Special camshaft high-frequency quenching device

A high-frequency quenching and camshaft technology, which is used in quenching devices, heat treatment equipment, and energy efficiency improvements, can solve problems such as uneven heating of openings, burns, and uneven depth of quenching layers, and achieves solutions for burns, good quenching, The effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

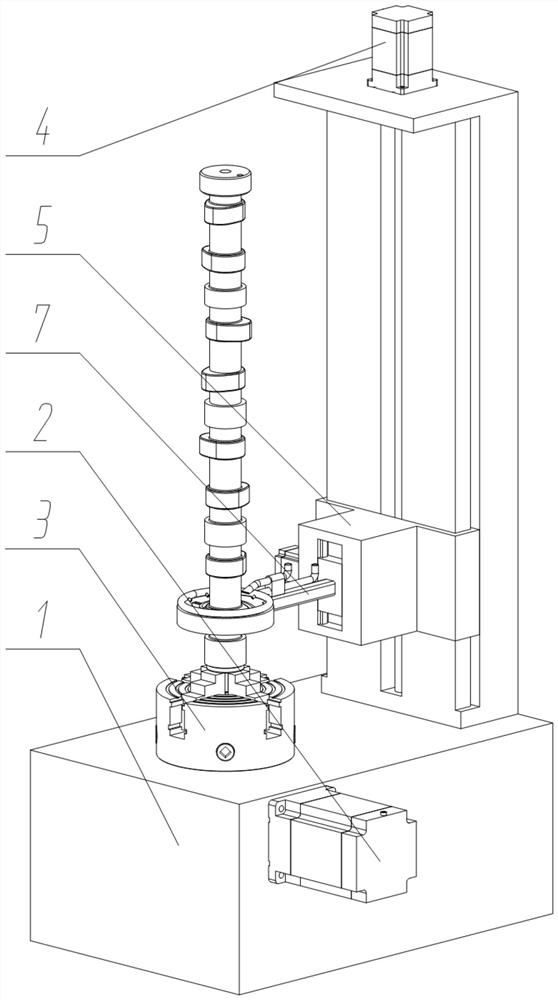

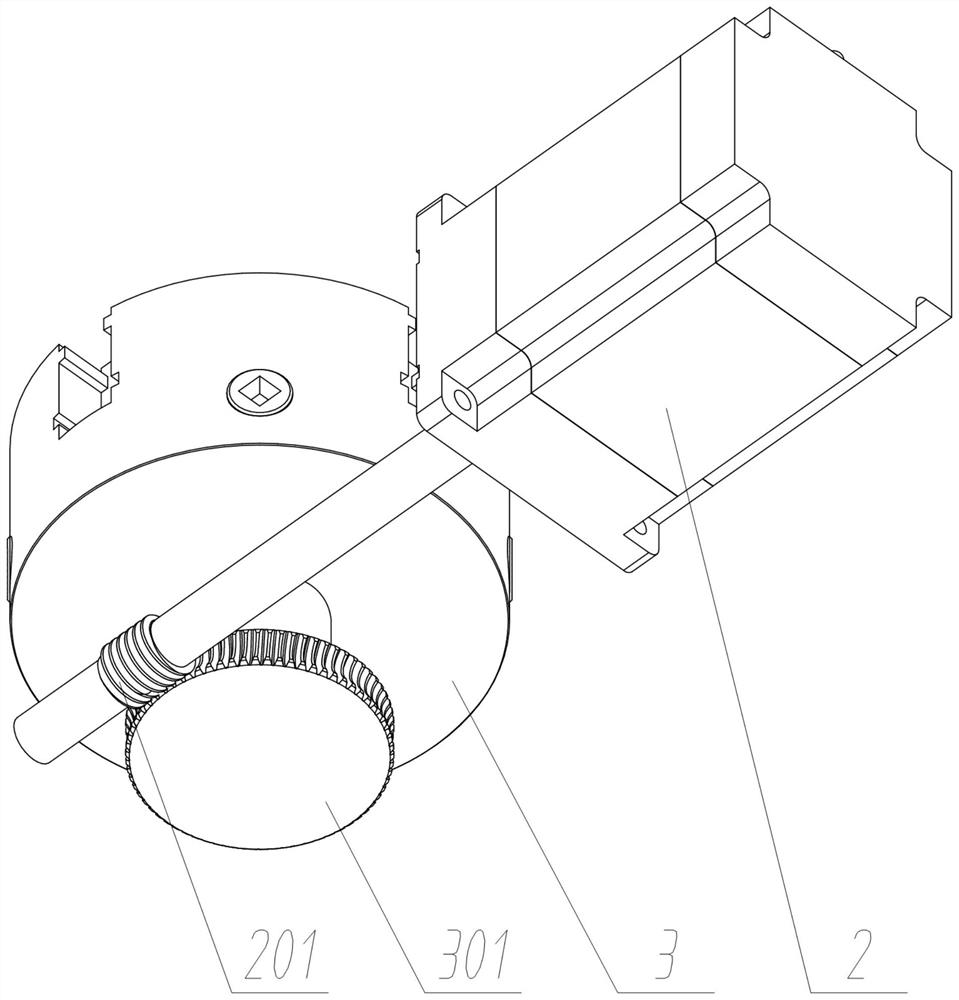

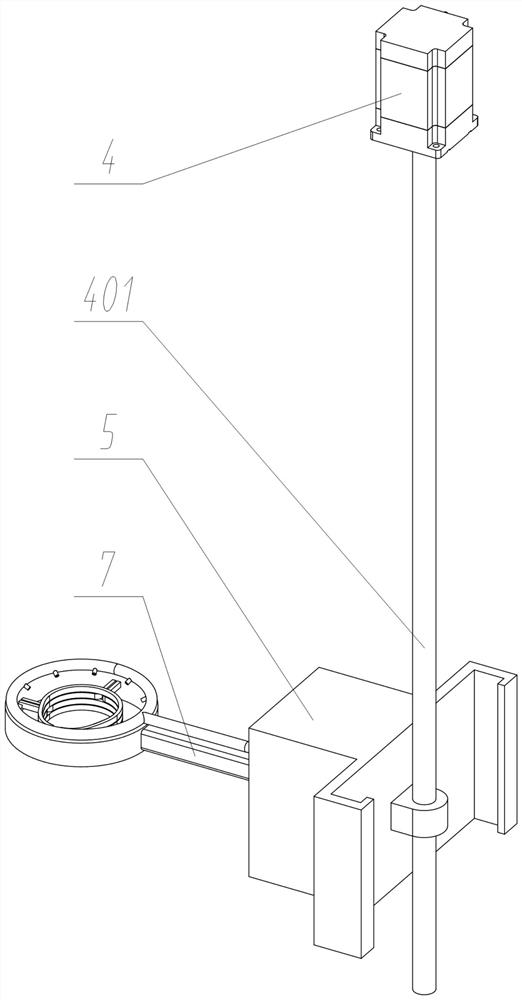

[0028] See Figure 1 to 8 In one embodiment of the present invention, a special cam shaft high frequency quenching is equipped with a base 1; a set of cam shaft rotary drive 2 is fixedly connected to the front end surface of the mounting base 1; the lower rotation connection of the base 1 There is a set of camshake fixing clamp 3; a set of lifting drive parts 4 at the top of the mounting base 1; the left side sliding connection of the mounting base 1 has a set of lifting sliding seat 5; a set of sliding sides of the rear end surface of the lifting slider 5 Driver 6; the left end surface of the lifting slider 5 slides a set of upper sliding seats 7.

[0029] Further, the cam shaft rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com