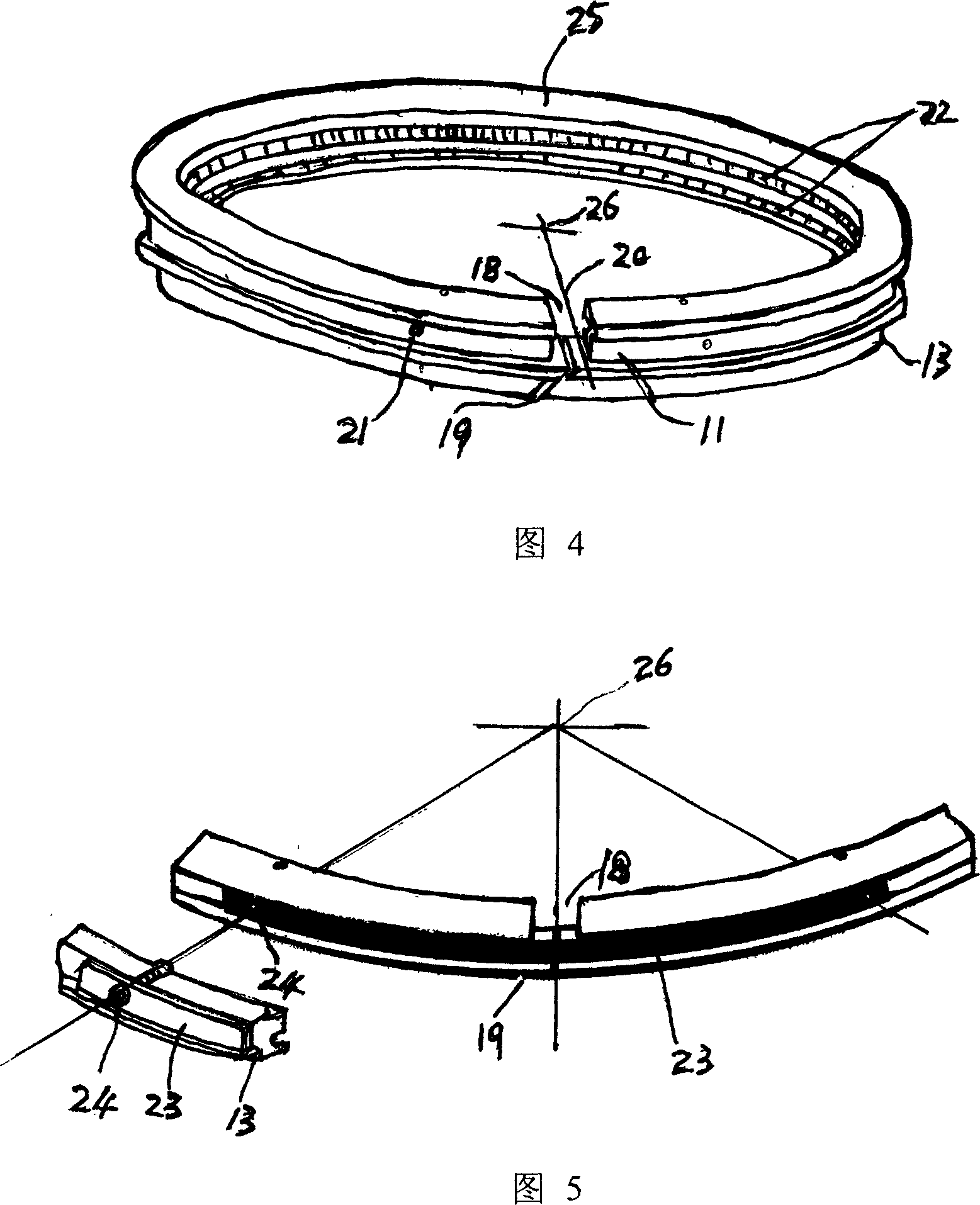

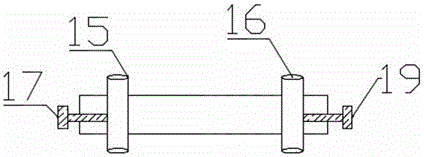

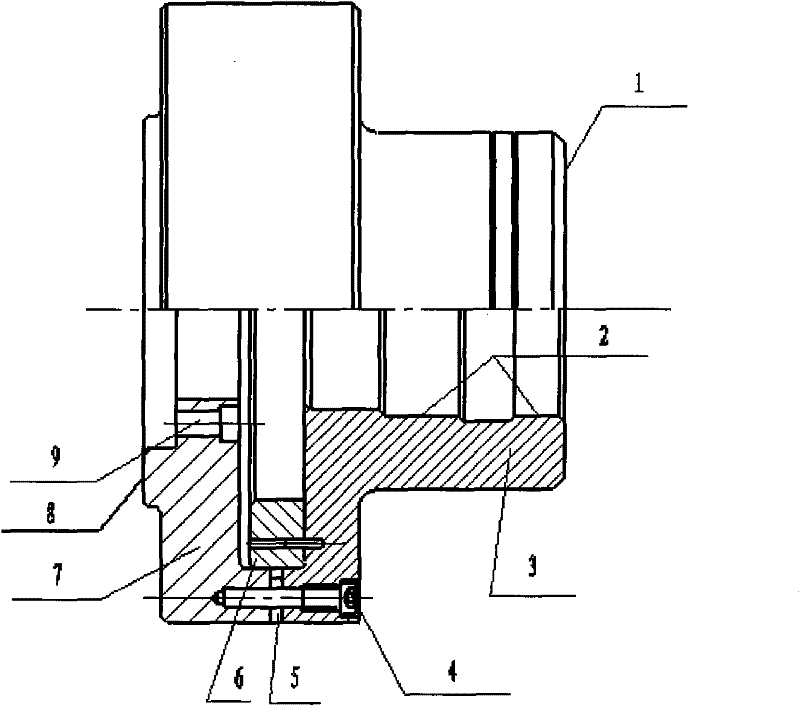

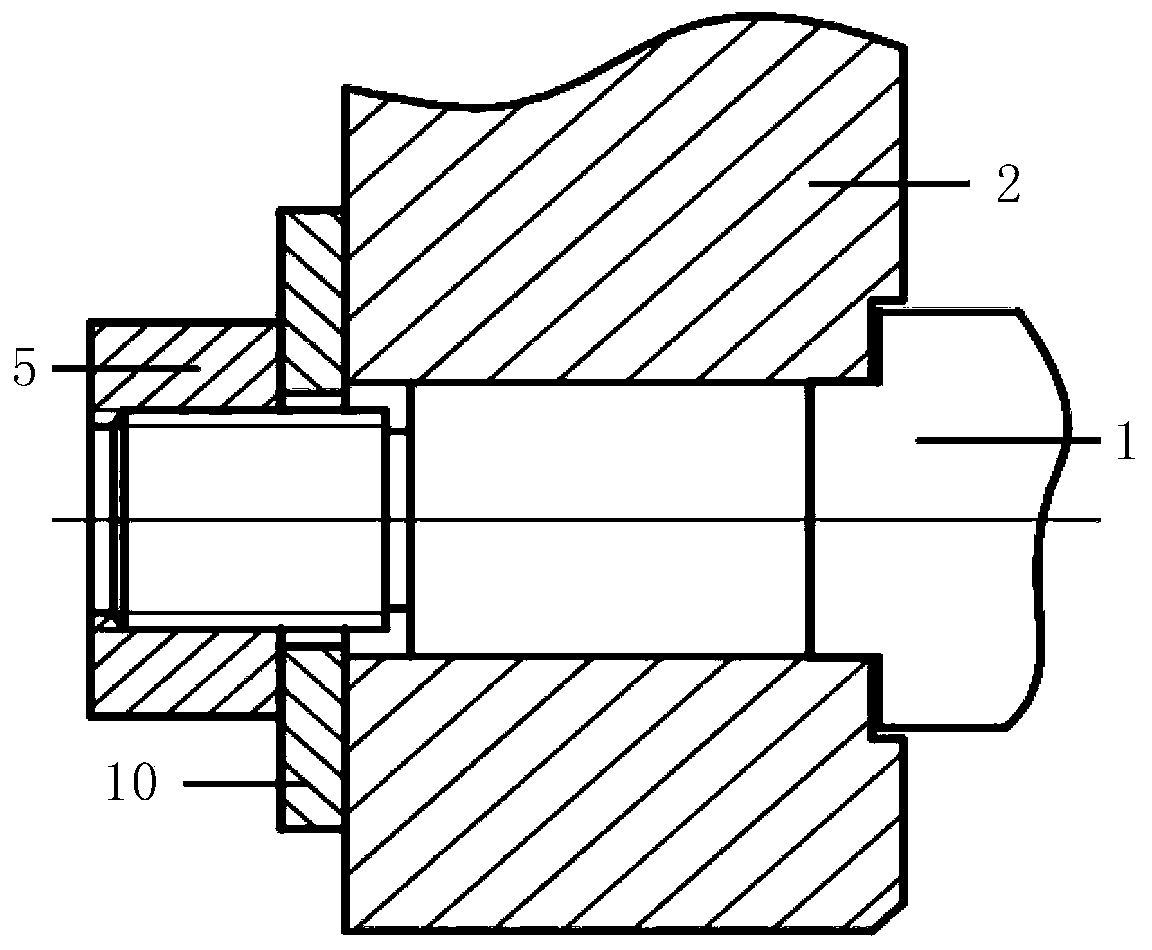

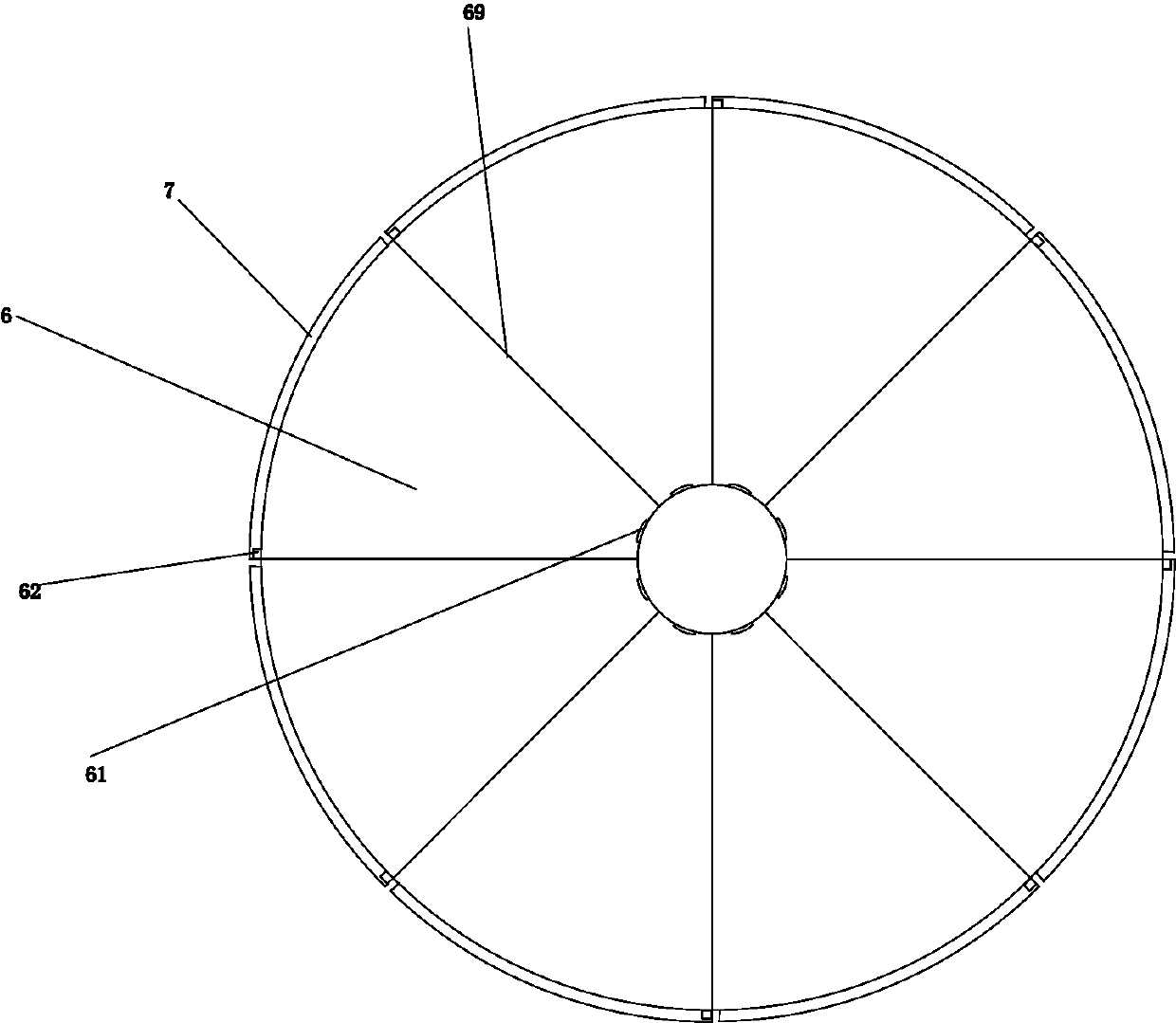

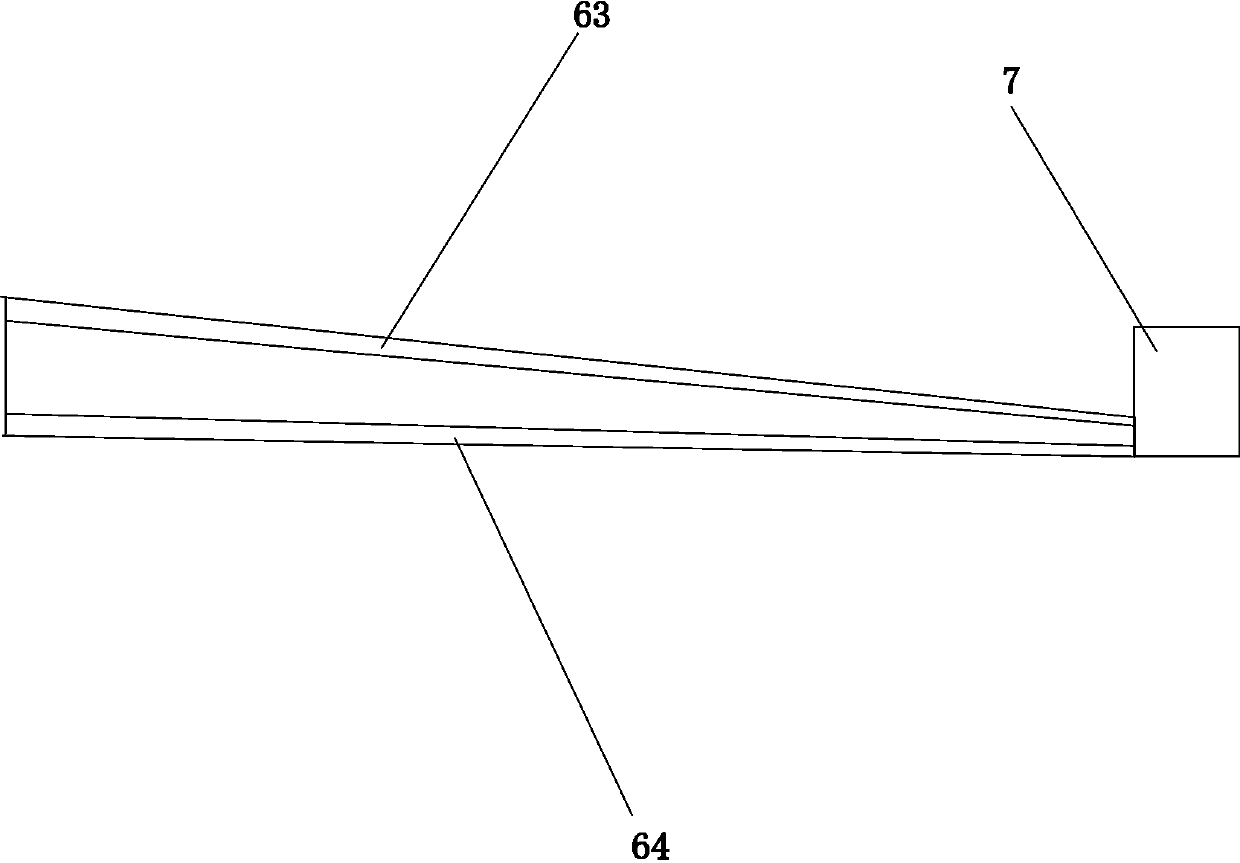

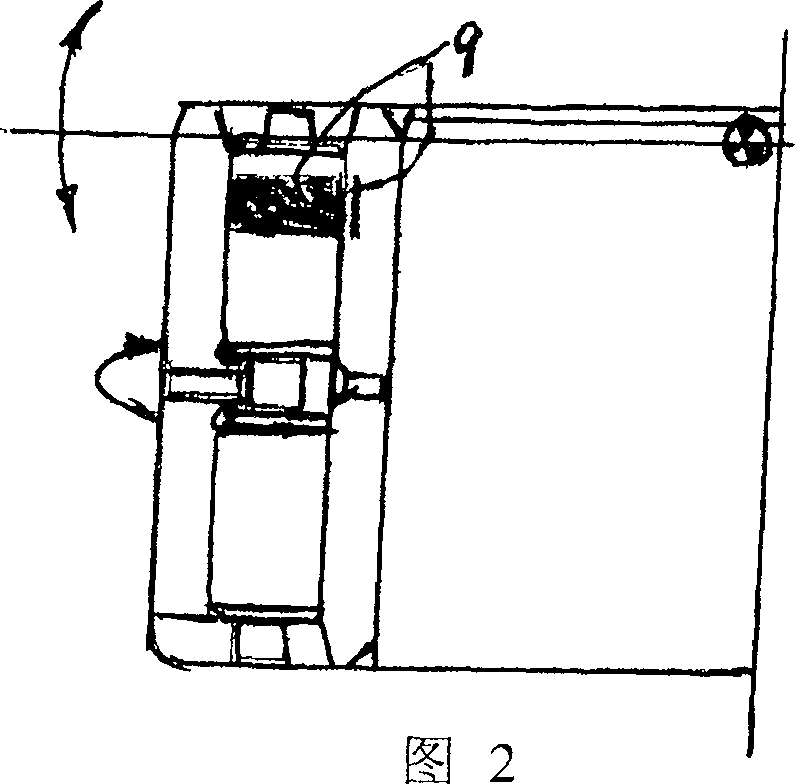

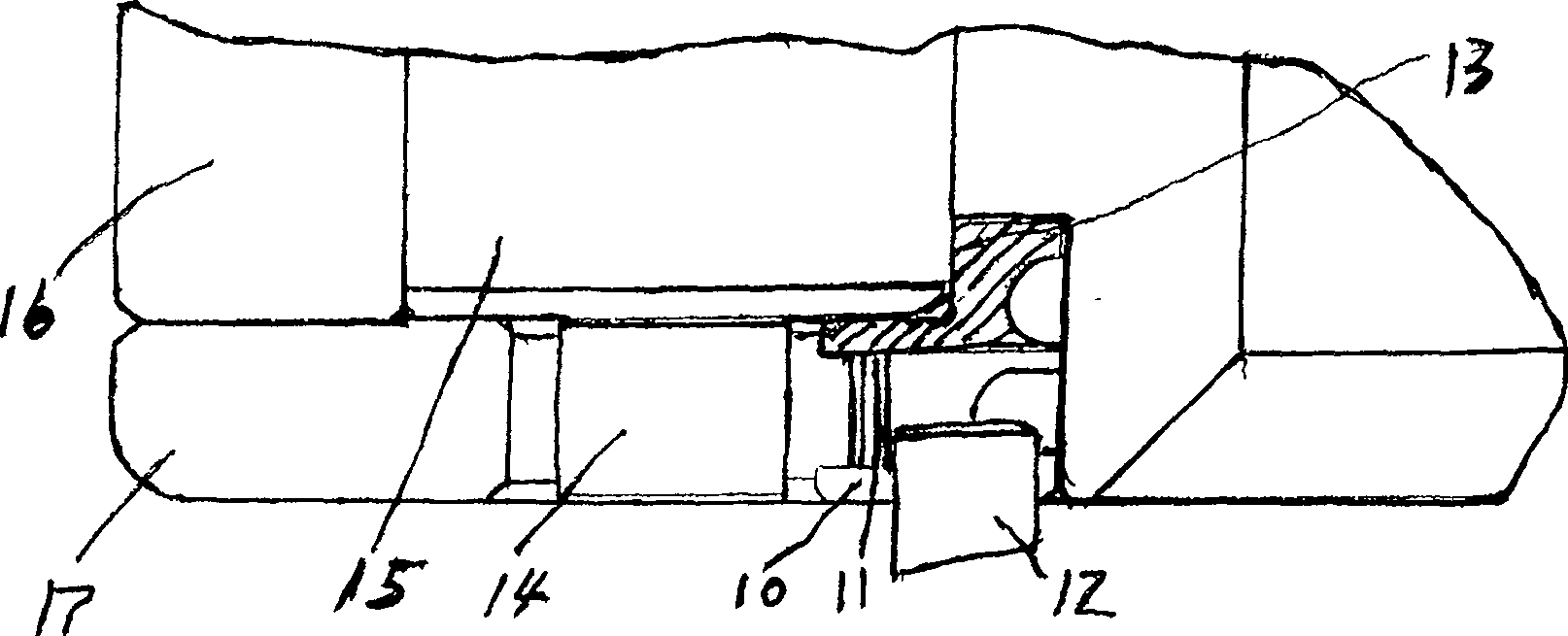

Circlip for cylindrical roller bearing and its production method

InactiveCN101122309AEliminate relative slidingAddress burnsBearing componentsEngineeringSpring steel

A circlip is used in a cylindrical roller bearing. Two ends of the circlip are connected via two spring steel pieces. An opening is arranged on the lower end surface of the connecting end, while an oblique notch connected with the opening is arranged on the upper end surface of the connecting end. An internal ring of the circlip is equipped with two oil-seal grooves, which extend outwards from the left and the right of the opening and become shadow gradually. The external ring of the circlip is equipped with a raceway surface to give load to a roller, and a fixing groove to fix the spring steel pieces. The spring steel pieces are arranged in the fixing groove at an angle of 30 degrees with both sides of the central line of the circlip opening in a perimetric way. As two ends of the opening are fixed with the spring steel pieces due to the size of the opening, the circlip of the invention is provided with the inward elasticity to give load to the roller and press the roller to the raceway in the external ring. When the external ring of the bearing revolves, the roller is forced to rotate. As the circlip cannot rotate with the bearing, the roller will not slide so as to solve the problem of burning of the roller. The invention is simple in the process. The circlip is provided with the good elasticity, the long usable life and the low cost, can greatly promote the working efficiency.

Owner:SHIBIAI SPECIAL BEARING LUOYANG

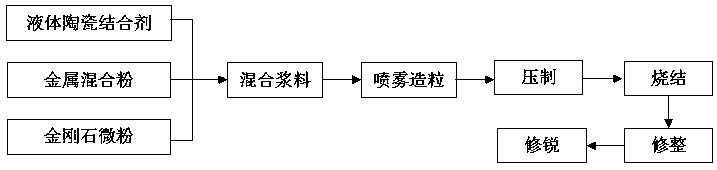

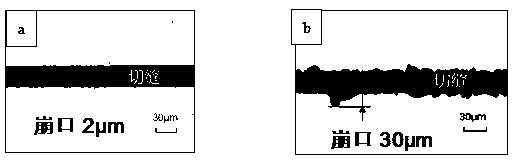

Ceramic metal composite binding agent grinding wheel and preparation method thereof

ActiveCN110842799AImprove consistencyHigh strengthAbrasion apparatusGrinding devicesSpray GranulationSlurry

The invention relates to a preparation method of a ceramic metal composite binding agent grinding wheel. The preparation method of the ceramic metal composite binding agent grinding wheel comprises the steps that (1), a liquid ceramic binding agent is prepared, specifically, a certain proportion of Al(NO3)3, H3BO3, LiNO3 and NaNO3 is dissolved in water, and then SiO2 sol is added to obtain the liquid ceramic binding agent; (2), a ceramic metal composite binding agent is prepared, specifically, diamond micro-powder and metal mixture powder are added to the liquid ceramic binding agent and mixedwell to obtain mixture slurry; (3), spray granulation is carried out, specifically, the mixture slurry obtained from the step (2) is subjected to spray granulation to prepare a molding material; and(4), sinter molding and post-processing are carried out, specifically, the molding material obtained from the step (3) is pressed and molded, sintered, trimmed and sharp fixed to obtain the ceramic metal composite binding agent grinding wheel. According to the preparation method of the ceramic metal composite binding agent grinding wheel, the microstructure consistency of the grinding wheel is improved, the phenomena of large dents, S-shaped cutting joints, burn, unstable cutting quality, uneven consumption speed, falling off of large pieces and the like caused by the prior art are solved, andmeanwhile, the grinding wheel further has higher strength and longer service life.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

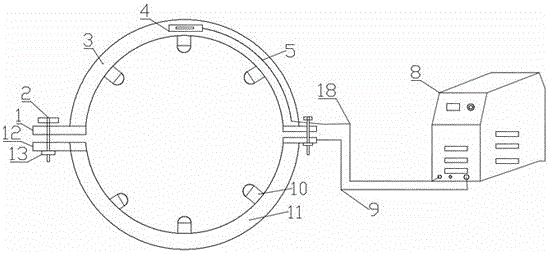

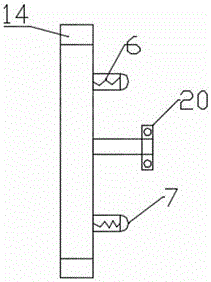

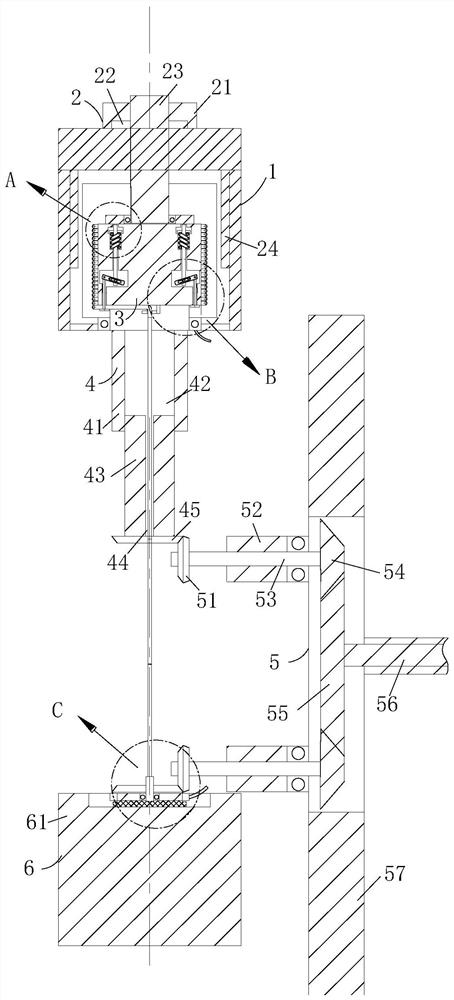

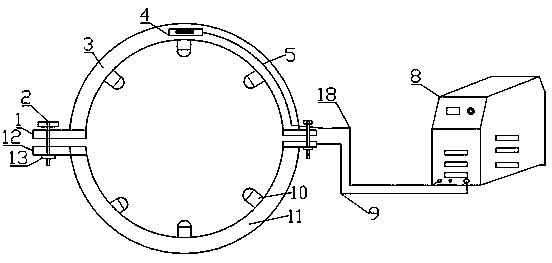

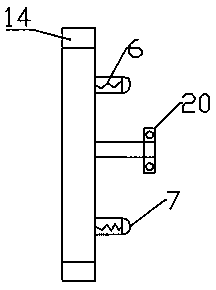

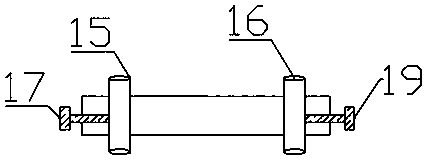

Novel welding and cutting dual-use device

ActiveCN106736105AAddress burnsSolve welding and cutting problemsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld line

The invention discloses a novel welding and cutting dual-use device. The novel welding and cutting dual-use device comprises an upper clamp ring and a plasma welding-cutting machine. A lower clamp ring is arranged under the upper clamp ring, and a welding-cutting gun fixing support is arranged in the upper clamp ring. Power wire slots and six conductive devices are arranged in the upper clamp ring and the lower clamp ring, and springs and balls are arranged in the conductive devices. Extension feet I are arranged on the left side and the right side of the upper clamp ring, and round holes are formed in the extension feet I. Extension feet II are arranged on the left side and the right side of the lower clamp ring, and nuts are welded to the bottoms of the extension feet II. The nuts and the round holes are in central symmetry. The extension feet I are connected with the extension feet II through bolts, and a welding-cutting device is arranged on the right sides of the upper clamp ring and the lower clamp ring. The upper clamp ring and the lower clamp ring are arranged and matched with the welding-cutting gun fixing support, so that weld line deviation is small in the welding process; additionally, the balls in the conductive devices can roll on the surface of a workpiece, so that burns, caused by poor ground in the welding process, on the surface of the workpiece can be reduced, and therefore the novel welding and cutting dual-use device has high practicality.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

Protecting, cooling and chip collecting device used when laser cutting inner wall of cylinder and using method thereof

The invention discloses a protecting, cooling and chip collecting device used when laser cutting an inner wall of a cylinder. The device comprises a first splicing pipe, wherein the inner wall of thetop of the left half part of the first splicing pipe is in threaded connection with a connecting pipe; the bottom of the connecting pipe communicates with the inside of the first splicing pipe; and aU-shaped box is arranged above the connecting pipe. The device has beneficial effects of being simple in structure and convenient to operate, and successfully solving a series of problems that scratch, burn, sinter and the like to the inner wall of the cylinder are caused by molten chips sprayed when the outside of the cylinder is cut by a laser; a laser cutting head can be symmetrically tracked inside the cylinder by the U-shaped box according to a cutter path of the laser cutting head, and the molten chips are collected in the U-shaped cavity after being cooled when the spraying angle of themolten chips is small, and then conveyed by a U-shaped cavity, a first connecting pipe, a corrugated pipe and a second connecting pipe into a chip collecting pipe to be temporarily stored, so that itis convenient for people to clean, and meanwhile, the damage to people caused by chip splashing is prevented.

Owner:吴善方

Composite processing method for grinding vane apex of rotor vane of aeroengine at high speed

ActiveCN101722459BGuaranteed GrindingMeet the design requirementsGrinding machinesHigh-speed grindingControl theory

The invention relates to a composite processing method for grinding the vane apex of a rotor vane of an aeroengine at a high speed, which comprises the following steps of: firstly, balancing a rotor in advance, controlling unbalance quantity which is permitted to be used for balancing the rotor in advance to be within 254g.mm, then installing the rotor on a fixture, enabling the rotor to be in a stretching state and grinding at a high speed. In the grinding process, the rotational speed of a processing part is 1600-2000r / min, the linear speed of a grinding wheel is 33-36m / s, the rotational speed of a scrubbing brush is 1500-1900r / min, and the control temperature during grinding is 20+ / -5 DEG C.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

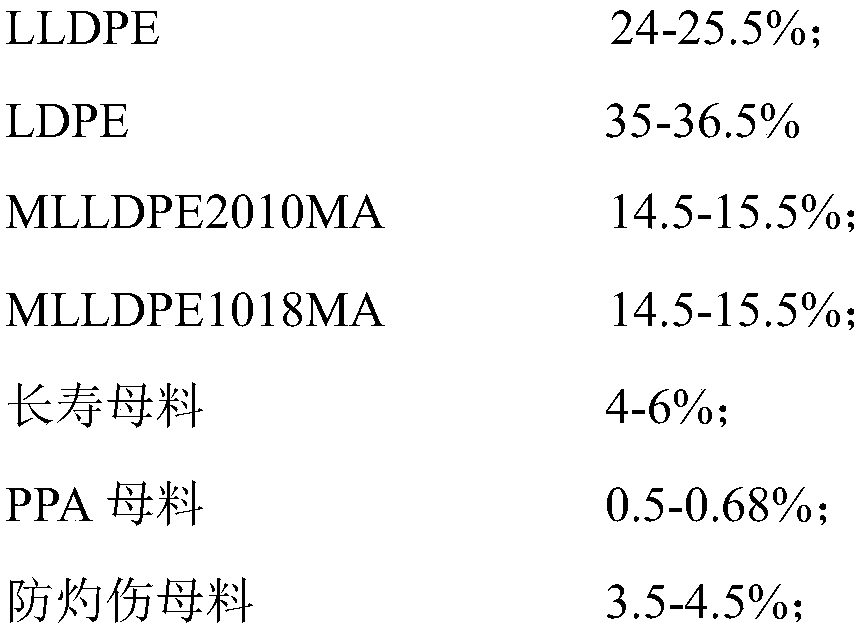

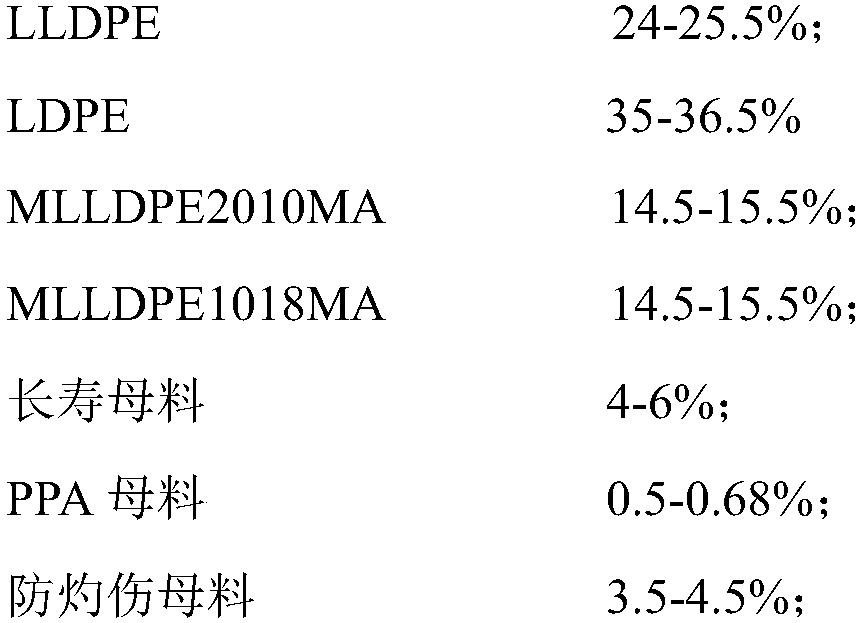

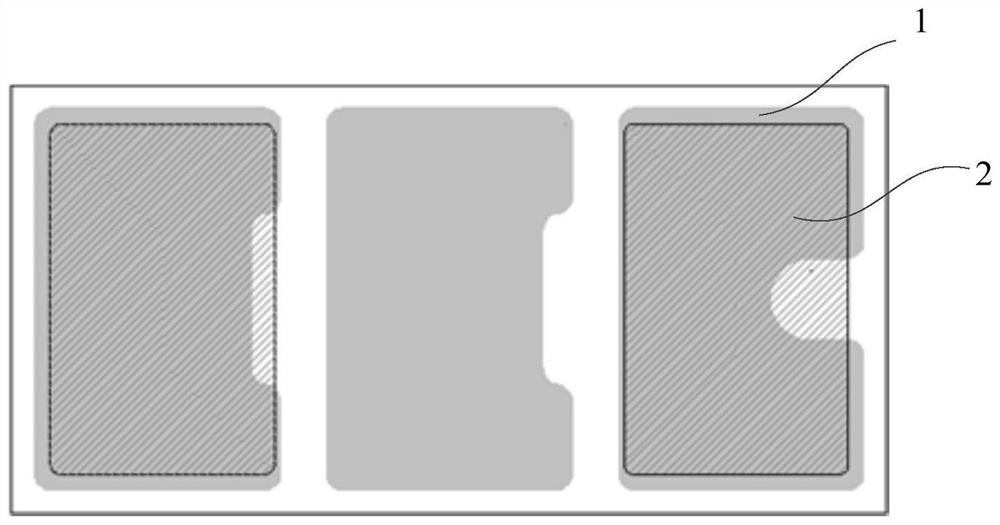

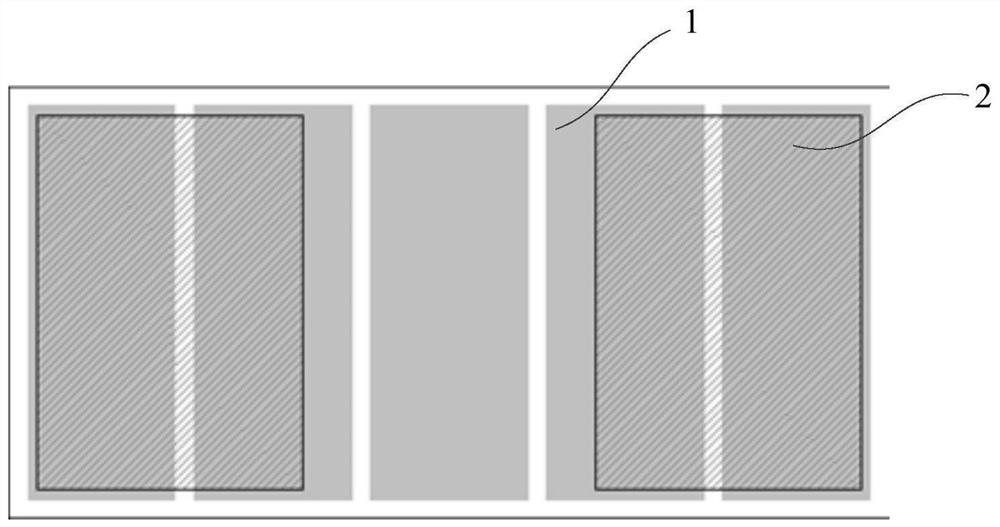

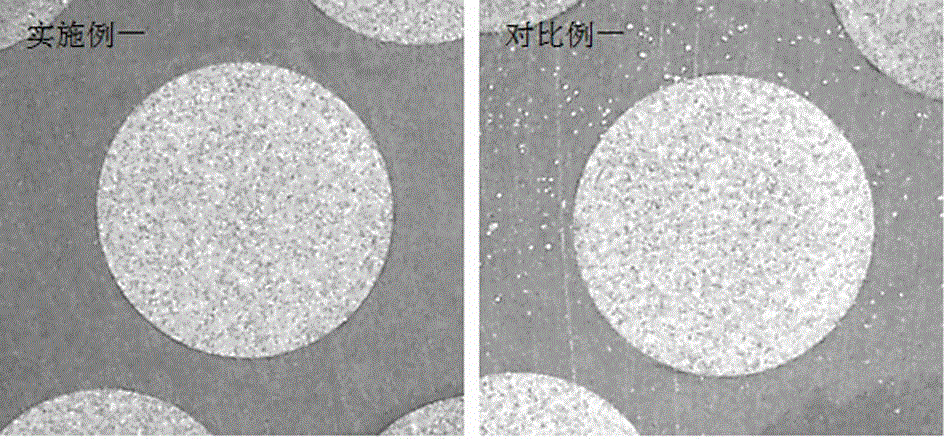

Anti-scorching diffuse-scattering greenhouse film special for fruits and vegetables and preparing method thereof

ActiveCN109287334APromote growthAddress burnsAgricultural articlesClimate change adaptationGrowth plantGreenhouse

The invention relates to an anti-scorching diffuse-scattering greenhouse film special for fruits and vegetables and a preparing method thereof, and belongs to the technical field of film manufacturing. The anti-scorching diffuse-scattering greenhouse film special for fruits and vegetables is prepared from, by mass, 24%-25.5% of LLDPE, 35%-36.5% of LDPE, 14.5%-15.5% of MLLDPE2010MA, 14.5%-15.5% ofMLLDPE1018MA, 4%-6% of a long-lived master batch, 0.5%-0.68% of a PPA master batch and 3.5%-4.5% of an anti-scorching master batch. Through the greenhouse film prepared with the method, the directionof light rays is changed, strong light is changed into soft light rays, a spectrum transmitted on plants is changed, and is matched with the wave length absorbed by chlorophyll, plant growth is betterfacilitated, and the problem that crops are scorched is solved. The invention also provides the preparing method for the anti-scorching diffuse-scattering greenhouse film special for fruits and vegetables, and the preparing method is scientific, reasonable, simple and easy to achieve.

Owner:房乾

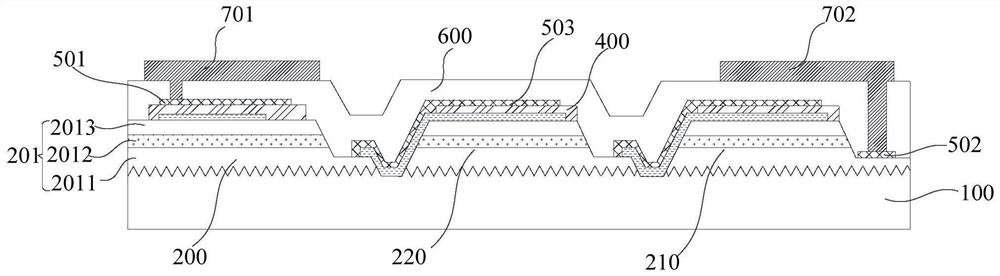

Light emitting diode and preparation method thereof

ActiveCN112802953AAddress burnsImprove reliabilitySemiconductor devicesElectrical connectionMaterials science

The invention discloses a light emitting diode and a preparation method thereof. The light emitting diode comprises a plurality of sub-chips which are electrically connected with one another, a first bonding pad, a second bonding pad and other bonding pads, wherein the adjacent sub-chips are spaced by a groove, at least one sub-chip comprises a first semiconductor layer, an active layer and a second semiconductor layer, and the plurality of sub-chips comprise a first sub-chip, a second sub-chip and at least one other sub-chip except the first sub-chip and the second sub-chip. The first bonding pad is electrically connected with the second semiconductor layer of the first sub-chip; the second bonding pad is electrically connected with the first semiconductor layer of the second sub-chip; and at least one other sub-chip is provided with one other bonding pad, and the other bonding pad is electrically connected with at most one of the first bonding pad or the second bonding pad. The phenomenon of non-uniform heat dissipation of the chip can be avoided, the problem of chip burning caused by poor heat dissipation of the light-emitting diode is solved, and the reliability of the chip is improved.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

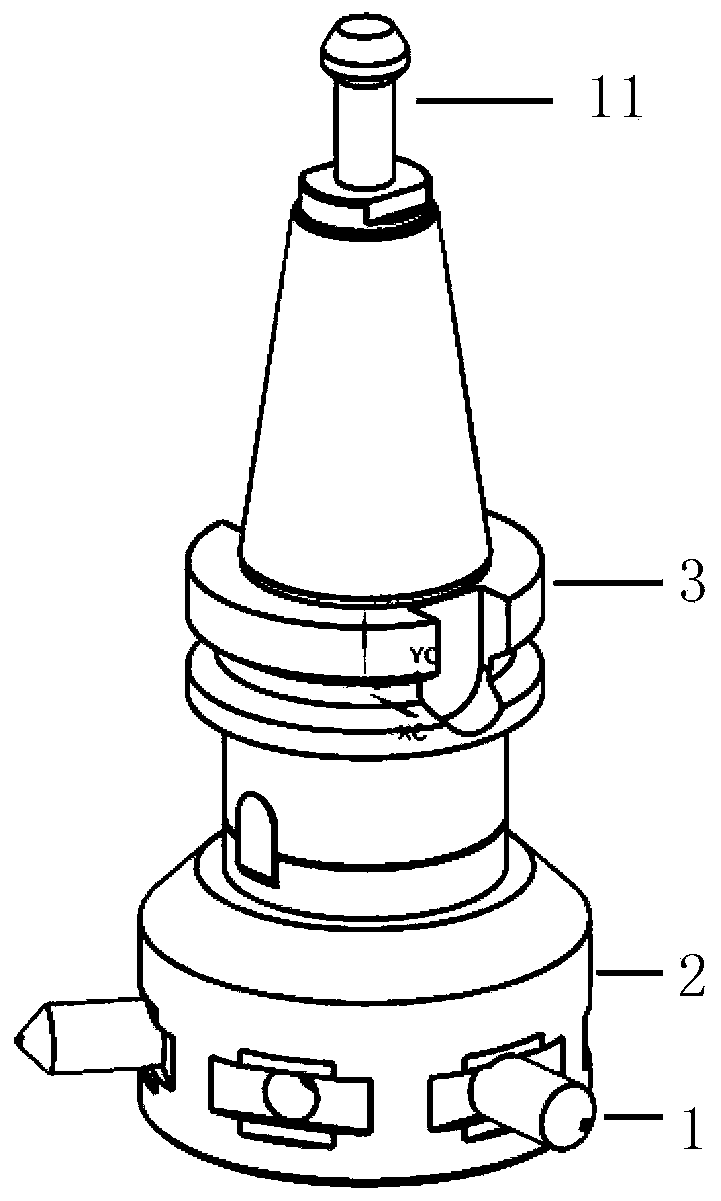

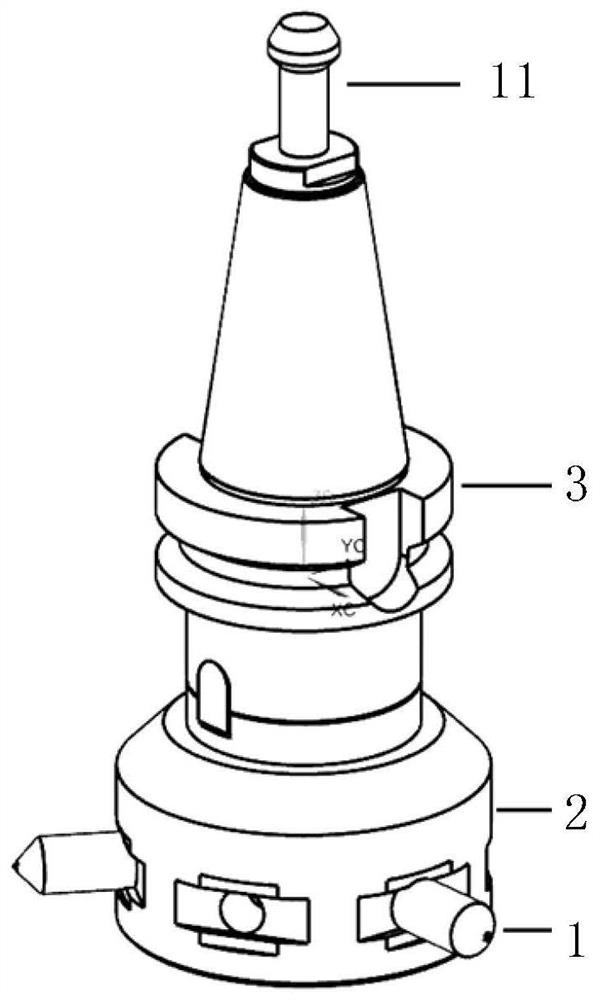

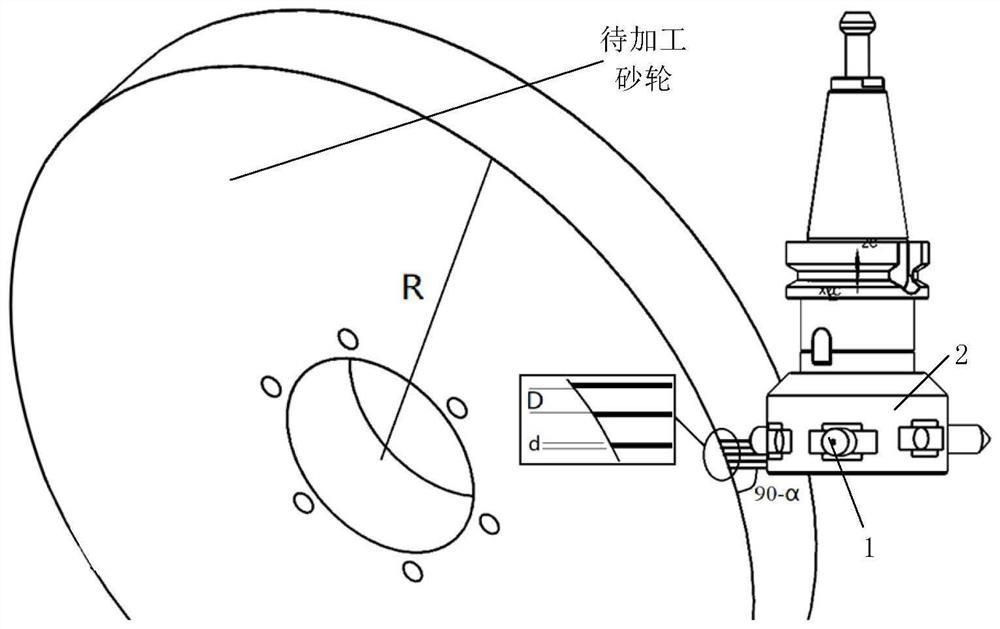

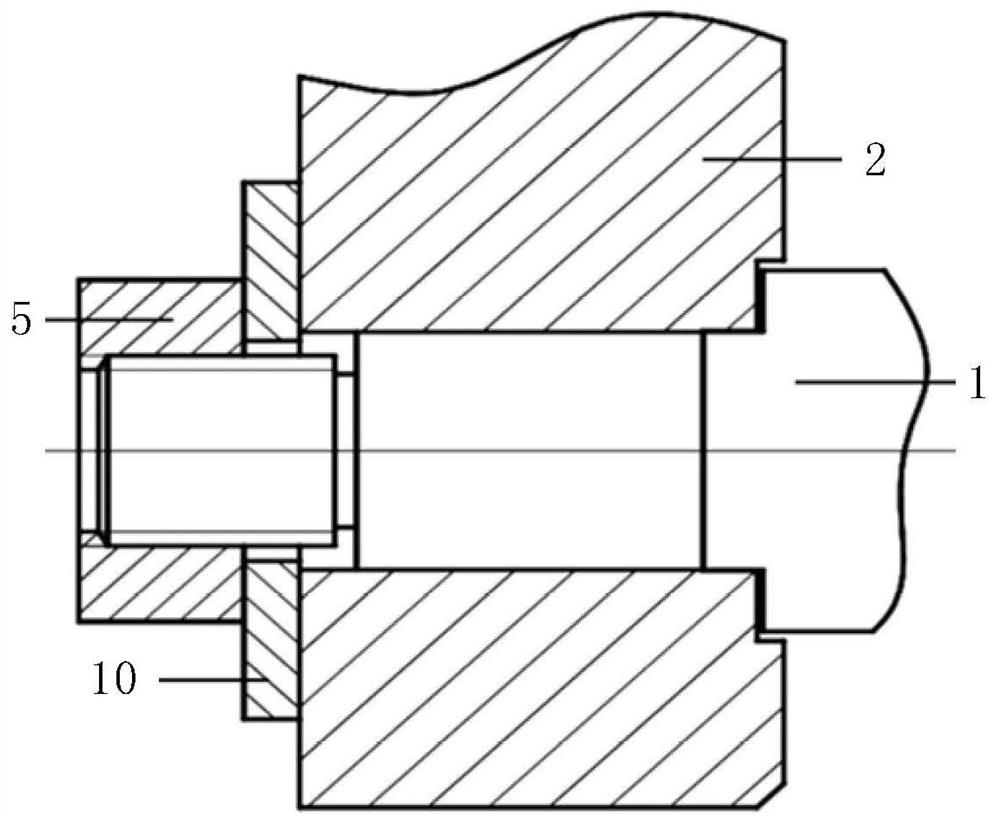

Grinding wheel slotting tool and slotting method

ActiveCN111283553AAddress burnsExtended service lifeAbrasive surface conditioning devicesLaser beam welding apparatusMilling cutterThermal deformation

The invention provides a grinding wheel slotting tool and a slotting method, and belongs to the field of machining. The grinding wheel slotting tool comprises grinding wheel dressers, a connecting block and disc milling cutter shanks; the disc milling cutter shanks are mounted on the connecting block and are arranged in the circumferential direction of the connecting block; and the grinding wheeldressers form a spiral mounting track along the circumferential direction of the connecting block and the orientations of the grinding wheel dressers are perpendicular to the tangential direction of the spiral track. According to the grinding wheel slotting tool and the slotting method, relying on that the grinding wheel dressers move relatively in a grinding wheel grinding area and cut the grinding wheel to form a grid of a circumferential surface structure of the grinding wheel, the grinding wheel dressers and a grinding wheel to be machined can rotate around the axes respectively and perform the movement of a worm and a gear that are engaged with each other; in an overlapped part of the grinding wheel dressers and the grinding wheel to be machined, the quick grinding wheel slotting toolcuts the grinding wheel to complete a slotting operation; the grinding wheel is slotted and grid grooves are formed in the circumferential direction of the grinding wheel; the defects of workpiece burning and thermal deformation caused by grinding in the prior art are overcome; the slotting quality is good; and the efficiency is high.

Owner:SHANGHAI JIAO TONG UNIV

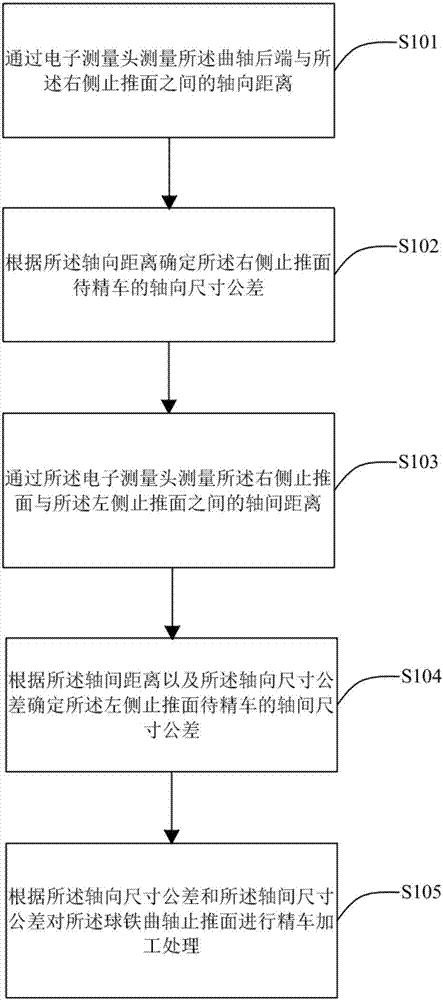

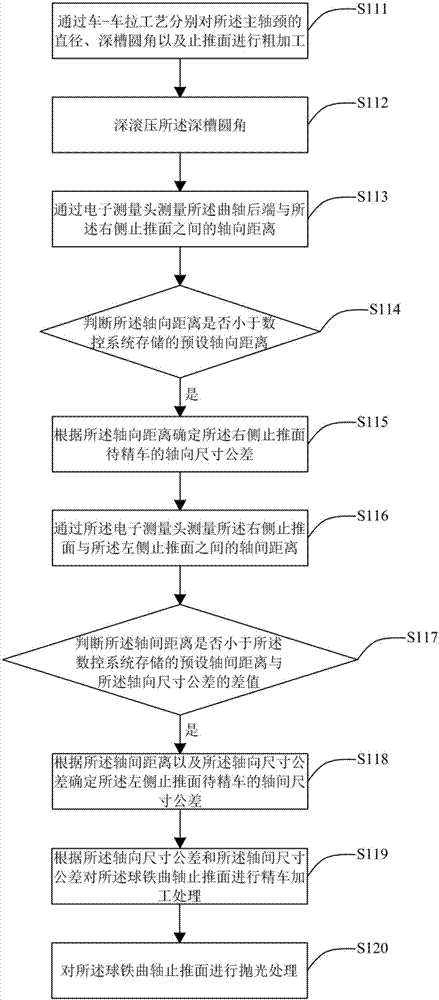

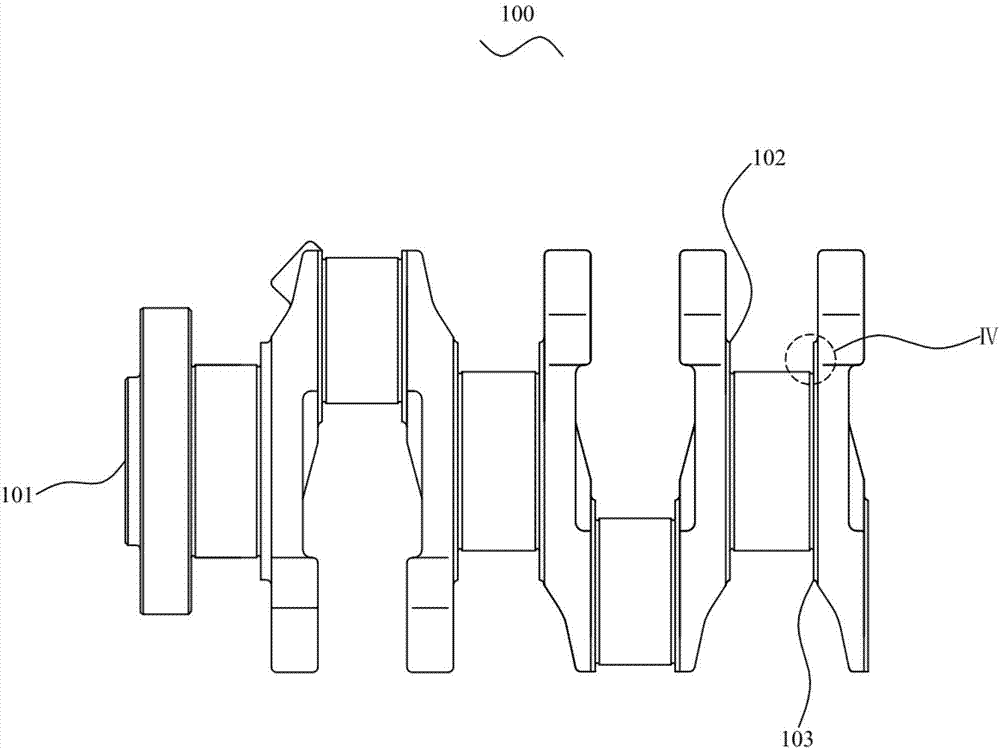

Machining method for ductile iron crankshaft thrust surfaces

The invention discloses a machining method for ductile iron crankshaft thrust surfaces. A crankshaft comprises a crankshaft back end and main journals, and the thrust surfaces of each main journal comprise a left-side thrust surface and a right-side thrust surface which are arranged oppositely. The method comprises the steps as follows: the axial distances between the crankshaft back end and the right-side thrust surfaces as well as the inter-axis distances between the right-side thrust surfaces and the left-side thrust surfaces are measured by an electronic measuring head; to-be-finish-turned axial dimension tolerance of the right-side thrust surfaces is determined according to the axial distances; the to-be-finish-turned inter-axis dimension tolerance of the left-side thrust surfaces is determined according to the inter-axis distances and the axial dimension tolerance; and finish-turning machining is performed on the crankshaft thrust surfaces according to the axial dimension tolerance and the inter-axis dimension tolerance. According to the machining method for the ductile iron crankshaft thrust surfaces, the axial distances and the inter-axis distances are measured by the electronic measuring head, the to-be-finish-turned machining allowance of the thrust surfaces is determined, finish-turning is performed, the problem of grinding burning caused by grinding machining of the thrust surfaces is solved with the finish-turning technology, and the equipment investment cost is less than that of the finish-turning and rolling technology.

Owner:JIANGLING MOTORS

Plane millstone filling system with self-sharpening function

The invention discloses a plane millstone filling system with a self-sharpening function. The plane millstone filling system is prepared from the following raw materials: epoxy resin, a curing agent, microcrystal fused alumina, chromium sesquioxide and absolute ethyl alcohol. An inorganic abrasive material in a filled layer has a micro-crushing function and can be automatically crushed during passivation in the milling process to generate a novel milling cutting edge, so that the self-sharpening performance of the filled layer is improved. When the plane millstone filling system is used for filling a gap of a plane millstone, the preparation process is simple, no special recruitments for raw materials are required, the leveling property is good during filling, and a filler can be in favorable contact with an abrasive block; the filled plane millstone is favorable in heat radiating capability, strength and rigidity, capable of favorably solving the problem of scrap and workpiece burning in the existing milling process, prolonging the finishing intervals and further increasing the milling efficiency and suitable for industrial production and application.

Owner:SUZHOU SAILI PRECISION TOOLS

Grinding wheel slotting tool and slotting method

ActiveCN111283553BAddress burnsExtended service lifeAbrasive surface conditioning devicesLaser beam welding apparatusMilling cutterThermal deformation

The invention provides a grinding wheel grooving tool and a grooving method, belonging to the field of mechanical processing, comprising a grinding wheel dresser, a connecting block and a disc milling cutter holder; the disc milling cutter holder is installed on the connecting block and along the With the circumferential arrangement of the connecting blocks, the grinding wheel dresser forms a spiral installation track along the connecting circumferential direction, and the orientation of the grinding wheel dresser is perpendicular to the tangential direction of the spiral track. The present invention relies on the grinding wheel dresser to move relatively in the grinding wheel grinding area and cut the grinding wheel to form a meshing of the circumferential surface structure of the grinding wheel. The grinding wheel dresser and the grinding wheel to be processed can each rotate around the axis and perform mutual meshing worm gear movement. The overlapping part of the grinding wheel dresser and the grinding wheel to be processed, the grinding wheel quick slotting tool cuts the grinding wheel to complete the slotting operation, realizes slotting on the grinding wheel and makes the grinding wheel circumferentially form grid grooves, and solves the problem of grinding in the prior art. The defects of workpiece burns and thermal deformation caused by cutting, good grooving quality and high efficiency.

Owner:SHANGHAI JIAOTONG UNIV

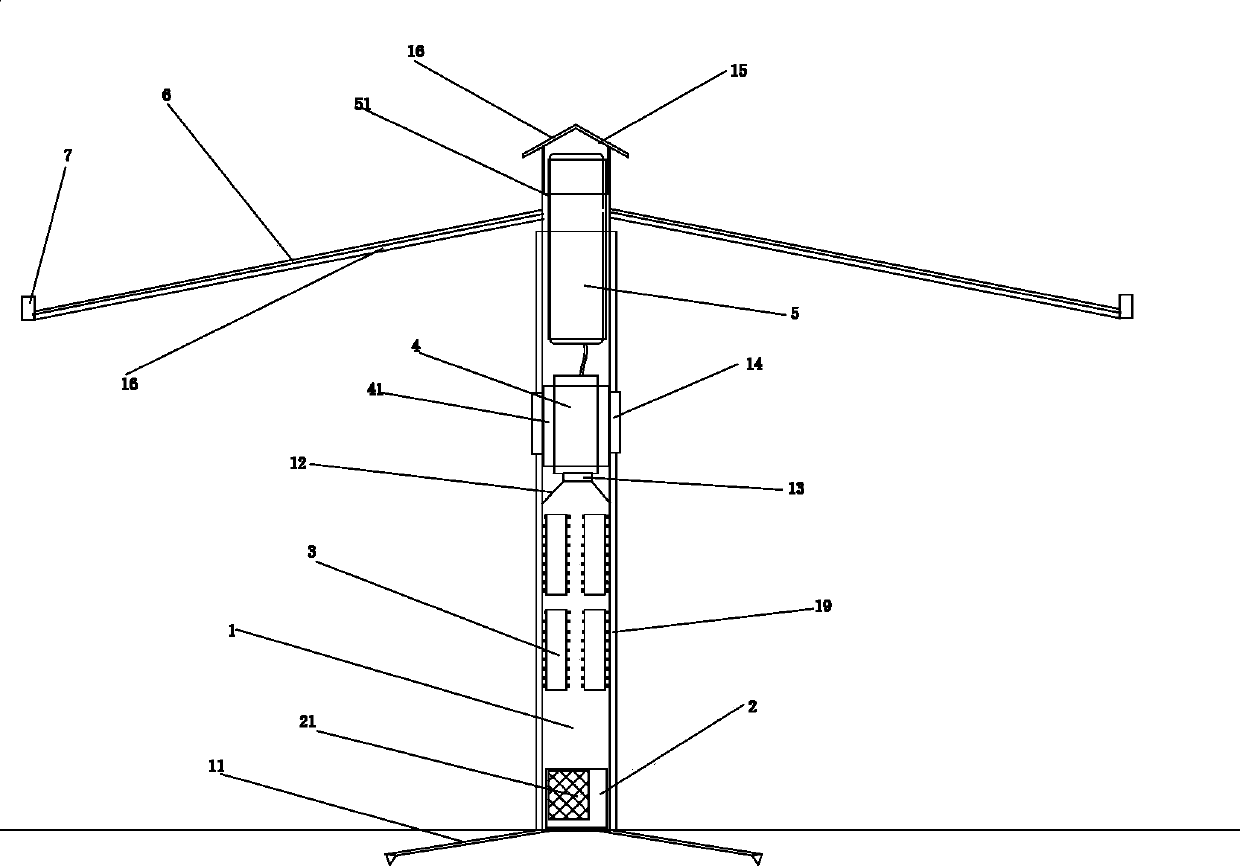

Beach umbrella

The invention discloses a beach umbrella and relates to beach umbrellas capable of absorbing ultraviolet radiation. The beach umbrella comprises an umbrella stem, a suction pump is arranged on the lower portion of the umbrella stem, ozone ceramic tubes are arranged in the umbrella stem, an air compressor and a gas storage tank are arranged on the umbrella stem, supporting rods are arranged at the top of the umbrella stem, a hollow transparent disk is fixedly arranged on the supporting rods and is provided with gas inlets and gas outlets, the gas inlets are connected with the air compressor, annular air curtains are arranged at the edge of the hollow transparent disk, connected with the gas outlets and arranged on the supporting rods, and partition boards are arranged in the umbrella stem and provided with openings connected with the air compressor. Compared with the prior art, the beach umbrella has the advantages that the beach umbrella is capable of absorbing ultraviolet radiation in sunlight automatically when people sunbathe, and the problem that the people are burned by intense ultraviolet radiation possibly or suffer from skin diseases induced by long-time ultraviolet radiation during sunbathing can be solved.

Owner:安徽格太信控科技有限公司

Wire cut electrical discharge machining device with convex tooth structure and wire electrode

InactiveCN113634832AEasy to fixAdjustable lengthElectrical-based machining electrodesElectrical-based auxillary apparatusGear wheelWire cutting

The invention relates to the technical field of wire electrodes, in particular to a wire cut electrical discharge machining device with a convex tooth structure and a wire electrode. The wire cut electrical discharge machining device comprises a shell, a fastening mechanism is mounted on the shell, the fastening mechanism is in threaded connection with the shell, a wire tightening mechanism is arranged in the shell, and the wire tightening mechanism is abutted against the fastening mechanism; and a telescopic mechanism is fixed to the bottom of the shell. A fifth gear rotates to drive a second bearing to rotate, the second bearing drives a conductive block to rotate, a conductive seat on the second bearing rotates synchronously, and a wire electrode body on the conductive seat rotates. According to the wire cut electrical discharge machining device with the convex tooth structure and the wire electrode, working liquid can be promoted to be brought into an interelectrode, meanwhile, the discharging of interelectrode corrosion removal products is accelerated, the interelectrode discharging condition is improved, the discharging rule is easier to control through regular protruding point crests on the surface of the wire electrode body with the convex tooth structure, and therefore the machining efficiency can be improved, and the surface quality can be improved; and the volume and the pitch of the chip containing space of the wire electrode body with the convex tooth structure can be controlled according to the rolling tooth shape size and the thread pitch.

Owner:TONGLING YUANYI FINE MACHINERY CO LTD +1

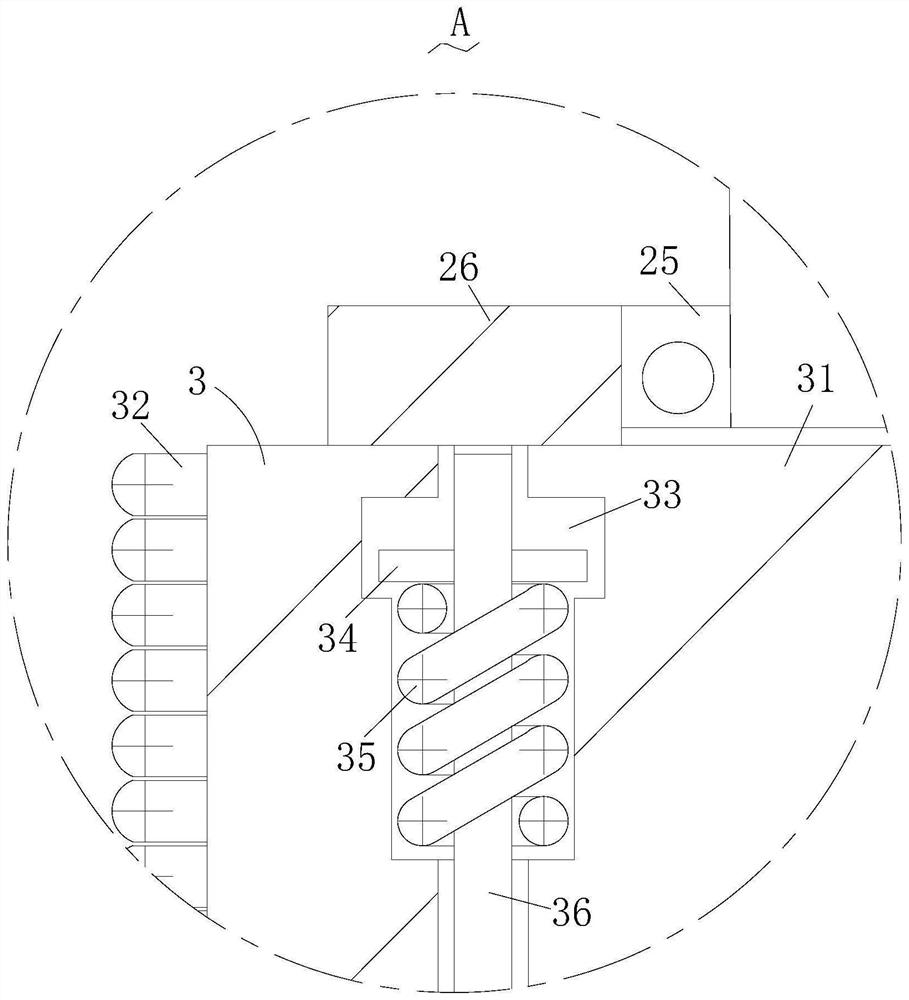

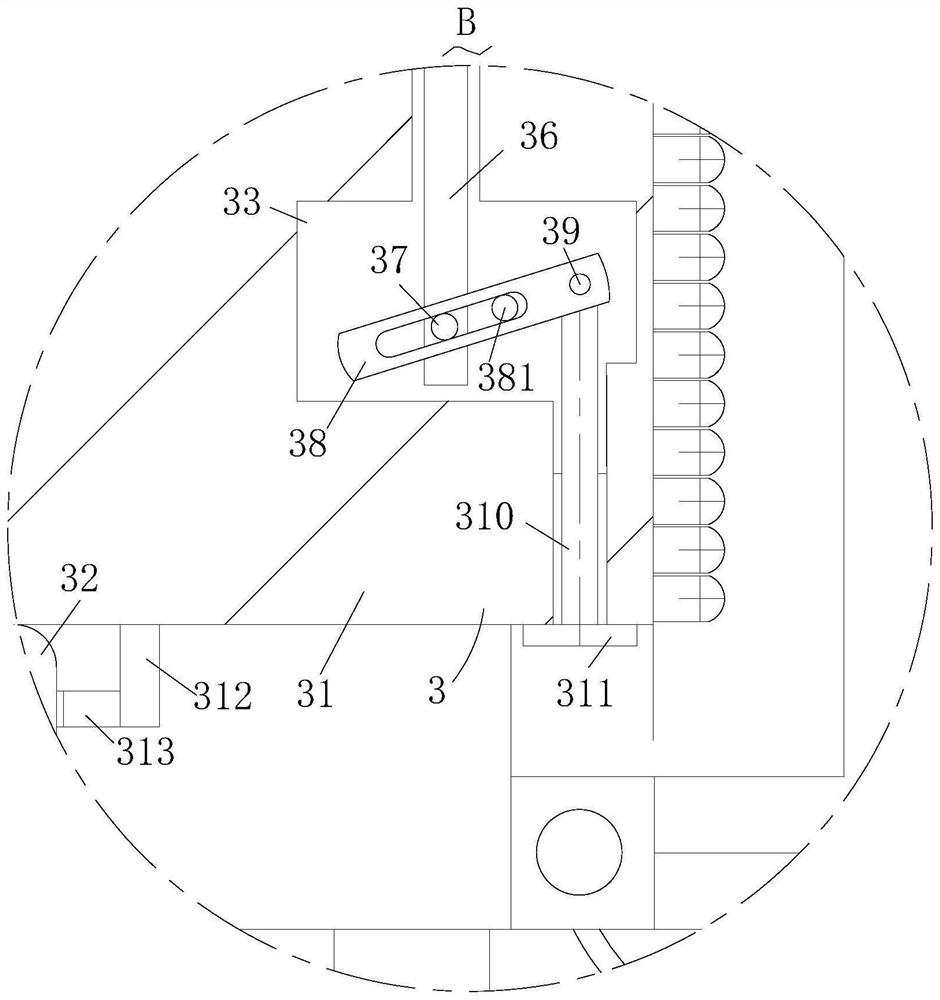

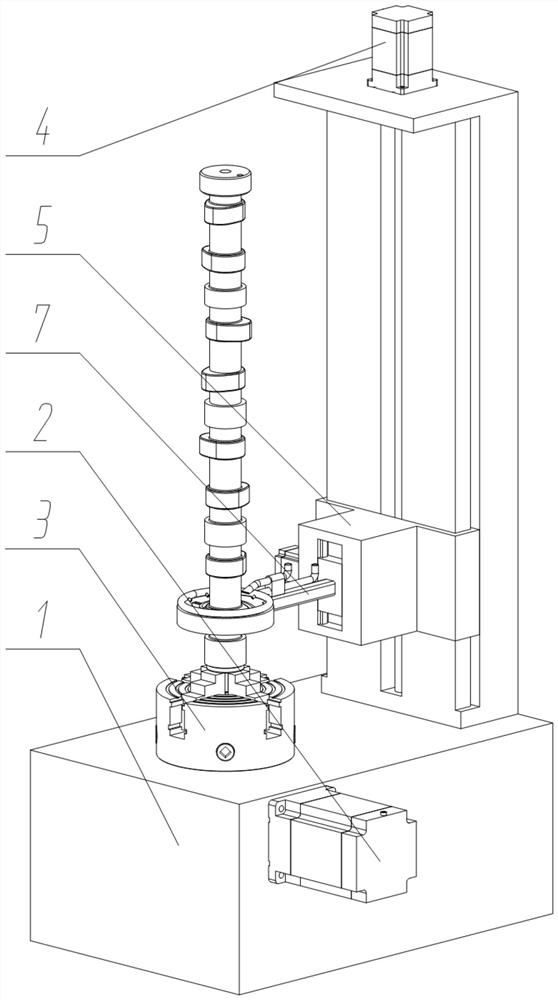

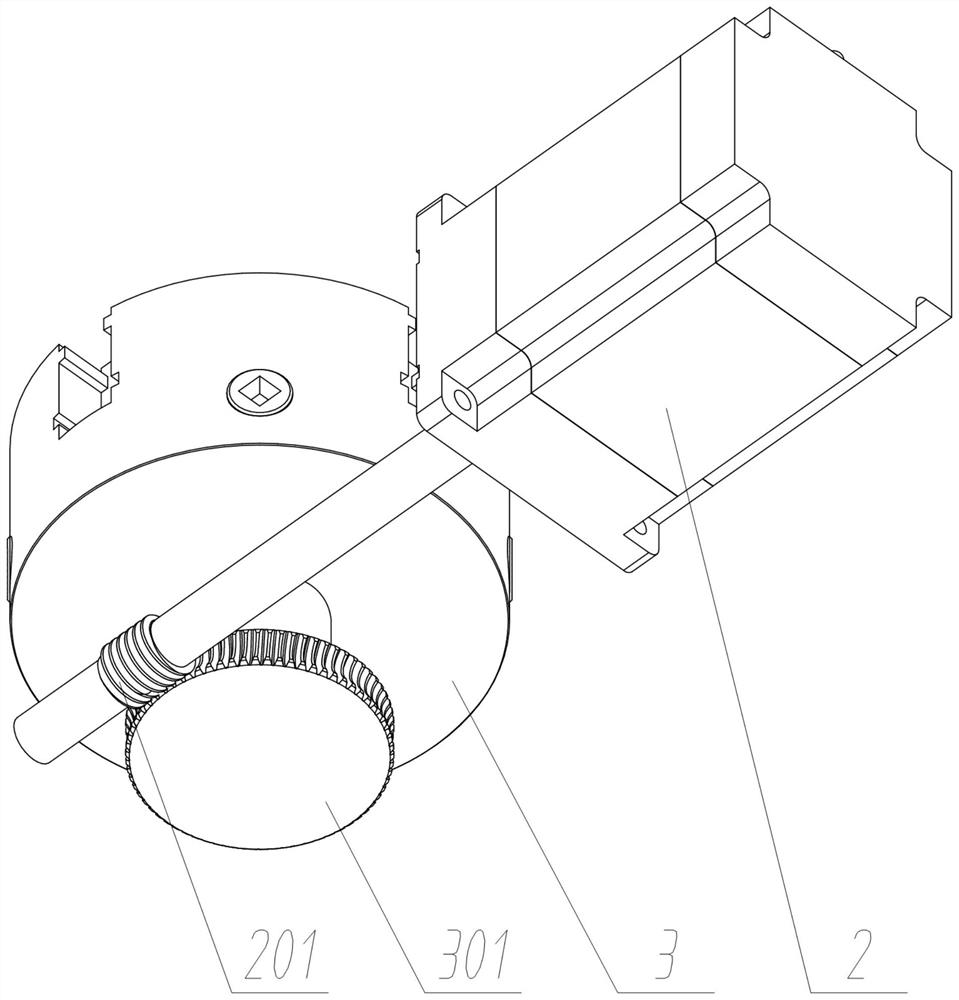

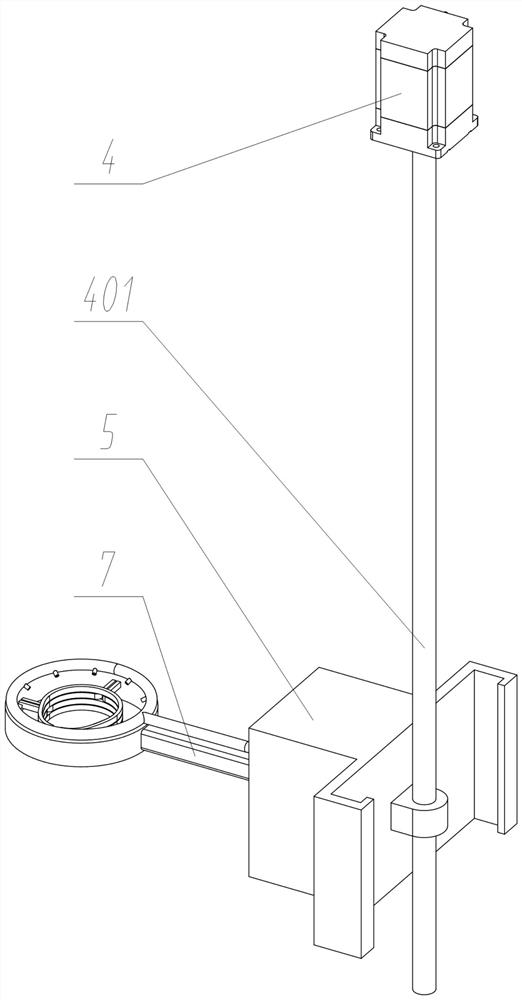

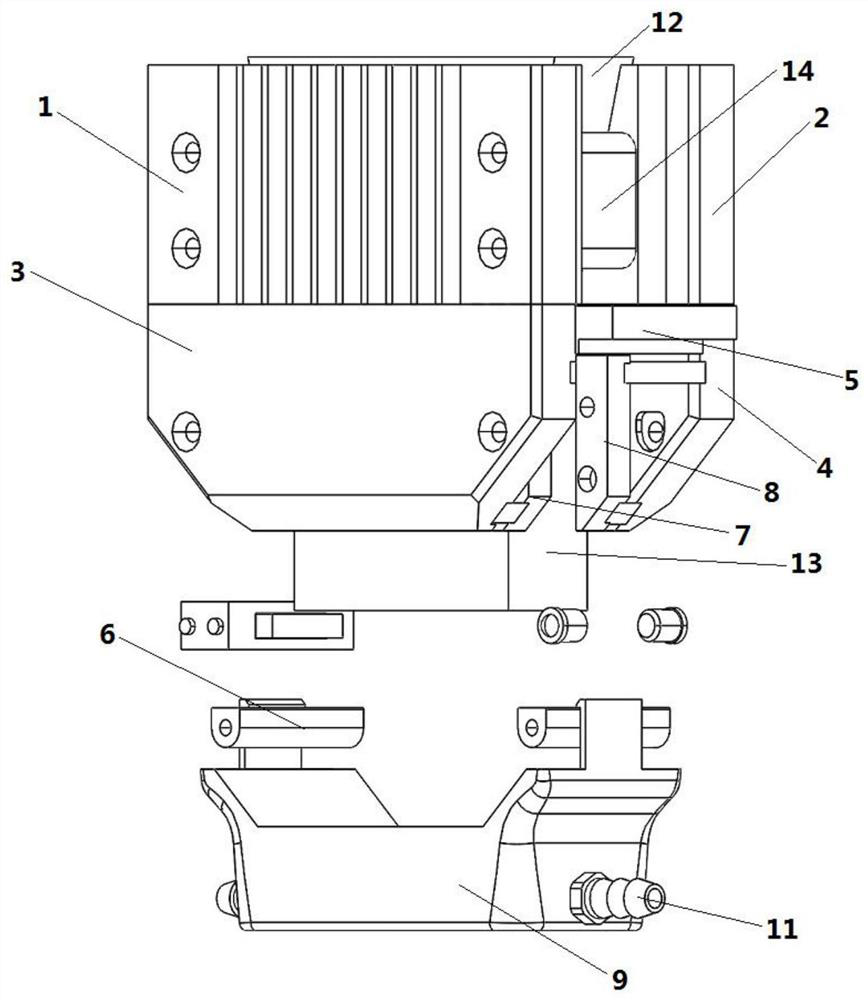

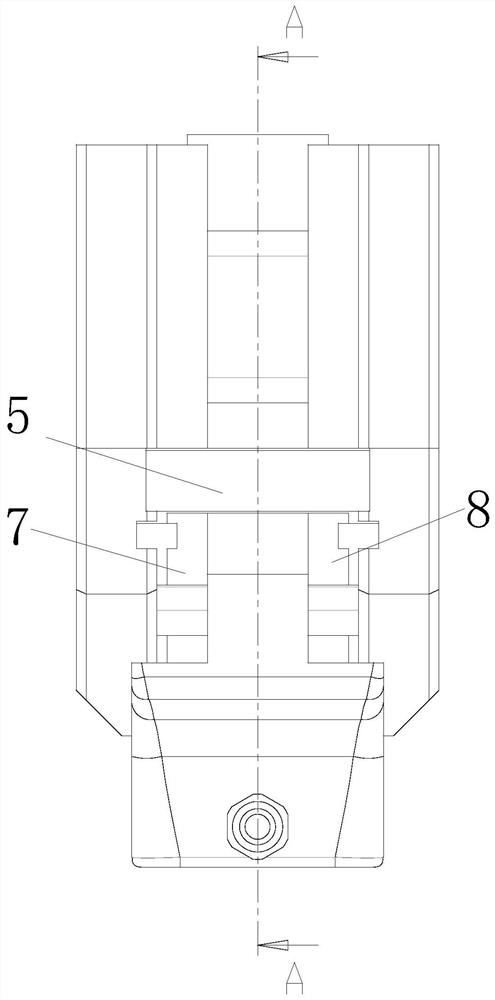

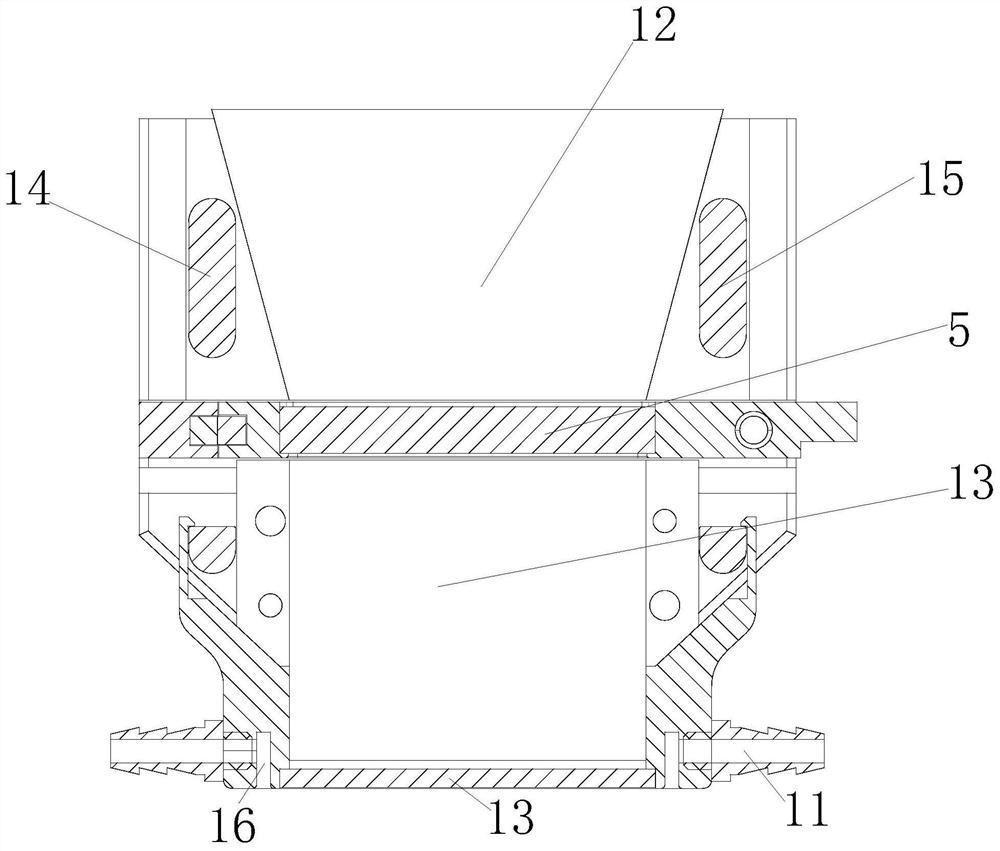

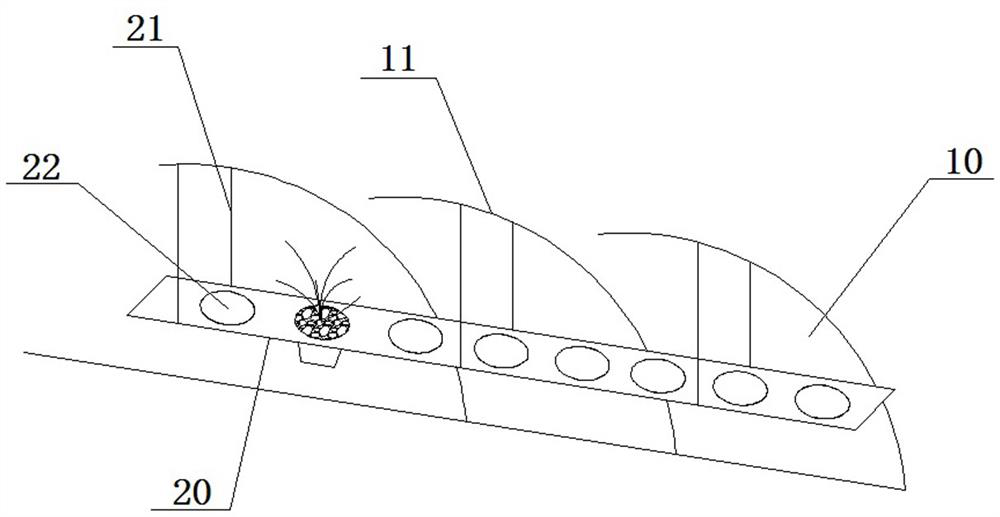

Special camshaft high-frequency quenching device

ActiveCN113088665AAchieve rotationEasy to quenchIncreasing energy efficiencyFurnace typesEngineeringMachining

The invention discloses a special camshaft high-frequency quenching device, and relates to the technical field of heat treatment equipment. The problems that during quenching machining of an existing camshaft, an existing induction coil is provided with an opening, during heating, opening heating unevenness, burning, cracking, hardness unevenness, quenching layer depth unevenness and the like are prone to happening, cracking is prone to happening, and the product quality is influenced are solved. The special camshaft high-frequency quenching device comprises an installing base, wherein a set of camshaft rotation drive pieces are fixedly connected to the lower portion of the front end face of the installing base; a set of lifting drive pieces are fixedly connected to the top of the installing base; a set of lifting sliding bases are in sliding connection to the left side of the installing base; and a set of slippage drive pieces are fixedly connected to the rear end faces of the lifting sliding bases. The special camshaft high-frequency quenching device solves the problems of burning, cracking, hardness unevenness, quenching layer depth unevenness and the like existing in the heat treatment process, the quality of the camshaft is improved, oxidation residues on the surface of a part are cleaned away, and the machining quality of the part is improved.

Owner:十堰宏兆汽配实业有限公司

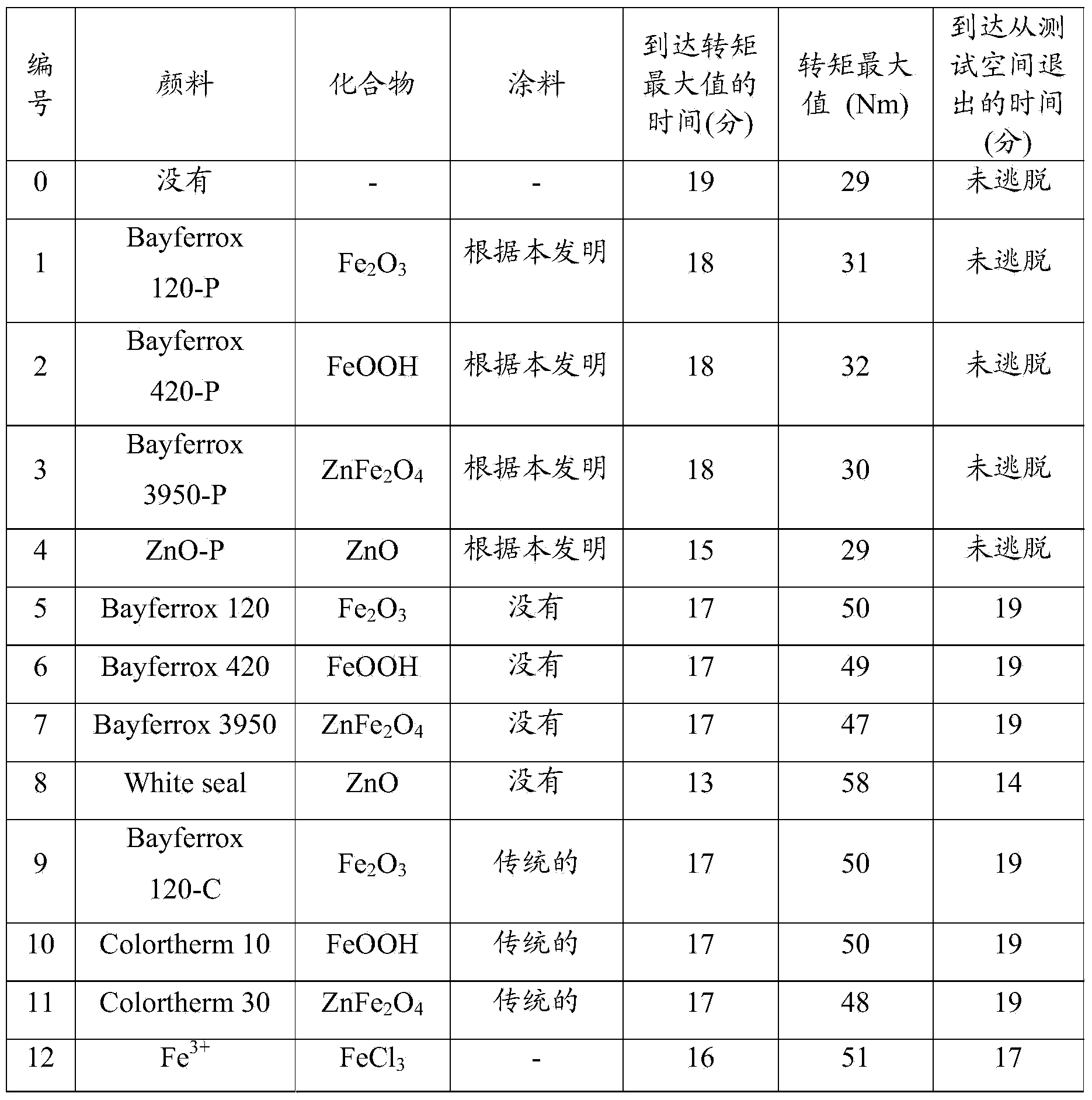

Acid-resistant coated pigments

The invention relates to the use of acid-resistant coated pigments in PVC plastic. Acid-soluble pigments are provided with a coating consisting of an organic compound that melts at a temperature of T>200°C, and as a result the otherwise acid-soluble pigments are still protected from HCl vapour even at PVC processing temperatures of between 180 and 200°C.

Owner:LEY & FARBENWERKE WUNSIEDEL

Pigments applied in an acid-resistant manner

InactiveCN104114648BAddress burnsPigmenting treatmentCoatingsSimple Organic CompoundsOrganic compound

The invention relates to the use of pigments applied in an acid-resistant manner in PVC synthetic materials. Acid-Soluble Pigments Coatings with organic compounds that melt at temperatures T > 200°C so even at PVC processing temperatures between 180°C and 200°C other acid-soluble pigments are protected from damage by HCl vapor.

Owner:LEY & FARBENWERKE WUNSIEDEL

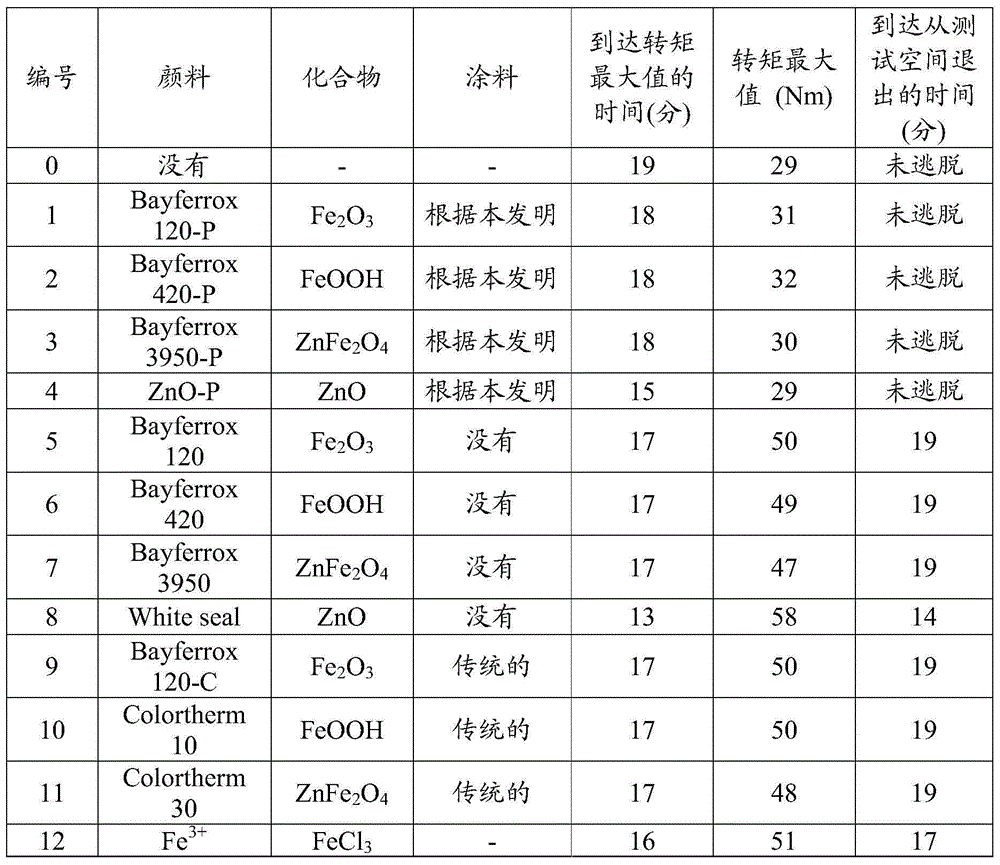

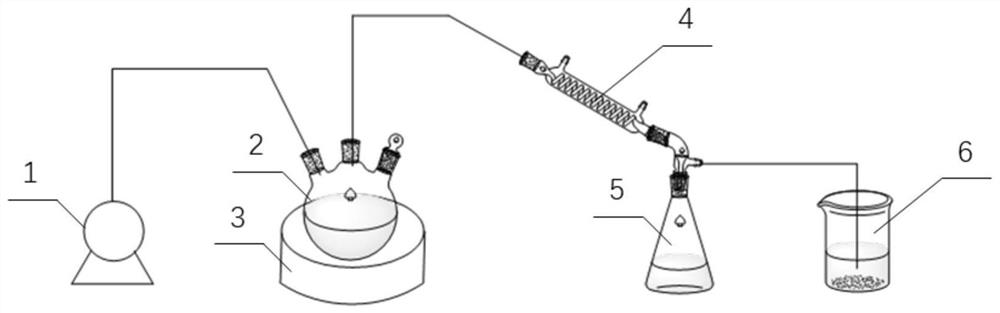

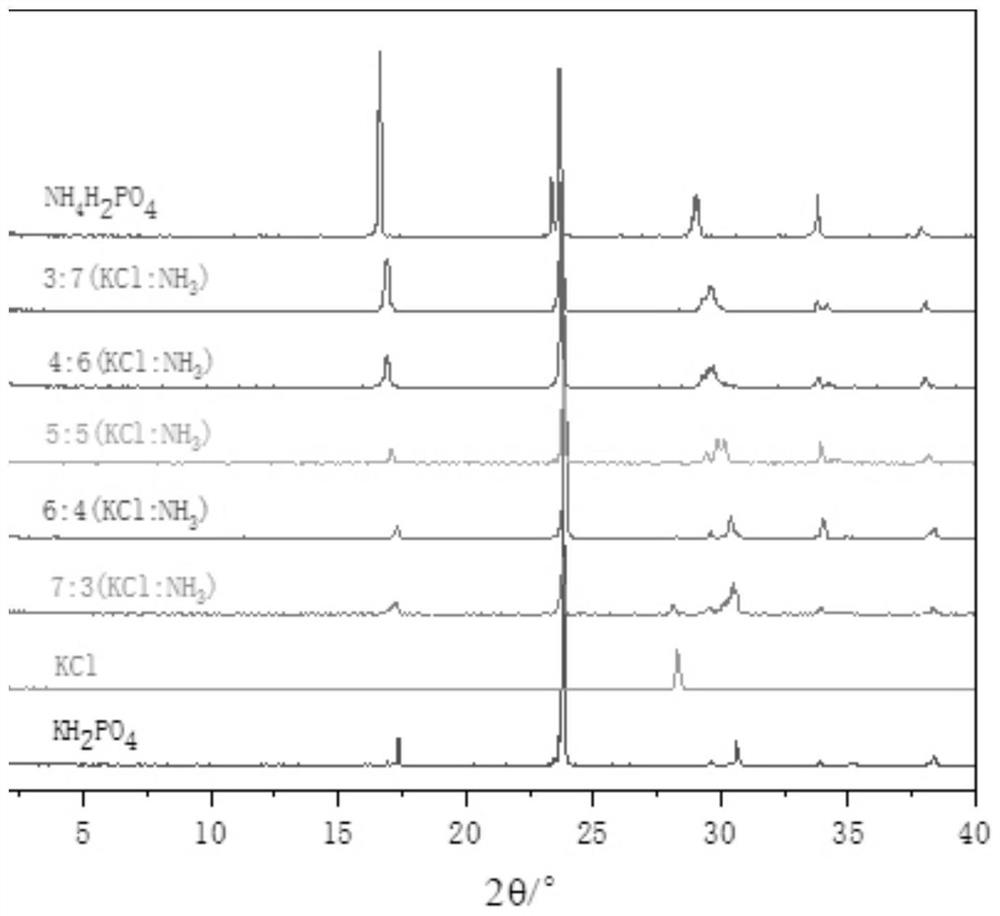

Method for preparing nitrogen-phosphorus-potassium compound fertilizer from fertilizer-grade phosphoric acid eutectic

The invention provides a method for preparing a compound fertilizer with an adjustable nitrogen-phosphorus-potassium ratio from a fertilizer-grade phosphoric acid eutectic. The method comprises the steps of (1) conducting double decomposition reaction; (2) conducting a neutralization reaction; (3) crystallizing and refining; and (4) filtering and drying. The method has the beneficial effects that the cost of raw materials is low, zero emission of the whole process is also realized through reutilization of crystallization mother liquor and recovery of a reaction byproduct hydrogen chloride, and efficient utilization of the raw materials is realized; the reaction is segmented, so that the conversion rate of potassium chloride in the reversible reaction is improved, and the problem of crop leaf burn caused by overhigh chlorine ion content of the fertilizer is solved; and the content of nitrogen, phosphorus and potassium in the product is regulated and controlled by simply regulating and controlling the feeding ratio of the reaction raw materials, the controllable range is large, and different requirements of actual agricultural production on the fertilizer can be met.

Owner:TIANJIN UNIV

Hand tool with function of intense pulsed light negative-pressure suction

The invention discloses a hand tool with the function of intense pulsed light negative-pressure suction, and belongs to the field of medical instruments. The invention relates to a technology of intense pulsed light negative-pressure suction. The hand tool is used for solving the problems that light emitting portions and vacuum grooves of existing devices are planar, and therefore, when the skin is convex, light emitting openings and the skin are uneven in energy receiving, and the focus is incorrect, leading to burning or the noncompliance of the treatment effect. A suction shell is buckled to positioning columns on the hand tool through buckles on the suction shell to form the hand tool with the function of intense pulsed light negative-pressure suction; after a power supply is switchedon, a preparation button is pressed down, an air pump starts to work, and bidirectional negative pressure suction is performed through air pipe joints and air pipes; and when the suction shell is tightly attached to the skin of a human body, the air pump sucks out air in an annular groove, so that a small part, tightly attached to the suction shell, of the skin is sucked into the annular groove inthe suction shell. Since the annular groove is higher than a lens hole, the effect is better when the tool acts on a place with more proud flesh.

Owner:广州瑞恺迪光电科技有限公司

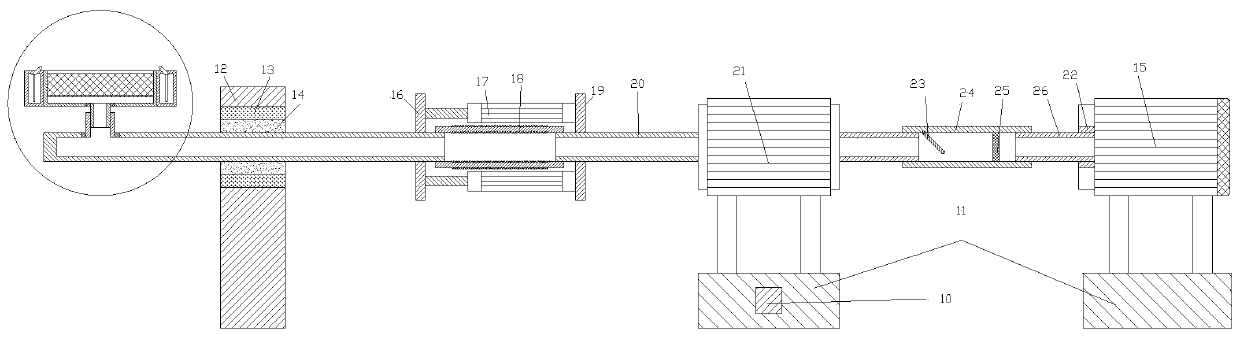

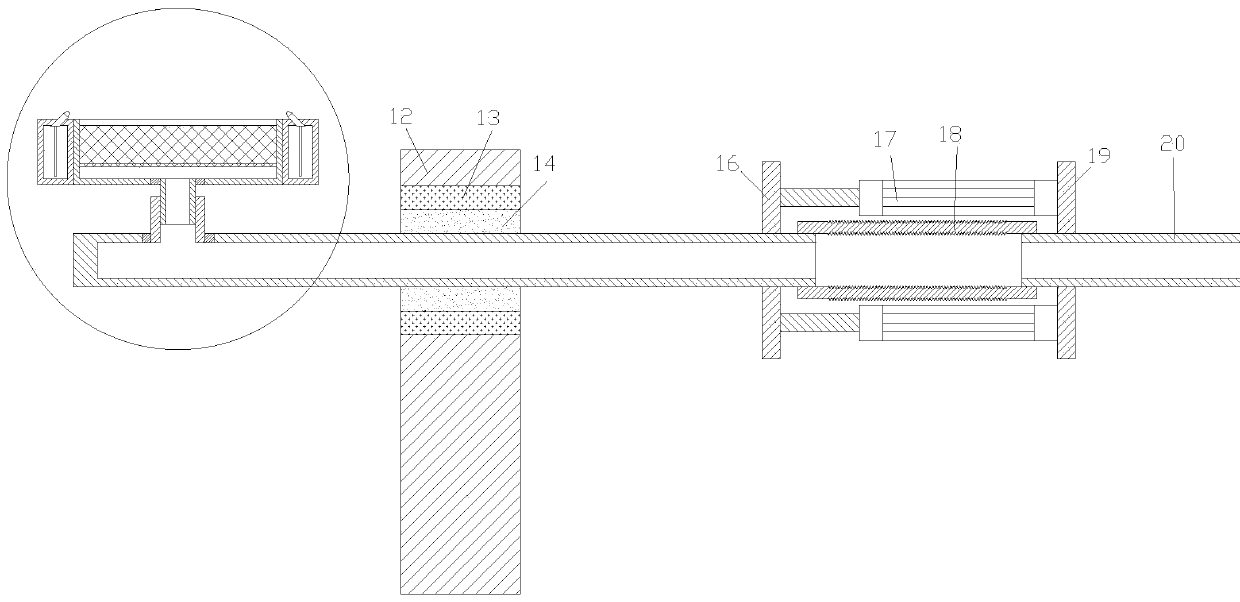

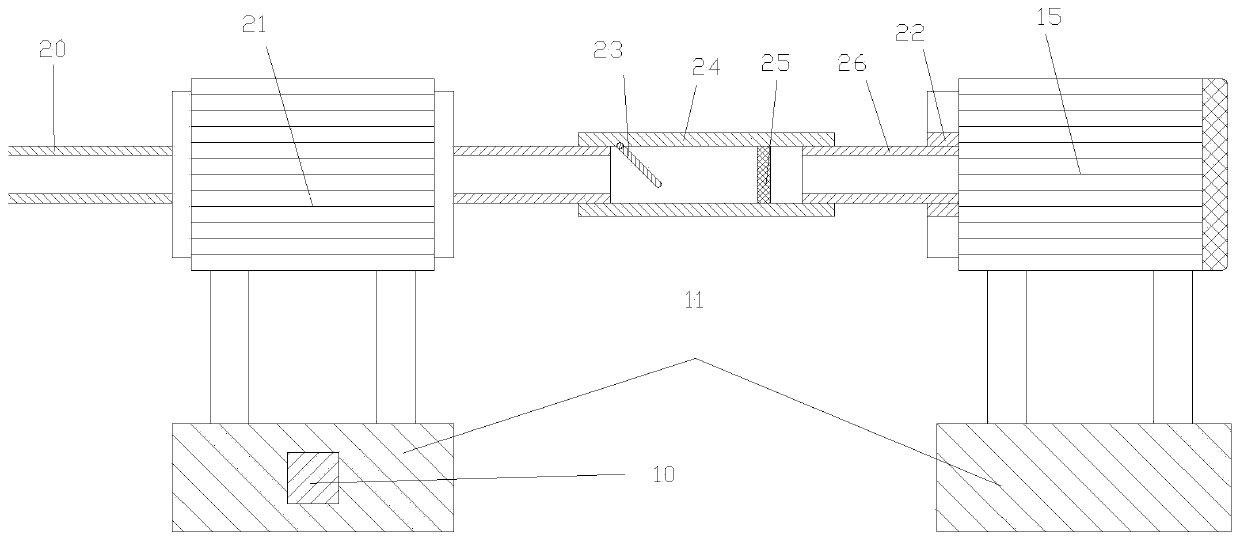

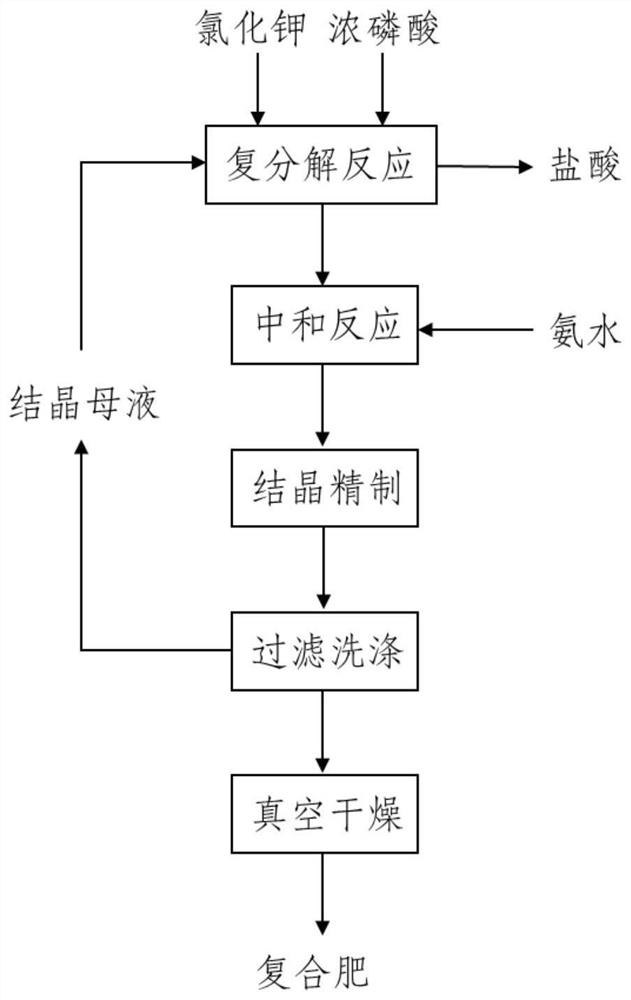

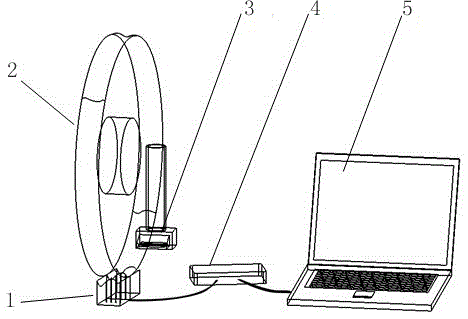

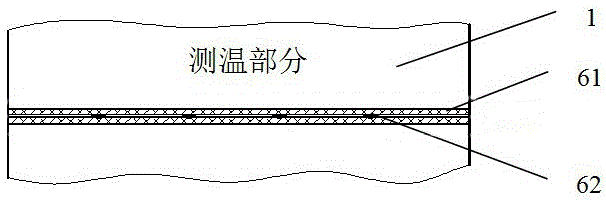

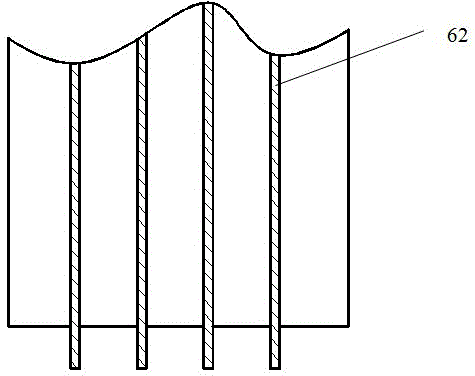

Difficult-to-machine material forming grinding cooling state monitoring device

ActiveCN103406833BImprove grinding efficiencyAddress burnsGrinding feed controlData acquisitionEngineering

The invention discloses a forming grinding cooling state monitoring device for a material difficult to process. The forming grinding cooling state monitoring device comprises a temperature measurement part, a coolant pressure measurement part, a data acquisition card and a computer. Signals measured by the temperature measurement part and the coolant pressure measurement part are collected by the data acquisition card and then transmitted to the computer through a data line to be stored and processed. After stored and processed through the computer, the collected data can provide the basis for optimization of grinding process parameters and a cooling mode, the problem of burning of the workpiece molded surface in the forming grinding process of the material difficult to process is further solved, and forming grinding efficiency is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fusing switch

InactiveCN101202179AIncrease in sizeHigh costHeating/cooling contact switchesEngineeringContact resistance

The invention relates to a melting switch, belonging to the manufacturing technical field of mechanical electric apparatuses switches. The invention solves the problems of overcoming damage and contact resistance of pole contact of a mechanical switch. The invention adopts a technical proposal that a low melting-point conductive substance is adhered to a mechanical contact of the pole or the low melting-point conductive substance is adopted as the contact directly. When in switching, the contact is heated firstly to melt the low melting-point conductive substance and then switching action is carried out, and finally the heating is stopped to cool the contact. Then the contact is fused into a whole after close. The invention is especially suitable for a site with big current and low requirement to the time of switching action.

Owner:刘爱民

A dual-purpose device for welding and cutting

ActiveCN106736105BAddress burnsSolve welding and cutting problemsWelding/cutting auxillary devicesAuxillary welding devicesWelding process

The invention discloses a novel welding and cutting dual-use device. The novel welding and cutting dual-use device comprises an upper clamp ring and a plasma welding-cutting machine. A lower clamp ring is arranged under the upper clamp ring, and a welding-cutting gun fixing support is arranged in the upper clamp ring. Power wire slots and six conductive devices are arranged in the upper clamp ring and the lower clamp ring, and springs and balls are arranged in the conductive devices. Extension feet I are arranged on the left side and the right side of the upper clamp ring, and round holes are formed in the extension feet I. Extension feet II are arranged on the left side and the right side of the lower clamp ring, and nuts are welded to the bottoms of the extension feet II. The nuts and the round holes are in central symmetry. The extension feet I are connected with the extension feet II through bolts, and a welding-cutting device is arranged on the right sides of the upper clamp ring and the lower clamp ring. The upper clamp ring and the lower clamp ring are arranged and matched with the welding-cutting gun fixing support, so that weld line deviation is small in the welding process; additionally, the balls in the conductive devices can roll on the surface of a workpiece, so that burns, caused by poor ground in the welding process, on the surface of the workpiece can be reduced, and therefore the novel welding and cutting dual-use device has high practicality.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

Suspension type strawberry germplasm resource preservation method

PendingCN112273170ASolving Confounding ProblemsAddress burnsClimate change adaptationGreenhouse cultivationContinuous croppingFragaria

The invention discloses a suspension type strawberry germplasm resource preservation method. Seedling substrate soil is adopted, a bio-organic fertilizer is added, the adding amount of the bio-organicfertilizer accounts for 5% of the volume of the seedling substrate soil, and the seedling substrate soil and the bio-organic fertilizer are uniformly mixed to obtain a seedling substrate; a seedlingpot is fully filled with the seedling substrate, and thorough watering is carried out; healthy and disease-free strawberry plants are selected, and the specification of seedlings is that 10 nutritionpot seedlings which are 1.0 cm in rhizome thickness, short, strong, solid and free of plant diseases and insect pests are selected; roots are dipped with a medicament before planting, and transplanting is carried out after root dipping of plants; during planting, no core is buried at the upper part, no root is exposed at the lower part, then the seedling pot is placed into a fixing ring of a suspension device, watering for 1-2 times every day is carried out within 7 days after field planting, local moisture of rhizomes and root systems is kept, and germination of new roots is promoted; and strawberry stock plants are preserved through the suspension type strawberry germplasm resource preservation method, the continuous cropping problem and the disease infection problem caused by open-fieldcultivation of the stock plants are solved, the germplasm resource mixing problem is effectively solved, and meanwhile space can be effectively utilized.

Owner:XUZHOU INST OF AGRI SCI IN JIANGSU XUHUAI DISTRICT (JIANGSU XUZHOU SWEETPOTATO CENT)

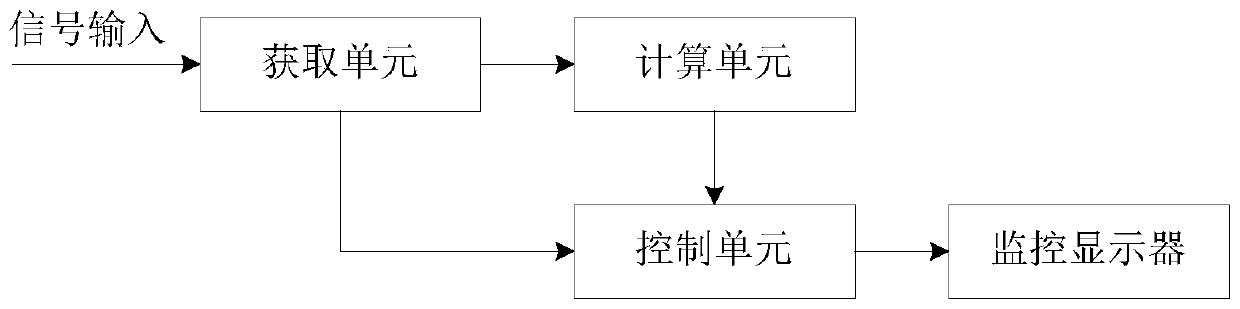

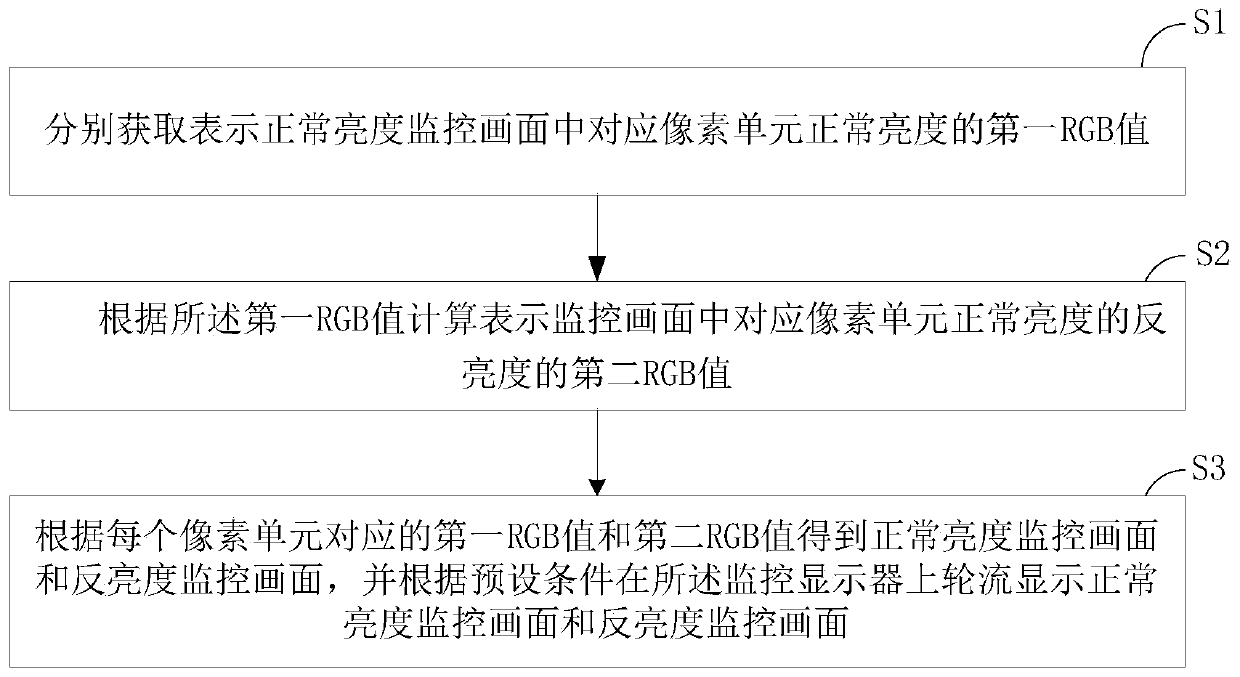

Anti-burn monitoring display and display method thereof

InactiveCN110062213AResolving power unchangedGuaranteed image qualityCathode-ray tube indicatorsClosed circuit television systemsDisplay deviceBrightness perception

The invention relates to the technical field of display. In order to solve the problem that a display panel of an existing monitoring display is prone to burn, the invention provides an anti-burn monitoring display and a display method thereof. The anti-burn monitoring display comprises an obtaining unit which is used for obtaining a first RGB value representing the normal brightness of a corresponding pixel unit in a normal brightness monitoring image; a calculation unit used for calculating a second RGB value representing the inverse brightness of the normal brightness of the corresponding pixel unit in the monitoring image according to the first RGB value; a control unit, used for obtaining a normal brightness monitoring picture and an inverse brightness monitoring picture according tothe first RGB value and the second RGB value corresponding to each pixel unit. The internal working condition of the display panel of the monitoring display is balanced by displaying the normal brightness monitoring image and the reverse brightness monitoring image in turn. The problem of burn of the monitor is effectively solved, and the method is suitable for the liquid crystal monitoring display.

Owner:SICHUAN CHANGHONG ELECTRONICS SYST

Circlip for cylindrical roller bearing and its production method

InactiveCN100462581CEliminate relative slidingAddress burnsBearing componentsEngineeringSpring steel

A circlip is used in a cylindrical roller bearing. Two ends of the circlip are connected via two spring steel pieces. An opening is arranged on the lower end surface of the connecting end, while an oblique notch connected with the opening is arranged on the upper end surface of the connecting end. An internal ring of the circlip is equipped with two oil-seal grooves, which extend outwards from the left and the right of the opening and become shadow gradually. The external ring of the circlip is equipped with a raceway surface to give load to a roller, and a fixing groove to fix the spring steel pieces. The spring steel pieces are arranged in the fixing groove at an angle of 30 degrees with both sides of the central line of the circlip opening in a perimetric way. As two ends of the opening are fixed with the spring steel pieces due to the size of the opening, the circlip of the invention is provided with the inward elasticity to give load to the roller and press the roller to the raceway in the external ring. When the external ring of the bearing revolves, the roller is forced to rotate. As the circlip cannot rotate with the bearing, the roller will not slide so as to solve the problem of burning of the roller. The invention is simple in the process. The circlip is provided with the good elasticity, the long usable life and the low cost, can greatly promote the working efficiency.

Owner:SHIBIAI SPECIAL BEARING LUOYANG

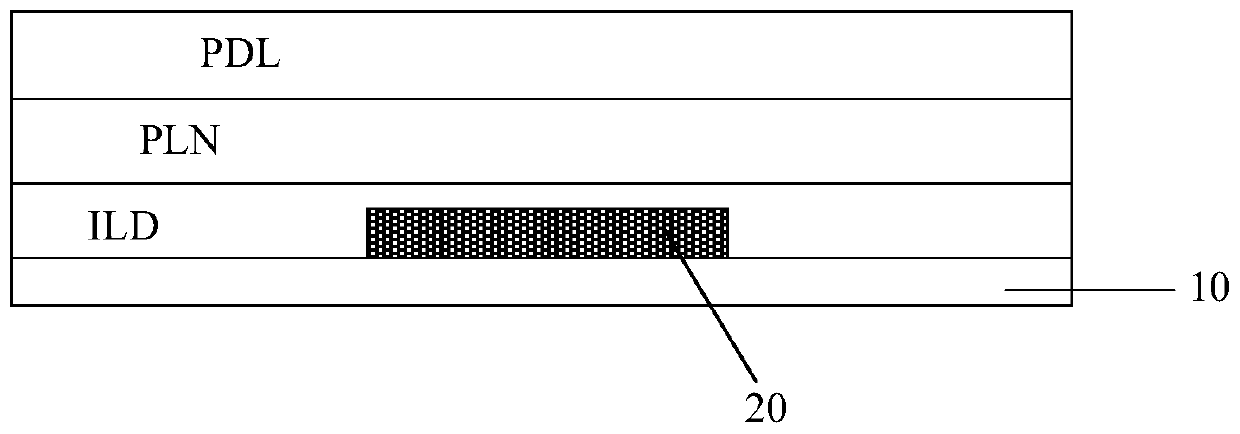

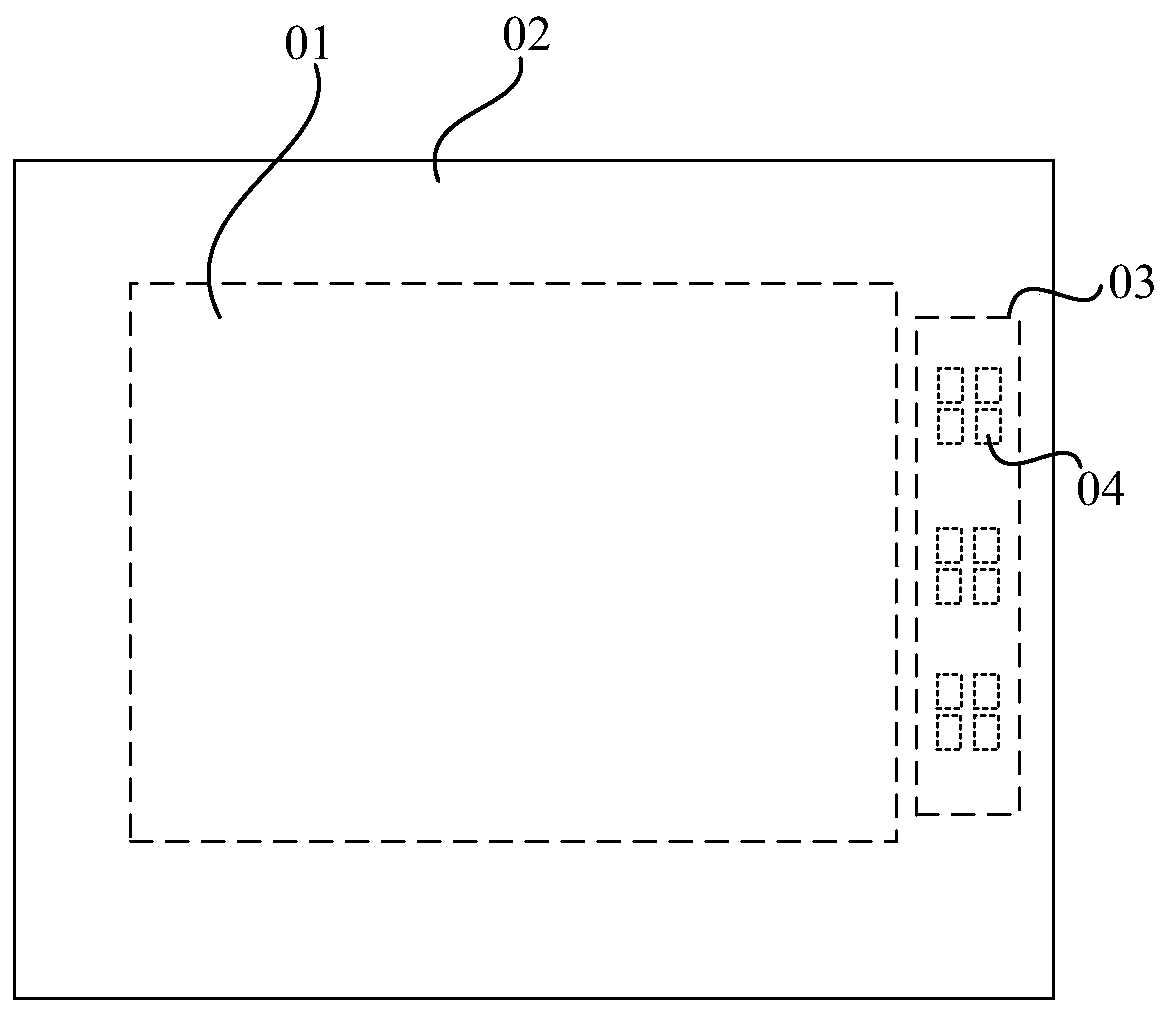

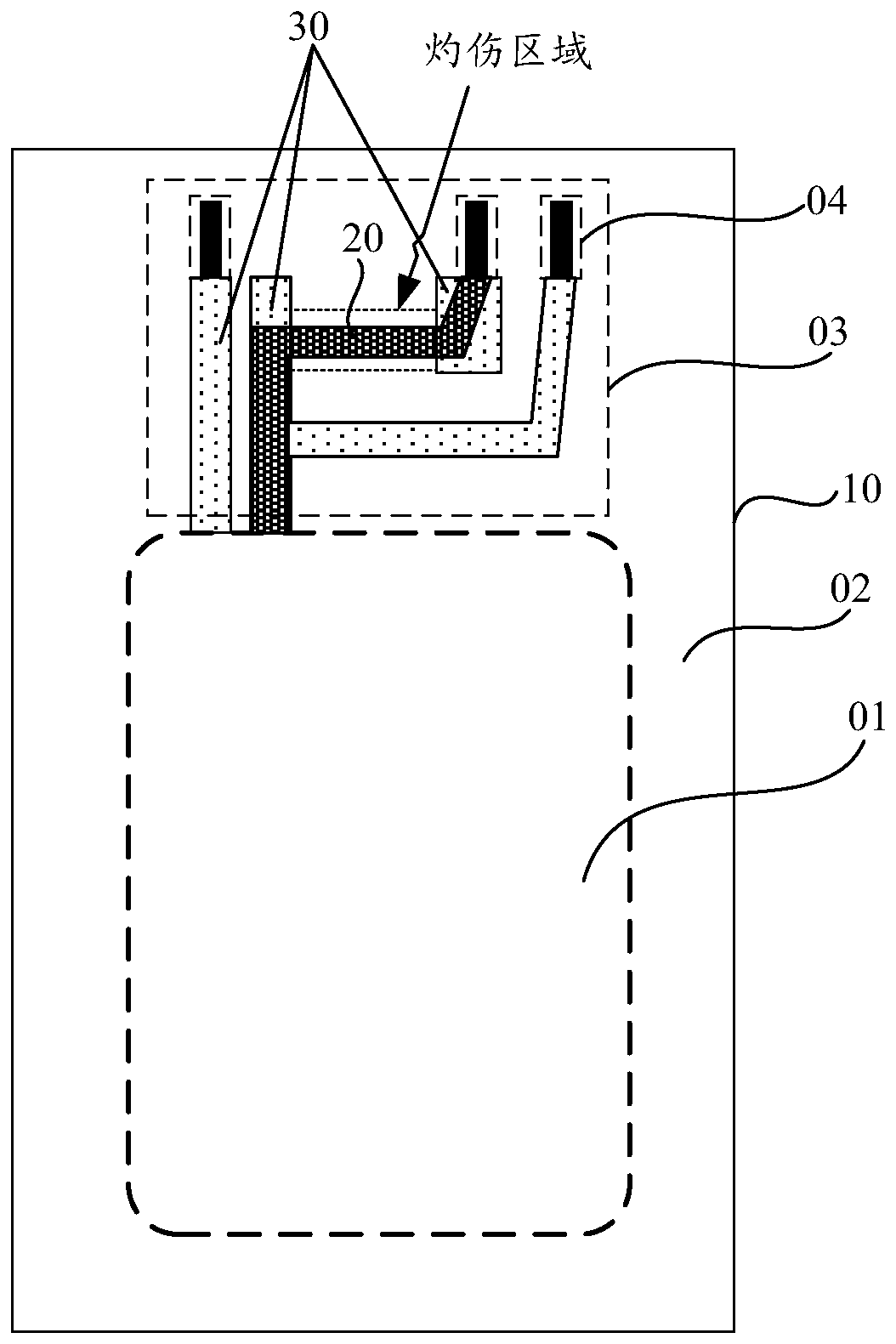

An array substrate, a display device, and a mask plate

ActiveCN108962850BAddress burnsAvoid localized overheatingSemiconductor/solid-state device detailsSolid-state devicesInsulation layerDisplay device

The invention provides an array substrate, a display device and a mask plate, relates to the display technical field, and solves the problems that an insulation layer above a first power line lead isburned due to the local overheating condition on the first power line lead. The array substrate comprises a binding zone that has the first power line lead and a signal line lead; the signal line leadis arranged on one side, far away from the substrate, of the first power line lead; the binding zone also has a heat conductive pattern arranged on one side, far away from the substrate, of the firstpower line lead; the positive projection of the signal line lead on the substrate covers a portion of the positive projection of the first power line lead on the substrate; the positive projection ofthe heat conductive pattern on the substrate overlaps with the other portion of the positive projection of the first power line lead on the substrate.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com